[1]While much of the focus in drag racing suspension seems to rest on the rear of the car, what’s going on up front is every bit as important to producing a well-balanced, efficient chassis with solid driving characteristics. In an upcoming feature we’ll be taking an in-depth look at the JRi [2] front strut that will be helping us to accomplish this on our Project BlownZ06 radial tire C7 Corvette, but before we can get to that, we first have to center in on the mechanisms for mounting the strut to our PMR Race Cars-built chassis. For that, we sourced one of Quarter-Max’s [3] trick Threaded Adjustable Strut Mount kits.

[1]While much of the focus in drag racing suspension seems to rest on the rear of the car, what’s going on up front is every bit as important to producing a well-balanced, efficient chassis with solid driving characteristics. In an upcoming feature we’ll be taking an in-depth look at the JRi [2] front strut that will be helping us to accomplish this on our Project BlownZ06 radial tire C7 Corvette, but before we can get to that, we first have to center in on the mechanisms for mounting the strut to our PMR Race Cars-built chassis. For that, we sourced one of Quarter-Max’s [3] trick Threaded Adjustable Strut Mount kits.

What makes this strut mount kit different from your more traditional setup? It’s in the simplicity of adjustability. In the past, struts were mounted directly to the upper framerail and could not be located up and down in any fashion; in order to adjust ride height, you were forced to adjust your spring setting, therefore affecting the compression and travel of the strut. Other setups on the market employed the use of spacers that could be added or removed above the spring cup to provide some adjustability, but as Rickie Jones comments, such methods were time-consuming and rudimentary by comparison.

With traditional welded brackets, there is no adjustment at the top without it affecting your strut and shock. All you can do is raise or lower the spring perch to raise or lower the car – Rickie Jones, Quarter-Max

“With traditional welded brackets, there is no adjustment at the top without it affecting your strut and shock. All you can do is raise or lower the spring perch to raise or lower the car,” Rickie shares. “You can raise your spring to raise the car, but that reduces your amount of travel. With our threaded kit, you can fine-tune both the ride height and the travel independently, so you can manipulate either one to be exactly where you want it to be. If the car is sitting too low and you’re happy with the amount of travel you have, all you have to do is turn the threaded collar down, thus raising the car, and you haven’t affected the spring in any way. So you can fine tune just the ride height without changing travel, or you can do both. It’s infinitely adjustable and you can have it where you want.”

[5]

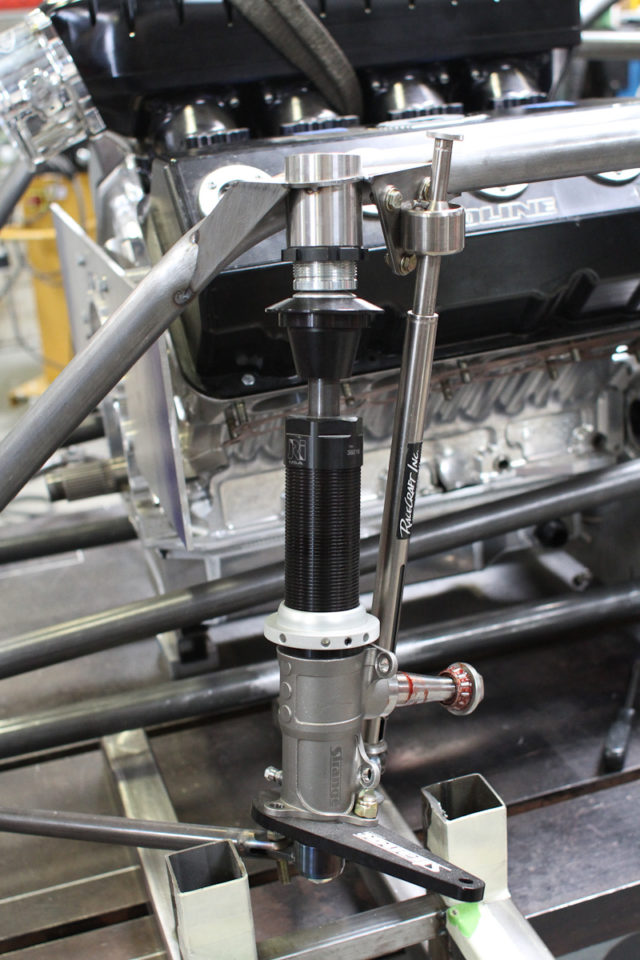

[5]PMR Race Cars tacks the outer mount and the fabricated gussets in place for mock-up purposes. To the left of the outer, you can see the bracket for the Racecraft strut extension limiter that we’ll be utilizing, as well.

So user-friendly is the Quarter-Max threaded setup that ride height can be adjusted right in the staging lanes, by using the supplied tool to release the spanner nut and a 3/8-inch ratchet with its proprietary and supplied tool to loosen the threaded mount from the top.

“If you go up there and the track is hot, there’s been an oildown and you’ve been sitting there for an hour and you need more weight transfer, you can just screw the mount out and raise the front of the car a turn or two and get the center of gravity up.” Rickie explains.

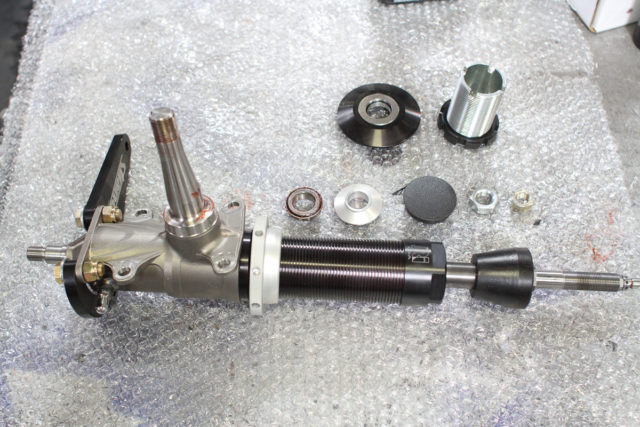

The Quarter-Max kit comes with a threaded outer mount that you'll want to adequately gusset for strength, whether you're notching it or welding it externally to the framerail. The threaded inner mount is roughly 2-2.5-inches in length, providing an estimated 1-1.5-inches of safe adjustment (with enough thread still inserted in the mount) in ride height. At right, you can see the spanner nut that locks the mount in place once the desired ride height is achieved. Quarter-Max provides the tool to lock the spanner nut down with the kit.

The mount provides roughly 1.5-inches of ride height adjustment—Rickie says there’s about 2- to 2.5-inches of thread, but for the sake of safety, maintaining a minimum length of thread inside the mount is necessary.

Four notches are positioned on the top of the cup, each of which is a quarter of a turn, which will allow for fairly accurate adjustments from one side of the car to the other when doing so on the fly in the staging lanes. You can, of course, always measure the car afterward to ensure accuracy, as well.

PMR Race Cars installing the JRi strut for final mock-up purposes. At right, you can see the inner threaded strut mount being adjusted with the supplied tool from Quarter-Max.

Quarter-Max, the mail order division of the world class chassis builders at Rick Jones Race Cars, have left no stone unturned with its threaded strut mount kit, providing virtually everything needed to complete your strut install except the strut itself, a set of lower control arms (which they sell), and the structural gussets for the outer mount (which they also sell).

Even with an older car, it’s a great investment and upgrade as a tuning tool. – Rickie Jones, Quarter-Max

For smooth operation, the mount features a bushing that goes inside the spring cup that sits up against the spherical bearing inside the strut mount. This bearing acts as a misalignment bushing to provide the pivot point and eliminate binding during strut travel.

“As the strut goes through its travel, it can bind more, but with this, it’s going to pivot as it goes through its range of motion. With a welded bracket, you can only get it neutral in one spot, and once it begins to move it wants to either push the bottom strut in or out. So this allows the strut to be neutral and not bind, which makes it smoother and actually allows the strut to work easier,” Rickie explains.

Jones and company utilize the threaded mount on all of the racecars they build these days, and recommend it to others building new cars, as it saves time and money to do it upfront.

“Even with an older car, it’s a great investment and upgrade as a tuning tool. Previously, if you wanted to change your travel, you actually had to take the strut off the car and send it back to the manufacturer, they would take it apart and actually change the spacers internally between the top of the piston and the inside of the body to alter the stroke. With this, now we can do anything we want to do, after the fact.”

[12]

[12]Ride height is typically set up on the jig sans the spring installed to the strut. Once the car is on the ground under its own weight, fine tuning can then be done on both the strut and the strut mount to achieve the desired balance.

Rickie says Drag Week racers, in particular, have found the adjustable mount to be a perfect solution, as they can lower the ride height for the track and then adjust it back up for the highway miles in between stops. The adjustability also allows for the exchanging of front tire sizes without compromising the ride height, Rickie adding “years ago when we built cars we had to ask the owner what front tire they were going to use, because it was going to change where we would mount the top strut mount to achieve the correct ride height. Now, if you want to change the front tires, you have plenty of room to adjust it.”

[13]

[13]The finished product, with the supplied cover over the outer mount to give a nice, clean appearance.

In this day and age of not only instant gratification, but crossover use of racing vehicles and incredibly precise tuning windows, Quarter-Max’s threaded strut mount gives racers one additional tool at their disposal that, more than anything, just makes their lives that little bit easier.

As Rickie Jones shares in closing, “It’s just another tuning tool that racers never had before.”