As it did last season, COMP Cams assembled a Dream Team to compete in the Horsepower Wars $10K Drag Shootout. And once again, the team ended up with an LS-powered Mustang as its entry into the competition. Led by Dave Henninger, with Jim Styke as the team’s engine man, the team is made up of some of the best in the business.

With a similar suspension setup to the previous Dream Team effort in its 2002 Mustang (1979-2004 all use the same suspension), the engine combination is remarkably similar this go-around as well. Although a slightly larger turbocharger is being utilized this time.

Not Too Big, Not Too Little

While one team opted for a 4.8-liter LS and another went for a 6.0-liter variant, the Dream Team split the difference, taking on a 5.3-liter for a little more stroke than the 4.8, but still with the same 3.78-inch bore. “It was the most cost-effective option for the budget. The 5.3 was cheaper than a 6.0 and better than a 4.8,” says Henninger. After a thorough tech inspection, the junkyard core was found to have been freshly rebuilt prior to the competition, which bumped up its cash value, per the competition’s rules.

With the freshly rebuilt core torn down, the cast 3.622-inch-stroke crank was reused, along with the fresh OEM-spec main bearings. As with all the other LS engines in competition, an ARP main-stud kit was installed. But unlike the other LS engines in the competition, the Dream Team decided to concrete-fill the engine block.

Using the fresh OEM rod bearings found in the core engine, a set of Lunati Voodoo H-beam connecting rods were chosen. Made from forged 4340 steel, the 6.125-inch rods come equipped with upgraded ARP2000 rod bolts with a 200,000psi tensile strength.

The Dream Team was the only LS combination to go with the old-school concrete block fill, using Quickrete in its 5.3L gen-III block. The plan of attack is absolute reliability in the face of a ton of cylinder pressure.

For the pistons, the Dream Team opened the bore up .020 inch, to 3.800 inches, and had MAHLE work up a set of custom pistons for its combination. A domed piston was spec’d out to bring compression up to 11.8:1 with the 61cc combustion chambers.

In addition to the Grafal skirt coating and overall phosphate coating, the ring lands are hard-anodized. Going a step further, the Dream Team also spec’d both vertical and lateral gas ports on the piston, to ensure maximum ring seal.

For the rings, the Dream Team went with a thicker ring pack than usual to hold up to the boost they are planning. In addition to size, beefed up materials were selected from Total Seal as well. An M2 tool-steel Dykes-style top ring was chosen to maximize sealing with the gas ports, along with a standard second ring and oil control ring. Finishing off the short-block, the OEM oil pump and oil pan from the core engine are reused.

In the name of reliability under boost, the Dream Team took no chances. It worked with MAHLE and Total Seal to get a piston with vertical and lateral gas ports, coupled with a thicker ring pack as well as Dykes-style tool-steel rings to maximize strength.

Stockish Top End

For this engine combination the Dream Team did the opposite of Midwest Mayhem. Instead of a stock bottom end, the team is running a pair of stock, nearly untouched 706 cylinder heads. “When you blow through the engine, the airflow isn’t as crucial as something naturally aspirated,” explains Henninger.

To that end, the team didn’t bother touching the intake and exhaust ports or worrying about the valve sizes, keeping the OEM 1.890-inch intake and 1.55-inch exhaust valves. They did, however, add a valve job and a small relief next to the exhaust valve. With the amount of boost the team is planning on running, there were some other tricks to be performed.

Starting with a set of ARP head studs to increase the clamping load, the team ran copper-wire O-rings with OEM head gaskets to ensure sealing under the extreme cylinder pressures the team expects out of the combination.

Lunati H-beam rods, forged from 4340 steel, connect the MAHLE pistons to the OEM 3.622-inch crankshaft. The rotating assembly combination should handle into the four-digit-horsepower range reliably.

The core engine came with upgraded valvesprings of indeterminate specs and origin, so they decided to keep them in and cross their fingers since they are planning to spin the engine to 8,500 rpm. With the free custom COMP Cams camshaft, the team opted for a hydraulic roller grind that will work with the OEM lifters, since the team chose to reuse them.

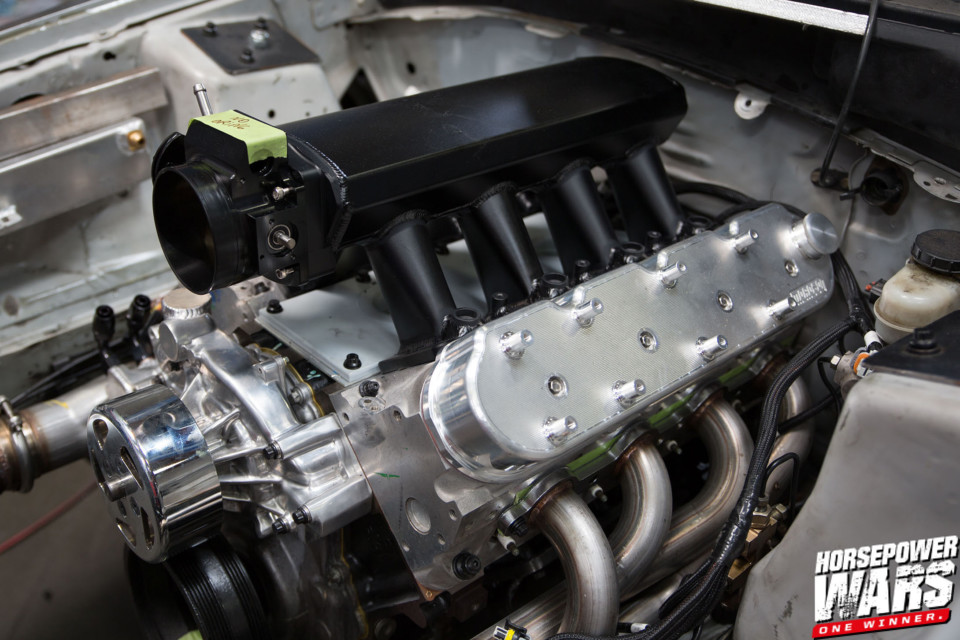

Covering the valvetrain are a set of trick CNC-machined billet aluminum tall valve covers from Moroso. with integrated coil-mounting stands, and an oil-fill port on each valve cover, the billet pieces are as useful as they are shiny.

The Dream Team kept the upgraded pushrods found in the tech inspection of the core. Other than the valvesprings, they are the only non-OEM components used in the valvetrain. The OEM rockers, trunnions, and timing set were all reused on this engine.

ARP provided main stud kits to all the teams, outside of their $10,000 budgets. With the amount of boost planned on being crammed into the engine, the main stud kit is a welcome upgrade for all the teams.

Getting Wild Up Top

Topping off the engine is a Summit Racing fabricated-aluminum intake manifold kit, which includes the manifold, a 102mm billet throttle body, and a set of aluminum fuel rails. Inset into the fuel rails reside a set of used Bosch 160 lb/hr fuel injectors the team scored for $100, which are the largest injectors used in the competition. That gives the Dream Team plenty of room with the additional volume demands of the X85 race-blend ethanol fuel offering from VP Racing Fuels they chose to run.

Feeding X85 to the injectors are a pair of Holley 450lph in-tank fuel pumps, in Holley’s in-tank fuel pump module assembly. A pair of K&N aluminum fuel filters and a Summit Racing fuel pressure regulator, plumbed with Fragola lines and fittings, get the ethanol from the cell up to the injectors.

For winning the Drag Racing Trivia Challenge on day-two of the competition, the Dream Team won a Holley EFI HP ECU and harness kit, which will handle the tuning of the engine. It interfaces perfectly with the Holley fuel pumps and will ably control the spark from the E3 LS coil packs, 8.5mm spiral-core plug wires, and E3-101 spark plugs.

The Summit Racing fabricated manifold kit comes with the fabricated-aluminum manifold, a 102mm throttle body, and a fuel rail kit. It’s a great way to get the key top-end LS components in an affordable package. While the Moroso valve covers aren’t exactly a budget item, their cost wasn’t factored into the total for the build.

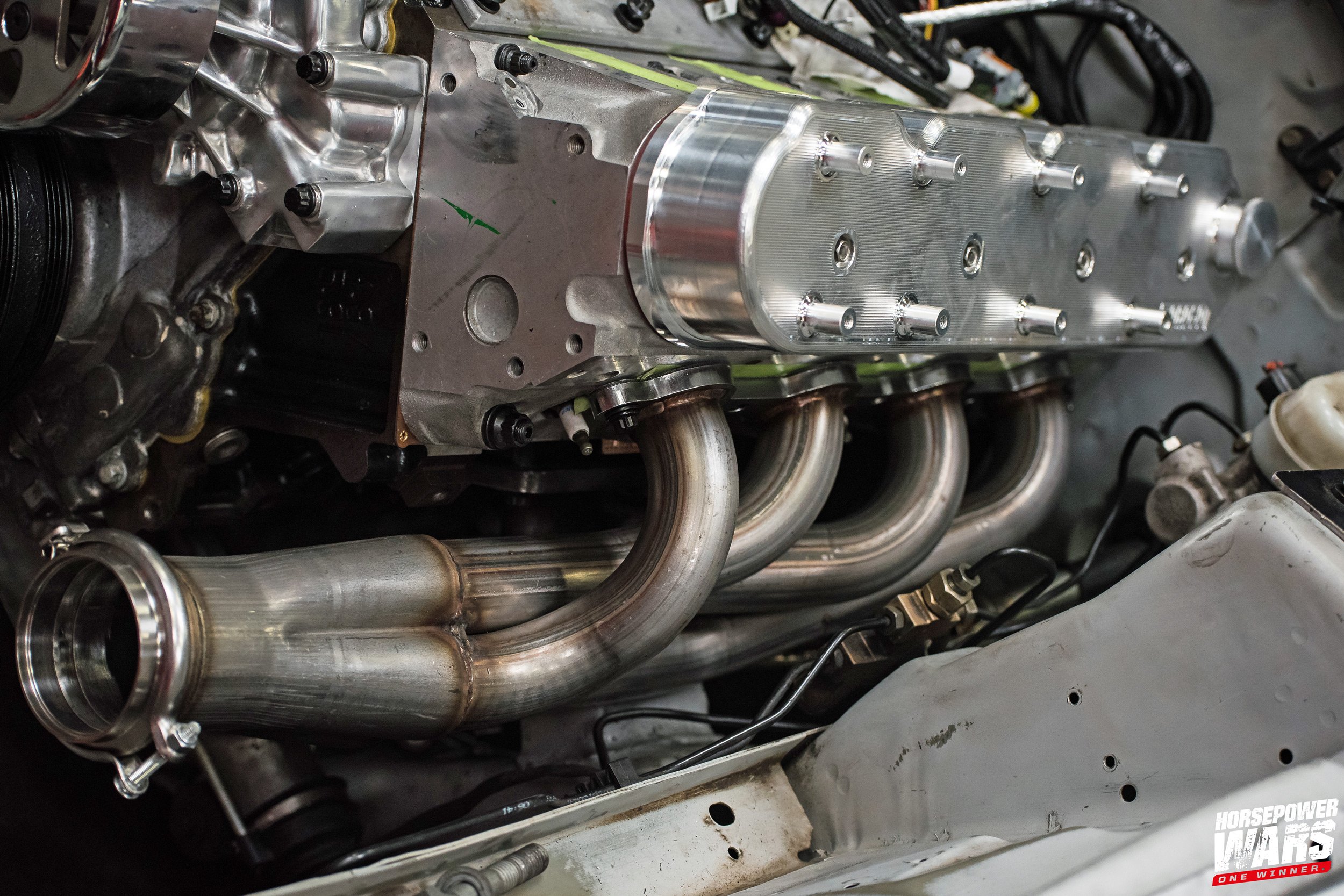

For the turbo kit, a set of Flowtech 409 stainless-steel 1-3/4-inch forward-swept turbo manifolds coupled with some used CX Racing exhaust tubing feeds the used Precision Ultimate 80mm turbocharger. Forgoing an intercooler because of the X85 fuel choice saves budget and weight in the build. The team also opted for no blow-off valve and a Precision Turbo 40mm wastegate.

“The best turbo we could buy within the rules was required, and we have the best turbo on the show. It should be capable of 25-plus pounds of boost,” Henninger says. “We are hoping for 1200-plus horsepower, depending on the turbo’s capability.”

The Dream Team feels the used Precision 80mm turbo they sourced is the best turbocharger being used in the competition. They are also the only team to actually run proper turbo manifolds, instead of the OEM LS exhaust manifolds. They believe the 1-3/4-inch stainless steel Flowtech manifolds with increase the performance enough to be worth the cost.

COMP Cams' Dream Team Spec Sheet

| Team: | COMP Cams Dream Team |

| Engine: | 5.3L Gen-III LS |

| Total Displacement: | 328 cubic inches |

| Bore x Stroke: | 3.800 inches x 3.622 inches |

| Block: | OEM 5.3L, concrete-filled |

| Crankshaft: | OEM 5.3L |

| Main Bearings: | OEM |

| Rod Bearings: | OEM |

| Rods: | Lunati Voodoo 6.125-inch, forged 4340 steel H-beams |

| Pistons: | MAHLE Custom, vertical and laterally gas-ported |

| Rings: | Total Seal M2 tool-steel Dykes |

| Oil Pump: | OEM |

| Oil Pan: | OEM |

| Timing Set: | OEM |

| Cylinder Heads: | OEM 5.3L (706) |

| Port Work: | None |

| Head Gaskets: | OEM with copper O-ring |

| Valves: | OEM 1.890-inch intake, 1.550-inch exhaust |

| Valvesprings: | Unknown (used) |

| Locks/Retainers | OEM |

| Camshaft: | Custom COMP hydraulic-roller grind |

| Lifters: | OEM |

| Rockers: | OEM |

| Pushrods: | COMP, unknown specs (used) |

| EFI System: | Holley EFI HP |

| Injectors: | Bosch 160 lb/hr |

| Throttle Body: | Summit Racing 102mm billet |

| Intake Manifold: | Summit Racing fabricated aluminum |

| Headers: | Flowtech stainless steel turbo manifolds |

| Power Adder: | Precision Turbo & Engineering Ultimate 80mm (used) |

| Coil Packs: | E3 LS |

| Spark Plugs | E3-101 |

| Plug Wires | E3 8.5mm spiral-core |

| Fuel Pump: | Holley dual 450lph in-tank |