As the old saying goes, “There’s no replacement for displacement.” And drag racing engine builders know that to be a indisputable fact. But over the years, they, along with their customers, have continued to push the bleeding edge of performance by not replacing displacement, but rather supplementing it with power adders in the form of superchargers, nitrous oxide, and more recently, turbochargers. And this practice is none more evident than in the Pro Modified and Outlaw doorslammer realm.

In order to learn more about the history and evolution of the mega-inch powerplants bordering on and even exceeding 1,000 cubic inches that have overrun the sport, we sought out and picked the brains of some of drag racing’s most revered and decorated engine builders:

• Multi-time Pro Street champion Pat Musi

• Race engine builder Sonny Leonard

• Mike Janis, who is leading the charge in 5.300″ bore space supercharged engines

• Alan Johnson Performance Engineering’s Rick Wilkinson

• Dart Machinery’s Jack McInnis

From Big To Bigger

Today’s mega-inch powerplants are the result of two decades of progression in engine technology, as the pursuit of cubic inches have snowballed, and the rules governing the different categories that utilize them have opened up.

During the late 1980’s, Pro Stock teams were using the common large bore space big block engines of the time, namely the 4.900″ for the Ford camp and 4.840″ on the GM side. In response to the wishes of GM engine builders and in an effort to align the two combinations from a competition standpoint, the NHRA made provisions to allow the use of 4.900″ blocks, and when the first iteration of the GM Pro Stock engine, the Oldsmobile DRCE was released, it fit within that new regulation from the NHRA on bore spacing.

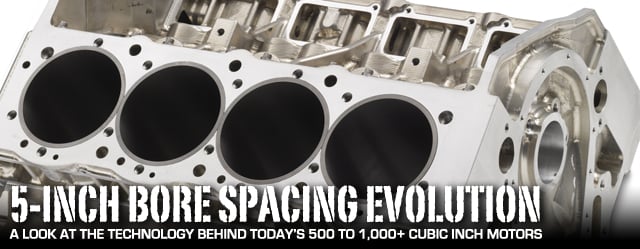

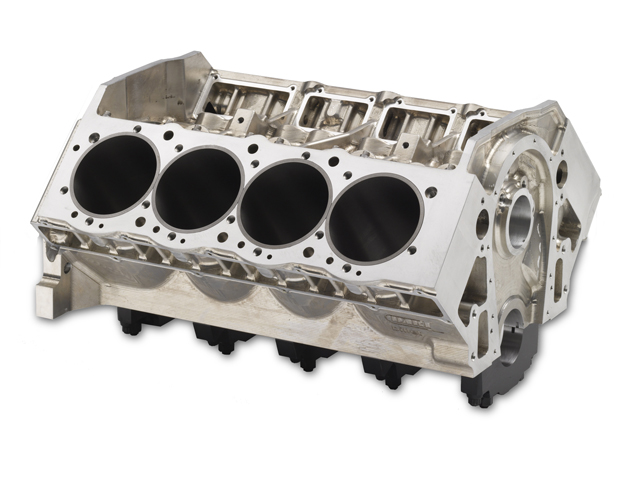

Dart Machinery is among the producers of 5.300" bore space engine blocks, which measure roughly 1.5-inches longer than a traditional 4.840" GM block.

“Of course racers being racers, as soon as the NHRA allowed spread-bore spacing in the rules, they began saying, well, let’s see if we can do five-inch, because they’ll let us do that pretty soon,” explains Dart’s Jack McInnis. “But, they never did in Pro Stock, though it opened the door for experimentation with it, and eventually it was allowed in Pro Modified; although that was more recent.”

From there, manufacturers and engine builders took the leap from 5.000″ bores spacing up to 5.200″, driven by Mountain Motor Pro Stockers and Pro Modifieds where their use was allowed. Engine blocks that large were of course no longer of the production variety, because as McInnis explains, when an engine is that large, nothing is normal anymore in terms of cylinder heads, cranks, and other components.

For more than a decade, sanctioning bodies contesting in the Pro Modified category surveyed and tweaked their rules in an effort to balance the supercharged and nitrous oxide-equipped cars that competed in the category, but between the 2006 and 2007 seasons, the NHRA awarded the nitrous cars an unlimited cubic inch allowance, and Pandora’s Box was wide open.

The Pro Modified sanctioning bodies, including the NHRA Pro Mod Series, changed the bore space and cubic inch limitations between the 2006/07 seasons, opening the floodgates for larger cubic inch engines, such as the 800+ cubic inch bullets from Sonny's Racing Engines.

As each of the individuals we spoke with agreed, it was this free reign to take the internal combustion V8 engine above and beyond even the 800-plus cubic inch mills in the Mountain Motor Pro Stock category that led to the 5.300″ bore spacing engines that are virtually the status quo today.

Why The Larger Bore Spacings?

Sure, wider bore spacing paves the way for larger cubic inch engines, but the real advantage of these engines isn’t in that result, but how that result is achieved. “When you get up around 800 cubic inches, the bore and stroke are really out of proportion, but with these new engines, we can go with a larger bore and smaller stroke,” explains Sonny Leonard. “If you want a more efficient engine, you’d run a larger bore and less stroke, therefore your power band would be broader and higher. You’d make power and less torque, which in most cases is the optimum method to get the best of both worlds.”

As anyone with knowledge of performance engines is aware, a larger bore, smaller stroke combination is the superior approach. And with larger bores, comes the need to move more air, thus requiring a cylinder head with larger ports and valves.

Just like peak horsepower, torque is an important ingredient to a bleeding edge drag racing engine, and peak torque is produced at the RPM where the engine is most efficient. As Reher-Morrison’s David Reher once explained in his National Dragster column, “Efficiency is the result of several factors, including airflow, combustion, and parasitic losses like windage and friction.” And as Reher put bluntly, a short-stroke/big bore engine is more efficient than a large-stroke/small bore engine.

“Larger bores simply breathe more air, and the resulting larger cylinder heads and larger valves, producing better airflow and therefore, more horsepower,” said Reher. “Likewise, the shorter stroke crankshaft means the pistons have less distance to travel, reducing the parasitic loss associated with ring drag. Windage and oil pressure issues are also lessened with shorter strokes.”

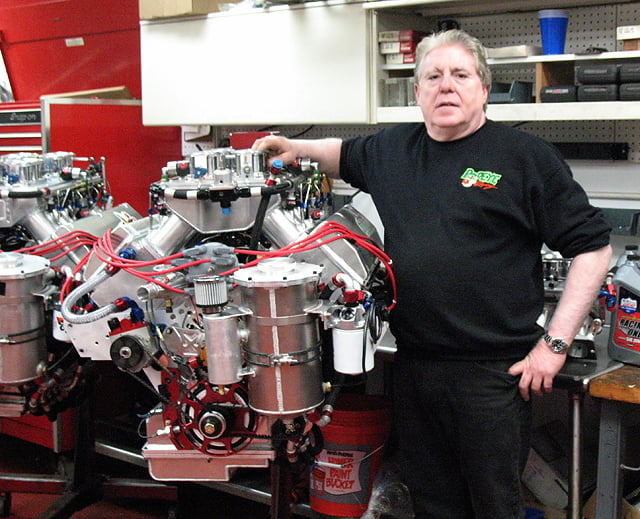

Multi-time Pro Street champion and legendary engine builder Pat Musi was the first to take the 5.300" bore space Pro Modified engines beyond 900 cubic inches, with his 903-inch powerplant. Sonny Leonard, whom Musi works closely with, also builds the 903's.

On naturally-aspirated engines, Sonny’s Racing Engines feature bores as large as 5.080″, while forced induction engines and their bread and butter nitrous-fed bullets sport bores up to an even 5.000″ with 5.500″ strokes. These maximum bore sizes, as Leonard explains, are put in place in order to retain a thicker overall cylinder sleeve so that they won’t experience distortion from the increased cylinder pressure.

A longtime nitrous oxide engine builder, Musi points out another advantage of the larger cubic inch capabilities of the 5.300″ engines beyond the efficiency of larger bores. “Displacement and the amount of nitrous you can put in an engine is all part of it,” says Musi. “The bigger the displacement, the more nitrous can you put to it, and there’s no substitute for cubic inches. Everyone else stopped at 865 and I was the first to do the 903, but then everyone caught on to that.”

As Musi goes on to explain, the differences between carburetors and fuel injection has much to do with how far one can push the cubic inch envelope.

As Musi explains, the use of carburetors is a restrictive points in a monster cubic inch engine. The use of electronic fuel injection, however, doesn't pose the same bottleneck.

“You can’t really get enough carburetor on these big engines, and so some engine builders are limited by that. But use fuel injection, and we can put as much air to the thing as we want.” Similar to Sonny’s engines, the Musi-built powerplants sport 5.000″ bores with 5.750″ strokes to arrive at the 903 cubic inches. And to flow all of that air, throttle bores as large as 2.750″ move the incoming air through 2.720″ intake valves and 2.02″ exhaust valves, to the tune of more than 600 CFM on the intake side.

So How Do They Differ?

While the external dimensions on the blocks and heads for a 5-inch engine are physically the same size as the OEM GM 4.840″ parts, as one can imagine, everything on a 5.200″ and 5.300″ engine is stretched out and made larger, with the external dimension on the block and heads measuring about an inch a half longer than a traditional block according to Leonard, and with larger intakes, valves, and so on and so forth.

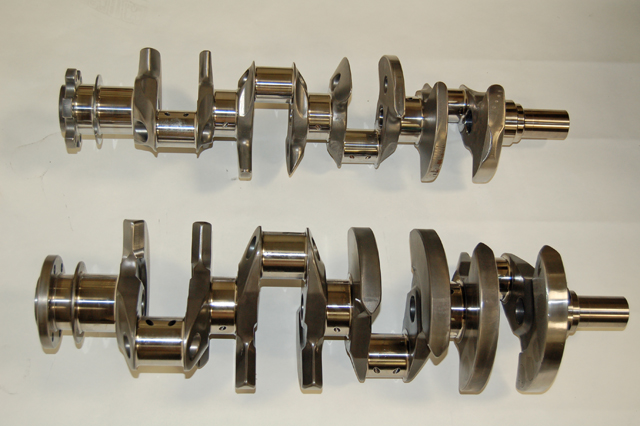

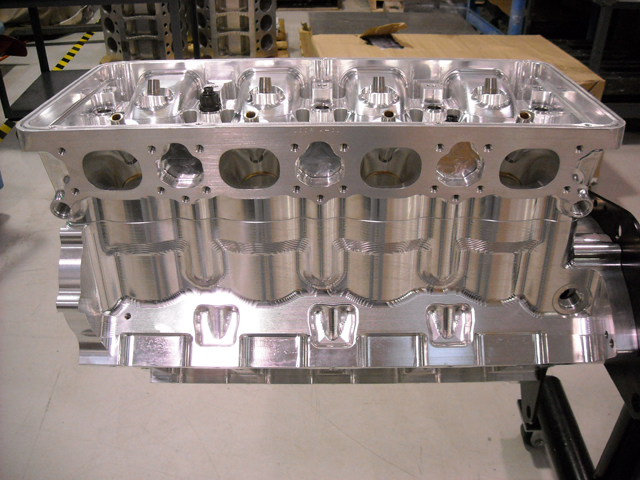

With bores larger than anything else on the market, manufacturers such as Diamond, JE, Ross, and others have put into production pistons sized and designed specifically for these engines. Crankshaft and camshaft manufacturers have also had to lengthen the design of their pieces to accommodate the longer block and wider rod journal spacings. Right in line with those requirements, the intake manifolds, rocker system, and headers all necessitate a larger design.

The raised camshaft location also takes negates the standard belt drive systems on the market, requiring a special piece to do the job.

With larger blocks comes the need for larger cranks, pistons, cylinder heads, intake manifolds, rocker assemblies, and other components.

“The limiting factor in these things really starts to become what you can obtain to bolt onto it and what you can use for parts,” explains McInnis. “The billet block you can create to be whatever you want it to be, but then you have to find the parts to fit it.”

The Challenges

Developing these engines and making them perform isn’t simply a case of making it bigger, slapping it together, and going. Like any other foray into unknown territory, there are challenges in finding what these engines like and how and where they produce peak horsepower and torque numbers.

“It’s definitely difficult,” said Leonard. “Just imagine an engine with a restricted carburetor on top of it: it just limits the air you can flow and the power you can produce. If you just want a large cubic inch engine and don’t accommodate for a larger valve, than you can’t accomplish much. To make more power, you’ve got to flow a lot more air, and to flow more air, you’ve got to have an extremely good flowing set of cylinder heads. That means larger valves, improved valve angles, and great valvetrain geometry.”

With bores of 5-inches, moving all of that air has been one of the biggest challenges for engine builders in the early stages of their development and testing.

Beyond pushing all of that air, the nagging issues that plague any new piece were dealt with early on in their development and dyno and track testing. Said Musi, “We’ve always made plenty of power, but we had some troubles in the beginning with oiling problems because there’s a lot more windage going on in the oil pan. It’s a bigger engine, and it took a lot to get it right, but we got it, and they’re staying together pretty darn good right now.”

5.300″ – No Longer Just For N/A And Nitrous Engines

In the NHRA, supercharged engines are limited to a 5.000″ bore spacing, but in the American Drag Racing League, where virtually anything goes, that same limitation is nonexistent.

In January, Alan Johnson Performance Engineering announced a new partnership with veteran Mike Janis and his Jan-Cen Racing team for the development and testing of a brand new, 5.300″ supercharged powerplant in his new Pro Extreme ’70 Duster for use in ADRL competition, and the pair believe in due time, this new engine will revolutionize outlaw doorslammer racing.

This season, Mike Janis debuted a 5.300" bore space supercharged powerplant developed by Alan Johnson Performance Engineering that could likely revolutionize outlaw doorslammer racing.

“That’s the idea,” says AJPE’s Rick Wilkinson. “Everything that’s out there now is really at its limit: where the bores are as large as they dare make them, the sleeves become thin, the ring seal doesn’t become as efficient, the pistons get lighter and thinner, and just a lot of other things that racers are using with the conventional engine that we can get away with because we’ve got so much more room with the bore size.”

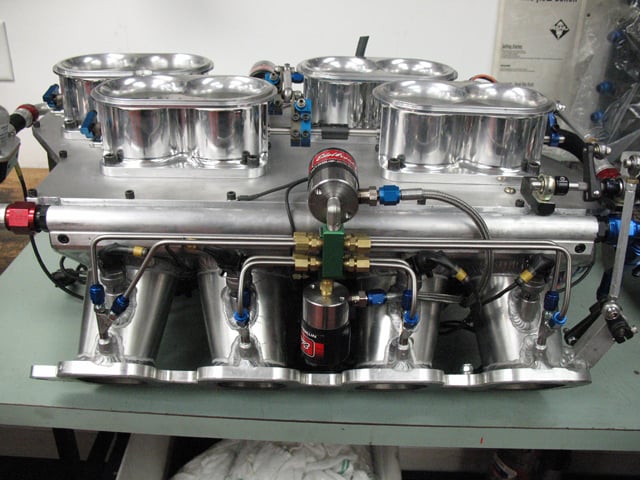

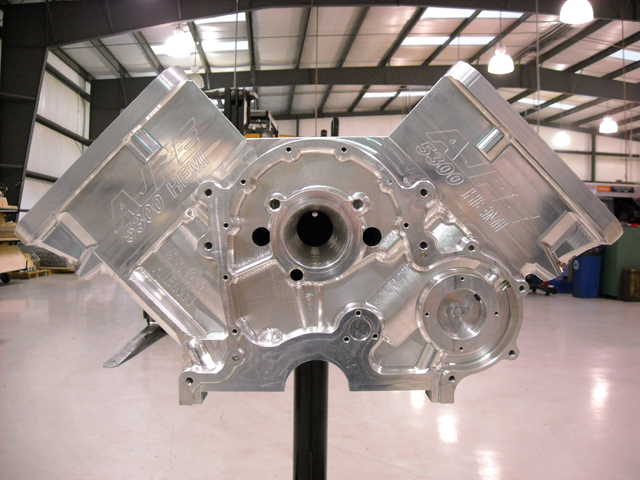

The AJPE 5300, as it’s known, features thicker cylinder walls, a shorter deck translating to shorter pushrods, a fuel pump that’s run off an auxiliary drive off the gear drive, and a divorced camshaft tunnel with a location raised some one-inch from the previous 481X and HEMI blocks. And as Janis explains, one of its greatest attributes is in the cylinder heads. “It’s got a big 2.600″ intake valve, which is exactly what the screw blower wants. We can give it everything we can possibly give it.”

Janis’ current powerplant, one of just two that AJPE has built, measures 531 cubic inches, with a 3.750″ stroke and a 4.750″ bore. Like the nitrous engines, the AJ Hemi cylinder heads are physically larger, featuring raised exhaust ports and enlarged intake ports that Janis estimates to produce about 100 CFM more flow than the smaller HEMI heads. “It’s just a matter of getting enough blower to feed it,” Janis explains.

The 5.300" bore space block from AJPE features thicker cylinder walls, a shorter deck translating to shorter pushrods, a fuel pump that's run off an auxiliary drive off the gear drive, and a divorced camshaft tunnel with a location raised some one-inch from the previous 481X and Hemi blocks.

AJPE designed the new bullet with maintenance in mind, placing the head studs as such that the heads can be removed without removal of the intake manifold and supercharger, something that wasn’t possible in previous Hemi engine designs.

Janis debuted the AJPE combination at the ADRL season opener in Houston and has ran into the mid-3.70’s while learning the new engine combination and ironing out a new race car. This indicates plenty of potential as the knowledge base progresses. “We’re still working with some different camshafts and things, but every time we’ve had it out, it’s been a big plus,” Said Janis.” We take it apart after each time we’ve run it, and it’s sparkling; it looks like it hasn’t even been run.”

The HEMI cylinder heads, designed by AJPE for their 5300 engine, feature a 2.600-inch intake valve, which can adequately flow the air produced by the screw superchargers, according to Janis.

What’s Next, You Ask?

The 5.300″ standard is likely to remain in place for some time; however, larger bore spacing is possible, and if all goes to plan, will soon be a reality. Washington native Craig Olson recently became the quickest and fastest naturally-aspirated, automatic transmission-equipped doorslammer in the world at 6.28 seconds and 223.02 MPH with his 935-inch Sonny’s bullet, and according to Leonard, a 1,000 cubic inch, 5.400″ bore spacing engine is in the works for Olson’s immaculate ’69 Camaro Top Sportsman machine that could very well make 6.0’s a reality.

Regarding the supercharged engines, the AJPE 5300 has opened up the possibility of experimentation with larger bore sizes and cubic inches beyond the traditional 500 and 526 cubic inches, and that’s a discussion that Wilkinson doesn’t rule out. “I would imagine that an increase in cubic inches would be an advantage at some point, but we don’t know that yet; it’s kind of an unknown territory. The cylinder head is the restriction in the system, and now that we have a head that flows much better, we don’t know if the supercharger will become a weak link at that point and be insufficient at pumping enough air to feed the engine. I’m sure there’s a balancing point in there, but we just don’t know that point yet.”

Not that it needs to be said, but race engines and the technology behind them have come a long way in the last two decades . The wheels inside the minds of the innovative figures of the racing engine industry are continually turning, and the only limiting factor to the continued evolution of race engines is the guidelines from the organizations for which they’re utilized. The 1,000-plus inch engines from Sonny’s are but a hint at what we might expect over the next couple of decades. It’s been an interesting ride, and one can only imagine what’s to come.