It has been proven for decades; if you put a tightly controlled ruleset on an engine builder and racer, the desire to be on top will lead to all kinds of innovation. While we aren’t talking Formula 1 here, we are talking about one of the hottest classes in sportsman drag racing, one of the most ingenious racers, and an engine-building powerhouse. Enter Artis Houston’s X275 engine built by Bischoff Engine Services – or BES.

This particular project started off as a general rebuild, but quickly escalated. An engine failure suffered a few years back set Houston off on a quest to get back into action.

“When it broke, I was just going to rebuild it,” says Houston. “The whole bottom end, including the block, is brand new. The heads are the only things that aren’t new, but they’ve been completely redone as well. So technically, I’d say it’s kind of in-between an all-new build and a rebuild.”

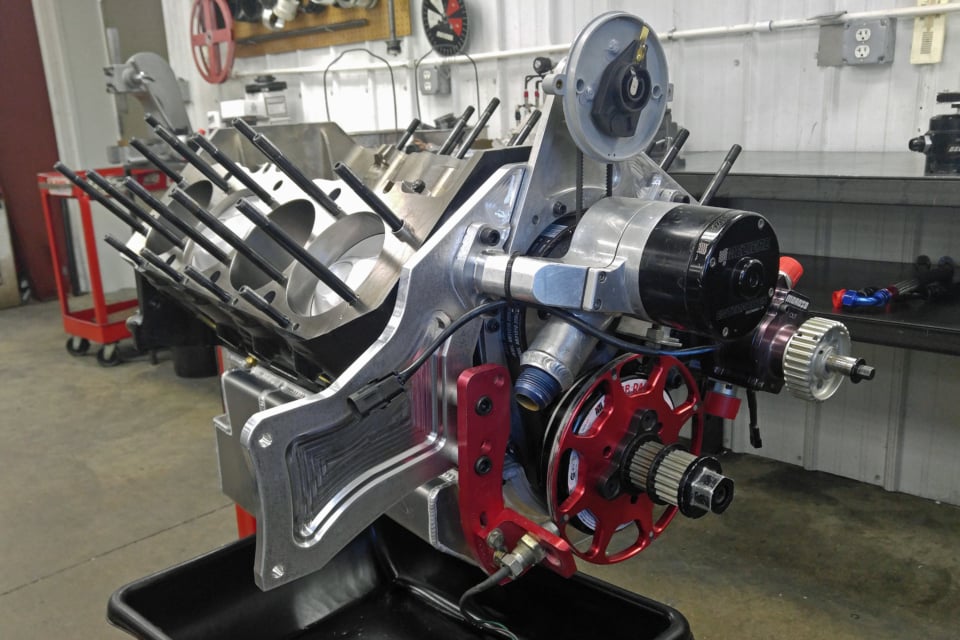

Starting with the aforementioned brand-new Dart Big M block, BES bored the cylinders out to a massive 4.600 inches. Next, with Calico CT-1-coated Clevite bearings in place, a Callies 4.375-inch stroke crankshaft was dropped in. Attached to that are a set of GRP aluminum rods—with a set of Ross custom 4.600-inch pistons hanging off of them—for a total displacement of 582 cubic-inches, which is less than the 598 cubes of the previous engine.

Bronze lifter bushings are used, while roller cam bearings help to minimize as much drag as possible.

The piston rings come from Total Seal, and are a competition configuration of a .043-inch top ring, .043-inch second ring, and 3/16-inch oil control ring. With today’s ring technology, the .043-inch top and second is still strong enough to handle heavy nitrous use, while still offering less drag. A Williams aluminum oil pan seals up the bottom of the engine, while a Moroso external oil pump keeps the shortblock supplied with its lifeblood.

Inside the block sits a set of rollerized cam bearings to maximize the efficiency of the combination. The custom-ground camshaft is from Comp Cams—the specs of which are a closely guarded secret. Atop the bumpy lobes are a set of Jesel’s badass tie bar solid roller lifters. 7/16-inch Trend pushrods then actuate a set of equally badass Jesel 1.80:1 intake, 1.80:1 exhaust rocker arms.

The shortblock is filled with some of the best components money can buy. Custom 4.6000 inch Ross pistons, GRP aluminum rods, a Callies billet 4.375 inch stroke crankshaft, and .043-inch/.043-inch/3/16-inch piston rings from Total Seal.

Up top, BES started with Brodix BBC cylinder head castings which were carved using a big dose of CNC magic in order to get the big 490 cfm intake and 360 cfm exhaust flow numbers required for this engine to perform as needed. Titanium valves from Victory sit in both the intake and exhaust seats, and while their exact sizes are being held close to the vest on this engine, we can imagine there is a beautiful competition valve job on them as well. PSI valve springs handle everything the camshaft throws at it and keeps the valves in check at over 8,000 rpm.

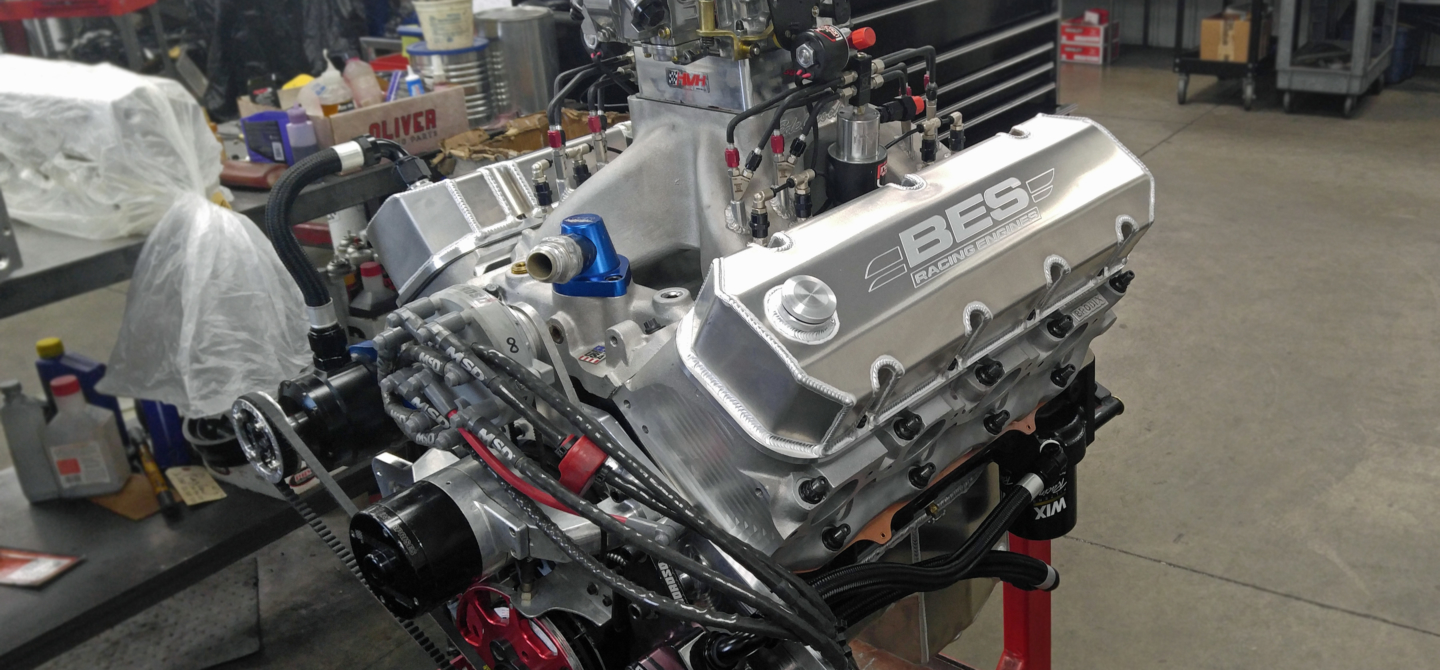

Topping off the combination is an Edelbrock single-plane manifold that BES has worked over to improve flow through all eight runners, as well as installing bungs for the direct-port nitrous system. A CFM 4500 custom carburetor sitting atop an HVH carb spacer provides the fuel and air to the engine, while an Induction Solutions X275-specific direct-port fogger nitrous system will be Houston’s power-adder of choice. Along with the nitrous, Houston will be running an Induction Solutions Mist A Fire direct-port water-injection system.

A Jesel belt drive system keeps the timing in check, along with an MSD crank trigger and front-drive distributor system. A Meziere electric water pump provides serious water flow and pressure to the engine, while a cogged belt drive turns the vacuum pump and remote oil pump.

Jesel Sportsman-series shaft rockers play a big part in allowing the engine to spin to north of 8,000 rpm. Also, notice below the Induction Solutions direct-port system, is an Induction Solutions direct-port water injection system.

If you were to look at the X275 field closely, you might wonder why Houston is building a big-block nitrous combination when the turbos and blowers seem to be at the top of the ladders more often than not. If you look at Houston’s history as the driver of one of the few leaf-spring cars to be competitive in a class going 1.0 and 1.1 sixty-foot times, it starts to become a little clearer.

“I’ve always liked variety, and I’m not one of those guys who goes with the masses,” says Houston. “Sure there are people who run a turbo because it’s “easier”, but I’ve always been the underdog, and doing things that people say can’t be done. My goal is to go 4.40s or better before I would ever consider going blower or turbo. That may be in my future, but I need to accomplish my goals with this first.”

As you can see, ARP head studs are used to help hold the head onto the block under the harsh cylinder pressures generated from a nitrous combination. Also note the cool cogged accessory drive and MSD front-drive distributor and crank trigger setup.

With Houston’s race operation based on the west coast, it might seem odd to build an engine for a class primarily run east-of-the-Mississippi.

“I plan on dragging it out to Georgia for Duck’s races,” Houston says. “I’m going to make the best out of what I can out here on the west coast in the meantime. We have the West Coast Hot Rod Assocation, and Team Boddie Racing is going to be putting on some races up north, so I’ll be doing some grudge racing and shootouts, too. Plus, there’s the Street Car Super Nationals in Las Vegas in November.”

With a history of setting goals that other people think are overly-difficult and accomplishing them, coupled with having one of the best – BES Racing – in his corner, we would be surprised if we don’t see Houston smash his ET goals by the end of the 2018 season.

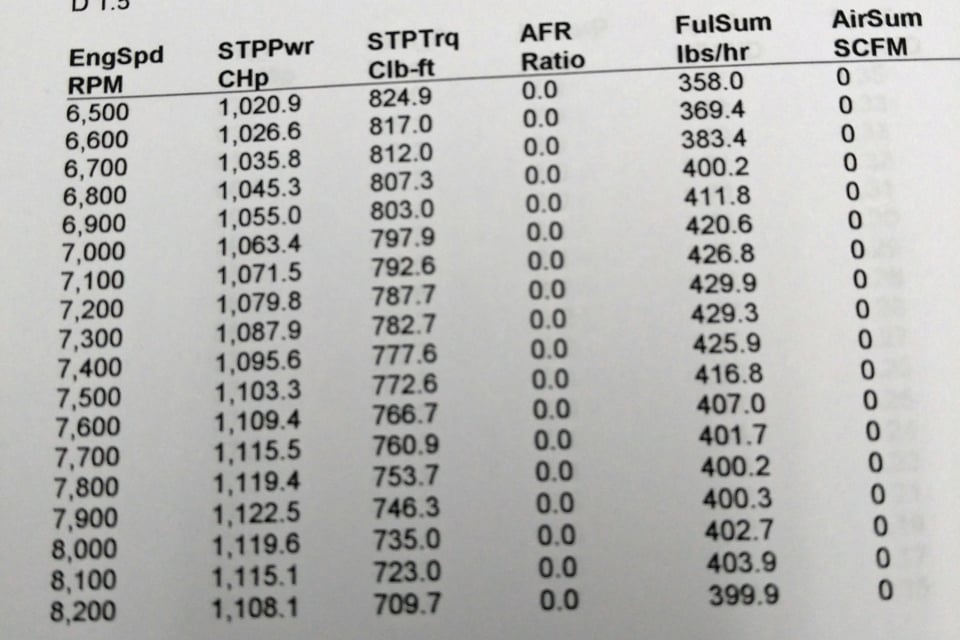

We were able to coax this much of a dyno sheet out of the team at BES. Obviously in a heads-up and grudge-racing arena, racers aren’t super-keen on revealing everything, but Artis Houston and BES really gave us a good look at what’s gone into his combination.