Nitrous oxide is a drug – literally – and for many racers who catch their first whiff of serious speed at the hands of the pressurized liquid, life is never the same again. One such individual is Steve Johnson, none other than the proprietor of Induction Solutions [2], a former Pro Mod racer, and one of the go-to authorities on the application and use of nitrous oxide within a racing engine.

Johnson, who grew up in the Chicago area and spent his youthful years testing out the limits of the local street racing venues, eventually took his leave into the legitimate world of racing at the dragstrip.

“My dad, Gene, was a car guy, and I started messing with cars with him when I was little, eventually doing side jobs and stuff. Once I got into high school, I started running with a crowd where we were street racing and hot-rodding around town. I used to street race on the south side of Chicago with Chuck Samuel, Spiro Pappas, and those guys,” says Johnson.

After graduating from high school, he took a job at the local speed shop working in the machine shop by day and the counter at night, and from there it was off to the races – literally.

“I met a guy through that place who put me into a Trans Am for the 1992 Hot Rod Fastest Street Car Shootout – he owned it and I drove it and tuned it. He put me into the Pro Mod deal, and I ran it with him for two years, then I went off to race on my own. Financially, I just couldn’t swing it, so I sold off all my stuff,” he says. Even so, he scored two Top 10 points finishes in three years in the IHRA’s Pro Mod class with limited funding.

Entering the World Of Manufacturer Support

At the time, when it came to nitrous oxide, Nitrous Oxide Systems was really the only game in town. Through his affiliation with the company, Johnson was approached by then-owners Mike Thermos and Dale Vaznaian to provide at-track racer support, as the company didn’t have anyone in that capacity who could provide the assistance to their large customer base. Back then, the Pro Mod and Pro Street-style class racers relied largely on big-inch nitrous engines, as the turbo- and supercharged engines you see today weren’t developed to the same level they are today – big squeeze was the racer’s choice for competition purposes.

The opportunity with NOS, while he didn’t realize it at the time, provided him with a career direction he’s still following today. As the motorhome he owned was the only piece of his racing operation he hadn’t sold off, when NOS approached him, he was able to use that as his rolling home for the next seven years, gaining invaluable insight into all sorts of different racing combinations; learning what certain setups liked and didn’t like.

From nitrous system design to chassis setup, he soaked up the information like a sponge, while he was able to collaborate with the best minds in the nitrous and engine building businesses in the process. This knowledge proved invaluable as his career progressed.

[5]

[5]Way back when, Johnson was called the NOSMan; as a traveling technician for NOS, he gathered a following of racers who would also send in their manifolds for his modifications.

“When their regular techs couldn’t answer questions for the serious racers, they’d send them to me. These guys would call me and tell me they needed their systems flowed. So I’d ask about the tuneup and then be able to tell them that their system was fine, it was the tuneup that was screwed up,” Johnson says.

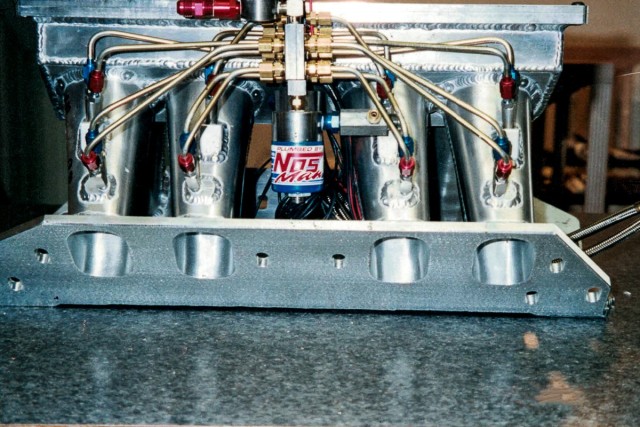

“But they were convinced their systems needed to be flowed. I finally heard that enough that I built a flowbench. I did some research and started flowing systems. It is an awesome tool, especially now. It allows us to blueprint and flow the complete system. We field-strip the system, go through each of the lines and fittings, make some modifications if necessary, and make sure everything is working properly.”

[6]

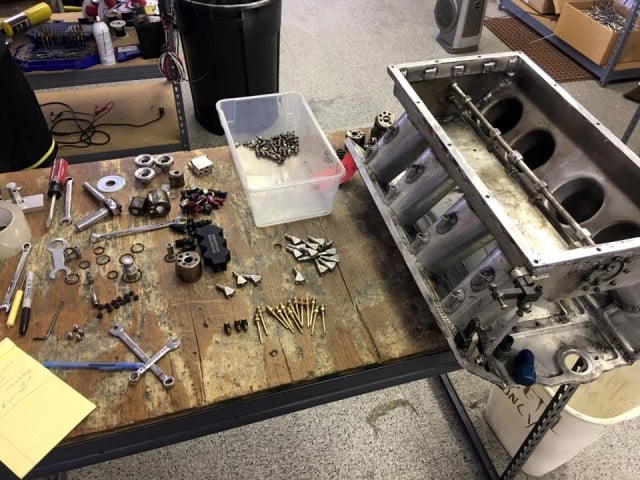

[6]To properly flow an existing nitrous system, Johnson and his team first disassemble everything down to the jets, to ensure it’s plumbed properly and there are no obstructions or other weirdness going on.

Nitrous solenoids are still nitrous solenoids, nozzles are still nozzles, and plates are still plates. The principles to build a good nitrous engine have evolved. – Steve Johnson

But he didn’t just focus on the company’s nitrous systems – he was their Director of Motorsports, again working with some of the most talented and dedicated racers in the business and soaking up every nugget of information he could. Toward the tail end of this partnership with Edelbrock, he also started Induction Solutions as a side gig, modifying intake manifolds and plumbing nitrous systems for various customers.

[7]

[7]In the heyday of the NMRA’s Pro 5.0 class, Johnson was Edelbrock’s Director of Motorsports, working closely with racers like driver Joe Morgan (center) and crew chief Tom Sanders on their nitrous-injected big-block Mustang.

To make a long story short, in 2008 when the economy took a dump, Edelbrock cut back their program a bit, and Johnson found himself turning all of his attention toward his fledgling company – which today has become one of the world leaders in nitrous technology, with customers, event winners, and champions all across the globe.

Changes in Nitrous Technology

To hear Johnson tell it, nitrous oxide technology with regards to racing hasn’t changed all that much over the years.

Instead, the technology surrounding the nitrous system has had revolutionary changes occur, which has manifested itself with drastically improved performances, and capabilities which were unheard of just a short time ago.

“The biggest things that have changed aren’t so much the products themselves as it is the tuneups, the camshafts, pistons, and electronics,” Johnson states. “Nitrous solenoids are still nitrous solenoids, nozzles are still nozzles, and plates are still plates. Most of the products are still the same – within reason – that they were 30 years ago. The tuneups and principles to build a good nitrous engine have evolved.”

Today, Ron Rhodes is perhaps the most recognizable Induction Solutions-sponsored driver; he dominates in X275 with his single-stage system.

Johnson says many of the gains have come through the development efforts of today’s engine builders and the data collected by the racers, which allows adjustments to be made to combinations quickly and easily. Builders like Tony Bischoff, Scott Shafiroff, and Charlie Buck, among others, have been instrumental in advancing the cause.

“The camshaft is a big part of it. Getting the valve events right and realizing that in a nitrous engine you need to have a lot more exhaust duration and lobe separation and the means to get the heat out of the engine is critical. We’re putting all this extra nitrous and heat and fuel into the engine and you have to get it out,” he says.

[10]

[10]From mild-mannered systems to the top-flight systems found on today’s Pro Mods, the Induction Solutions team has the equipment and know-how to make them work properly.

Piston compression height is also important to the power equation. Racers are shortening up the overall package, through shorter connecting rods or a shorter stroke to get more compression height and a bigger ring stack has helped quite a bit to make for a much tougher ring stack.

“By gaining compression height from the midpoint of the pin to the top of the piston, we’re able to put more material between the rings. In the earlier days, there might have been .050-inch between the top and second ring, to where if you hydraulic the thing just a little bit with fuel you’re killing the piston. Today it wouldn’t surprise me if it were .100-inch on some of the pistons in that spot,” he explains.

Progressive Control

He touts progressive system controllers as one of the more important advances, especially when it comes to come of the larger single-stage systems.

Induction Solutions recently introduced their own progressive controller, called the Nitrous Power Commander; Johnson says it’s unique within the industry as it seriously simplifies the connections for the end-user – all of the relays are internal with battery-fed dedicated ground and power connections that drive each of the functions in the box.

It allows easy hookup of multiple systems, along with providing a transbrake/clutch activation input, internal solenoid drivers, and datalogging capability. It also offers the racer the ability to run two progressive systems and up to three additional stages. Another super-sweet feature is built into the controller program, which permits the user to set up quick ramps and resume ramps in case the throttle is lifted.

“The way the controller is built, if you get creative with the wiring, you could actually progress four systems with the NPC-2006,” says Johnson.

A Trend In Squeeze

Years ago, many racers believed that the most efficient way to use the spray was through a couple of stages; a direct-port system combined with a plate, two direct-port systems, or even a dual-stage plate system, but Johnson says those trends have started to fall by the wayside as of late. This has been partially led by the performance he’s been able to show with a few of his sponsored racers, like X275 sniper Ron Rhodes of Rhodes Custom Auto [12] in Delaware.

“That’s one of the newer trends that’s really evolved over the last few years. At first, I resisted it, but I got my arms around it and really looked at the benefits of using the large single stage. There are a lot of guys who are a lot better off with a single stage with a progressive controller to manage it,” says Johnson.

“We used to do a ton of two-stage manifolds, and now I would say there’s probably 50 to 75 percent of the guys who would have done a two-stage system before will now do a big single stage. It’s a lot more cost-effective for them even with the purchase of the controller.”

He also took a moment to debunk the myth that progressive controllers are hard on the solenoids, instead sharing a tidbit he learned a few years back from the failings of one of the racers he was working with at the time.

“Truthfully, the biggest thing that kills a nitrous solenoid faster than anything is nitrous bottle pressure. High pressure, or long durations of pressure,” he says.

“The racer had the pressure jacked up to 1,300 psi in the bottle, and the line open all the way up to the solenoid – because that’s where the gauge was. His thinking was that the pressure would drop down to where it needed to be in the lanes. We put in a new pressure gauge and a quarter-turn valve inline, and he never had a problem again.”

One thing is for certain: Steve Johnson and nitrous oxide injection have a long, intertwined history. It’s an association which spans decades of use and hundreds, if not thousands, of race combinations and programs he’s been involved with over that time period. And each one of them has taught him something new when it comes to the ways of the squeeze.