When you’re limited by tire size, as competitors in Outlaw 8.5 and 235 radial-style categories are, pure, unbridled horsepower becomes slightly less vital to success than other parts and pieces on a racecar. Now, that isn’t to suggest that horsepower isn’t mandatory, but with so little contact patch on the racing surface, if you can’t navigate the first sixty feet, what happens beyond that point is largely irrelevant.

For this reason the suspension system — and the tuning of such — is key to any racer that wants to win in these categories. In all reality, Outlaw 8.5 is a tuners’ game, and the better equipped with the knowledge and proven, quality parts you are, the greater chance of consistently outrunning the other guy. For that very reason, we’ve teamed up (no pun intended) with the crew at Team Z Motorsports to assemble a top-notch suspension setup for our Project Evil 8.5 Mustang and paired it with bulletproof driveline components from Strange Engineering to ensure we can quickly, and reliably, get hooked-up and moving when we hit the track this spring.

The NMCA WEST’s Outlaw 8.5 class, which is where we’ll primarily be running the new car out here on the West Coast, mandates the use of stock-style suspension and mounting points. Fortunately, the Fox-body Mustangs were equipped with more-than-adequate (for drag racing) triangular 4-links from the factory, which presents an excellent platform for our needs; it’s also one of the reasons why Fox-bodies are so common in drag racing. When you consider that Team Z-sponsored racer Brad Edwards shattered the three-second barrier on drag radials with stock suspension using some of the very same components we are, any perception that the stock-style setup can’t handle big power is definitely not reality.

Let’s take a look at what’s under the fenders of Evil 8.5 …

Rearend Housing And Suspension

The central component, of course, in the suspension setup in Evil 8.5 is the rearend housing, and we’ve sourced a killer piece from Team Z to fill that void: the company’s beefy Fab 9, Ford 9-inch housing. While a feature-packed part in and of itself that serves as their top-of-the-line housing, the defining highlight is the infinitely adjustable upper and lower control arm mounting brackets that Team Z’s Dave Zimmerman and his crew developed.

The complete Team Z Fab 9 housing assembly, including the upper and lower control arms and shock mount brackets. This is Team Z’s all-out race offering and has been into the three-second zone on Brad Edwards’s radial tire Mustang.

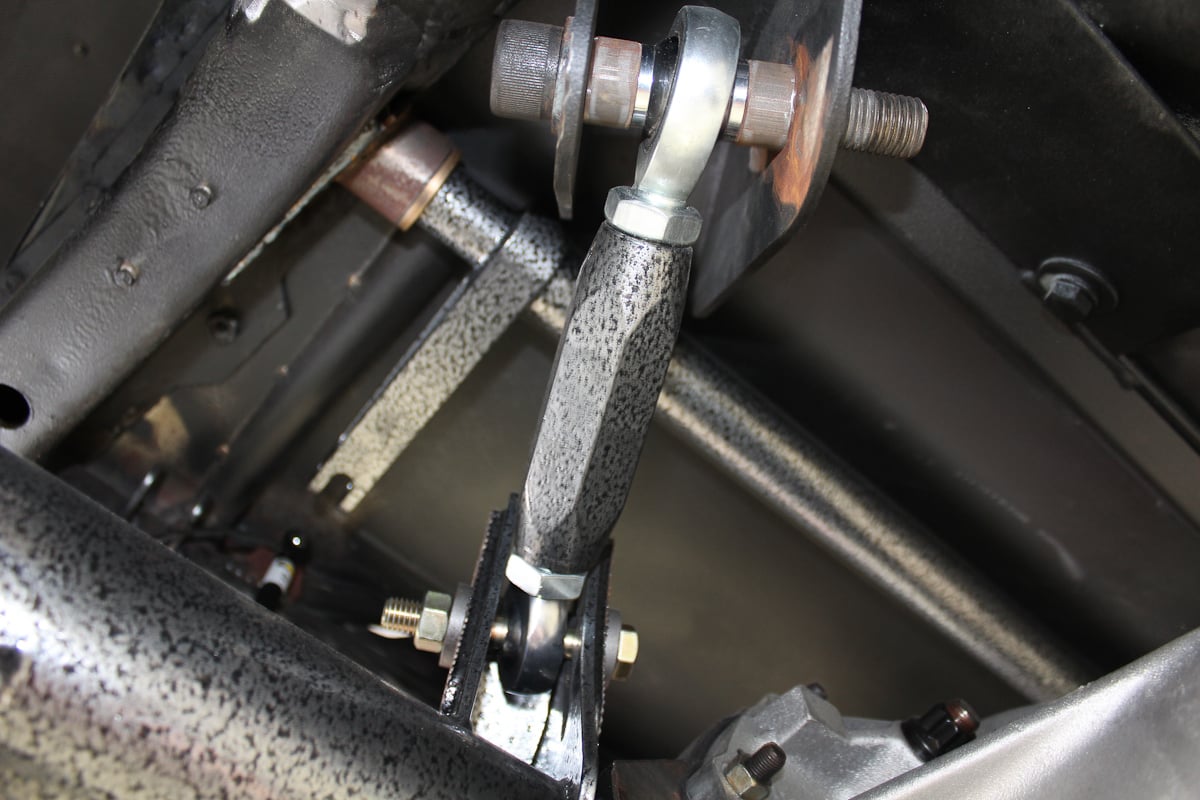

While typical rearend housings feature brackets with control arm mounting eyelets that measure about 1/2-inch and are staggered somewhere in the neighborhood of 7/8-inch apart, the Team Z Fab 9 instead has a free-floating slot with locking serrations spaced out vertically every .125-inches. Through the use of a special locking washer, the control arm is held firmly in place, but can be adjusted up and down in the aforementioned .125-inches to achieve the needed instant center and anti-squat for the conditions.

At left is the short triangulated upper control arm, which is specific to the Fab 9 Team Z housing. At right, you can see the serrated design that Team z has instituted, allowing for very fine instant center and anti-squat adjustments -- much moreso than a standard 4-link bracket.

On the lower control arms, we have them figured out that three teeth (serrations) equates to a 10 percent anti-squat or specific length, depending on whether its the upper or lower control arm that the instant center moves. So you can make very fine adjustment. – Dave Zimmerman

The face plate of the housing is made of 5/8-inch, 1018 steel, while the axle tubes are 3-inch 4130 chrome-moly, creating what Team Z believes is a superior, high-strength housing able to cope with the demands of today’s high-power racing machinery.

Team Z produces a set of upper and lower control arms that are available standalone in their catalog, however, the Fab 9 housing requires a unique upper control arm due to the use of the serrated bracket, and so both of the control arms are supplied when you purchase the housing. Team Z machines the upper arms from 1-3/8-inch hexagon billet steel, while the lowers are 1-3/8-inch chrome-moly.

According to Zimmerman, the wide range of adjustability on the housing is of particular value to small-tire racers, like those in Outlaw 8.5.

“With the smaller tire, sometimes it’s pretty hard to get a shorter instant center, which you may need, depending on the track, in order to hit the tire harder. The Fab 9 housing will really allow you to fine-tune for the tire, which is definitely going to be more finicky on lesser-prepared tracks because you’ve got a contact patch that’s only 8.5-inches wide.”

Despite the triangulated design of the Fox-body rear suspension, the concept of instant center (or the imaginary intersection point of the upper and lower control arms) remains the same as a traditional 4-link. While this is an entire topic in and of itself that we could devote thousands of words to, the short explanation is that instant center is combined with the center of gravity point and anti-squat line to tune how a racecars’ suspension reacts. The only difference, however, in our case is that we don’t have four points of adjustability for the control arms, since the chassis-side mounting points are fixed. This, Zimmerman explains, simply gives you a smaller tuning window to work within.

“Some classes allow you to adjust your pickup points on the body side, but Outlaw 8.5 leaves you stuck doing it all on the rearend side, so that’s part of the reason we designed the serrated bracket on the housing to provide as many pickup points as possible given the constraints,” Zimmerman says.

Switching from an 8.5-inch slick to a 235 radial — tires of similar dimension but with vastly different characteristics — something some racers will do depending on track conditions, is a matter of adjusting your instant center height once you have a baseline instant center length, as Zimmerman shares.

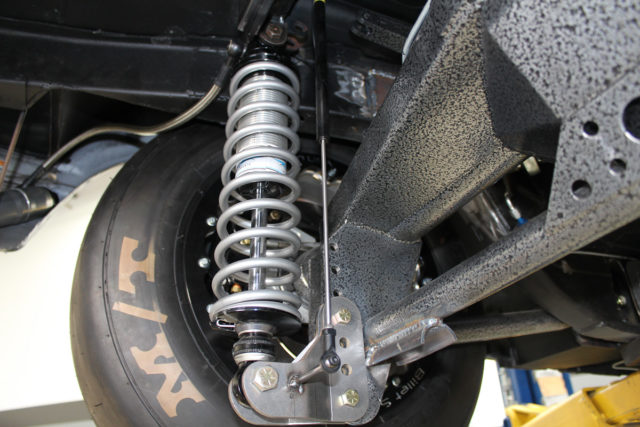

Our rear suspension assembly in nearly complete form. Before we hit the track, we’ll be dialing in the instant center according to baseline numbers from Team Z to give us a solid starting point for our testing.

“The main thing is finding an instant center length that works on a tire; I’d say somewhere between 36 and 42-inches in length should be your sweet-spot. You could run more anti-squat (the height of your instant center point vertically from the ground) with the radial versus the slick, because the slick has the bias-ply sidewall and it’s soft, so you can use more anti-squat and hit the tire harder, creating a mechanical force pushing the tire into the track,” he explains.

Lastly, comes Team Z’s Fox body Billet Sway/Anti-Roll Bar (P/N TZM-RB-BILLET). Because the triangulated upper control arms handle the job of locating the rearend housing side-to-side, we don’t need a wishbone or Panhard bar. We do, however, need to combat body roll, thus the need for a sway bar, or anti-roll bar, to reduce excessive body pitch during the launch. The new Billet Sway Bar, which will be officially released this spring, is made from 1-3/4-inch diameter, .250-inch wall 4130 chrome-moly with billet CNC-machined arms from 4130 plates. The sway bar is fully TIG-welded, while the anti-roll bar arms are an I-beam-style construction with CNC-machined pockets, giving it a great deal of strength.

The Driveline

In addition to serving as the centerpiece of the rear suspension, the rearend housing is also the very structure of the driveline of any vehicle, and a bulletproof housing demands equally bulletproof internals. For that, we turned to Strange Engineering for everything from the transmission yoke clear back to the axles and the brakes.

The driveshaft (P/N U1702) is a tubular, seamless, 3-inch diameter, TIG-welded chrome-moly shaft with an .083-inch wall thickness. Strange has built these shafts with beefy 4130 forged weld ends that accept larger-than-OEM U-joints. The supplied Spicer 1350 or 1480 U-joints have a 1-3/16-inch cap size for strength and are non-cross-drilled for rigidity. Strange can customize these shafts on request, based on length and maximum operating engine RPM. Strange recommends pairing them with matching 1350 U-joints and rear yoke, pointing out that “driveline integrity is limited to the strength of the weakest component.”

Strange’s tubular shafts are electronically balanced and have a total run-out of less than .008-inches. These are also available in 3.5-inch outer diameter for those whose applications demand something a little larger (the length of the shaft and horsepower are the determining factors, although Strange’s J.C. Cascio suggests vehicle weight can potentially come into play).

The driveshaft is driven by Strange’s 1350 Series transmission yoke, a GM 32-spline severe duty piece intended for use with Turbo 400, 4L80E, and Super T-10 transmissions. The yoke is forged from 4340 chrome-moly fully machined steel, giving it a high degree of strength for extreme racing applications. The yoke has additional material in critical areas to add to said strength, and sports a black oxide finish to resist corrosion under the vehicle. It accepts large 1350 Series U-joints.

The 9-inch Ultra case, already assembled with the pinion yoke, spool, carrier, bearings, and ready for installation.

The center section, fittingly the centerpiece of the driveline, is Strange’s tough 9-inch Ultra (P/N PF225), a case designed with maximum gear life in mind. Strange has designed the case with both pinion bearings inside, offering greater support than more typical designs with the bearings outside the case. The pinion support also has a tight fit to the case bore to eliminate flex, and an oversized tail bearing holds the pinion gear in proper alignment with the ring gear under even the most extreme of operating conditions.

The 9-inch Ultra, available in three different variants of bore size (3.812 and 3.250) and/or internal components, accepts 9-, 9.5-, and 10-inch gear sets (the 10-inch requires the proper pinion support), and is designed for heavy duty, lightweight 40-spline steel spools that feature thicker bearing journal walls to eliminate any possibility of a collapse under load.

We’ve utilized the Pro Series lightweight 40-spline for the 3.812-inch bore case (P/N D2002) in Evil 8.5’s build. The spool is paired with a 9-inch, 3.70 US Gear/Strange Pro Gear with a 35-spline pinion. The Pro gears are valuable in applications where standard gears are prone to breaking teeth; the Pro gears are produced from softer heat-treated 9130 forged steel material, allowing the teeth to flex rather than crack or break.

The ring gear measures a 9-inch outer diameter with a 37-tooth count, while the pinion is, likewise, 35-spline with a 10-tooth count.

Strange's 40-spline, lightweight Hy-Tuf axles are designed to take just the kind of beating we're going to deliver them.

The pinion yoke (P/N U1604) is a forged chrome-moly piece for Ford 9-inch cases, and has a 35-spline shaft. The yoke is made from 4140 steel, accepts 1350 U-joints, and fits 9-, 9.5-, and 10-inch, 35-spline Pro gears.

The final piece of the driveline puzzle is Strange’s 40-spline Pro Race Axle Package (P/N P1014), a gun-drilled set of Hy-Tuf axles optimized specifically for drag racing. These axles are forged from a low carbon, high manganese, high nickel, and high molybdenum steel and are compatible with Dana 60 and Ford 9-inch applications. The gun-drilled design removes about a pound of weight per foot, and the further addition of lightening holes removes an extra .4 pounds per axle to keep them light and durable. The axle kit is supplied with sealed ball bearings, retainer plates, and stud kit, and comes with a range of options regarding stud sizing, spool additions, a 35-spline option, C-clip eliminators, and more.

Stopping it all is Strange’s drag race-specific Pro Series rear brake kit for later model Big Ford Ends with a 2.5-inch brake offset (P/N B1706WC). This setup features a forged, one-piece steel slotted rotor for improved air flow and less risk of warpage, while dropping a little weight at the same time. The calipers are a four-piston, directional design with stainless steel pistons (which are corrosion resistant) and measure 1.625- and 1.750-inch to apply varying pressure on the pads to decrease pad taper over time. The directional calipers accomplish superior bridge bolt strength at only 2.70 pounds.

The aluminum caliper bodies also reduce the weight of the complete package. Strange has created billet aluminum caliper mounts with a one-piece design that eliminates spacers and bolts and the necessary routine maintenance of such, and they’ve also included the housing stud end kit, which brake kits often don’t come with. The brake pads themselves are a soft metallic that give more starting line holding power when cold (which drag race brakes typically are at that point).

With the soft metallic pads, the Pro Series kit weighs 23.70 pounds.

Travel Limiters To The Front

As well-seasoned racers know, getting a racecar to hook isn’t limited to fine-tuning the rear suspension; what’s going on up front is just as vital to the overall recipe. No matter the vehicle or the conditions, proper weight transfer in necessary to help plant the rear tires and carry the car through the early part of a run where power is being applied.

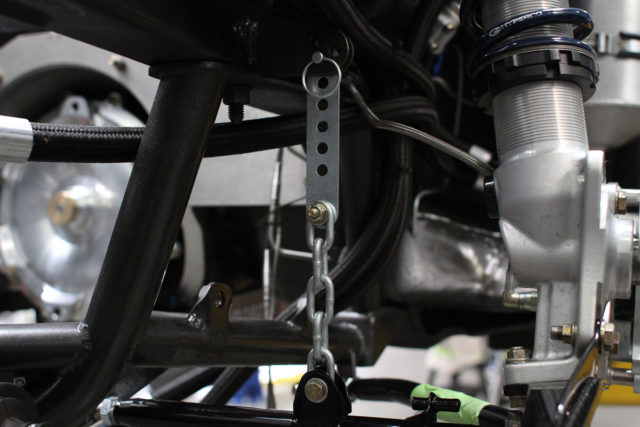

The need to tune the front end is of particular importance on hot, greasy race tracks, and out here on the West Coast, where the summer temperatures can soar over 100 degrees and push track temperatures into the 130’s and 140’s, a controlled degree of weight transfer is key. That’s where travel limiters come in, allowing one to adjust the maximum extension of the front shock and effectively “carry” the front wheels to transfer the weight back to the rear tires at the launch.

Travel Limiters In Practice

The job of travel limiters is not to alter how quickly the front shocks extend or compress — that’s the job of the valving within the shock body — but to physically limit how far the shock can extend from the body at the launch. Ultimately, the goal is to not waste any time or momentum carrying the front wheels, but to still transfer the weight to the rear tire in an optimum manner. By increasing the amount of travel, you can transfer more weight to hook up on a bad track — as much as 5-6 inches. On a perfect track, you might have as little as zero travel.

“The kit has three-hole plates that mount to the framerail and then a tab that will bolt to the A-arm. With the holes in the adjuster, you can move your travel up in 1/8-inch increments,” Zimmerman says.

So how do you go about using them?

“Judge the track,” Zimmerman explains. “If the track is fairly good, we rarely ever use more than about 1-1/4-inches of front end travel, even on the little tire. But sometimes it’s the middle of the day, the sun is out, the track is hot and you need more weight transfer to keep the tire planted and more weight on the tire. In those instances, you might go as much as two or three inches of travel on the front. If the track is really tight, you probably only want that 1-1/4-inch.”

With the engine complete, our driveline setup all bolted in, and the suspension system finalized, we’re down to the final nitty, gritty details on Evil 8.5. In upcoming installments, we’ll be highlighting some of the smaller parts and pieces, along with our new ATI converter and our fuel injection and data acquisition system. And then, it’ll be time go to racing!