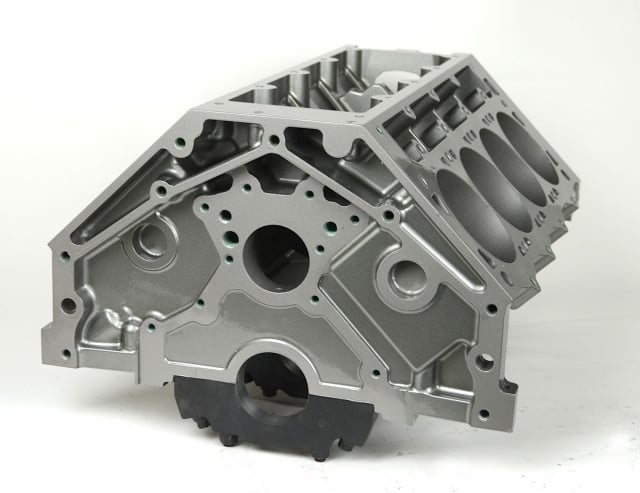

[1]An alloy version of Dart’s revolutionary LS Next cylinder block will soon be available.

[1]An alloy version of Dart’s revolutionary LS Next cylinder block will soon be available.

“We are once again in the tooling stages on our all-new LS Next aluminum block,” says Richard Maskin, founder of Dart Machinery [2]. “The new LS Next aluminum block will be machined and delivered in two phases. Phase one will be a standard deck and standard cam location. Phase two will have a raised deck and raised cam location for big-cubic-inch engines.”

[3]The new blocks will be cast using Dart’s proprietary RMR alloy and will come with billet-steel main caps, ductile-iron cylinder sleeves, a cam-retaining plate and a full block kit with coated cam bearings, screw-in freeze plugs, oil galley plugs, dowel pins and oil restrictors. Expected delivery date for the first units is January 2014, and Dart has begun accepting pre-production orders.

[3]The new blocks will be cast using Dart’s proprietary RMR alloy and will come with billet-steel main caps, ductile-iron cylinder sleeves, a cam-retaining plate and a full block kit with coated cam bearings, screw-in freeze plugs, oil galley plugs, dowel pins and oil restrictors. Expected delivery date for the first units is January 2014, and Dart has begun accepting pre-production orders.

The iron version of the LS Next was introduced at SEMA last year with favorable response. The basic strategy behind the block’s development is to accommodate popular LS-based components, such as the cylinder head and crankshaft, but offer an open Gen I-style crankcase that eliminates windage problems associated with the LS architecture. The LX Next block also improves lubrication and strength over the stock LS block in addition to offering options for increasing displacement.

Deck height for the LS Next will be 9.240 inches with a 5/8-inch thick deck surface. Head-bolt design is 6-per-cylinder, and head bolts are upgraded to 7/16-inch for additional clamping force in boosted applications. Also, all head-bolt holes are blind and do not invade the water jackets. The cylinders will extend .375-inch over stock length, providing added stability to pistons at BDC. Maximum suggested stroke is 4.100 inch for the standard-deck block.

[4]The block will be available in either a 4.000- or 4.125-inch bore, and the cam bore will support either 60mm babbitt or 55mm roller bearings. Lifter bore is .842-inch with an option for .937-inch keyed. Rear seal is 1-piece design. Other design features include both LS and Gen I motor mounts, enlarged water jackets, splayed outer bolts on #2-3-4 mains and starter mounts on both sides. The block also features true priority main oiling with a Pro Stock-style stepped main galley at 9/16-, 1/2- and 7/16 inch,which provides required volume without loss of pressure or velocity at the front of the block. An external oil filter must be used with either stock or aftermarket oil pumps. Oil pans specific to this new block design and oil-pan-rail spacing are required, but the aftermarket is already providing suitable wet- and dry-sump options.

[4]The block will be available in either a 4.000- or 4.125-inch bore, and the cam bore will support either 60mm babbitt or 55mm roller bearings. Lifter bore is .842-inch with an option for .937-inch keyed. Rear seal is 1-piece design. Other design features include both LS and Gen I motor mounts, enlarged water jackets, splayed outer bolts on #2-3-4 mains and starter mounts on both sides. The block also features true priority main oiling with a Pro Stock-style stepped main galley at 9/16-, 1/2- and 7/16 inch,which provides required volume without loss of pressure or velocity at the front of the block. An external oil filter must be used with either stock or aftermarket oil pumps. Oil pans specific to this new block design and oil-pan-rail spacing are required, but the aftermarket is already providing suitable wet- and dry-sump options.

EngineLabs has covered the LS Next block extensively, starting with the introduction [5] followed by lubrication tests [6] and an interview with Maskin [7]. The first deliveries of the iron block have already been shipped, and engines from leading builders should start hitting the track and street soon.