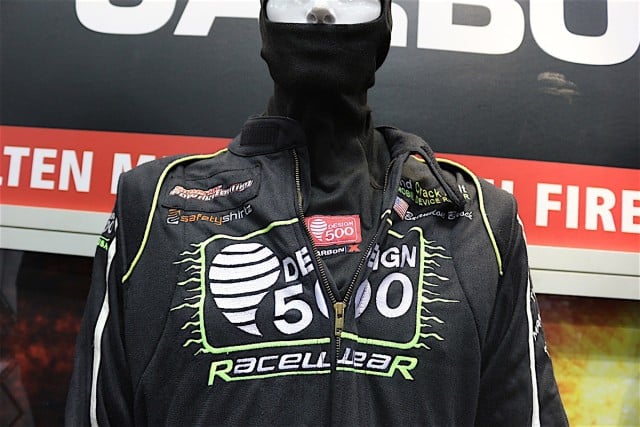

A fire suit is the iconic uniform of the race car driver. Not only a symbol of sponsorship, identity, and competition — it is fundamentally the most personal piece of safety equipment. Required by any reputable racing organization, a fire suit should not be confused with being fireproof, rather it is a part of a system — one made of several components that are designed to give you the best chance of survival in an accident.

A fire suit is the iconic uniform of the race car driver. Not only a symbol of sponsorship, identity, and competition — it is fundamentally the most personal piece of safety equipment. Required by any reputable racing organization, a fire suit should not be confused with being fireproof, rather it is a part of a system — one made of several components that are designed to give you the best chance of survival in an accident.

Fire suit technology has come a long way over the history of racing, but the importance of the design remains largely the same across all types of motorsports. Usually manifesting in a one-piece jumpsuit, these often multilayered coveralls are designed not to burn, and to protect the wearer from direct flame and heat exposure. No fire suit makes the wearer immune to fire, but they range in certification and offer more time to escape the flames.

Fire suit technology has come a long way over the history of racing, but the importance of the design remains largely the same across all types of motorsports. Usually manifesting in a one-piece jumpsuit, these often multilayered coveralls are designed not to burn, and to protect the wearer from direct flame and heat exposure. No fire suit makes the wearer immune to fire, but they range in certification and offer more time to escape the flames.

If you remember from biology class your skin, or dermal layer, is the largest organ of the body. Apart from providing obvious protection for the more delicate and extended muscular, nervous, and cardiovascular systems it provides important functions like vitamin D generation with sunlight, and cellular respiration — that is the ability for cells to breath. Sustaining burns obviously damages these functions and presents health problems that extend beyond cosmetic damage.

Certification

Fire suits are not simply defined by their number of layers or material. Distinct levels of certification exist to better define the classes of protection offered from these garments. To better understand the complexity of this system we turned to some of the industry experts at Impact Racing. While serving all motorsports markets with seats, helmets, restraints, and more, Impact tailors custom and off-the-rack suits for racers.

Kelli Willmore of Impact illustrated the differences to consider when determining an appropriate level of certification. “It is important for consumers and racers to understand the requirements for the series they will be competing in, and ensure they invest in the most appropriate safety equipment. Most grassroots racing organizations accept SFI 3.2A/5 rated suits,” Willmore began.

Kelli Willmore of Impact illustrated the differences to consider when determining an appropriate level of certification. “It is important for consumers and racers to understand the requirements for the series they will be competing in, and ensure they invest in the most appropriate safety equipment. Most grassroots racing organizations accept SFI 3.2A/5 rated suits,” Willmore began.

“While a 3.2A/1 suit may be perfectly acceptable to a series, typically these suits only feature a single layer of material and minimally only offer three seconds of protection to a second degree burn. Comparatively, an SFI 3.2A/5-rated fire suit is usually a two or three layer suit and offers 10 seconds of protection to a second-degree burn,” continued Willmore.

Consider this, you are strapped in the confines of your race car’s cockpit, it’s on fire, and it may be on fire due to a crash distorting the body, chassis, frame, and by extension the normal exit routes. Under the best of conditions a typical race car is difficult to exit, has five or six-point harnesses, head and neck restraints, hydration, air, and communications leads, arm restraints, etc. — making for a challenging speedy egress.

Custom sponsor embroidery is the norm these days, and is carefully completed using fire retardant thread.

In the panic of a fire the normal means of exit may be encumbered — doors jammed, window openings compressed, etc. Buying enough time to get out unscathed goes much further than considering when was the last time your 2.5-pound extinguisher was certified.

“Running an alcohol or nitro-powered drag car? Chances are the racing sanction will require a suit that is manufacturer’s certified to the 3.2A/15 (30 seconds to second-degree burn) or the 3.2A/20 standard (40 seconds to second-degree burn),” concluded Willmore.

Consult with your sanctioning body, and then buy the best protection you can afford.

Textiles

Fire suits are often characterized by the industrial fabrics from which they are tailored. Fire proof is a misnomer in the safety world. Fire retardant is the correct terminology for purpose-engineered fabrics designed to resist burning. The most well-known fabric is Nomex — a DuPont product that has been around as a concept since the 1950s and a commercially available product since the ’60s.

According to DuPont, “When exposed to extreme heat, Nomex undergoes a special reaction, changing its properties to capture more energy in the fabric, giving the wearer valuable extra seconds of protection from the heat transfer.” When exposed to open flame Nomex visibly chars and withers but does not hold a flame. Adding to the function of this textile are the behaviors of the individual fibers in the presence of flame.

DuPont illustrates two reactive traits Nomex employs to protect the wearer, firstly, “The fibre swells and thickens in the fabric helping to eliminate air movement and convective heat transfer to the interior of the garment,” and secondly, “As the fabric thickens, it entraps air which increases the insulating barrier, thereby reducing heat transfer to the body.”

As flame is applied to Nomex it chars but does not hold flame or melt.

A relative new comer to the game of fire retardant fabrics, Chapman Innovations is the root company behind CarbonX — a new age material that boasts impressive stats for utility and safety. According the the CarbonX website, “After intense exposure to 250 degree C heat, the CarbonX fiber blend possesses 100 percent of its original strength. Turning up the heat to 500 degrees C, our innovative fiber blend retains an astonishing 40 percent of its strength, even after 10 minutes of exposure.”

CarbonX offers impressive flame-resistance even with a hand-held behind the tested fabric. Warning: DO NOT ATTEMPT!

“Unlike treated cotton, the heat and flame performance of aramid fabrics cannot be washed or worn away,” Willmore pointed out. It is still important to be conscious of the laundering instructions for fire suits, while many can be washed others indicate dry-cleaning only.

Construction

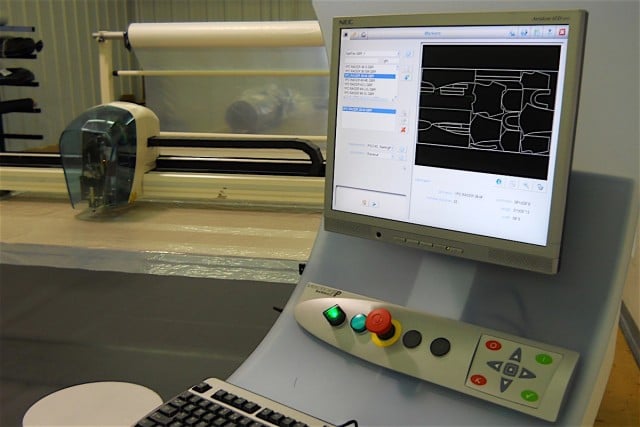

The role of the tailor armed with shears has gone by the wayside. Digital templates are arranged for material use efficiency, and a computer-guided razor makes the cuts.

While the textiles lend their inherent fire retardancy, the real protection of a fire suit comes from the specific construction techniques. Quilting is the specific layering technique used to join plies of fire-retardent textiles. Benefiting from more insulative qualities than just adding layers of material, air pockets are entrapped to slow the transfer of heat to the wearer.

“Surprisingly, most burns in racing are caused by radiant heat rather than direct flame. The air pockets created between the quilting and the layers of aramid material provide thermal barrier and provide valuable additional seconds of protection. Similarly, a suit that is too tight will compress the air gaps and allow radiant heat to reach the skin much more quickly,” illustrated Willmore.

Going hand in hand with the construction of a fire suit is the proper fitment to the wearer. A constrictive and tight suit reduces insulative qualities, while and overly baggy suit may impede movement in the cockpit. Visual cues can indicate certain comfort-enhancing features built-in to certain suits.

“Impact introduced enhanced parabolic patterning, inner leg and arm gusseting options — offering the wearer an even higher level of comfort and flexibility. These newly introduced options are in addition to Impact’s standard floating 360-degree sleeves, and a lower lumbar gusset that provides maximum flexibility and prevent the suit from riding up during the seated position,” explained Willmore.

“Impact introduced enhanced parabolic patterning, inner leg and arm gusseting options — offering the wearer an even higher level of comfort and flexibility. These newly introduced options are in addition to Impact’s standard floating 360-degree sleeves, and a lower lumbar gusset that provides maximum flexibility and prevent the suit from riding up during the seated position,” explained Willmore.

Even specialty stitching is implemented to create flat seams and joints — improving strength and comfort. “Impact crafts our epaulets with an overlock flat stitch along the shoulder line to improve the strength and reduce pressure points created by FHR devices and race restraints,” Willmore offered.

Undergarments

What to wear under a fire suit is often an easily overlooked topic — while they are known for being hot and stuffy that is a function of their insulative qualities. Far and away the worst clothing you can wear under a fire suit is moisture wicking sports wear.

While these popular garments will keep you feeling cool and fresh under your whole body oven mitt they are comprised of synthetic materials. Synthetic materials are for all intents and purposes plastic — when heat is applied they melt. Clothing that melts and chemically bonds with the skin is bad news.

Single-layer fire retardent long-johns are the correct option, effectively turning the suit your wearing into one with an additional layer they provide head to toe coverage when combined with corresponding socks and a balaclava. Many racers don’t spring for the 100 mph long undies, and in a pinch a 100 percent cotton base layer offers the comfort without the melting.

Closing Considerations

The moral of the story is not to go cheap on safety equipment, get a two-layer suit at a minimum. A fire is scary when you are clamoring to get out of the car, but an unconscious driver can’t help themselves. The more layers in the suit the more time safety crews have to extract you, add a fire suppression system on top for even more time, but that’s another story.