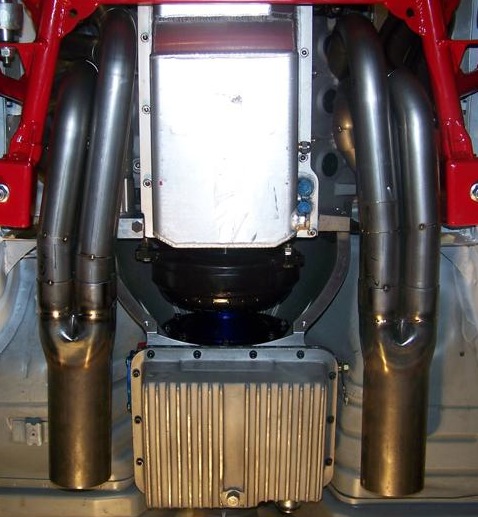

The engine bay in our 2000 F-body Camaro is a tight fit for the massive World Products 454 Warhawk, which should surprise no one considering the stock engine that we removed was an economy grocery getter GM stock V6. For our purpose built drag car, performance is critical, but trying to get our 454 cubic inch monster, with all the high performance trappings and the required massive header tubes, into the stock engine bay where the 232 cubic inch V6 previously lived, was going to take some ingenuity and skill. Enter Lemons Headers.

Dan Lemons hand builds each set of headers for maximum performance in tight spaces. Our F-body Camaro has limited room in the engine bay but Dan custom-made a set of headers that provided plenty of clearance around the oil pan, starter and steering linkage while keeping the primary tubes equal length for performance.

Our previous updates on this 4th Gen Camaro have detailed the specifics on the World Products 454 Warhawk powerplant in the update entitled “454 Warhawk: The Powerhouse,” and the tight space under the hood after mounting the massive engine and ATF Powerglide in the project car update entitled Mounting the World 454 and ATF ‘Glide.” It doesn’t take too much imagination to understand that space in the engine bay was at a premium.

Unwilling to sacrifice power for space saving off the shelf headers, we contacted Dan Lemons of Lemons Headers to craft a set of custom made headers for the beast. The car was hauled up to the Lemons’ facility where the master craftsman fabricated a hand built set of racing headers. In return, Lemons used the freshly built headers as a template for customers with the same engine/chassis combination desiring racing headers. Lemons doesn’t keep any headers in stock – each set is made to order, many from templates like this one.

About Lemons Headers

Dan Lemons started out by building headers for a major header manufacturer in the late 60’s and early 70’s before seeking his fame and fortune as a cabinet maker in Paso Robles, Califonia. It wasn’t long before the local guys that knew of Lemons previous header work drew the cabinet maker back into making headers. Once the passion for making custom headers was rekindled, Lemons began making headers for anyone wanting a custom set.

One of his early customers, a Georgian that was very pleased and excited about Dan’s work, convinced Lemons that he could do this full time. With no business plan, boardroom or list of company officers, Lemons set off to make custom headers under the name Lemons Headers in 1997. “We started by building drag race headers where there were two big demands, spark plug room and ground clearance,” said Lemons. Most of our new drag racing designs have the primary tubes higher than the bottom of the oil pan, so if your wheelstand bottomed out your suspension, it got to your oil pan before the headers.”

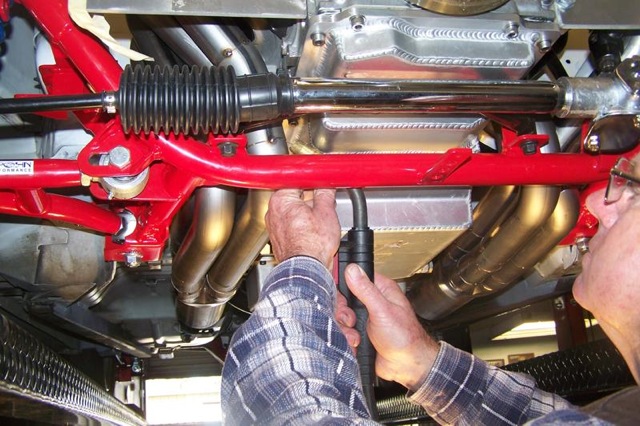

Our custom made Lemons Headers offer plenty of access to the spark plugs and clearance for the starter.

Exhaust Theory

Years of experience has proven that exhaust headers improved engine performance significantly by allowing the exhaust to be efficiently moved out of the combustion chamber. That is, when space permits, a long tube with minimal bends for each cylinder to reduce back pressure. More often that not, the engine bay does not allow for this ideal exhaust configuration. Fenders, firewalls and necessary components like the steering linkage cut down on the space available for header tubes.

When this unavoidable situation happens as a result of replacing a small engine with a much larger high performance motor or when the engine combination you are using doesn’t have an off the shelf set of headers available, the optimal solution is a set of custom built headers. “Building a set of performance headers requires putting a big tube into a small chassis and trying to get them as close to the same length as possible. This is not an easy task,” says Lemons.

For our project car, Lemons opted to use 18 gauge mild steel stepped from 2″ diameter out of the block to 2 1/8″ at the slip on collector. According to Lemons, “For the weight of the car, stall speed of the convertor, horsepower and cubic inch size of the motor, this design will put the torque and power bands where you want them. Our collectors are fitted with Lemon’s transition cone that helps with the scavenging of exhaust gases from the cylinders.” Lemons says, “this is our typical race collector.”

There was a concern that because of the space limitations, the headers would not be able to removed or installed without raising the engine off of the mounts. “What we did was split the header flange into pairs, meaning two primary tubes on each flange, so that the headers could be removed or installed without lifting the engine.” Even with the tight space, only the steering shaft has to be disconnected to remove the driver’s side headers. “Being able to remove the headers without lifting the engine will make a huge difference at the track if you have to take the headers off for any reason,” added Lemons.

Designing Headers

Dan has a couple of principles that he tries to keep in his header design; large radius bends and keeping the primary tubes as close to the same length as possible. Lemons says these principles help keep the headers flowing freely. Another goal that Lemons always stays true to is building each header by hand so that he is free to bend the tubes in order to fit into the chassis and over the frame.

Even hand building each header does not mean that it is an easy project. According to Lemons, “The most problematic ones would be the late model Camaro. Everything is very restrictive, especially on the passenger side.” The limited space on the late model F-body chassis is more of challenge and with our specific engine combination, Lemons required us to bring the car in for a custom fitting. For the most part, Lemons says he can make a header system for just about any car; “Ninty-nine percent of the time everything is trouble free and works like it is supposed to.”

From start to finish, it takes Dan and his crew about two days to complete a set of custom headers. Understanding racers, Lemons is even willing to work on weekends if you need your headers quicker than normal. There is an extra charge for a rush job, but Lemons tries to make sure that his customers are taken care of.

In a perfect world headers would only have one bend, out from the engine and back. With modern chassis and component designs, multiple bends are required. Lemons works to get the largest radius bends that provide ground clearance and performance.

Choosing the Right Headers

With so many different factors to consider when choosing headers, the selection process can be terrifying. To take away some of the fear, Lemons offered this advice, “If you have a stock or mild engine and chassis build, an off-the-shelf header is probably the right way to go.” If you have a wild combination and are looking for every advantage, custom headers are the optimal choice.

Custom Header Options:

- Flange design – one-piece or split

- Primary tube diameter – stepped or single-diameter

- Primary tube length

- Collector diameter

- Collector length

- Stainless or mild steel

- Coated or uncoated

Choice in custom headers for cars bound for the drag strip comes down to a couple important factors; lengths, diameters and bends. Lemons explained, “In a perfect free flowing exhaust world, there would only be one bend in the exhaust system. Flow would go straight out from the engine and then directed 90 degrees to the back of the car.” Engine bay and chassis design makes that an impossibility in just about every case. Lemons compromises by “trying to keep our designs as free-flowing as possible by using as large a radius in the bends as possible while keeping the primary tube square to the exhaust port without back-cutting the bend at the flange.”

One advantage of custom headers is having the most clearance possible for engine and drivetrain components.

Improving a Tried-and-True Product

Even with a tried and true product, Lemons is always looking to improve. “We put a lot of effort into improving and redesigning our headers. If we feel we can pick up a little more ground clearance, increase space around the starter and oil pan, or improve access to the spark plugs, then we’ll redesign a header.”

The primary tube length can have a big effect on power curve, but when limited space does not permit longer primaries, Lemons uses different diameters of tubing to compensate for length. “The ability to use different tube sizes allows much greater flexibility in designing a header. Smaller diameter tubes act like longer tubes and bigger diameter tubes act like shorter tubes,” said Lemons. As far as stepped headers, Lemons says that a stepped header scavenges better than a straight-tube header and broadens the torque curve. Getting more exhaust gasses out of the combustion chamber means you can put more ignitable fuel in. And we all know what that means: More power!

Lemons takes several other factors into consideration when building a custom set of headers, “Cubic inches of your engine, your compression ratio, how much horsepower you intend to make, the size and weight of the car and tire size, should also be considered,” adds Lemons.

Other information about the vehicle can play into designing a great set of custom headers. If you plan on running mufflers, X-pipes or H-pipes, exhaust flow is affected. According to Lemons, “If a car utilizes a full exhaust system, we may lean toward a larger tube or collector size because of the added back pressure.” Even the type of torque converter can have a dramatic effect on the header design. A higher stall converter requires more power to spin up while “converters with lower stall speeds will require more torque and smaller tubes. Nitrous and blower motors tend to like bigger tube sizes,” advised Lemons.

Header leaks can be irritating and could risk burning a valve so it’s an issue that Lemons takes seriously. “We have had great success with copper gaskets, since they’re extremely flat, which promotes an excellent seal, and do not expand or contract as much as fiber gaskets.” The properties that make copper gaskets successful also provide its only drawback. According to Lemons, “Copper can’t crush like a fiber gasket, so we recommend using a thin layer of copper silicone on each side of the port opening.”

Because copper doesn’t expand and contract like fiber gaskets, there is an added benefit of your header bolts not backing out. “The combination of heavy-duty header flanges and flat copper gaskets that don’t expand and contract like thin flanges and fiber gaskets, virtually eliminates the potential for bolts to loosen over time,” states Lemons.

Header Material

“We build headers in mild steel and stainless steel with the most significant difference between the two is that stainless costs about twice as much,” Lemons says. “Stainless is a stronger material and won’t rust, but it discolors and weighs more. Mild-steel headers that are well-coated inside and out make a lot of sense, because they’re cheaper, lighter, and very durable.” Regardless of the type of material selected, Lemons says they use 3/8″ thick header and collector flanges with 18 gauge tubing and 16 gauge collectors that are all TIG welded.

Ease of Installation

While designing a set of headers that is simple to install is important, “we won’t sacrifice performance or fitment to make a header easier to install,” Lemons assured us. As the master header builder explained earlier, getting a good fit with good spark plug access and plenty of ground clearance with room around the oil pan and starter is most important. With the options of individual tubes and slip on collectors, even the most complicated set of headers can be installed relatively easily. “Many of these headers can be installed in 15 minutes with the engine and starter in place,” says Lemons.

Header Installation Tips From Dan Lemons:

- Header flange gaskets: With all Lemons headers, Lemons recommends using a flat gasket, either a fiber type or an annealed copper gasket. Do not use an embossed copper gasket that has a raised rib around the port. If an SCE flat annealed copper gasket was sent with your order, Lemons recommends applying a thin layer of Permatex Ultra Copper high temp silicone on both sides of the gasket port opening.

- High temp anti-seize: Lemons recommends Permatex Copper Anti-seize to be used on header bolts and slip on collector mounting bolts. For header with Lemons slip on collectors, use a generous amount inside the slip on tubes. This will stop corrosion and help the collector to slip on much easier.

- Individual header tubes: If your header was built as a race style with individual tubes and slip on collectors, the headers will be installed one tube at a time. As you install each tube just snug the header bolts evenly, do not tighten. With all tubes installed, slip the collector on and tighten the mounting bolts. Then go back and tighten the header bolts. Always check around header tubes for brake line, wiring and fuel line clearance.

- Slip on collectors: If your race header has been ceramic coated, there may be overspray inside the slip on tubes at the front of the collector. This should be smoothed off either by hand sanding with 80 grit sand paper or by using a 40 grit flapper wheel on a die grinder or high speed drill motor. Sand just enough to take the roughness off. When installing slip on collectors, coated or not, always apply a generous amount of high temp anti-seize to the inside of the slip on tubes. Cover the entire area inside of the slip on tubes. This will keep the connection from corroding and help the collector to slip on much easier. Lemons slip-on collectors are held on by tabs and bolts. One tab on each collector will be stamped left or right that tab needs to match up with the stamped tab on the header tube.

- Ceramic coated headers: When installing polished silver ceramic coated headers, they should first be wiped down with rubbing alcohol. Use a clean white cloth to apply the alcohol, then a clean dry white cloth to remove the residue. After the headers have been installed, repeat the alcohol cleaning process to any areas that are accessible. This will remove the fingerprints, grease, excess anti-seize, smudges, etc. Start the engine and let it idle for about 5 minutes, then shut the engine off and let it completely cool down. Next run the engine again for about 10 minutes and then let it cool down. This process will help to bake the new finish on, making it tougher and will greatly reduce the chance of any dulling of the finish in the future.

- Spark plug wiring: For Big Block and LS headers Lemons recommends a 45 degree wiring boot and for the Small Block headers Lemons recommends a 90 degree wiring boot.