Building a naturally-aspirated engine that will generate a respectable amount of horsepower requires more than just sheer displacement — it needs to have a good set of cylinder heads that move some air. For our Project Number Cruncher Firebird, we’re using a set of Dart’s Pro1 LS 12-Degree 285cc CNC cylinder heads, plus a Pro1 Single Plane LS7 to make some serious N/A power.

The name of the game in bracket and index racing is consistency, and since that’s what we’re going to use Project Number Cruncher for it only made sense to go with a naturally-aspirated combination. We planned on using a Dart LS block as the foundation of our engine build, so also using a set of cylinder heads and intake from Dart was sure to provide us proven, guaranteed combination. By going with the Pro1 cylinder heads and intake it saved us the time of trying to have another top-end package matched together and CNC-machined to maximize its performance.

The Dart Pro1 LS 12-Degree 285 CC CNC Cylinder Heads

Dart took GM's LS7 cylinder head and found new ways to make them flow even more air.

When GM released the LS7 as an engine option it cranked out over 500 horsepower and 470 lb-ft of torque without the aid of a power-adder. This made the engine very desirable to those who loved naturally-aspirated horsepower, and it gave companies like Dart a great base to create some wicked new hardware. From the beginning, Dart saw the LS7 style of cylinder head as a way to help any street or racecar make a lot of reliable horsepower.

When Dart began the design process for the Pro1 cylinder heads it wanted to be sure the heads would have plenty of strength, so it selected premium HIP aluminum alloy as the base material. These 285cc rectangular port heads are fully CNC’d and have large 2.200/1.625-inch valves in the 66cc combustion chambers. To clear those valves these heads have to be used on an engine with a 4.125-inch or larger cylinder bore.

On a set of stock LS7 heads the combustion chamber is a healthy 70cc’s, but that was changed for the Pro1 cylinder heads. Dart’s Mike Sanders explains why the combustion chamber was actually reduced with the Pro1 heads.

“A lot of thought went into how we could improve these heads overall before they were created. The combustion chamber was designed to increase overall flow characteristics and promote highly efficient flame propagation for maximum tunability. The 66cc chamber volume was purpose-built to be used with most shelf-stock pistons and allows for multiple pump gas compression ratios.”

Besides the combustion chamber size, the Pro1 heads from Dart have a different valve angle than its OEM cousin. When the LS family of engines was released it featured a 15-degree valve angle, an improvement over the standard small block Chevy 23 degree valve angle. By changing the angle of the valves, you can drastically improve how air flows into the combustion chamber; this improves efficiency, and that means more horsepower.

According to Sanders, there were two main reasons Dart decided to stand the valves up more inside the Pro1 cylinder heads.

“The 12-degree valve angle and 2.200-inch valve diameter increases line-of-sight from the port opening to the valve seat, which increases port efficiency. It also allows OEM and aftermarket valvetrain components to be used for factory or high-performance applications,” he explains.

A lot of thought went into how we could improve these heads overall before they were created. – Mike Sanders, Dart Machinery

How a set of cylinder heads flows is important, but in a naturally-aspirated combination, it becomes critical if you desire a lot of horsepower. Dart wanted to be sure the Pro1 heads would flow more than a stock set of LS7 heads, so it did a lot of research before the heads were released. A big focus was put on the port volume, plus the cross-sectional area of the heads. This was done so plenty of air velocity could be generated, and also allowed the non-turbulent airspeed to be maintained. This created a situation where the air was maximized in the cylinder fill through the Pro1’s flow curve.

You can purchase a set of Pro1 LS7 heads from Dart assembled and ready to be finished with the rocker arms of your choice.

Dart’s line of Pro1 LS7 heads has several variations, with the full race version being the most radical of the bunch.

“We offer our race version fully CNC ported with copper seats and Jesel machining that we moved .030-inches closer to the valve to optimize valvetrain geometry. This increases valvetrain stability during high RPM and high cylinder pressures associated with power-adder applications. In addition, our 285cc intake and 104cc exhaust port cross-sectional area work well with naturally-aspirated, nitrous, and turbocharged applications,” Sanders explains.

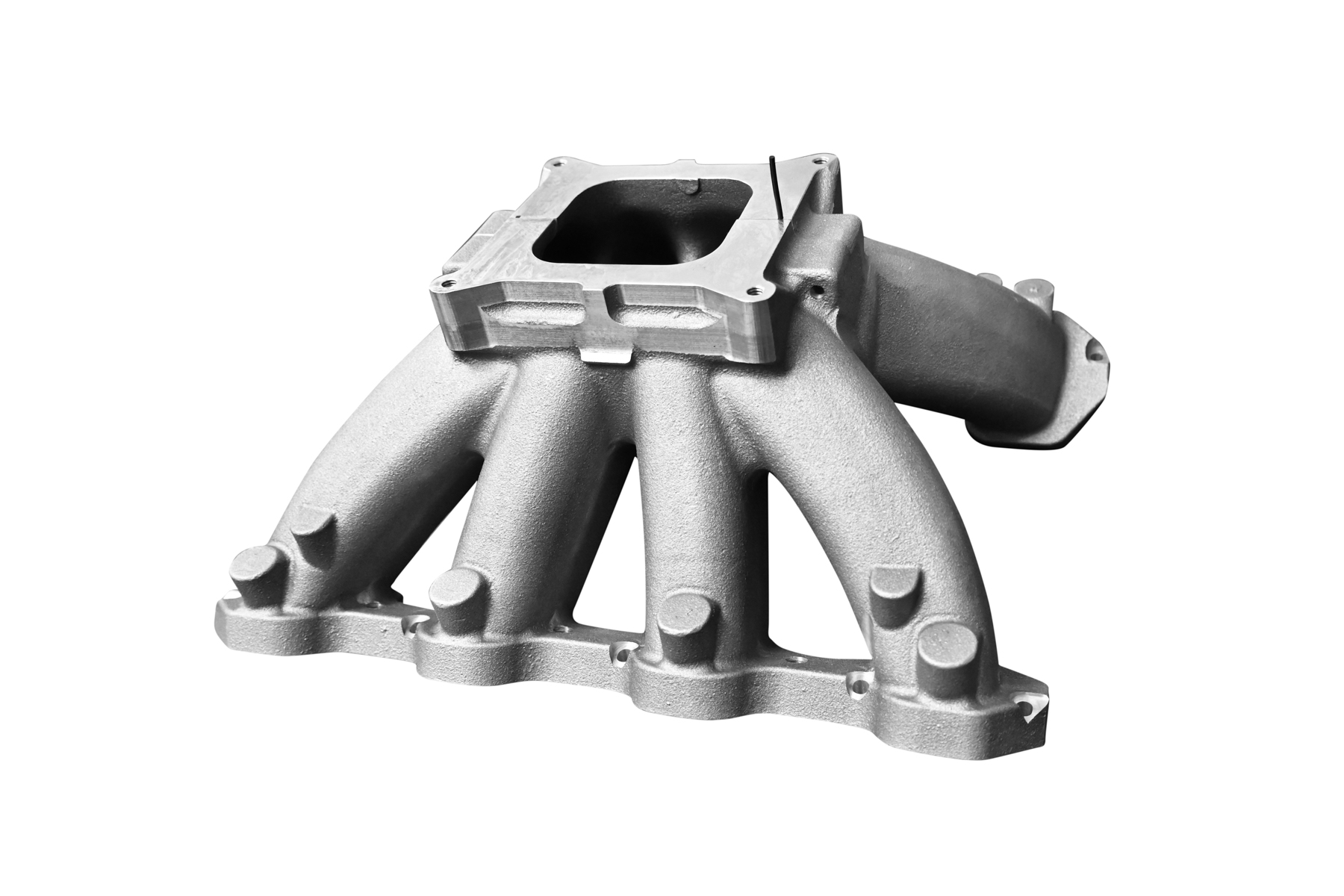

The Dart LS Pro1 Single Plane LS7 Intake

It’s very important that a set of cylinder heads and intake work together if maximum horsepower is to be achieved. To make this happen Dart developed its own intake to match the Pro1 LS7 cylinder heads: the LS Pro1 Single Plane LS7 Intake.

By using a two-piece split design for the Pro 1 intake, Dart was able to ensure all the critical areas of the intake could be massaged for optimal airflow. If you want to CNC port the intake yourself, Dart offers the intake in an as-cast state. You can also order the intake with all of the bosses machined for fuel injection if you’re going to go that route for fuel delivery.

The Pro1 LS7 intake is a versatile unit that can be used with fuel injector or with a carburetor.

The name of the game when it comes to perfecting an engine induction system is how well you can move air into the cylinder heads. Dart wanted the Pro1 Intake to have as few twists and turns as possible so the air has a straight shot into the cylinder head ports via the intake’s runners. This required a lot of research in how to get the most of out the plenum volumes, port shapes, and the angle of the runners for the Pro1 intake.

Sanders explains Dart’s thought process behind the Pro1 intake.

“Using a two-piece design is beneficial because we can split the two halves and efficiently CNC-port all areas with better cutter paths and stepovers. The port shape, plenum volume, and runner angles were designed to maximize airflow, fuel distribution, and line of sight to the valve, it complements our Pro1 LS7 cylinder head quite nicely. Full CNC porting allows for more consistent runner volumes and port shapes bank to bank for consistent and repeatable tuning.”

Full CNC porting allows for more consistent runner volumes and port shapes bank to bank for consistent and repeatable tuning. – Mike Sanders, Dart Machinery

There are many different intake designs out there for an LS-based engine that hav3 been proven to work well. The intake you decide to use should match your specific application so you can get the most horsepower possible out of that combination. Dart looked at why a single-plane intake works so well in drag racing and made sure to incorporate all of those features into the Pro1 intake.

“Single-plane intake manifolds have larger plenum volumes and, in some cases, shorter runner lengths depending on the plenum design. They start to mix fuel and build airspeed at a higher RPM, making them ideal for drag racing applications. Our manifold is a good fit for drag racing if you run it as-cast or fully CNC-ported,” Sanders says.

Dart designed the Pro1 LS7 intake with drag racing in mind.

The team at the School of Automotive Machinists & Technology (SAMTech) designed the Dart-based engine for Project Number Cruncher. They understand how important it is to use a set of heads and intake that can flow plenty of air for a naturally-aspirated engine like the one we’re going to use in our Firebird.

“Dart is a leader in aftermarket engine parts development. By using its parts we will be able to optimize airflow to the engine while achieving maximum casting integrity. Heavy airflow and airspeed are critical, but being able to hold the power can be even more important at times. So, a mixture of airflow, airspeed, and casting integrity are crucial to maximizing performance for an engine like this,” says SAMTech’s Shawn Hooper

The Dart Pro1 LS7 cylinder heads and intake manifold are the perfect match for our Dart LS block. This combination of parts should help Project Number Cruncher make gobs of naturally-aspirated power when SAMTech is done with the engine. Make sure you follow along on Dragzine as we get into the build-up of the engine and how it performs on the dyno.