Last month, we revealed the plans for our latest drag racing project vehicle here at Power Automedia, targeted at the popular Outlaw 8.5-inch tire category and centered around a Fox body Ford Mustang, known officially here in the offices as Project Evil 8.5. The 25.3-spec car will receive its motivation from a 427 cubic inch small-block Chevrolet built by none other than Steve Morris, featuring a Brodix tall-deck block and cylinder heads, a Comp camshaft, and a laundry list of carefully-spec’ed components inside and out.

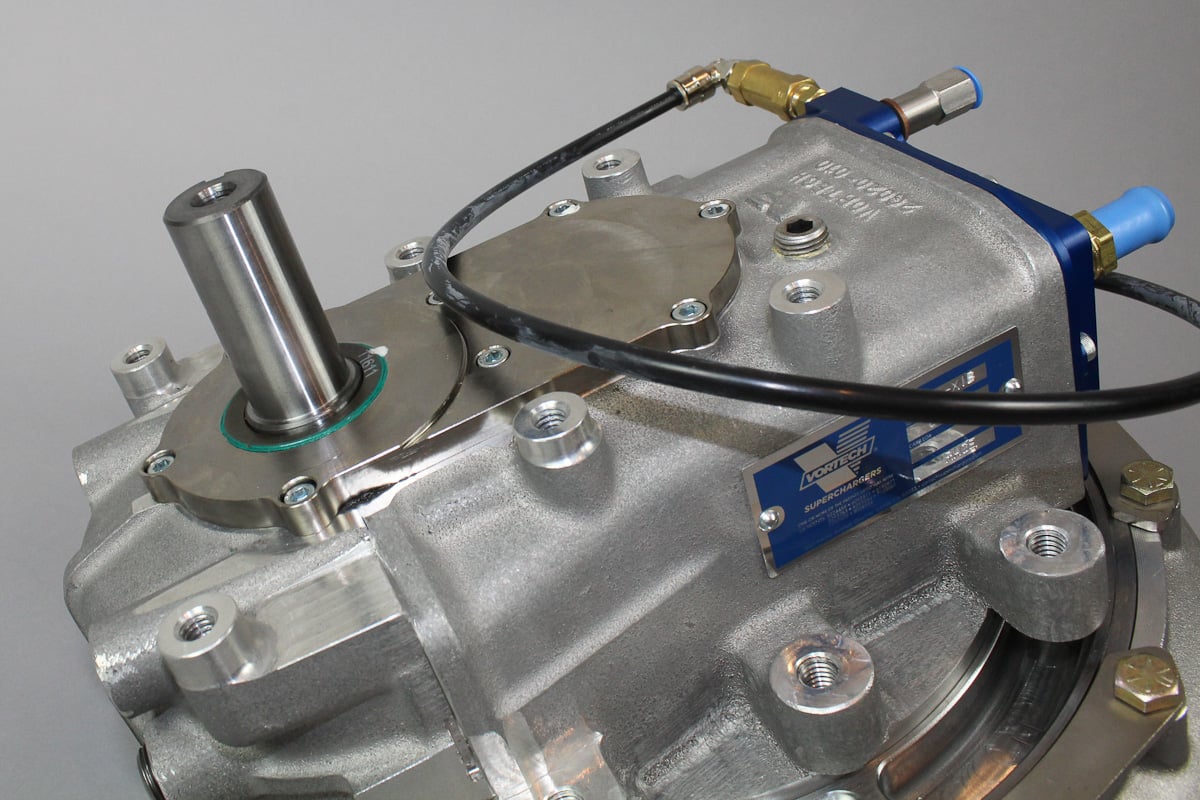

To help produce the more than 1,400 horsepower necessary to be competitive in the Outlaw 8.5 class, we’ll be running Vortech’s potent V-24 billet Xi supercharger driven by a Chris Alston’s Chassisworks Component Gear Drive system.

Helping to deliver the kind of power we’ll need to get into the four-second zone on the smallest tire in use in heads-up drag racing, however, will be a billet Xi supercharger from our friends at Vortech, which will be driven off the Bryant crankshaft by a gear drive from Chris Alston’s Chassisworks. With the help of Vortech’s Lance Keck and Chassisworks’ Chris Alston Jr., we’re going to take a closer look at these two main ingredients to the boost in our small block mill, while we give you an up-close look at the parts and their installation into our Mustang.

The Vortech Xi

The Vortech Xi blower is part of the V-20 family of superchargers — along with the XB105 and the V-28 123 — that are designed for racing applications with goals of delivering in excess of 1,300 horsepower. Vortech Superchargers utilizes state of the art software and design tools that result in the development of some of the most efficient and technologically advanced superchargers in the automotive industry.

The oiling arrangement is not a splash-type oiling — it’s a pressure system, so you can mount the gearbox at a 45 or 50 degree angle if that package fits better. – Lance Keck, Vortech

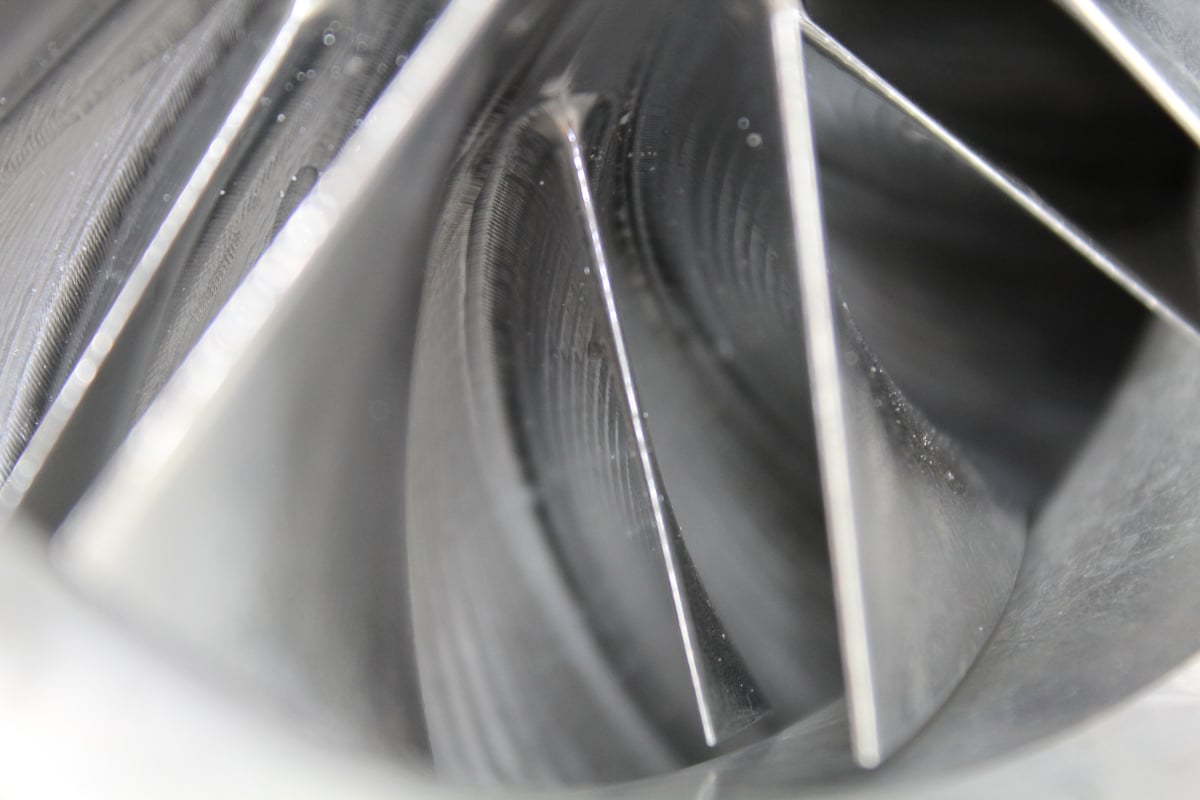

The V-24 billet Xi that we’re putting on Evil 8.5 is an evolution of the original cast Xi, which in itself was a descendent of the original Vortech X-Trim supercharger. Vortech’s exclusive billet racing impellers are machined from custom forged blanks from a proprietary metallurgical blend, which has superior hi-temp characteristics when compared to 7075.

“The V-20 series was developed for a certain horsepower range, and to some extent, to specific classes,” says Lance Keck from Vortech. “The rules for X275, for instance, state that the inducer can be no larger than 4.090-inch. It can also depend on what cylinder heads you have on the car — so if you have traditional inline cylinder heads, you can run our XB105, which has a 4.200-inch inducer. If you have a non-traditional valve angle cylinder head, you can run the Xi without adding weight.”

The V-20 series of blowers have a higher step-up ratio than Vortech’s traditional V-1, V-2, and V-7 style blowers, at 4.21:1. The V-20 name, as Keck pointed out to us, is the name given to the gear case, which comprises the YSi, Xi, 110, 105, and the 123 and 128 superchargers. “The gearbox itself was designed to be somewhat modular so we could have multiple compressor stages on one gearbox,” explains Keck.

The YSi, Xi, 110, 105, and the 123 and 128 blowers all share the same V-20 supercharger gear case, allowing Vortech to compliment the same gear case with a number of different compressor stages.

Vortech (or rather, their bearing manufacturer) rates the maximum operating RPM of the Xi supercharger at 65,000. But, as Keck shares, “racers will be racers, and they don’t always tell us how fast they’re spinning them. We build to the standard that the bearing manufacturer presents to us, but are there guys out there spinning them faster? Absolutely.”

The V-20 series was developed for a certain horsepower range, and to some extent, to specific classes. – Lance Keck, Vortech

A unique design element of the V-20 series blowers is that the gearbox can be clocked at different angles, including full vertical, which opens up options for component layout at the front of the engine. The vertical orientation is particularly useful for our setup, as we’ll get into in the next section.

“The oiling arrangement is not a splash-type oiling — it’s a pressure system, so you can mount the gearbox at a 45 or 50 degree angle if that package fits better,” says Keck.

An additional bit of tech built into the Xi and other Race Series Superchargers is Vortech’s Diverging Diffusion Technology (DDT). This technology is utilized to optimize the compressor stage for specific applications and engine set-ups for maximum horsepower gains. This technology and compressor stage performance is quantified and developed using Vortech’s in-house SAE J1723 compliant test cell.

The Gear Drive

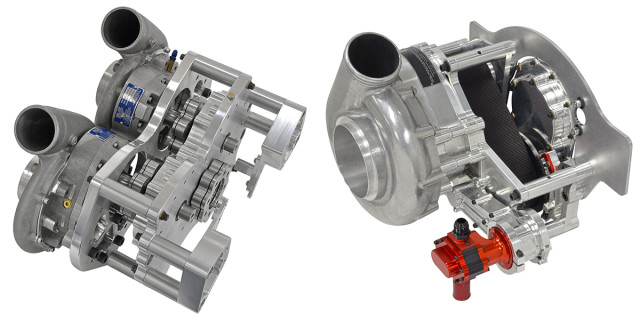

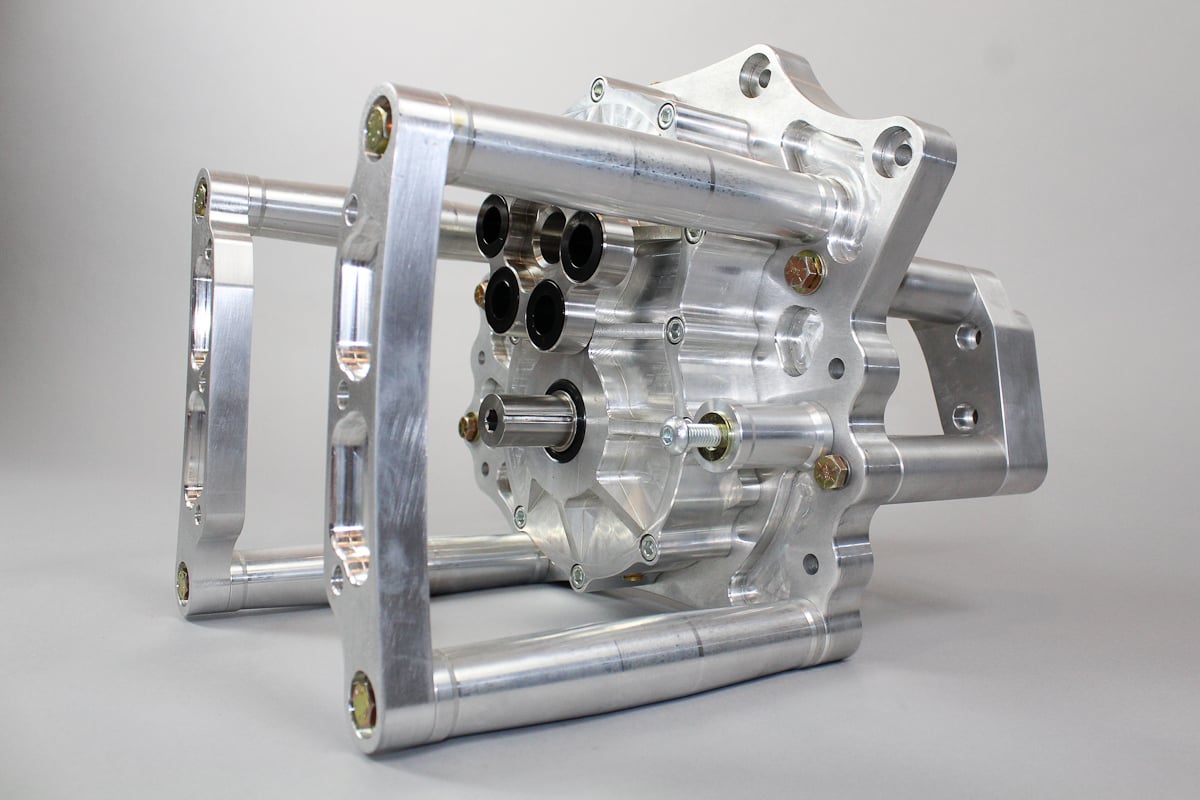

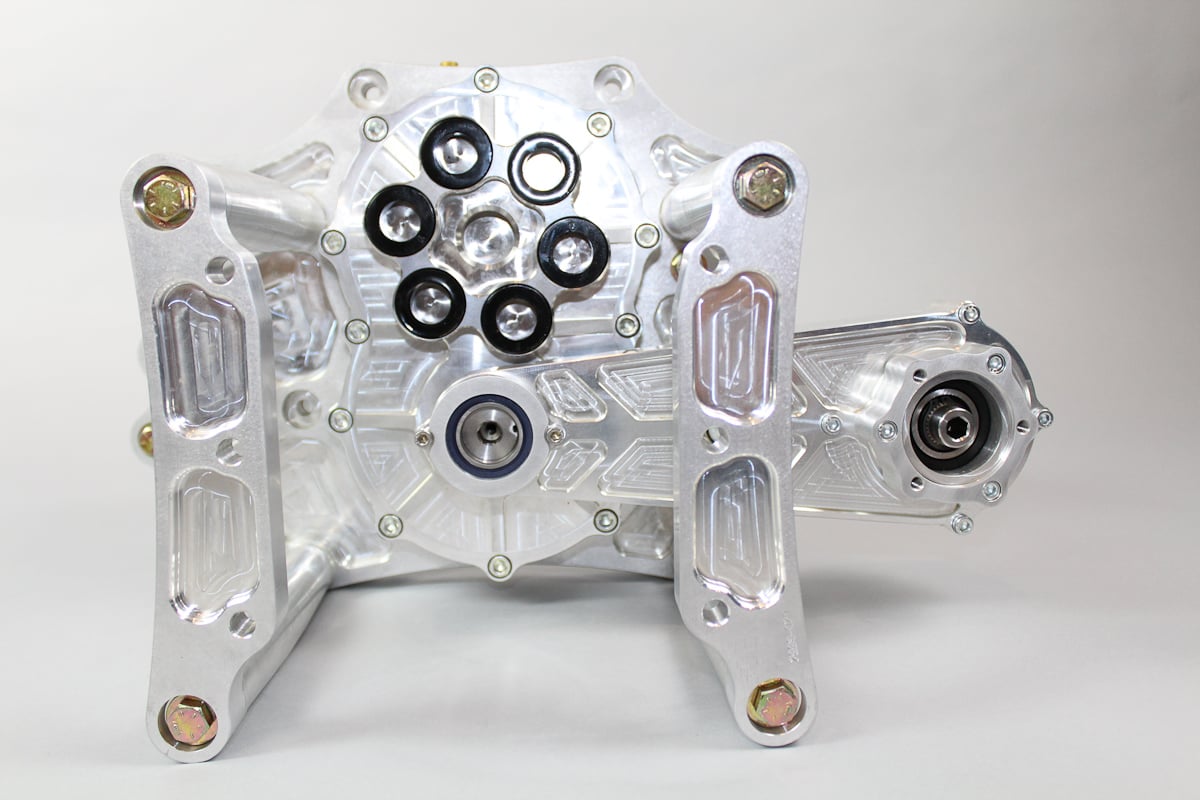

This is the very basis for Chassisworks’ Component Drive System (CDS), providing gear-driven operation of the Vortech and other brand superchargers off of the crankshaft. From here, the options are nearly limitless for driving accessory items.

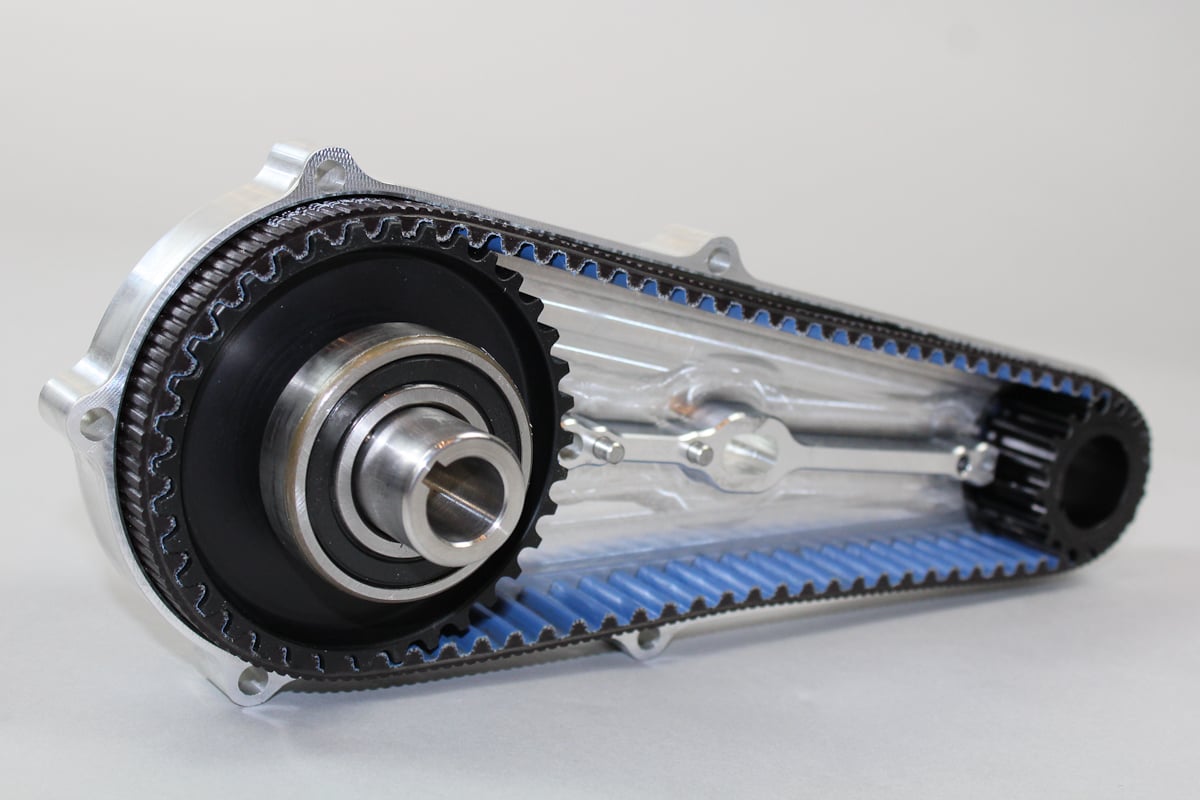

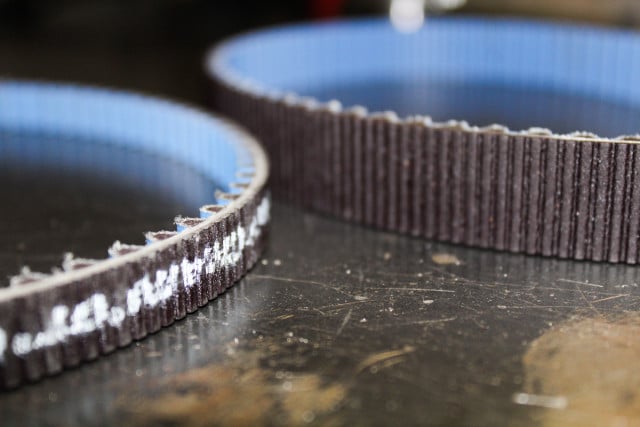

The other half of our supercharging equation comes in the form of a Component Gear Drive System from the crew at Chris Alston’s Chassisworks. Gear drive units for centrifugal superchargers have proven themselves in recent years as the most efficient way of transferring the torque from the crankshaft to the blower through a gear case, eliminating situations of broken drive belts and putting far less strain on the snout of the crankshaft. Chassisworks has been among the leaders in gear drive development, and today boasts the largest complete system of gear drive accessories on the market (they also continue to produce belt drive systems for those that prefer to go that route).

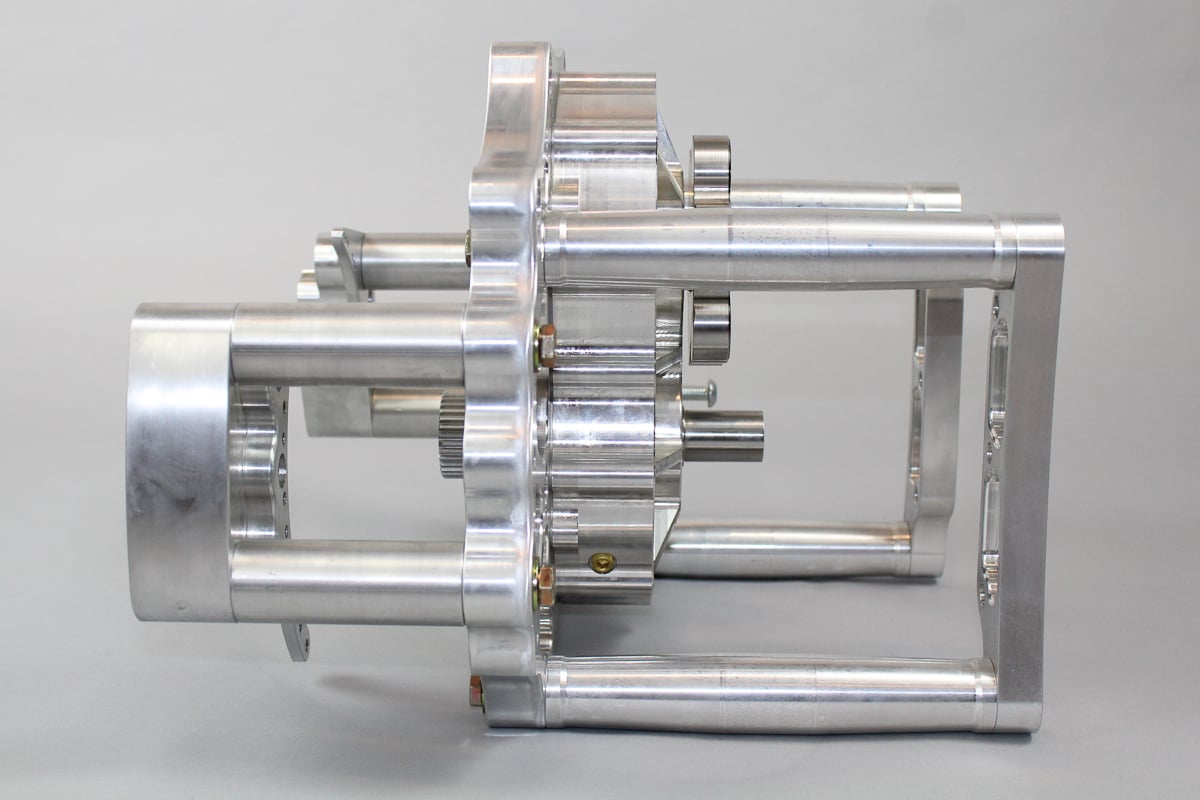

This angle provides a look at the inner workings of the reduction drive unit, which drives a mechanical fuel pump and serves as the heart of the accessory drive ecosystem. Through the use of a line drive, multiple additional accessories, from vacuum pumps to oil pumps and other items can be run directly off of the gear drive.

“We’re just trying to make a lot of accessories for racers to attach to the drive to make it easier for them, so they don’t have to fabricate components to make all of their drive systems work. We want to make it a lot simpler and more complete,” says Chris Alston Jr.

The last time we took an in-depth look at the Component Gear Drive System was in the infancy of the project when we installed one on our then-Limited Drag Radial class Camaro. Since that time, Chris Alston Sr. and Jr. and the team at Chassisworks have added to the CDS lineup tenfold, with several new accessory drive options that can operate such components as fuel pumps, alternators, distributors, and more, right off the gear drive itself. Such a design is necessary, as the gear drive inhibits many of the crank-driven partd one would normally have on the frontside of the engine. But Chassisworks has and continues to develop add-ons to satisfy almost any need one might have.

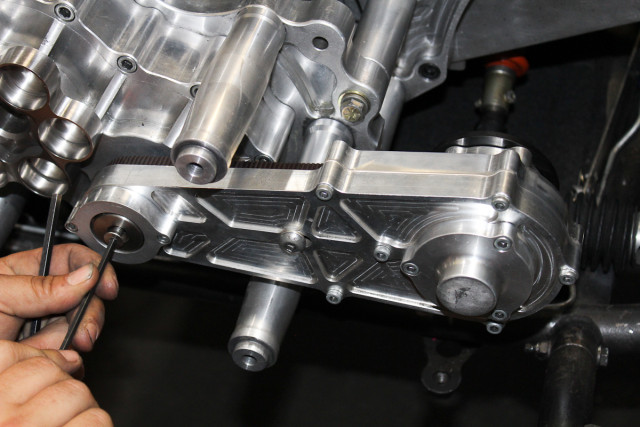

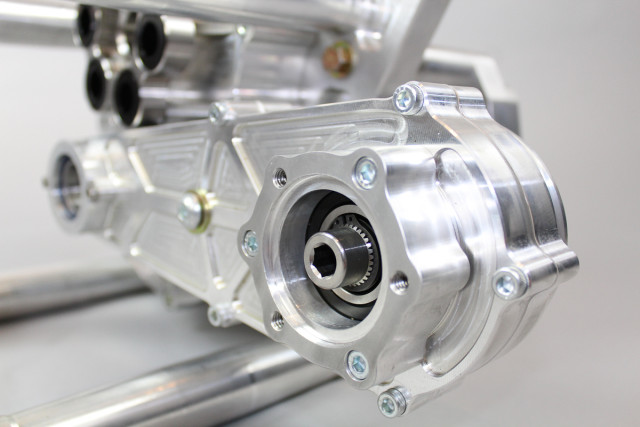

To mate the crankshaft to the gear drive and the gear drive to the supercharger case, Chassisworks' utilizes 6- and 12-bushing drive hubs, which sport high-density urethane coupler bushings to dampen the harmonics and extend bearing life.

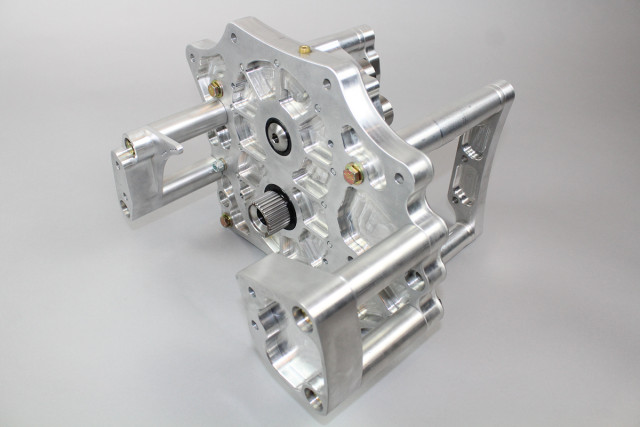

As a basis, Chassisworks produces both single and dual supercharger gear drives, along with the aforementioned offset belt drive unit. Our combination, in specific, will utilize a single drive setup for the Vortech Xi with its vertically-positioned gear case — a layout that will allow us better placement of the accessory drive (we’ll hit on this shortly).

The gear drive units feature large 1-3/8-inch quick change gear sets, of which many options are available, and have aluminum blower and crankshaft hubs, along with a built-in timing pointer, crank trigger pickup mount, and oil level sight glass. Chassisworks has also machined the scalloped gearbox and mount plates to remove excess material, and the plates are pocket milled to reduce overall weight.

We’ll be running an Aeromotive mechanical fuel pump off of the main reduction drive in our Project Evil 8.5 Mustang. This arm is dual-drive capable, meaning you can also run an oil pump or other accessory off the backside. This reduction drive operates at 50 percent of crank speed.

By way of a number of auxiliary shafts off the gear box, one can run a range of accessories directly off the drive. This is done via an accessory reduction drive, which reduces operational speed to 50 percent of crankshaft speed, and is driven off of an available output shaft of the gear drive. Modular output ports accept V-clamp, Aeromotive-style clamp, cable-drive adapters, or can be fitted with a drive cap when the port isn’t being used. Single or dual accessories can be mounted off the front or rear of the drive.

Early on in the release of the CDS system, Chassisworks had developed an alternator and a mechanical fuel pump drive. Since then, the company has added mechanical fuel pump drives with an optional cable drive (for Waterman-type pumps) and dry sump pump adapters for Moroso, Peterson, and other popular pump brands. There’s also a belt-drive distributor attachment with a 1:1 ratio that a distributor drive can be put on, with a five-inch diameter cap and rotor assembly with a built-in number one cam sync pickup with adjustment for phasing and rotation in either direction. As well, you can also run a camshaft bridge for driving a belt-drive distributor, with rotation adjustment to 30 degrees in each direction. A mechanical fuel pump can also be driven off the frontside of that camshaft bridge accessory drive. The bridge, available only for the small-block Chevy at this time, mounts off of the water pump mounts and is driven by a belt drive.

In addition a dry sump pump adapter is optional, which adapts Moroso single-stage and dry sump oil pumps to a V-clamp style mount, with a rear support made available for the pump that one can mount to a fabricated bracket to support the weight.

Along with the auxiliary drive systems, Chassisworks also provides the ability to run up to four direct-fit accessories off the gear case itself, including an oil pump, alternator, power steering pump (one of the newer additions to the CDS accessory drive lineup), and air conditioning compressors.

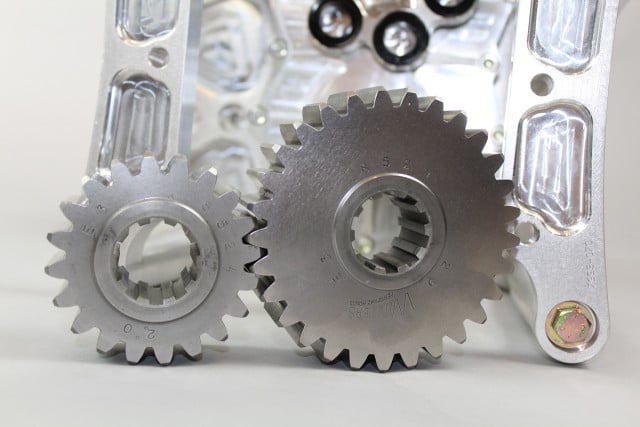

The CDS gear drive uses standard 10-spline quick-change rear end gearsets internally to operate the supercharger. Chassisworks has a range of gearsets available, and also outsources lower ratio sets to provide a host of custom gearing options, depending on the specific needs of the racer.

Our particular drive was custom machined and geared to spec and has been set up with provisions to drive a Moroso oil pump dry sump, along with an Aeromotive mechanical fuel pump. The Moroso pump, a six-stage Tri-Lobe dry sump unit (Part #22326), is a lightweight pump with scavenge sections with individual timing gears for proper clearance at high rpm, with variable spring rates and a spur gear section based off of their billet wet sump pumps. The pump is paired with a Moroso oil pan with four stages in the pan and one in the intake valley, cycling through a Moroso dry sump tank. The fuel pump, meanwhile is Aeromotive’s billet Hex Drive (Part #11107) with a 3/8-inch hex drive shaft, allowing it to be directly driven off a gear drive, the back of an external oil pump, or by the cam via a timing cover adapter. This pump, with a range of uses, supports 1,800 horsepower on methanol and caters itself to high-horse, forced induction, EFI applications.

The options for accessory item drives and configuration is nearly limitless, with provisions for vacuum pumps and adapters, offset and standard magneto drives, and others, all of which can be operated off of the mechanical fuel pump drive and, if necessary, an add-on accessory line drive that extends the accessory mounting range with four additional ports that provides the ability to operate three accessories off the front of rear output ports.

The configurations don’t stop there either, as the gear drive case itself can be set up with and modified with a wide range of custom gear ratios, depending on your supercharger and how fast you want or are allowed to turn it. The CDS gear drives uses standard 10-spline quick change rear end gears — Chassisworks makes a spacer set to allow for the use of narrower 0.800-inch aftermarket gears, which range around 1.95:1 up to 2.15 ratios. Chassisworks’ own custom gearsets can be spec’d above 2.15 on up to 2.40 for those who really want to wing their superchargers.

What Chassisworks has created with their Component Drive System is one of the most complete and user-friendly ecosystems in the performance aftermarket. In the process, they’ve made the lives of centrifugal supercharger racers infinitely better by allowing them to utilize and position the many necessary accessories under the hood of their race cars in an organized, simplistic-yet-semi-complex manner. Chris Alston, Sr. and Jr. launched the product line with a vision, and over the last handful of years, we’ve watched it mature with new accessory drives and adapters to make virtually any combination a possibility. And it’s safe to say, the Chassisworks team isn’t done with it just yet.