If you’ve ever built a race car, then you know the amount of extreme heat a high horsepower engine can produce. The under hood temperatures can reach as high as 400 degrees, and with all of the excessive heat, comes the loss of power. A loss of power means slower times at the dragstrip, and that’s something you definitely don’t want from a drag car!

There are many ways to reduce engine heat, but one way in particular is having Jet-Hot Ceramic Coatings [3] prepare your racing headers and exhaust. Having your headers sprayed in Jet-Hot’s ceramic coating not only adds a protective, unique, and beautiful luster to your exhaust, but it also helps repel unnecessary, power-robbing engine heat.

With Project BlownZ [4] making close to 1,500 HP this season, we could definitely benefit from additional cooling properties from our high horsepower powerhouse. We previously brought you the installation story of BlownZ’s Kooks headers and Vibrant exhaust [5], but we were running them uncoated, and it had an effect on our engine temperatures. We wanted to remedy that problem this season, so we put in a call to the good folks over at Jet-Hot Ceramic Coatings for their Extreme 2500 treatment.

But we’re not going to simply call them, have them coat our pipes, and reinstall the exhaust. Because frankly, there’s no story in that. Instead, we’ve decided to document the Jet-Hot process from start to finish, with plenty of photographs and information to help you get a better understanding of the processes and procedures involved in accomplishing that Jet-Hot coating!

To provide expertise and further insight is Dave Burton, of Jet-Hot’s Research & Development team. Burton will be helping us explain the history, benefits, and what you can expect from Jet-Hot Coatings.

Jet-Hot Coatings, and What They Do…

There are many benefits to having your headers coated by Jet-Hot, and we’re going to share all of them with you in this story. But before we do, we think it’s only best that you give a breif history on their company.

Their beginnings start humble and interesting, when the company founders, former servicemen, had begun coating jet-fighter engine and submarine components that are typically subjected to high temperatures, cyclical stress loads, and corrosive environments.

[6]

[6]If Jet-Hot's ceramic coatings suffice in the military's war vehicles like the Stryker, we're pretty sure it's more than adequate for your drag car.

Eventually, Jet-Hot earned a contract to coat the exhaust system on the Stryker combat vehicle [7], a vehicle that the U.S Army continues to rely on today. But they found their real calling with the performance automotive aftermarket during the 1980’s, and they’ve become one of the go-to sources for the enthusiast’s ceramic coating needs ever since.

If the United States government can rely on them when it comes to their multi-million dollar war equipment, then you know that they can be counted on for your project vehicle.

The Extreme 2500 Coating, and Why We’ve Selected it

So why bother with ceramic coating in the first place? Well the answer for that is a simple one. First, like we’ve mentioned earlier, it helps lower underhood tempretures by keeping heat from radiating/convecting out of the pipes. Secondly, it helps the exhaust flow by keeping the gases hot and energetic as they pass through. Thirdly, and perhaps most importantly depending on your climate, it protects against corrosion from the elements. In BlownZ’s case, corrosion isn’t really an issue with a stainless steel exhaust system, but it is very important to those utilizing mild steel tubing or cast iron manifolds.

Jet-Hot has three different levels of coating, all of which are high-quality and equally impressive. However, each grade has its specific requirements and limitations. The standard coating level is referred as the Extreme 1300 Series, and it’s essentially a form of basic corrosion protection and/or thermal management. The 1300 is perfect for keeping the heat inside of the pipes, while providing a gleaming show car finish.

[8]

[8]This is the driver's side header off of BlownZ, prior to having our pipes shipped to Jet-Hot. They'll be removing the debris gathered from all of the 8-second blasts down the track.

If you’re looking for a budget-friendly Jet-Hot coating that can give you the general benefits of corrosion protection and thermal heat management, than this is for you.

Plus, it can handle all of the heat and corrosive environments of a naturally-aspirated street/strip car. It’s even available in 50 different colors of coating, and Jet-hot can mix and match any color to your liking from their vast inventory of hues.

The next step up in the Jet-Hot line is the Extreme 2000 series, and it’s what Burton refers to as the intermediate level thermal coating, which is applied with thermal spray equipment, and only to the outside of the surface.

If you’re running an engine with boost, then we highly recommend the Extreme 2500 Series coating. -Dave Burton

As Burton tells us, “It’s able to withstand more heat than the 1300 Series (used on parts over 1,300 degrees), but isn’t quite up to task of holding up to extreme temperatures that are produced from supercharged and turbocharged engines.”

That’s where the Extreme 2500 Series comes in, and while it provides the roughest-looking outward appearance in terms of finish, it’s also the most heat-resistant ceramic coating that you can order from Jet-Hot.

Knowing full well the amount of heat that a supercharged, 388 ci. LSX can produce, we opted for this level of coating for BlownZ.”If you’re running an engine with boost, then we highly recommend the Extreme 2500 Series coating,” said Burton.

The Extreme 2500 Series is so durable in fact, that it can withstand temperatures of up to 4,200 degrees Fahrenheit! This level of coating is fully ceramic, and provides insulative properties that reduce the outside skin-temperatures of the parts.

As soon as Jet-Hot receives your exhaust components, they immediately issue them an identification number. They inscribe them with the number, and take photos for their records.

Applying the Extreme 2500 Coating to BlownZ’s Exhaust

Jet-Hot receives headers and exhaust systems from enthusiasts all over the world, every day! With so many components flooding their facility, they’ve developed a unique process that helps make sure that the customer receives the correct part(s) back, once the process is complete.

What they do is scribe each component with an identification number that ties the part(s) with the customer, the coating that has been requested, and any other special instructions that the customer requires. This is probably a good idea, considering the entire process can take up to three days to complete.

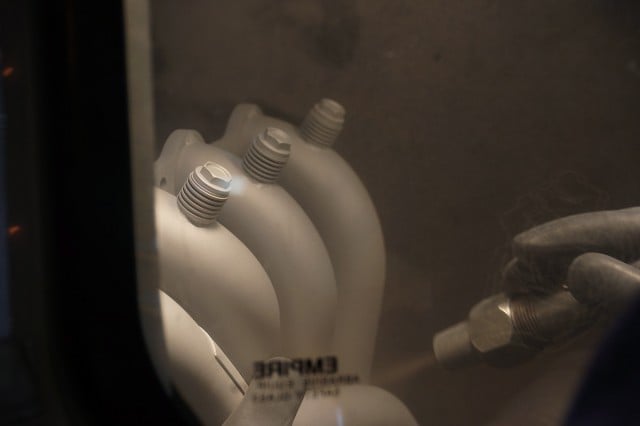

Once received into Jet-Hot's possession, the exhaust components go through the 'pre-blast heat' phase, which cleans all of the oil, grease, and random debris from the parts.

Once the components have been identified, each one is cleaned and freed from all oils and other contaminants (dust, dirt, road tar, traction compound, tire rubber, etc.) to ensure a proper adhesion of the Jet Hot coating. Following which, surface preparation takes place by grit-blasting every inch of the part to remove any oxidation, and also to provide a better anchor pattern for improved adhesion.

We make sure to thoroughly clean every part prior to applying the coating, to ensure proper adhesion.

Then the parts are blown off with “clean air” to remove any remaining debris and coated to various coatings that Jet-Hot’s customers request. “We make sure to thoroughly clean every part prior to applying the coating, to ensure proper adhesion,” Burton tells us.

Once free of the debris, the parts are cured in an oven to prepare for Jet-Hot’s ceramic coating. Finally, the parts will either get polished or sent back to surface preparation for a topcoat, that according to Burton requires yet another curing process.

Once the pipes are cleaned, they get grit-blasted (top left) and base coated.

To ensure that the right coating has been applied without any defects, the parts are given a final inspection prior to shipping. They are properly packaged to protect the components during transit back to the customer.

As you can see in the photos, that’s exactly what they did with our exhaust. To give our Camaro some individuality, we even had Jet-Hot apply their name and our parent company’s logo onto the header primaries – we think it looks great!

Once the parts are final coated in the selected hue, they are tested for any defects in the coating. The final stage, and obvious one, is shipping. Jet-Hot does a very good job making sure that all of their customers' products get shipped back to them undamaged, and in perfect condition.

Conclusion

Now that we’ve had BlownZ’s header and exhaust system coated, we’re looking forward to seeing how they perform. It will help keep our engine operating temperatures down, while giving BlownZ an additional, personalized touch.

After we had the opportunity to admire our newly coated headers, we promptly installed them back into BlownZ. After all, this is a race car, not a trophy queen!

The best part of the coating is that it can last for up to 20 years, and Jet-Hot provides a lifetime warranty on everything they coat – no questions asked! In a world filled with disposable everything, it’s good to know that some things can hold up to the test of time.

The warranty is even transferable to to future owners for the remainder of the component’s life. So if you ever change your setup, you can sell your exhaust components to someone else, and they can enjoy the benefits of Jet-Hot too! Now that you know everything about Jet-Hot Ceramic Coatings and what they can do you, is there any reason not to step up to the plate for your project car?