A number of different tunable variables play into the high-speed chess game that is bracket racing, all with varying ranks of importance over another, depending on the driver, the race car, and the style of racing. Consistency, reaction times, and reliability are all paramount, and this all comes with proper setup and good maintenance. Now, every race car has a transmission and unless you’re (sadly) one of the dying few bracket racers that still shifts gears manually, your car has a torque converter, as well, and it’s in these two components where great strides can be made in these key departments that will help your goal of cutting great lights, running the number, and keeping the parts together week after week.

Today, we’ve joined forced with four of the top drivetrain manufacturers in the racing industry to share their top tech tips are for maintaining racing transmissions and converters to make their perform at their peak potential and put you in the winners circle. These include Pete Nichols with Hughes Performance, JC Beattie Jr. and Dave Caine of ATI Performance Products, Scott Miller of TCI Automotive, and Joe Rivera at Pro Torque. Each of these individuals and the companies they represent have decades of experience, watching thousands of their transmissions and converters power countless thousands of race cars down the strip, and if there’s anyone that can guide us (and you) to a better understanding of what makes a race car do what the driver asks of it, it’s these gentlemen.

Bracket racers live and die by consistency, be it at the starting line or the finish line. With thousandths of a second often the difference between winning and losing, racers are wise to gain every advantage they can, and that begins with the race car.

Consistency

The importance of supplying all of the vital information to the transmission and converter manufacturers up front so that you have the right part for the combination from the get-go cannot be overstated. You can relieve yourself of a lot of troubles down the road in the consistency and reliability departments by getting it right the first time.

Let’s start by taking a look at tips to improve consistency. This is certainly important in any division of drag racing, but none more than in bracket racing, where running the number every lap isn’t just desirable, but the difference between running over or running under and going home or collecting the check.

Get It Right From The Start: Having the right transmission and converter combination from the get-go can certainly alleviate a lot of problems later, and Nichols cites the need to provide accurate information to the manufacturer upon ordering. Nichols shared that one must be realistic about their combination and desired performance goals. “Custom-built torque converters are much like computers: garbage in, garbage out. A combination that doesn’t perform due to a radically mismatched setup or lack of information provided to the manufacturer isn’t the fault of the converter,” he says.

Hanging Loose: As Nichols shared with us his next tip. A “loose” converter will always be more consistent than a “tight” one. For bracket and index racing, Hughes Performance typically builds converters to flash approximately 200-400 rpm higher than where the engine’s peak torque occurs. This setup allows the engine to fall back into an effective RPM range before the gear change, thus maintaining efficient acceleration down the race track and reducing the sensitivity to changing weather and track conditions. This all adds up to a combination that’s more consistent lap after lap.

Hughes Performance typically flashes their converters 200-400 rpm higher than where the engine’s peak torque occurs so the engine can fall back into its effective RPM range.

Converter Charge Pressure: Many of you reading this may be unfamiliar with this one, but Pro Torque’s Rivera was adamant of the importance of this in terms of performance and consistency, citing it as hands-down his number one converter-related tip.

Many racers have logged as much as 50 degrees per second increase while on the transbrake. That will wreak havoc on your consistency if you don’t have a temperature stable fluid. – Joe Rivera

As Rivera explains to us, a torque converter as a fluid coupling, is dependent on pressure and flow to function properly. If the pressure is inconsistent, so too will be the race car. “You will be tuning to a converter that you think will work one way and because of pressure losses you’re tuning to something else. I highly recommend a pressure sensor on the cooler-out line to monitor converter charge pressure,” says Rivera.

Transmission manufacturers generally have their own “recipe”, so Rivera recommends speaking with them on the matter, however, he goes on to suggest that around 90 psi on the transbrake is a good baseline.

Starting Line Fluid Temps: Monitoring the transmission coolant and temperature and heading to the starting line with the same temperature on each pass will go a long way to making your car more consistent.

As the fluid temperature changes, so does the way the transmission and converter operates. As Rivera tells us, “It’s imperative that you’re tuning to the same temperatures run after run.”

Doing a proper burnout is important to clean the tires and get them nice and sticky, but there’s more to it than that. Performing a routine and consistent burnout and staging procedure will ensure the transmission, the transmission fluid, and the converter (along with, of course, the engine) are all at a consistent temperature when you leave the starting line. Doing so permits better consistency across the board.

Continues Rivera, “Many racers have logged as much as 50 degrees per second increase while on the transbrake, so if you get hung out for 10 seconds, that could be 500 degrees. That will wreak havoc on your consistency if you don’t have a temperature stable fluid. Fluid viscosity and a temperature-stable fluid are critical to consistency and reaction times — something that will work the same at 150 degrees as it will at 350 degrees.”

In terms of preparing on race day, Beattie Jr. suggests a good warmup on jack stands in the morning, running through all the gears, which will help make the first pass closer to the second. You can also utilize heaters on the engine oil pan and transmission pan to help in this regard.

Routine and Repetition: Although it should be a given, developing a consistent burnout and starting line procedure helps produce consistent runs. In doing so, the transmission and converter will typically always be at or around the same operating temperature when you bump in for each pass.

“Doing the burnout exactly the same every time is one key way to make the car leave the line the same each pass. Practice like you race, and then the race becomes less stressful,” says Beattie Jr.

Reaction Times

Like consistency, bracket racers live and die on the starting line. Particularly in the electronics categories where, with the use of delay boxes, one can be double-oh on the tree and find themselves loading up to go home a short time later. While the driver can certainly adjust his “spot” on the tree and the delay box, it first takes a race car that reacts to the drivers’ input the same way run after run, and the transmission and converter are a key element in the equation.

A transbrake, built into the transmission to help hold the car during the staging process, is a vital tool for serious racers in the never-ending game to achieve consistency.

Use A Transbrake: This one could certainly be applied to consistency of both elapsed time and reaction time, but a transbrake is a great asset for nailing the Christmas tree, in situations where the rules allow it, as Nichols points out. By using a transbrake, you can launch at the same RPM every pass, where the engine is producing a consistently higher level of torque. This also lets the suspension (on a suspended race car) work more effectively be launching in a pre-loaded condition. Keep in mind that the driver’s reaction is only half the equation in reaction times, as the car must launch consistently each run, as well.

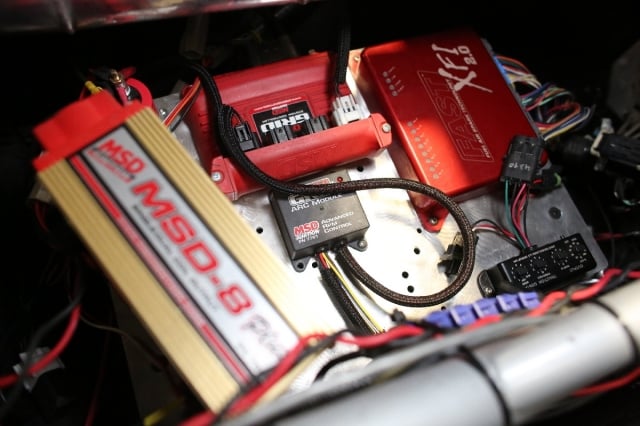

RPM Limiters: Along the same lines as the use of a transbrake, two or three-stage, low-RPM limiters, used for staging purposes, also allows the driver to stage and launch the car at a consistent RPM every pass. “This is going to ensure the most consistent performance from the torque converter as well as the entire combination,” says Nichols.

Rivera cites launch RPM as a vital ingredient as well, telling us, “This is very important to how the car ‘hits the tire’, and depending on the track conditions, you can raise or lower the launch RPM to hit the tire harder or softer.”

Of course this plays not only into the hands of improved reaction times, but more consistency across the board and better performance once dialed-in for the track.

The use of RPM limiters, configurable through your ignition or engine management systems, are a great tool for producing consistent reaction times, as the car will launch at a consistent RPM, thus hitting the tire the same run after run.

Reliability

Reliability is paramount to racers at any level in the sport. Transmissions and torque converters are a large up-front expense, and the longer you can keep them running in tip-top shape, the more money you can put into other areas of the car (or save to take your wife to dinner). Not to mention, a reliable drivetrain means a drivetrain that won’t fail you between rounds or leave you as “that guy” that just dumped a transmission on the starting line.

Transmission Temperature: TCI’s Scott Miller cites keeping a close eye on your transmission temperature temperature between passes and prior to making each pass. Of course maintaining a consistent temperature each pass plays into the consistency on the race track, but it also ensures things don’t get too hot, which can effect the long-term reliability of the internal components.

If the transmission fluid gets too hot, it can damage the seals and bearings in the transmission, so it can certainly play into the lifespan of the unit. – Scott Miller

Typically, if racers don’t have enough downtime between rounds, they’ll utilize either the onboard or external fan (like a box fan) to cool the transmission and converter down before rounds. This is especially important if you’re a bracket racer making round-robin passes.

As Miller commented, “If the transmission fluid gets too hot, it can damage the seals and bearings in the transmission, so it can certainly play into the lifespan of the unit.”

Checking Fluid Levels: It’s vitally important to check the fluid levels in the transmission after each pass down the race track. While this might seem redundant, it’s key to keeping your drivetrain happy.

Just like your daily driver, you always want to pay close attention to the fluid levels in the transmission. “Even if you don’t think that it’s blown any fluid out or anything, and even if you’re using a catch can — which most racers do these days — it’s best to check it each pass,” says TCI’s Scott Miller.

“Even if you don’t think that it’s blown any fluid out or anything, and even if you’re using a catch can — which most racers do these days — it’s best to check it each pass, and you always want to do it with the vehicle running,” explains Miller.

Circulating Fluid: While it may seem counterproductive to those less tech savvy, it’s a good idea to fire the engine and let it run for several seconds to a minute to help circulate the fluid from the torque converter during your cool down time. This gets the fluid moving without heating it up, as you’re not placing any load on the converter, allowing it cool quicker.

Maintenance Tips

Finally, we come to the all-important maintenance tips, which really encompasses all that we’ve talked about thus far. If you don’t properly maintain your drivetrain, you can forget about consistency, good reaction times, and most importantly, reliability. So that’s why we’ve reached out to our expert panel to provide some of the very best tips for maintaining your components.

Band Adjustment: Band adjustment is critical to keeping your Powerglide, TorqueFlite, C4, or C6 transmission (if that’s what you use) operating reliably, and it’s an often overlooked element until there’s a bigger problem.

Powerglide Band Adjustment

Powerglide transmissions are the most popular transmission in drag racing, and they all contain what’s known as a band, which is a steel (or similar material) band that wraps around sections of the gear assembly and connects it to the transmission housing while allowing action of the gear clusters. A improperly adjusted band can cause a number of problems, from shifting issues to rocking on the starting line and transbrake-related problems. While many believe running the band adjustment screw down until it’s snug will do, the common baseline is considered to be 3.5 turns out from snug. This adjustment is measured in inch-lbs. and every transmission comes with specifications for this adjustment, so while the 3.5 turns will get you in the ballpark, it’s best to always cite the transmission manufacturer.

Says Beattie Jr., “Keeping your band in adjustment will help to provide a crisp and clean transbrake release each pass. As OEM cores are no longer available to be re-lined, new cores are used and they will need to move and break in.”

Band adjustment is always set in inch-pounds, and it’s critical, as both Miller and Beattie Jr. tell us, to ensure you adjust it to the correct specification. Simply running it down until it’s snug won’t do the job.

Using An Overflow Tank: Although a benefit for safety more than anything, the use of an overflow oil tank can save one from dropping oil on the race track or under the tires. In addition to keeping an eye on the fluid levels, you’ll want to drain the overflow tank regularly to keep it available when and if needed. Another benefit, though, as Miller points out, is that, “…you can see how much fluid the transmission is blowing out. If you make a pass and drain a quart out of it, then you’ve got a problem.”

Annual Overhauls: It’s a good idea to pull the transmission and converter annually (typically during the off season) and do a thorough check of everything and replace any worn or damaged internal components. As Beattie Jr. explains, horsepower and usage effect when and if these items are checked. If you’ve got a 400 horsepower race car and only get it out a handful of times a year, you may be okay, but it certainly doesn’t hurt anything to check.

Check All Bolts: Part of your normal maintenance routine should include checking all of the bolts in the drivetrain, including the converter bolts, bell housing, pan, and rear mount bolts. Re-torque them as needed between events. Miller shares with us that the converter bolts in particular must be watched, because, “If they come loose, it’s going to create some havoc in the bell housing. Even with a shield on it, it’s going to do a lot of damage.”

As you can imagine, a loose bolt on any driveline component can be consistency of performance at best, and pure destruction at worst. It’s a good idea to routinely check all of the bolts, from the transmission to the converter, to the

Have Tested Spares: While not specifically a maintenance tip, Rivera suggests that if you have the budget to carry spares, to be sure that you test them, dial them in, and tag them with elapsed time, speed, and datalog information, in case you find yourself in a situation where you have to grab a spare and jump right back into the game, perhaps even during eliminations. Test both converters and get them equal on the track, so if and when something goes wrong, you always have a baseline to return to with the spare.

Fluid Levels And Filters: Another key ingredient to long life and solid performance from your transmission and converter, change the fluid and filter regularly, and be sure to properly monitor things each event and even each run. As Beattie Jr. puts it, “If you think you got the transmission and fluid too hot, drop the pan and take a look. In the grand scheme of the weekend, it’s cheap insurance.”

Miller adds to Beattie’s point, suggesting that racers change the fluid and filter every 25 runs. For a bracket racer competing on a weekly basis, this number could amount to once every 3-4 weeks.

Transmission Yoke: Regularly check the transmission yoke for any excessive or abnormal wear. To do this, you can jack the car up and let the rear end drop down, and it will pull the yoke out some so you can see if there’s any wear at the seal.

Regularly check your shifter linkage. You can do this by putting the car into neutral, then shift through gear and ensure it’s engaging into each gear detent. Although unlikely to fall out of adjustment from week to week, it’s a good idea to check it anyway.

Check Shifter Linkage: Finally, you’ll want to keep an eye on your shifter linkage adjustment. As Miller explains, this can be done by putting the transmission into neutral, and make sure that as you put the transmission into each gear, that is actually clicks into that detent. Although it’s not that common to fall out of adjustment week to week, it’s a good idea to add it to your normal weekly maintenance. An “off” adjustment can effect both performance and the life of the transmission.

If you’ve ever wondered to yourself what the tricks of the trade are for the many highly successful bracket racers out there, the truth is that they aren’t all tricks. Utilizing many of the important maintenance and procedural tips outlined here on a weekly or run-by-run basis, you can discover improvements in every department and give yourself a leg up on the cut-throat competition in handicap-style racing. And no question, you’ll save yourself some money and a lot of headache by making yourself a checklist, developing a routine, and being steadfast about every area of your racing program.