If you have been following the series [2] on our blown 1968 Camaro drag build, you know that we’ve covered the short-block [3], top-end, oiling [4], and wicked front-end conversion [5]. The build is now winding to a close as we pivot away from the bench and closer to the track. As we complete that pivot, we’re turning the page from building power to collecting the components needed to help plant the power through scant 275/60-15 Mickey Thompson [6] radial tires. One of the most critical components to any performance automotive build in regards to the suspension is the shock absorbers or strut.

[7]

[7]The Camaro before the upgrade, laying out a big smoky burnout before hitting the line for a sub-4-second 1/8-mile pass at Auto Club Famoso Raceway in Bakersfield.

After days of research about front suspensions and shock absorbers, we spoke to the staff at Chris Alston Chassisworks [8] about its bolt-in, tubular front clip that fits the first-gen Camaro and second-gen Nova. The setup is unique in that they provide a complete bolt-in package that includes everything from crossmember to spindle for these 50-year-old Chevys. The kit included the tubular frame clip, tubular control arms with 4130 rod ends, a billet-aluminum drag-race rack-and-pinion with extended-travel, billet rack clamps, bumpsteer adjustable tie-rod ends, a disc-brake kit with billet hubs, and the latest in strut technology – a set of double-adjustable VariStrut [9] struts.

[10]

[10]Chassisworks’ assembled front end and piggy back strut. The package from Chassisworks includes everything needed to make the front end a roller.

Where It Started

As mentioned in our last writing [11], one of the most prominent features of the Chassisworks package is the integrated strut conversion. The conversion starts with a custom strut that features an integrated spindle, brake mount, steering arm, lower A-arm mount, and a billet strut body. By using VariShock [12] (a Chris Alston’s Chassisworks company) strut components, the team at Chassisworks was able to keep the build in-house and maintain parts compatibility with our tubular bolt-in subframe.

Our package came with a high-rebound force, drag-specific strut, a piggyback reservoir body, and dual-adjustable mounts. VariShock had an existing line of drag-race oriented struts, but this strut, has been reengineered specifically for radial and Outlaw-style drag racing applications.

[13]

[13]The tubular bolt on front end and fully integrated strut as installed on our 1968 drag radial Camaro.

The resulting package provides a wide range of travel, fully adjustable A-arms, several mounting options, a sturdy billet construction, integrated brakes, and two readily accessible 16-position compression and rebound adjustment knobs for a total of 256 unique combinations.

[14]

[14]The tubular front end fully loaded with our blown QMP 440-inch LSX small-block. Chassisworks also manufactures the supercharger drive in the photo through their Component Drive Systems product line.

In their own words, “VariStrut is a new family of racing struts designed and manufactured in the United States. The CNC-machined strut assembly incorporates all the features of our double-adjustable VariShock. It uses our one-piece, self-locking lower spring seat, and the base is machined from high strength and corrosion resistant steel to incorporate the lower body with the axle. The steering arm, lower A-arm mounting stud, and brake-caliper bracket bolt directly to the base. This compact unit allows us to drop the shock reservoir below the center of the axle. Finally, the axle does not press in, which significantly increases available travel.”

Highlights:

|

The Details

[15]

[15]VariShock’s stem-mount, 6-inch travel, high-rebound force, drag-race strut system with piggyback reservoir.

We decided to dig into why these struts are different, and the first feature we noticed was the piggyback reservoir. The VariStrut’s piggyback reservoir is required for the new High Rebound Valving. The clever valve design drastically increases the low speed rebound force, and allows the adjuster knobs to be mounted side-by-side to make valving adjustments much easier. The rebound valving force can be set at a stiff enough setting to act as an adjustable, and more importantly, gradual, suspension travel stop. This is greatly preferred over limiting straps, bumpstops, or simply topping out the strut. Any of those methods cause an abrupt stop in the suspension travel that actually shocks the chassis and unloads the rear suspension. This results in an interruption of traction. Easing the strut’s extension to a soft stop, lets the tires do their job without that interruption. The 6-inch-travel strut used in our Camaro also provides additional range for slowing the suspension’s movement, to help prevent shocking the chassis. This makes extremely-short strut travel and travel limiters now obsolete.

(LEFT) The lightweight A-arm assembly features a high-misalignment, 5/8-inch bore, teflon-lined, spherical bearing, 4130 tubes; and 1/2-inch threaded tube adapters. (RIGHT) The lower A-arm installed on the strut assembly. The arms use fully-adjustable spherical rod ends for detailed alignment adjustments.

The next feature that really caught our eye was the adjustable A-arm assembly. Chassisworks removed the lower ball joint and incorporated the spindle mount into the billet steel strut housing. The result? A simple two piece A-arm assembly that is strong and lightweight. In addition to being extremely light, the arms are completely adjustable with two 1/2-inch rod end bearings. The guys at the alignment shop will be pleased to work with threaded ends instead of the OEM shims provided by GM.

After assembly, each shock is thoroughly dyno-tested and calibrated to meet VariShock’s strict performance goals. – Lino Chestang

Nearly everything at Chassisworks and VariShock is designed and manufactured in house. There is, however, one exception. In an effort to provide a complete assembly, the strut comes with a full brake assembly that is available in light to heavy duty varieties. As Alston Sr. stated, “Right now, we don’t make the calipers, and that’s because Bill Wood of Wilwood and I go way back, and I don’t have any trouble with his components.”

As a result, the brake caliper, one of the few outsourced components in the package, is still tightly integrated, reliable, and easily complemented or repaired with a call to virtually any performance parts retailer. By the way, those machine slotted rotors are also produced in house at the Chassisworks facility.

Built In Adjustability

[19]

[19]Knobs are clearly etched indicating the correct direction of rotation to decrease (-), or increase (+) damping stiffness. There are 16 special adjustment positions for each knob, with a total of 256 unique combinations possible. Chassisworks calls this the QuickSet system as the placement and labeling of the knobs allow for quick adjustments. Readily accessible, 16-position adjustment knobs can be operated by hand or with the aid of a common allen wrench.

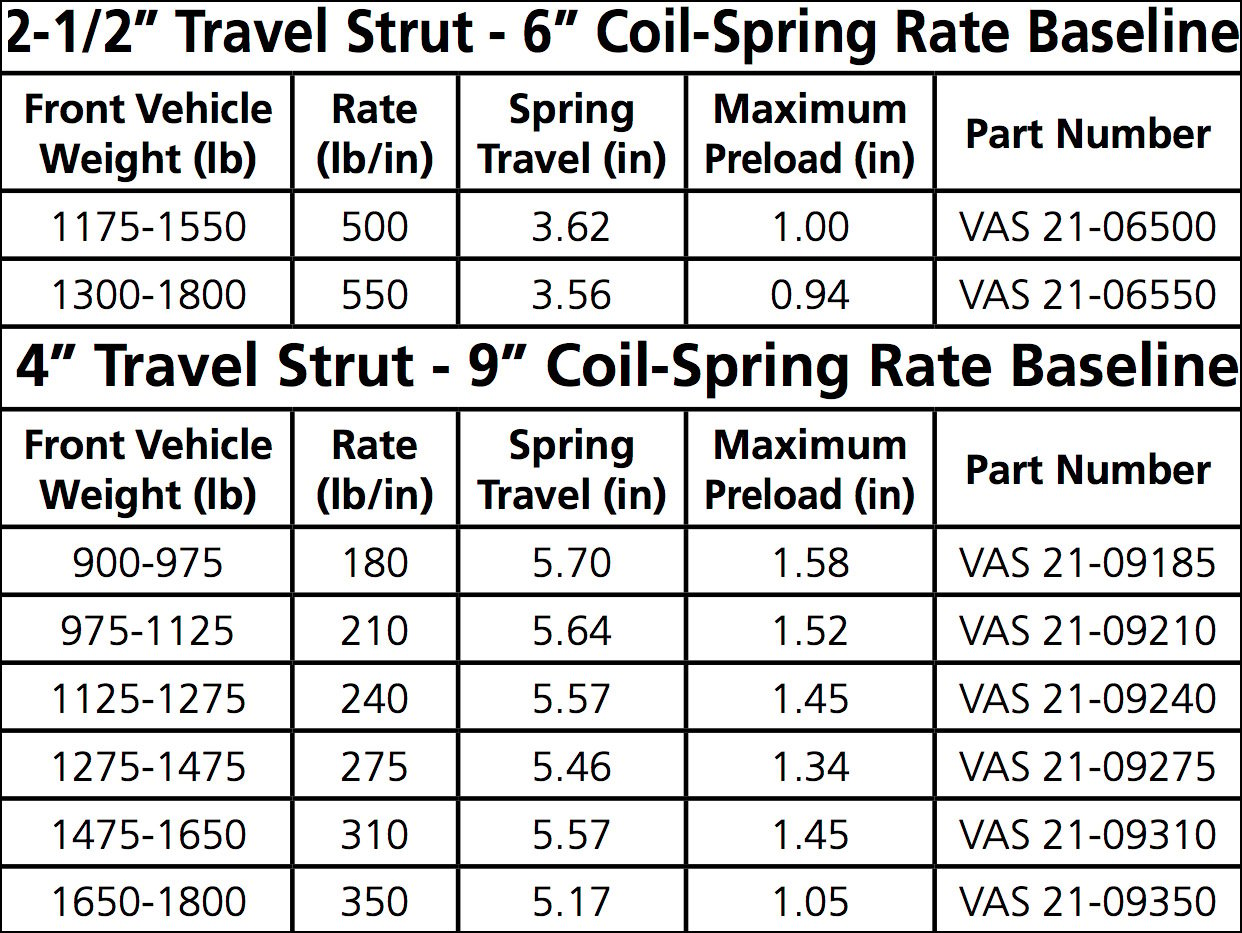

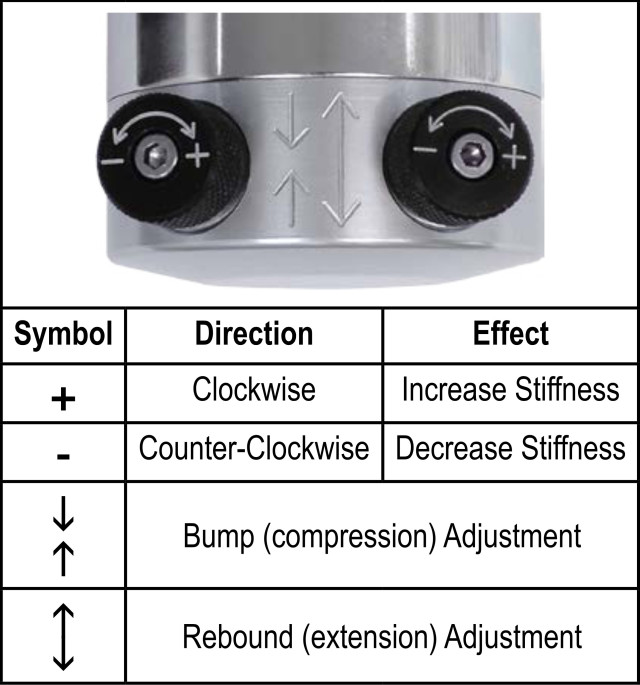

We’re dealing with a traction limited 2,000+ horsepower vehicle , and a three-way adjustable 90/10 shock just won’t cut it. In this application, independently controllable bump and rebound adjustments are critical to getting a radial tire equipped car off the line and safely down the track. Too soft on the rebound, and you’re guaranteed to get uncontrollable wheelies. Too stiff on the bump, and you risk tire spin down the track.

To help with this, the Varishock team came up with an adjustment mechanism called QuickSet. The QuickSet two valve system makes it easy to dial in quick adjustments by conveniently placing two adjustment knobs at the bottom of the strut. They independently control the bump and rebound damping stiffness of the strut, and are easily accessible after being installed on the vehicle. Dual-arrow symbols engraved into the shock body demonstrate the function of each knob. The arrows point toward each other to designate compression adjustment, and the arrows point away from each other to represent rebound adjustment.

The VariShock QuickSet series allows you to easily tune your suspension for improved acceleration traction, or to quickly adapt to current track conditions. Adjustment takes only a few seconds, and can be made while the shock or strut is installed on the vehicle.

(Left) The strut features individual extension and rebound dampening control knobs on the lower body. (Right) Each strut is equipped with a 1/2-inch spherical top mount, 7/8-inch chromed piston, aluminum reservoir body, one piece locking lower spring seat, billet machined steel strut base, and alloy-steel control arm pivot stud.

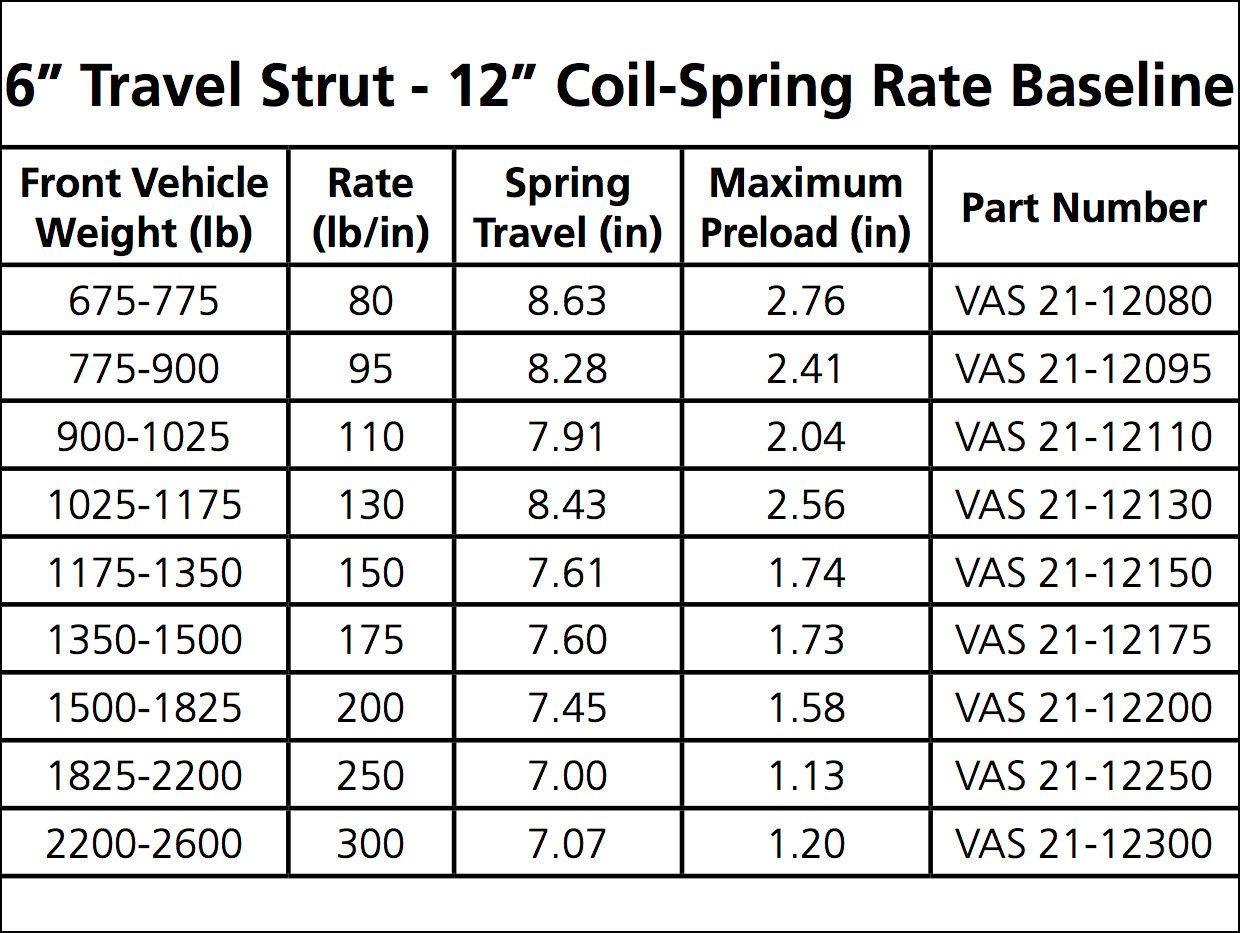

The struts also come with your choice of springs to help set ride height and stored energy for wheel-planting launches. The VariSprings are custom length coil springs that are made specifically for the VariShock strut application, and feature a wound 2.5-inch diameter high-tensile wire that is stronger than the chrome-silicon that is typically used by other companies. This allows VariShock to set the coils at a more aggressive coil angle, while maintaining resistance to fatigue.

The ends are then closed and ground to a 1.5-degree angle for proper seating. Chassisworks’ Lino Chestang explained, “The improved material allows VariSprings to compress until the coils touch without damaging the springs or causing them to take a set. As a result, the springs are able to provide more suspension travel from a shorter and lighter package.”

VariShock provides a tech sheet with spring rate and length recommendations based on variables including vehicle weight and spring travel. They also provide additional materials in the tech library that can be found on their website.

He further went on to state, “VariShocks are engineered, manufactured, and assembled in America using state-of-the-art engineering workstations and computer-numeric-controlled (CNC) manufacturing equipment. Each component, including valves, adjusters, and internal shaft seals, is designed and manufactured specifically for use in VariShock products. This level of clean-sheet engineering is the first step to producing longer lasting seals that keep dirt out of the shock absorber and extend service life between rebuilds.”

Optionally Available:

|

Chestang said, “To avoid the possibility of manufacturing debris contaminating the shock fluid and seals, the VariShock assembly clean room is housed in a separate facility from the machining area. After assembly, each shock is thoroughly dyno-tested and calibrated to meet VariShock’s strict performance goals.”

With the help of the folks at Chris Alston’s Chassisworks [8] and VariShock, we are looking forward to pavement pounding launches and insanely-fast short times. The car is almost together, and we can’t wait to get to the track.