Drag Week is the ultimate test of durability for a street-driven vehicle; it takes an immense amount of preparation and the knowledge to choose the correct parts to achieve that durability. Arizona’s Clay Forrester made the decision to build a hybrid Mustang to take on his first-ever Drag Week adventure for the 2015 event, but instead of using Ford power, Forrester made the decision to stick an LS engine under the hood — pumped up with a pair of turbochargers — and take on the challenge.

“Fast cars and building these things, putting them together and playing with them, that’s definitely my thing,” says Forrester. “I don’t have any other hobbies.”

Although he’s an aviation engineer during the day, he also spends time building LS race engines not only for himself, but also a number of customers through his hobby shop, Forrester Racing Engines, which focuses on the LS platform. Way back in 2005, he made contact with the fine folks at ERL Performance, and a relationship blossomed that continues to this day.

Forrester tests the company’s product regularly in some of the most demanding conditions one can imagine — not only does he have this Drag Week Mustang, he also has a ton of experience building LS engines for sand rail cars and dune buggies that produce well over 1,000 horsepower, and must do it for miles on end in the desert, dealing with sand and the intense heat in the process.

When the decision was made to build the Drag Week car, Forrester knew that there was one place to turn, in the direction of ERL’s Superdeck six-bolt engine block. The Superdeck has a number of substantial modifications that boost horsepower-handling capability well north of 2,000 horsepower, although Forrester is not pushing it that hard in this application.

Clay Forrester’s Drag Week LS behemoth features one of ERL Performance’s six-bolt Superdeck blocks and a slick air-to-water intercooler design from Shearer Fabrications. Photo credit: Ron Shearer, Shearer Fabrications

“We machine OEM 4th Gen blocks to make them bulletproof, and we cater to the racers all the way from naturally-aspirated combinations to racers using twin 88mm turbochargers and looking for 2,600-plus horsepower,” says ERL’s Andres Vivanco. “We like to use the aluminum block, because it allows the racer to take about 130 pounds off the front end of the car and place ballast where they need it.”

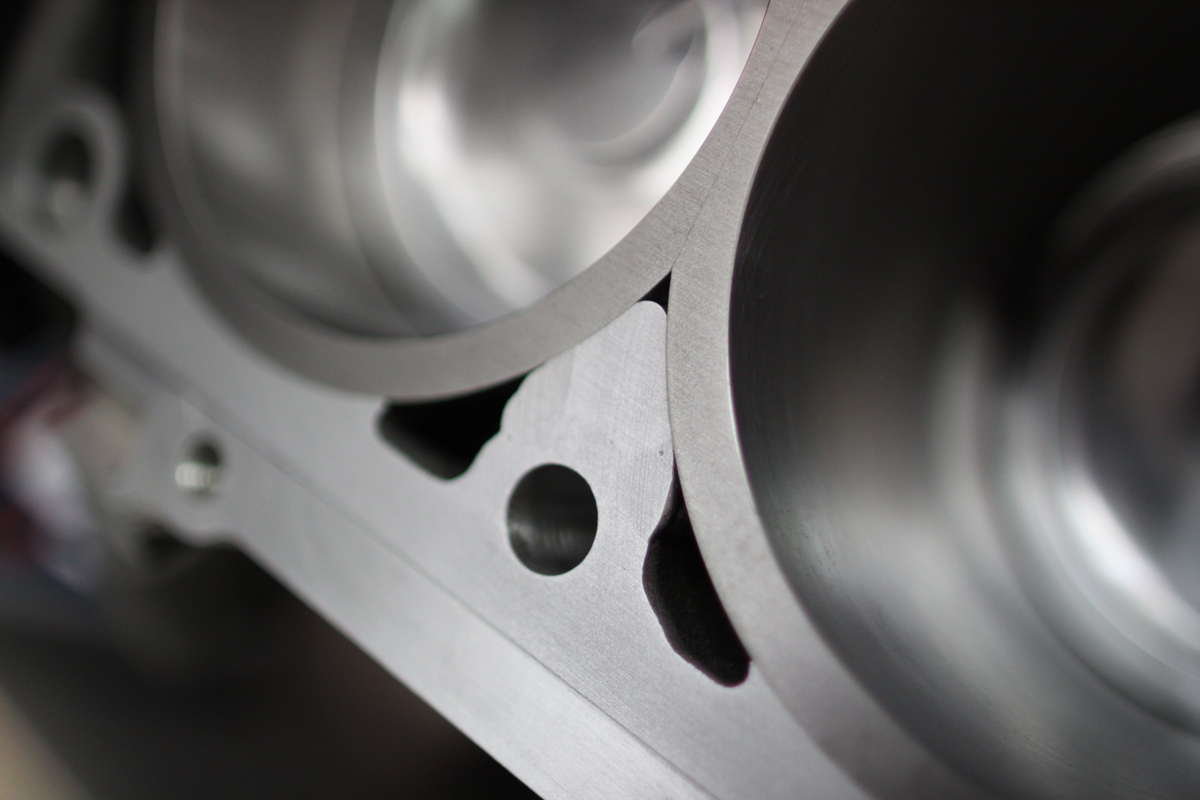

By removing the OEM sleeves, machining the block, then installing ERL’s own longer and thicker ductile-iron sleeves, the Superdeck’s strength is vastly improved over a stock casting. In addition, ERL adds welded-in aluminum trusses that connect each pair of head fasteners and spread the load across the block to aid in head gasket retention. The truss design also ties the main saddles to the deck, changing the load path and improving stability under power. And adding the extra two bolt holes per cylinder also provides additional head clamping force and longevity benefits.

Not only does ERL offer Superdeck blocks and other parts for those building their own engine, they also offer complete engines and can build the ultimate street/strip setup or go as wild as the customer desires.

(Left) In this cutaway, on the left is the flimsy factory sleeve – not the thickness of the ERL Performance sleeve on the right. (Right) Closeup of the trusses welded between the cylinders to improve strength. This block also has the six-bolt cylinder head configuration built in at ERL.

Forrester has extensive experience with making the LS platform run quick and fast, and he’s also engineered a number of parts for these engines, from valve covers to pulleys to the valley cover.

“If there’s a part that I thought I could make better and improve, then I do it. I even made throttle bodies for a while,” he says. Time has limited him from producing many parts recently, but once he hits retirement age he’ll be back in business.

Forrester’s engine is built around the aforementioned Superdeck block, and stuffed full of some of the aftermarket’s best equipment designed for longevity in the incredibly-demanding conditions faced during Drag Week. During the tuning process, Forrester is challenged by dialing the engine in under the tough conditions at his home track, Southwestern International Dragway in Tucson, Arizona.

“We’re not that high in elevation, but the density altitude is not very good. It can be in the 6,000-feet range. And in the summertime out here it can be 115 degrees. I had my limited testing and tuning going on here, and I didn’t have any wheelie issues at all there since the air was so bad and the engine wasn’t making as much power. I was making 7.70 passes at about 182 mph. Once I unloaded the car at Gateway to test right before Drag Week started, It went to the sky, came down and smacked the oil pan but luckily it did not damage it enough to eliminate me from competition. The air was so good that I had to take a bunch of power out of it to get it down the track without yanking the bumper off,” says Forrester.

In-car Video Of Forrester Hanging The Wheels On Drag Week

The 417 cubic inch engine uses a 3.900-inch-stroke Callies Magnum forged-steel crankshaft that’s been outfitted with big-block Chevrolet pin dimensions in the interest of increasing strength. As such, a set of Callies’ Ultra 6.125-inch connecting rods are attached to a set of 9.5:1 dished Ross pistons. A Cam Motion solid roller camshaft with mild dimensions of .619-inch intake and .629-inch exhaust lift, with duration set at 235 degrees at .050-inch lift is installed.

On top, a set of Mast Motorsports CNC-ported 72 cc LS7 castings are stuffed with 2.200-inch titanium intake valves and 1.600-inch Inconel exhaust valves. The top half of the induction system consists of a Holley EFI Hi-Ram intake manifold, and exhaust runs into the turbochargers through a modified set of Stainless Works 1 7/8-inch headers. Holley also gets the call for one of their Dominator EFI systems along with 160 pound-per-hour fuel injectors and ignition coils. Fuel is supplied from a pair of Aeromotive A1000 fuel pumps and MagnaFuel filters.

The assembled engine awaiting installation. This is one serious piece — 1,000 miles of cruising the highway, and 7.70s at will on the dragstrip.

A pair of Precision Turbo 76mm billet turbochargers provides the extra motivation, running the boost through a trick custom air-to-water intercooler from Shearer Fabrications. Forrester makes the trips between tracks with very light springs in the wastegates, bleeding off the boost until it’s time to hit the racing surface. Water is run through the intercooler system, and since there is no boost building during the cruise portion of the event, this keeps inlet temperatures down.

“Cruising around, it dumps the exhaust out of the gates so it doesn’t pressurize the air and heat it up. The water gets warm but not unmanageable, since I run it on pump gas between tracks,” says Forrester.

“Cruising around, it dumps the exhaust out of the gates so it doesn’t pressurize the air and heat it up. The water gets warm but not unmanageable, since I run it on pump gas between tracks,” says Forrester.

Forrester’s performance over the course of the week — solid 7.70 and 7.80 passes — earned him the runner-up spot in the small-block power-adder class. Not a bad showing for a guy who’s never attempted the torture test of Drag Week before.

Although he’s an LS engine enthusiast, Forrester has always loved the lines of the coupe Fox Mustang; he currently has two cars, both with LS engines. At the end of the conversation, he hinted around at building an all-motor LS to debut at Drag Week in 2017, with plans to lower the all-motor record substantially — with an ERL Superdeck block onboard, of course.