We’ve shown you some of the amazing things that have been dreamed up and created by the extremely talented team at Mazworx before. While their focus spans the gamut of performance engines, their latest standout is of the four-cylinder variety, earning a world record.

As a seven-year, ongoing project, Mazworx has been teamed with the Tekno Toyz team and owner/driver Muhammad Ali, out of Trinidad and Tobago, for the better part of a decade. This accomplishment is no lightweight, easily earned victory, but rather a path of research and development, and constant forward progress which has finally all come together at once. “This project started about seven years ago, and we have been running it for over five years,” says Mazworx’s Manuel Soler. “The car [and engine] were completely built at our shop.”

The car is a pro-class (tube-frame) Nissan S15, which was the last of the venerable Nissan 240sx family of vehicles, and was never available in the United States. As such the steering wheel is on the right hand side of the car. But most importantly, as this is EngineLabs, it is powered by an iconic Nissan four-cylinder engine – the SR20.

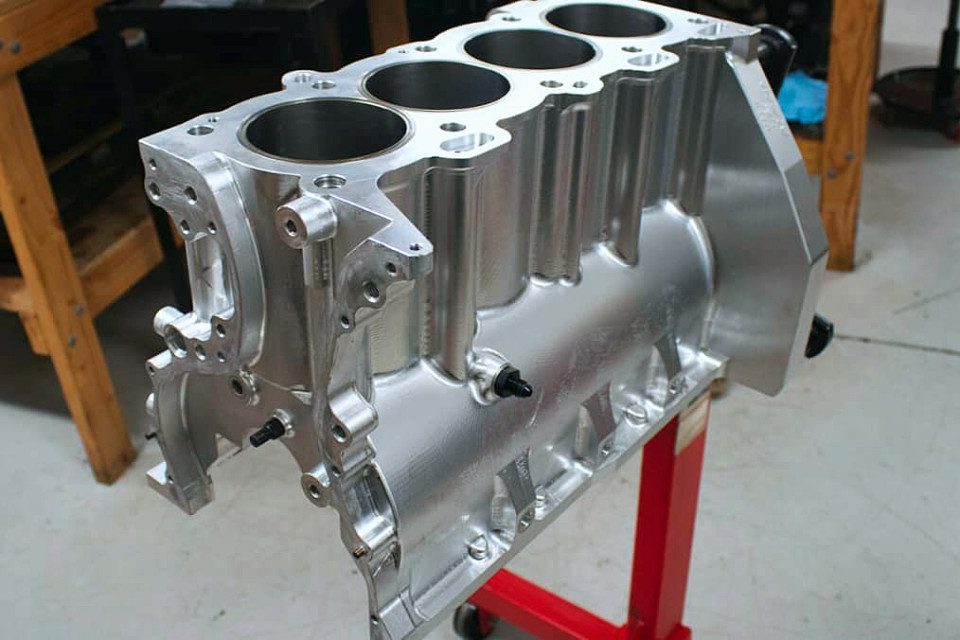

Mazworx has developed their proprietary billet 6061-T6 aluminum race block for applications in excess of 1,300 horsepower. It takes standard SR20 sleeves from Darton for ease of replacement, and can be had with massive 9/16-inch head studs.

A Brilliant Billet

The star of this particular engine combination is Mazworx’s billet SR20 engine block, which they have painstakingly engineered to be the absolute pinnacle of SR20 performance. Originally designed for applications that were surpassing 1,300 horsepower – which you have to admit is a pretty freaking amazing threshold for a stock four-cylinder block – the Mazworx block starts life as a solid block of 6061-T6 aluminum, and is carefully machined into something that is as much art as science.

Designed to not only accommodate a larger aftermarket stroke, the billet block will accommodate that stroke, even with aluminum connecting rods. Aimed specifically at drag racing, there are no water jackets, which adds strength and dimensional stability to the bores. A nice touch, is that Mazworx designed the bores to accept off-the-shelf Darton sleeves, so that if you damage one, there is no waiting time for a custom replacement. Normally offered with half-inch head studs, they bumped that up to 9/16-inch studs for this application.

The billet block uses billet four-bolt main caps made from 7075-T6 aluminum. While at first blush, aluminum main caps may have you scratching your head, It’s not exactly an uncommon practice, and there are a number of theories as to why aluminum would be a preferable material. The fact is, they are proven to work.

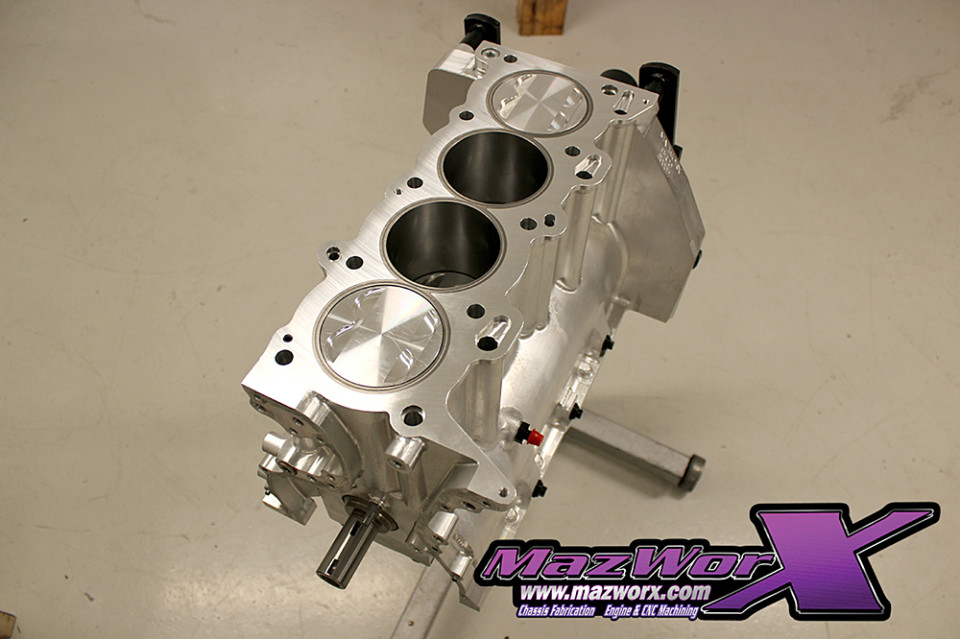

Billet 7075-T6 Aluminum four-bolt main caps are incorporated, for a balance of strength and weight, and they hold a custom billet steel 86mm-stroke (3.386-inch) crankshaft between a set of ACL race bearings. Attached to the crank are a set of R&R Racing Products custom aluminum connecting rods, which are made from a proprietary alloy that has been developed exclusively for R&R.

Attached to the rods are some serious slugs from CP-Carrillo. The 90mm (3.543-inch) bore makes for 2.2 liters of oversquare displacement, with the custom pistons wearing CP-Carrillo’s latest in PVD-coated piston rings, for a harder, slicker finish that makes for a stronger ring with less friction.

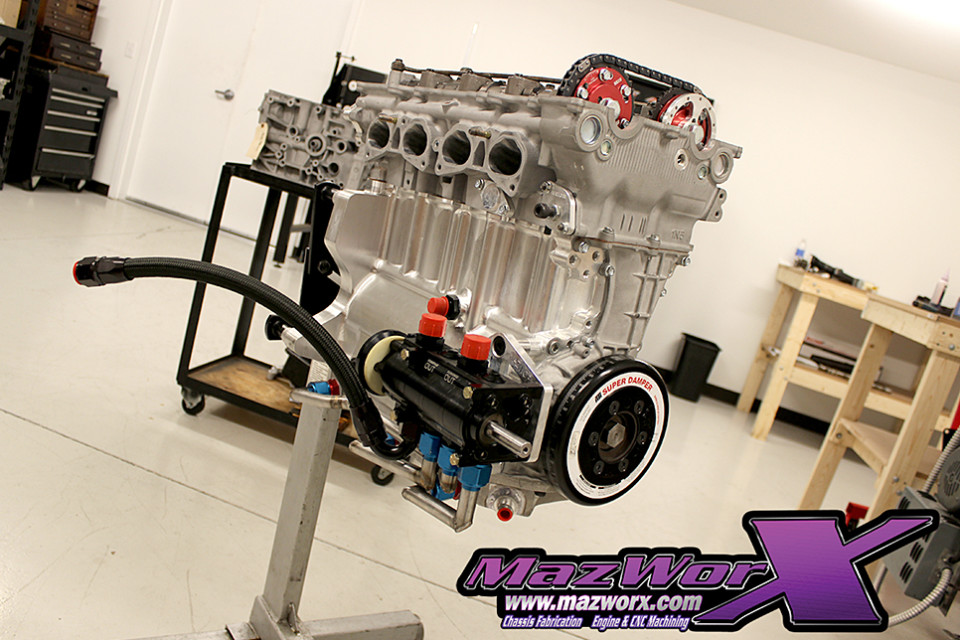

Providing the life-sustaining oil to the high-winding mill is a four-stage dry sump system from Armstrong Race Engineering. More than just a pump, tank, and fittings, the ARE system uses a unique cast – not fabricated – aluminum dry sump oil pan, which offers inherent strength benefits with all other usual dry-sump features.

The 90mm CP-Carillo custom pistons combine with the 86mm stroke billet crankshaft for 2.2 liters of displacement. The R&R Racing aluminum rods handle not only 80-plus pounds of boost, but also 11,000-plus rpm.

A Top Shelf Top End

With such a stout aluminum bottom end, you might assume there would be a billet aluminum cylinder head to top off the combination. You’d be mistaken. While not a billet cylinder head, the head used definitely isn’t your run-of-the-mill everyday SR20 head. This combo uses the factory head from an SR20VE – which is the variable valve timing variant, and most advanced naturally aspirated SR20 head to ever leave the factory.

Obviously, the head is far from stock, with Mazworx applying their porting magic to the intake and exhaust ports, along with the combustion chamber via their well-developed “Stage 4” CNC program. Then, Mazworx installed new guides, seats, and a multi-angle valve job on the Supertech valve blanks that Mazworks turns into their own creations –

but weren’t keen on disclosing the final size of. The final combination flows over 330 cfm at 28 inches of water, providing a stellar path for all that compressed air.

Topping off the all-billet bottom end is actually a factory cylinder head casting. An SR20VE head is given the full Mazworx Stage 4 treatment, bringing flow into the 330 cfm range. Custom cams, dual Supertech valvesprings, and – surprisingly – stock rockers, round out the high-RPM valvetrain.

Custom Kelford Cams camshafts act as the valvetrain’s brain, and Supertech dual valvesprings keep the valves in check at the instane 11,000-plus-rpm engine speeds. Surprisingly, OEM SR20 rocker arms are used in the otherwise completely modified combination.

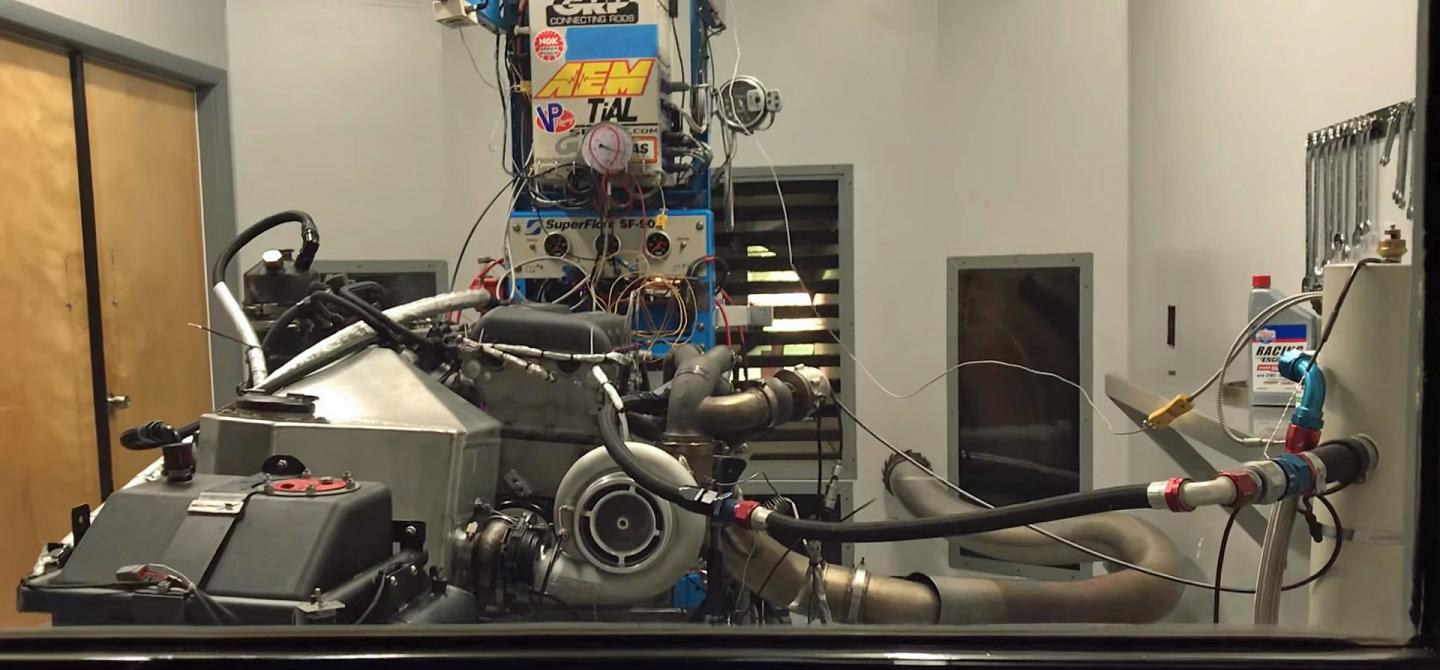

An 88mm Precision ProMod Gen2 XPR turbocharger provides the insane 80-plus pounds of boost pressure to the Mazworx billet intake manifold outfitted with a Ross Machine Racing 90mm throttle body. An Enderle 15 gallon-per-minute fuel pump provides massive amounts of M1 Methanol to the 12 Siemens 2200cc/minute injectors along with four 500 lbr/hr Billet Atomizer injectors.

Keeping the fires lit is an M&W Ignitions system outfitted with Denso pencil coils, while a MoTec M150 engine control unit controls the ballet of fuel and spark coordination, which is no easy task with 80 pounds of compressed intake charge entering the cylinders at 11,000 rpm.

A Precision 88mm Pro-Mod Gen2 XPR turbocharger stuffs over 80 pounds of boost into the combination via a billet Mazworx intake manifold. This whole combination uses top-shelf parts designed to make maximum power, period.

Theory Becomes Reality

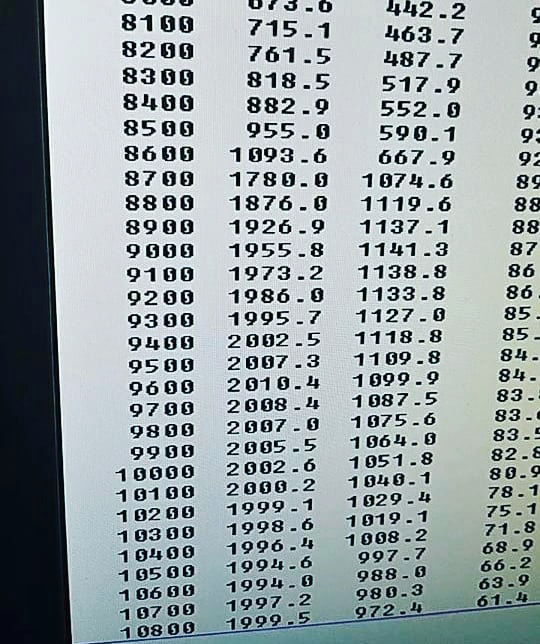

The last time on the dyno, the badass SR20 made just north of 2,000 horsepower at 11,200 RPM. “We made 2,010hp the last time at the dyno,” Soler shares. “As you can see on the dyno sheet, the engine picks up almost 800 horsepower from 8,600 to 8,700 rpm.” That incredible power jump is due to the inherent challenges of spooling an 88mm turbocharger with only 2.2 liters of engine displacement.

2,000 horsepower is impressive regardless of what powerplant you make it with. However, when you consider the horsepower-per-cylinder, you realize that this four-cylinder is doing the same work as a 4,000 horsepower V8 engine. As the old saying goes, “A burden shared is a burden halved.” But in this case, an engine halved is a load doubled.

With a 2,300-rpm powerband, where the engine is making more than 1,900 horsepower, the car can be a bit of a chore to get down the track, but the team did so in record-setting fashion at the recent Sport Compact World Challenge in Orlando, carding a 6.22 at 226.81 miles per hour for the four cylinder record, and then followed that up at Maryland International Raceway the following weekend at the World Cup Finals with a 6.26 at 223.39 mph to back up the pass and show that it was no fluke.

While the record is a feather in the cap of the Mazworx and Tekno Toyz team, it is by no means the end of the story. While the season is over, we’re sure that come springtime, we’ll see even more coming out of the teams.

A 2 week history, of making history. ALL our 6 second passes.

This is how we spent our last two weekends. Thank you to everyone on the team who made the car at this level of consistency. It was an honor to make this happen. Here's a video of all 15 passes from Orlando Speed World straight into the World Cup Finals.

Posted by Team Tekno Toyz Motorsport on Saturday, November 10, 2018

There is so much going on here. Look at the power spike between 8,600 rpm and 8,700 rpm. Also notice the “plateau” of power running from 8,900 rpm to 10,800 rpm which actually continues out to 11,200 rpm.