With ten different LS engine designs created for General Motors’ passenger car lineup since its initial installation in the ’97 Corvette, it’s no wonder that the LS platform has become as popular as it has in the hands of enthusiasts.

One of the platforms in particular—the LS3 and its derivatives like the L99/L76/L92/LS9/LSA—have quickly become the go-to unit for engine swaps into older vehicles. And that doesn’t include the owners of vehicles where the engine was installed from the factory, like the 2008-13 Corvette and 2010-present Camaro among others. The 6.2-liter LS3 engine offers outstanding performance in factory form, with 430 horsepower available at 5,900 rpm and 424 lb-ft of torque present at 4,600 rpm.

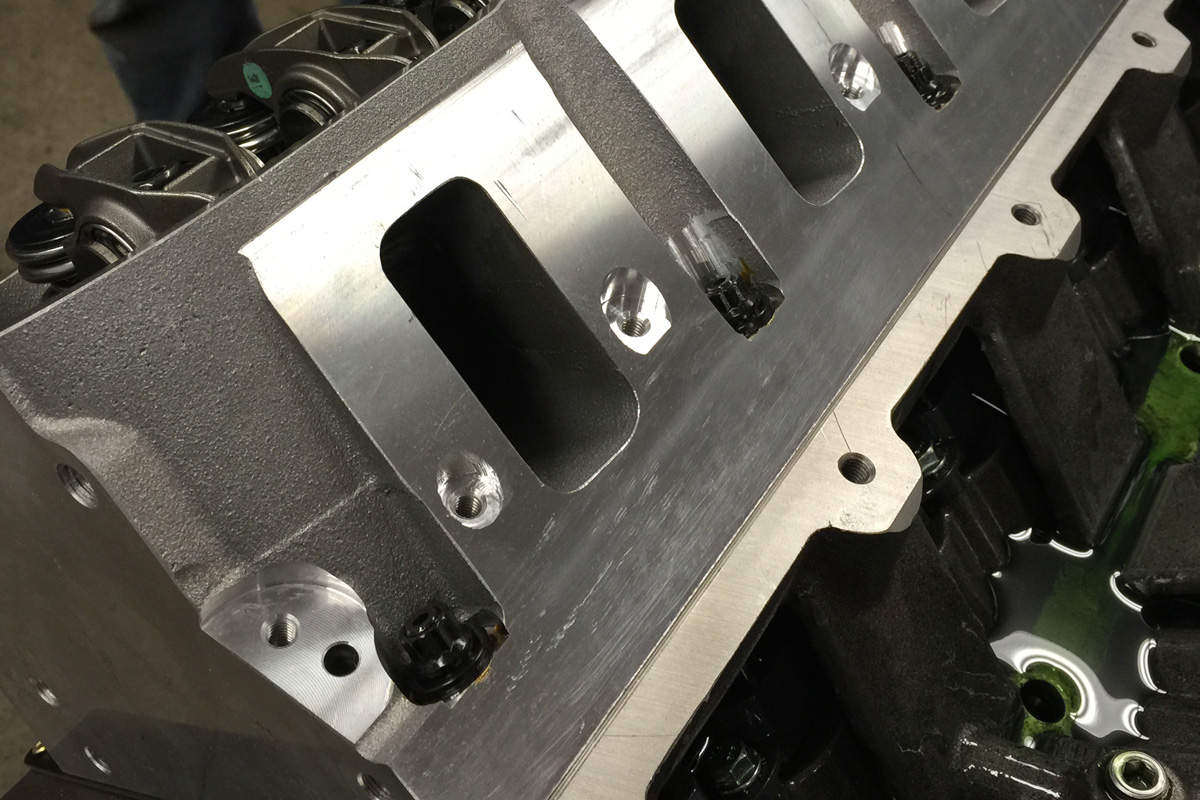

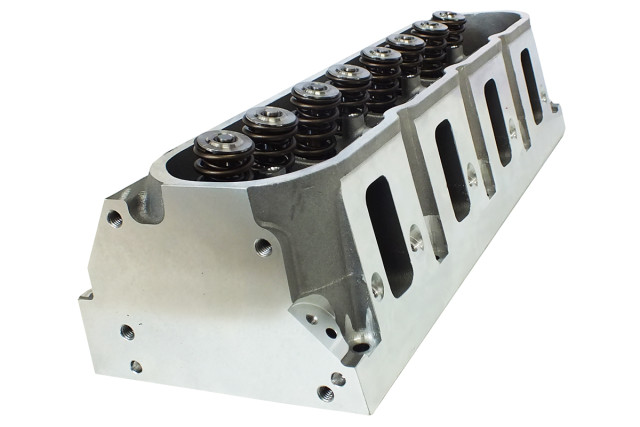

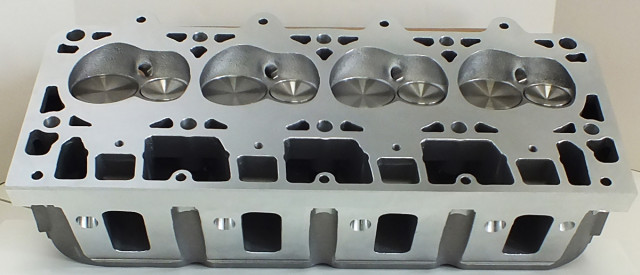

A long view of the Pro1 LS3; Dart has engineered these to use both stock valve dimensions and stock valvetrain components. They will also accept aftermarket replacements. The Pro1’s port profiles have also been optimized in as-cast form.

Hot-rodders can’t leave well enough alone, right? Right! That’s where Richard Maskin and the guys at Dart Machinery enter the LS3 equation. Maskin is a hot-rodder at heart, and with such an immense marketplace looking for performance improvements, he felt it was only natural for Dart to be in the market of producing LS3-style cylinder heads. From the looks of it, they aren’t waltzing in quietly; they’re busting down the door with a vengeance in the form of their all-new Pro1 LS3 aluminum cylinder heads.

“Now that we have a better understanding of the LS platform, we have redefined its architecture. Designed for racers by racers, we have combined our years of Pro Stock-inspired, championship winning engine experience and have added the Pro 1 LS3 cylinder head to our line. With this new LS3-based head, our intention is to lead the future,” says Dart’s Richard Maskin.

In this article, we’ll find out the results of external testing performed by Borowski Race Engines, Inc. as well as the internal testing performed by Dart, on two engines with different intended uses.

The combustion chambers have been optimized through Dart’s testing. The Pro1 LS3 cylinder heads are a six-bolt-per-cylinder design for maximum head gasket retention.

Maximizing Flexibility

The accuracy of our tooling and patterns is impeccable, and that’s why we can cast these in a ported form without having to port them. – Richard Maskin, Dart Machinery

By creating a cylinder head casting that performs like a ported design right out of the box, Dart has developed a serious advantage—especially when you take the price point of these cylinder heads into account, which Maskin says will hit the marketplace approximately $200 less per head than competing designs, while offering better performance.

One thing that Dart felt was important during the Pro1 LS3’s development process was to build the casting so that it could accept stock LS3 valvetrain components and intake manifolds. This gives the average enthusiast an easier entry into the world of aftermarket cylinder heads, which is often the first leap one will take when trying to improve the performance of a given engine platform.

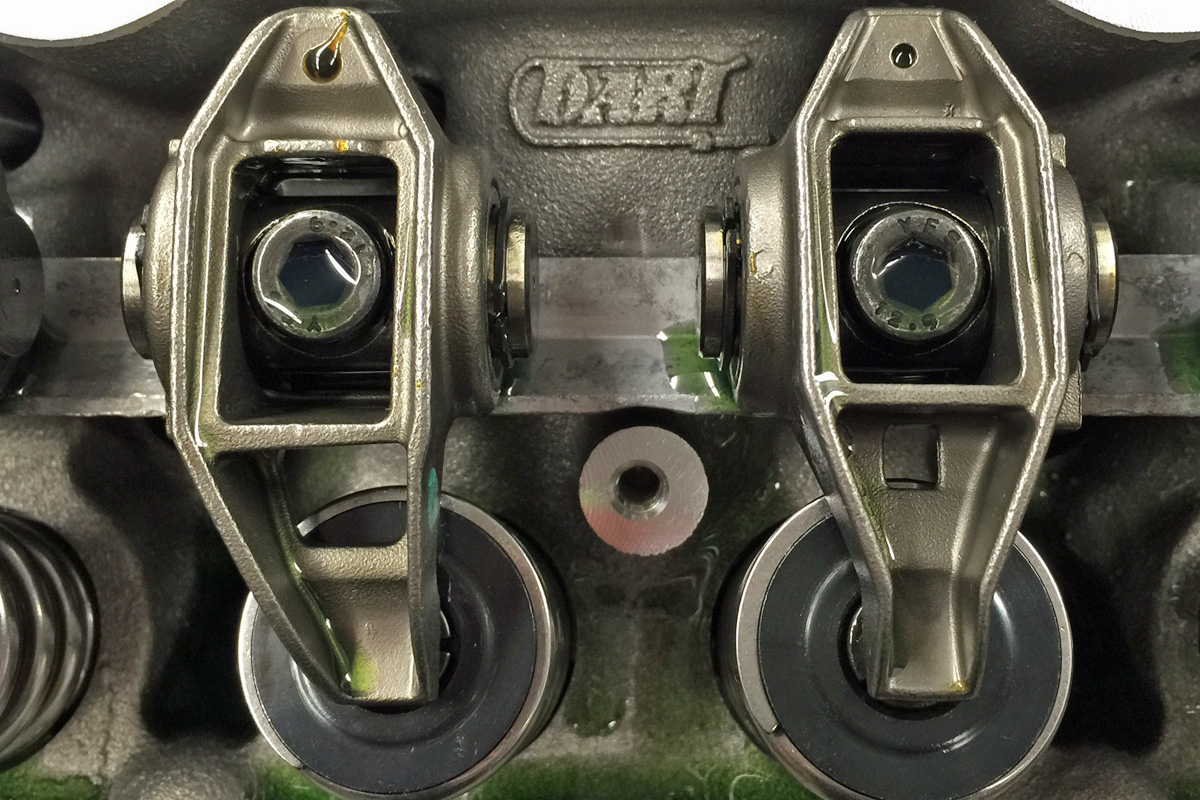

(Left) Exhaust ports match up with stock LS3 manifolds, yet offer room to grow in the future. (Middle) Borowski Race Enterprises, Inc. used stock LS3 rocker arms during their testing; Dart says the heads will also accept most aftermarket replacements. (Right) Those are the as-cast intake ports on Borowski's test cylinder heads--no port work has been performed.

The cylinder head casting is built to work with those OE components, thus the end-user has the ability to fit the stock valvetrain components yet still have room to grow in the future and replace those stock components with aftermarket pieces as their needs change.

The Specifics

Research And Development

Dart works very closely with a wide range of racers in many motorsports disciplines to develop and test their product designs. They also borrow heavily from previous racing experience; Maskin and his team have likely forgotten more about engine machining and material properties than most of us will ever know. They’ve invested an immense sum into providing the very best manufacturing machines to service their customers all over the world. As an aside, Maskin also says that an all-out LS race head designed for heavy power-adder use is coming from Dart in the very near future. “The very best small-block head there’s even been for the kind of racing that we do came from the Pro Stock Truck era, and that head now fits on an LS engine. Imagine that?” he muses. For now, we can only wonder what he’s cooking up, but rest assured—as soon as he’s ready to release it to the world—you’ll see the down-and-dirty details right here on EngineLabs.

“We have high quality castings, and the accuracy of our tooling and patterns is impeccable, and that’s why we can cast these in a ported form without having to port them,” says Maskin.

The heads feature 280cc intake runners and 68cc combustion chambers to go with the 2.165-inch intake and 1.600-inch exhaust valves. The use of the stock LS3 intake port location and pattern means that an OE or Fel-Pro LS3 intake manifold gasket can be used with a minimum of muss and fuss. Exhaust runners measure 102cc and accept OE or Fel Pro 1438 gaskets at the port opening.

“With a stock valve in the head, and no porting other than a bowl blend, which is what we do to all of our Pro 1 heads, these flow just over 370 cfm on the intake side at .800-inch lift, but it’s the exhaust side that’s the killer. These castings have 252 cfm of exhaust flow at .800-inch lift,” says an enthusiastic Maskin.

The heads are available in either bare or fully-assembled form; Dart offers them assembled with different styles of valvespring—a 1.290-inch diameter beehive spring or a 1.295-inch dual spring. Copper infiltrated valve seats and 8mm manganese valve guides are standard. Titanium retainers are standard, and the head accepts an Autolite AR3935 or equivalent spark plug.

Dart has also engineered a five-angle valve job into the intake seats, with angles of 32-45-60-70-80 degrees machined in right at the factory. On the exhaust side, 37, 45, and radius angles are used to promote smooth and efficient exhaust flow.

Views of the combustion chambers and ports with valves removed. Note the 'wing' cast into the valve guide area of the intake port--this substantially improves airflow and is often found on the best ported cylinder heads.

Important to note is the ability of the Pro 1 LS3 cylinder head casting to work with any of the six-bolt-per-cylinder engine block castings that are available to maximize clamping force in those boosted applications. Currently, Dart’s own cast iron and aluminum LS Next and LS Next2 engine blocks offer this capability, as well as other blocks on the market. The castings weigh 23 pounds each in bare form, and 26 pounds each assembled.

Test Engine Details

Our friends at Borowski were lucky enough to receive the very first set of heads Dart sent out for testing. As Borowski and Dart have worked very closely together on R&D for Dart’s LS Next program, it was fitting that Ken McCaul and his team had the opportunity to test out the Pro1 LS3 heads before anyone else.

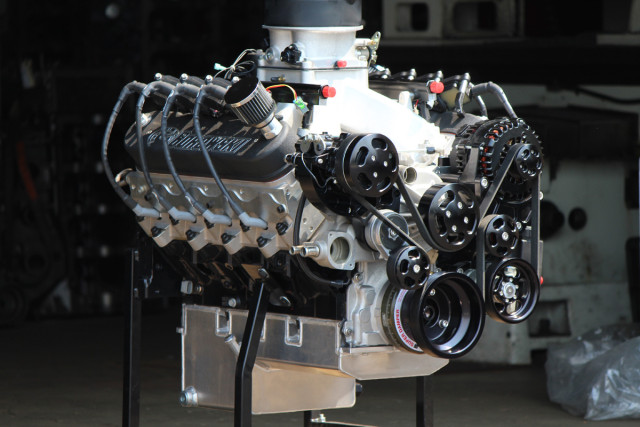

(Left) A view of Borowski's LS Next 427 cubic inch longblock topped off with the Pro1 LS3 cylinder heads. (Right) Check out the Nitrous Outlet Puck hiding down there in the manifold.

“Everything went well,” says McCaul. “We were chosen by Dart to try these out, and they performed very well in our testing.”

The 427 cubic inch “basic” shortblock used one of Dart’s LS Next blocks, and was topped with the Pro1 LS3 heads outfitted with stock valvetrain components, up to and including stock LS3 rocker arms.

An Edelbrock Super Victor Dominator-flanged LS3 manifold equipped with a Nitrous Outlet Puck nitrous oxide system topped the powerplant off. The Puck’s dry shot of nitrous uses fuel enrichment provided by a Holley Dominator EFI system complete with four-hole EFI throttle body.

On The Dyno

Putting the heads to the test on the dyno, the Borowski team knocked down 600 horsepower on the engine alone. However, they were using a camshaft that was optimized for the big hit of nitrous oxide from the Nitrous Outlet puck system installed in the bottom of the plenum. In addition, the compression ratio was lower than they’d build into an all-motor combination.

“It probably hurt our ‘on motor’ numbers by 75 horsepower or so,” muses McCaul. “I think the engine would make 650 to 675 if it were 11.0:1 compression with an NA cam, and had NA ring gaps set up.”

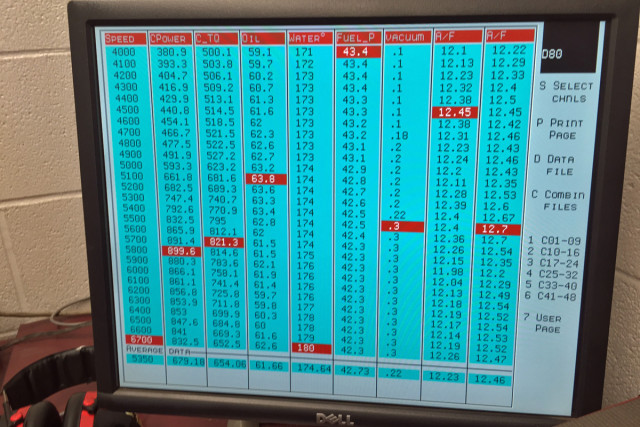

Borowski’s dyno results with their test 427, Pro1 LS3 cylinder heads, and a small shot of nitrous–899.6 horsepower and 821.3 lb.-ft. of torque. This from an engine on pump fuel, with stock valve dimensions and stock LS3 rocker arms turning less than 7,000 rpm.

During Borowski’s dyno testing. 600 on the pump, 900 on the squeeze. How’s that for 427 inches on pump fuel?

“It really liked the combination. On pump gas with nitrous, we were real happy,” says McCaul.

“The guys also had plans to hit it with the full load of nitrous and run on C16 race fuel, but ran out of time to do so.”

The nitrous system was set up to activate at 90 percent throttle—you can see in the video below how the engine goes from mild-mannered to monstrous in the blink of an eye.

“The puck is good for 700 horsepower worth of nitrous enrichment. The guys were planning on the 600 shot also, but we ran out of time to get the tuning quite right. In the video of some of our testing, you can see that the torque number hits 1,100 pound-feet around 5,000 rpm—it’s hard to see because the camera shakes, but it’s there,” says McCaul.

There was one simple reason why the Borowski team stopped tuning on the engine–it had a date with the Hot Rod Power Tour, as they loaded it up into the back of this Elky and took it to the big show.

Dyno Video At Borowski On The Big Load Of Nitrous

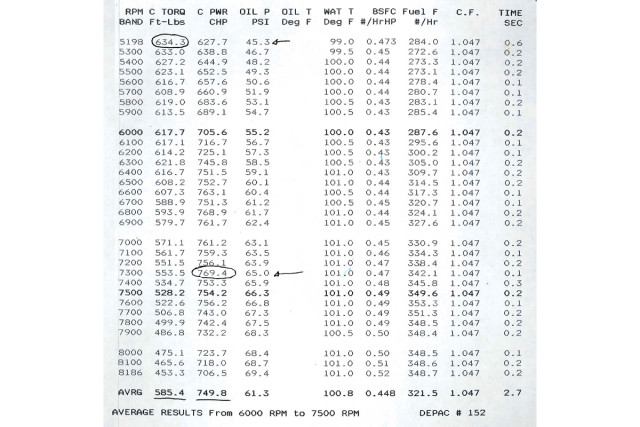

On Dart’s Own Dyno

While we were in the middle of writing this article, Dart completed internal testing on an engine equipped with the Pro1 LS3 heads using their in-house dyno. They used a 440 cubic inch engine built from an iron-block LS Next, stuffed with 11.0:1 compression, a Cam Motion solid roller camshaft, 1.7:1 rocker arms, and topped it off with a Book Racing BRX dual-blade carburetor, Dart’s test engine cranked out an insane 769.4 horsepower at 7,300 rpm and 634.3 pound-feet of torque at 5,200 rpm running on C14 fuel.

This impressive naturally-aspirated horsepower figure seen in Dart’s internal testing validates McCaul’s estimates that the Borowski engine was down on naturally-aspirated power due to camshaft selection and compression, and perhaps explains why the Borowski bullet picked up 300 horsepower on a 200-horsepower shot of squeeze. As they say, it’s all in the combination; both of these engines offer impressive performance.

Maskin was ecstatic during our phone call after their internal testing; these Pro1 LS3 heads are the culmination of hundreds of hours of testing and development work, and the proof is in the pudding, as they say.

Here are the final results of Dart’s internal dyno testing. They focused on a few specific things during the test–oil pressure was one of them. Note how the pressure stays rock solid throughout the test. Also important to note are the average power and torque figures listed at the bottom. As Maskin says, “We don’t race dynos. Average power is most important.”

Of particular note–Dart also completed testing on the same engine with a 4150-style carburetor and adapter to fit the 4500 flange on the intake manifold and noticed a power and torque difference of 10 below the dyno graph above. Maskin says that the engine would be better served on the street with the 4150 carburetor because of its improved idle and low-speed drivability performance. With 750-plus horsepower on tap, it’s not likely that you’d notice a difference driving the car around with that setup, except for the improved manners.

Dart’s In-House Dyno Testing

In Conclusion

The gains seen by the Borowski team backed up by the internal testing of Dart’s engineers proves out the performance of the Dart Pro1 LS3 cylinder heads in vastly different combinations, along with hinting at monster potential in boosted applications. Richard Maskin and his team have thrown themselves head-first into the LS engine components arena; the results of the testing in this article show their solid engineering plan and manufacturing capabilities have stepped up to the plate. The next task for the Dart team is to flog an engine equipped with the Pro1 LS3 heads and a ProCharger on the dyno; Maskin says the supercharger is already on the premises and waiting for him to clear the time in his schedule to twist up the dyno yet again.

LS all the things!