Most of us count our horsepower by the hundreds. However if you’re a racer or engine builder who counts in the thousands, you’re not building with parts you bought out of a catalog. Engine builders and racers at this level are in the upper echelon of the racing world. There’s only a handful of guys currently building horsepower at this level and many of those builders turn to Dart.

A finished Dart Machinery billet aluminum block is as much a piece of modern art as it is a hardcore racing part. CNC machines carve each block from a single 6061 billet block in a process that can take upwards of 40 hours.

- Dart’s billet block is the block of choice in the fastest Pro Modified, Top Fuel, and other high-powered vehicles in the world. If you’re in need of custom options for making big horsepower – and we’re talking in most cases from the 2,000-plus neighborhood to over 4,000 – a Dart billet block and matching billet heads can have a substantial technical advantage. Says Dart’s Jack McInnis, “When you’re making extreme levels of power, the billet block offers the best technology and materials available.”

Custom Built To Your Specifications

“The engine builders who work at this level tend to have very specific ideas about what they want. Everyone has their own specifications and Dart produces components to meet their needs,” explains McInnis.

When you are making extreme levels of power, the billet block offers the best technology and materials available.

Common design variations:

- Custom deck heights up to 12.500-inches

- Variations in deck thickness

- Variations in bore size from 4.840-5.300-inches, spacing, angle and location

- Raised camshaft location up to 1.915-inches

- May or may not include water jackets in the block

- Wider pan rails.

All of these options play into an engine builder and racer’s master plans for producing an optimized engine combination. Builders must be on their toes and prepared to account for a wide range of variances based on their design demands. When dealing with parts at this level, you have to assume that nothing is going to be normal.

According McInnis, “Using this approach, most custom block designs are completed in 2-4 weeks. A total new design of an engine platform we have not previously worked with would of course take longer.” This is because Dart has predetermined, pre-engineered CAD files already in their computer system. Those files serve as a design template and are altered to meet each individual engine builder’s design demands. This can also streamline the design process because engineers have information readily available as to what’s already feasible in the real world.

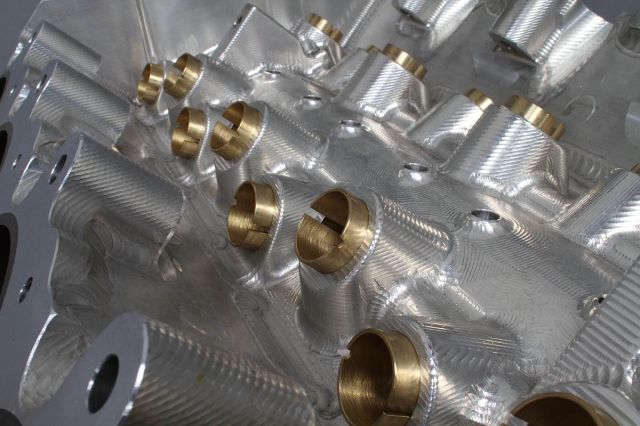

Offset and custom sized lifter bores are just one customizable feature available on a Dart billet block.

Dare To Be Different

McInnis explained to us,”You’re really only limited by the internal parts that you can source. You could theoretically do almost anything. Whether you can find the parts to use is another part of the story.” Dart engineers work one on one with engine builders to develop their design ideas, test them for real world feasibility and make them a reality.

Simple variations like adjusting tall deck heights or thicker pan rails, thickness, or unique head bolt patterns, to more radical alterations such as extreme bore spaces or combining engine platforms, the engineers at Dart are up to the task of helping the racer and engine builder achieve those goals. With a Dart billet block system, if you wanted to run a Ford Modular cylinder head on a Chevy big block or vice versa, the engineers at Dart can work with you to make that happen.

Making Big Cubic Inches

In small block applications builders can choose from 4.400″ or 4.500″ bore spacing, while big blocks have the option of running 4.840″, 5.000″, 5.200″ or a whopping 5.300″ bore spacing, which have become the staple in Pro Modified, mountain motor racing. Deck height for big blocks can also hit a ceiling of up to 12.50″ to help produce over 1,000 cubic inches.

Cylinder heads and valvetrain geometry often start to become a challenge at this level and you may need to communicate with a valvetrain engineer and a cylinder head expert. Dart can help compensate for these large bore sizes by offsetting the lifter bores. Lifters and other components must be able to handle the design parameters of such an engine operate properly. You could in theory design nearly anything in the CAD process, but the difference between theoretical and reality have to come into play at some point.

Camming Up

Changes in cam height in the blank are common when building engines on this level. Builders may want to move the cam in the block, and block builders can run a cam tunnel diameter of up to 70mm (60mm max size in small blocks). Dart billet big blocks can raise the cam by as much as 1.915″.

- Allow clearance for longer crankshaft strokes

- Allow for larger camshaft bores in the block

- Shortens the length of the pushrods to reduce or help control valvetrain

From CAD To The Real World

You Dream it, They Make it Reality

The combination of CAD and CNC technology allow for nearly anything an engine builder can dream up. Variations in pan rail design, bore size and spacing, water jackets, cam height, lifter bore size and offset are just some of the many design features that can be incorporated into each block.

Once all the details have been established and everything is worked out by the engineers in CAD it’s on to the next step. It is critical during the design phase that engine builders work very closely with Dart’s design engineers. Further, every component to be used by the builder must already be determined. These components must also be known as compatible for the application; at this level of design those small details make the difference between having a working racing engine and an expensive piece of decorative aluminum.

What is 6061 Billet Aluminum

Each billet big block starts life as a 500-pound block of 6061 aluminum. All of the billet material that Dart uses come from a drawn process where the aluminum is drawn over rollers while it’s still hot after pouring. This helps compress and align the aluminum’s grain structure to ensure quality, strength and durability. This process alone takes over 18 hours to ensure the proper heat treatment and strength. To withstand the demands of the highest horsepower engines the materials used must be superior.

Facts about 6061 aluminum:

- Material must be 95.8% or more aluminum by weight.

- Tensile strength of 45,000 psi

- Shear strength of 30,000 psi

- Rockwell A Hardness 40

- Rockwell B Hardness 60

- Fatigue strength 14,000 psi

- Melting point 1080-1205° F

Creating a block

Cutting a block from a single billet piece of rather than a traditional casting is a proven way to improve strength and durability. When casting a large part such as a block there can be core shifts and other errors in the process that can cost the manufacturer time and money. This can also compromise the structure of the block and could potentially be unnoticed during the manufacturing process. Carving the block on a CNC machine from design parameters created in CAD eliminates this type of potential error.

The foundry inspects each billet on a microscopic level to identify where the core is strongest. This designated area of the core is where Dart will machine the main crankshaft journals, ensuring this critical area of the block is in the strongest portion of the material.

Once received from the foundry, the blocks are rough cut or cut into a blank. At this point the block will truly begin to look like an engine block with the basic shape and form. Blocks are then given a proprietary heat treatment that further strengthens the billet. By doing this to a block when it’s still at the blank stage, it ensures that critical areas are not distorted during the final heat treatment process.

Finishing Up The Foundation

Following heat treatment, Dart’s billet blocks spend several more hours in the CNC machine receiving final machining to create a piece that’s exact to the design specifications. Completed blocks are thoroughly inspected for quality control, using tools such as CMM’s (coordinate measuring machine) to ensure optimum build quality and proper specifications.

Once this work is complete, the block can either be shipped to the engine builder so that they can perform their own final machining or reamins at Dart performs these steps in-house, including line honing and the installation of ductile iron cylinder sleeves. Once all is said and done, the original 500-pound billet has been transformed into a 150-pound big block Chevrolet engine block.

From the time Dart gets the go ahead and final approval on the CAD design, it takes 10-12 weeks to complete a custom block. This isn’t very long considering the amount of customization that’s available and the overall quality of the part.

Billet Cylinder Heads

Engine builds at this level will require custom built or billet heads as well. Dart’s billet offering can either be of Dart’s own design the engine builder’s. Because Dart controls the entire block design process, the head design and manufacturing process can be done in a similar fashion.

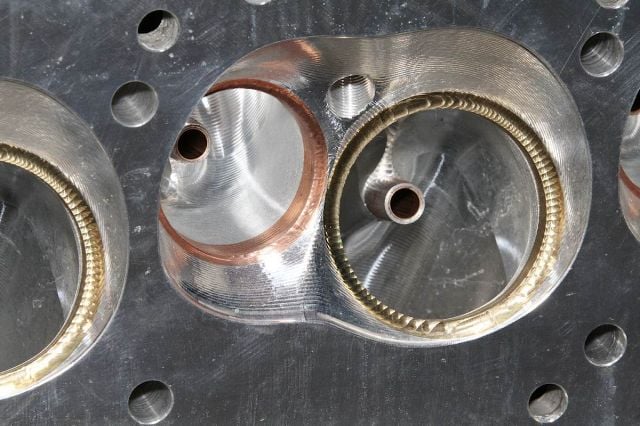

Dart Cast or Billet Aluminum heads can be run with Dart Billet blocks. These heads are not your typical off-the-shelf mail order pieces. All heads for billet engines are custom tailored to fit the design specifications of the builder and the block being used. Here you can see a set of custom heads for an engine with 5.20-inch bore spacing.

Says McInnis, “Depending on the type of racing and engine platform, some customers are running cast aluminum heads and some are using billet heads.” Either way, these are not direct off the shelf parts. While a raw casting may be waiting for machining at Dart’s facility it’s not a ready to ship part.

Everyone has their own specifications and Dart produces components to meet their needs.

Dart heads may feature valve sizes of 2.575″ on the intake side or conceivably larger in some applications. They in many cases also utilize titanium valves and copper beryllium seats. Cylinder head parameters are influenced greatly with changes in block and head design. For example when utilizing the 5″ bore spacing builders can be dealing with camshafts of 1″ or more of gross lift. Spreading the cylinder bores out this much also allows for massive runners in the cylinder heads. Heads in this case can flow in excess of 560 cfm.

More than Just Drag Racing

A Dart customer recently ran 3.74 in NHRA Top Fuel qualifying. While obviously the kind of power levels that we’re talking about required to even effectively use a billet block include, Pro Mod’s, Top Fuel and Funny cars, Dart billet products are not limited to just Drag Racing.

Billet blocks are used in dirt track, off road racing, marine, and even some street car applications. Due to the level of customization and strength, the billet blocks go well beyond the power levels a regular cast block can support. Dart also allows for engine builders to use their imagination to possibly create a whole new type of engine designed for one aspect…breaking records.