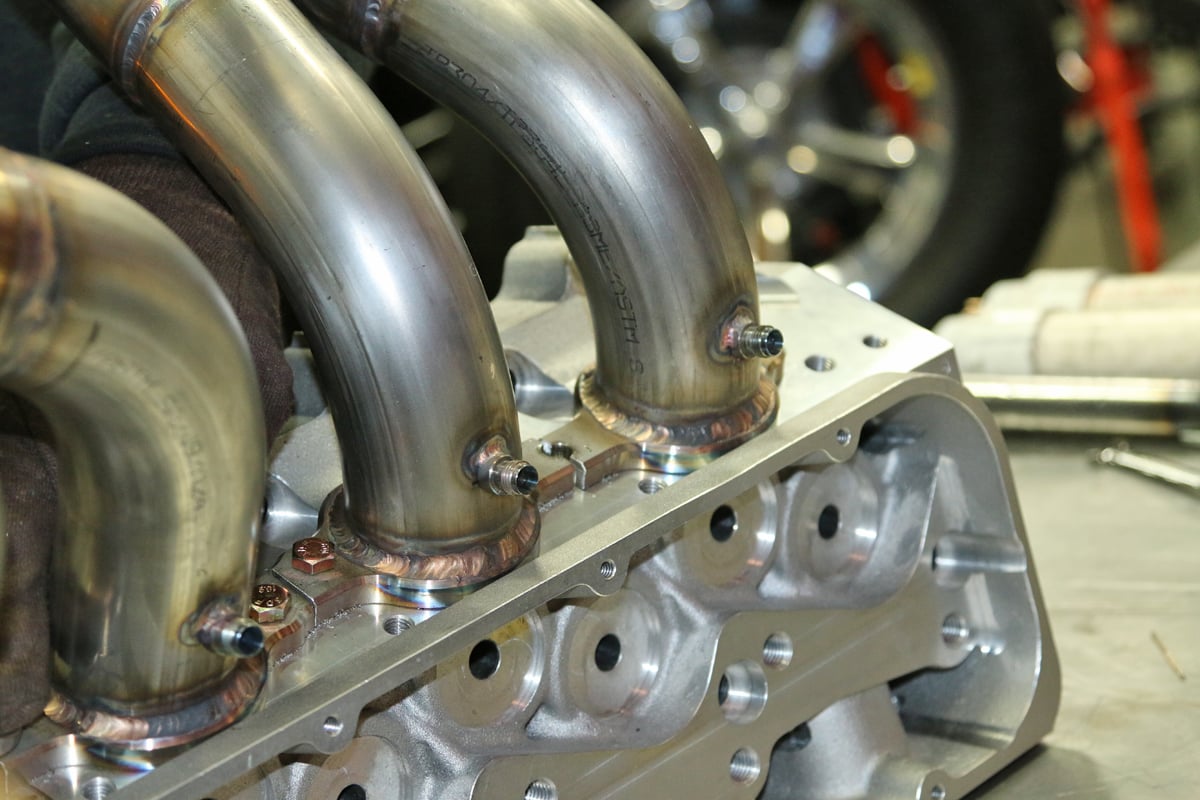

Building a racecar requires the use of many different materials for various components on the vehicle. Depending on the application, you may need to fabricate just a simple set of headers, or a complex system of piping to move boosted air into your engine. In this video, Vince Roman, the technical director for Burns Stainless [1], goes over the differences between the tubing and piping they offer that can be used on any high performance build.

One of the first things covered is how tubing is specified in size from the outside diameter, wall thickness, and is identified as a gauge. A very useful table of what size tubing Burns offers is shown in the video to help illustrate how you can choose the correct tube for your specific need.

Piping is also covered in this video by Roman. One of the big differences between tubing and piping is how it’s measured. Piping is measured by the inside diameter, wall thickness, and is identified by what schedule it is. The overall measurements of piping are more complex than tubing.

Seamless and welded tubing are also examined in this video. Roman goes over the how each of these types of tubing are made, what their strengths are, and what applications they best fit. Understanding the difference between seamless and welding tubing can help you make the best choice for whatever you’re fabricating.

Make sure to check out the Burns Stainless video that’s full of great technical information you can use to make the best decisions for your next exhaust or turbo system build.