What if you could design a turbocharger from a clean sheet of paper – no legacy hardware, no limits on what you could do, other than those imposed by physics? What if you had years of data on aerodynamics, materials science, and real-world testing from one of the largest suppliers of OEM and industrial turbos in the world? What would you come up with, if you had the resources to build anything you could dream of?

That’s the question being answered by BorgWarner’s new EFR Series of performance turbochargers. Their engineers took the best their company had to offer in terms of R&D, and turned it into an exceptional line of new turbos that are Engineered For Racing.

A slew of advanced features make these turbos an exciting new option for turbo kit manufacturers and racers:

A slew of advanced features make these turbos an exciting new option for turbo kit manufacturers and racers:

- Forged Milled Compressor Wheels – Cut from custom forgings for strength that exceeds typical wheels machined from bar stock or castings.

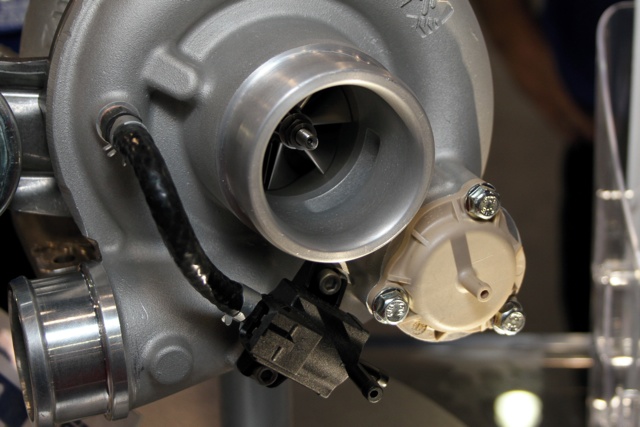

- Gamma-Ti Turbine Wheel and Shaft – Reduces inertia by approximately 50%, dramatically improving turbo response. Available with 55-80mm exducer diameter.

- High Efficiency Turbine Wheel Design – “Superback” back-disc shape adds a curved profile which lowers centrifugal stress and allows higher rotational speeds.

- Investment Cast Stainless Steel Turbine Housings – Improved durability, reduced weight, and an extremely smooth internal flow channel compared to typical cast iron housings.

- Dual-Row Ball Bearing Cartridge – Ceramic ball bearings with a metal cage reduce friction at low speeds, improving turbo response.

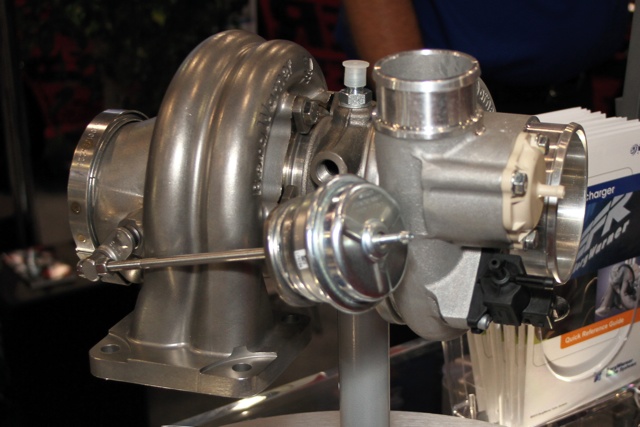

Integrated Compressor Recirculation Valve – Built-in recirculating “blow off” valve helps avoid compressor surge during lift-throttle. This feature simplifies installation and lowers the overall system cost.

Integrated Compressor Recirculation Valve – Built-in recirculating “blow off” valve helps avoid compressor surge during lift-throttle. This feature simplifies installation and lowers the overall system cost.- Boost Control Solenoid Valve – Included with every EFR turbo – one less thing to buy to complete the installation.

- High Flow Wastegate – Select EFR models include purpose-designed integrated turbine wastegate valves and adjustable actuators available in three different canister sizes.

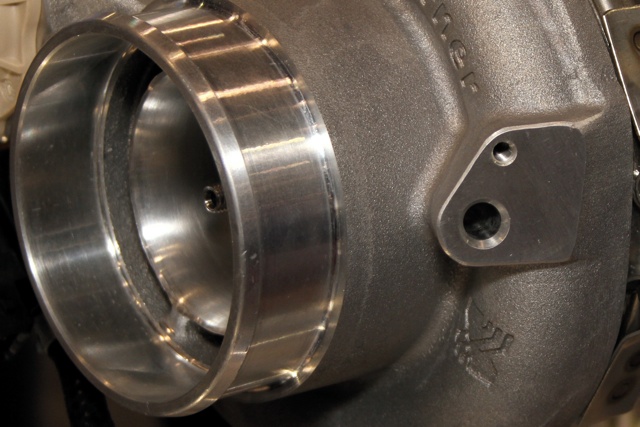

- Integrated Sensor Mount – A pre-drilled blind hole is included for speed sensor mounting. No fixtures are necessary to drill the hole to install a sensor; the hole can be finished with a hand drill if desired.