Any business owner or life-long gearhead that personally does the majority of their own wrenching, knows the value of things beyond money. Time, for one, is huge. It is rewarding to work on your own stuff, but nobody likes doing a job more than once. Using good tools is paramount to success – as is the confidence in knowing a job you completed is going to be rock solid.

Success on the track, street, and/or the show field comes down to preparation. Many people who don’t find the same success of others – but try everything they can think of – will often blame money or politics. The truth however, is different. Successful people know a few tips, tricks, and techniques, to prioritize things in a way that less successful people might regard as luck or even magic.

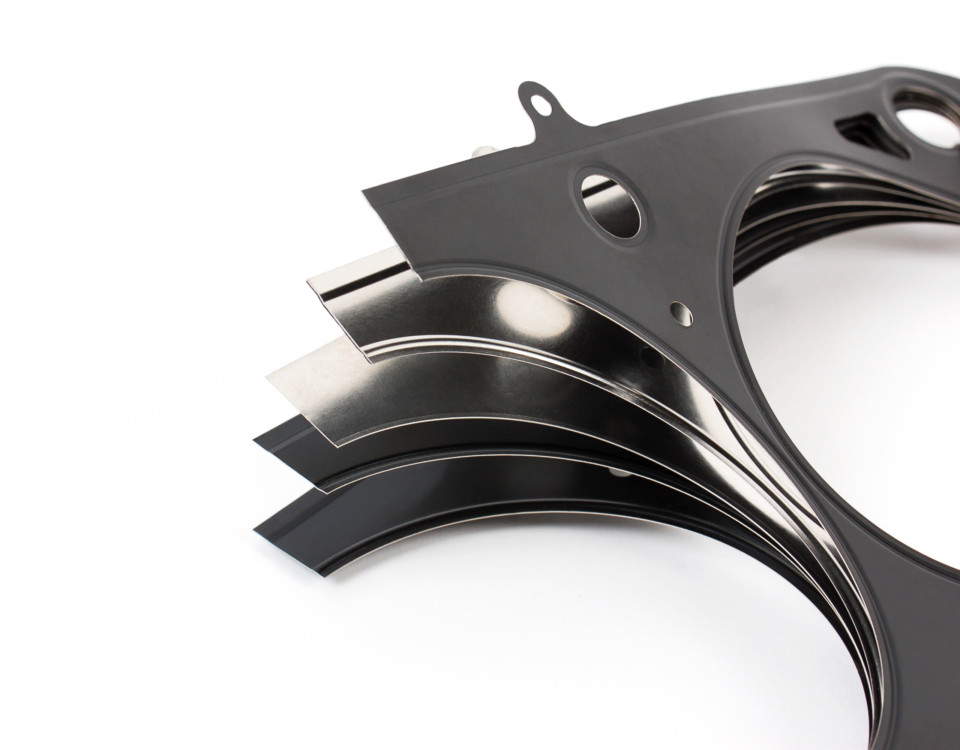

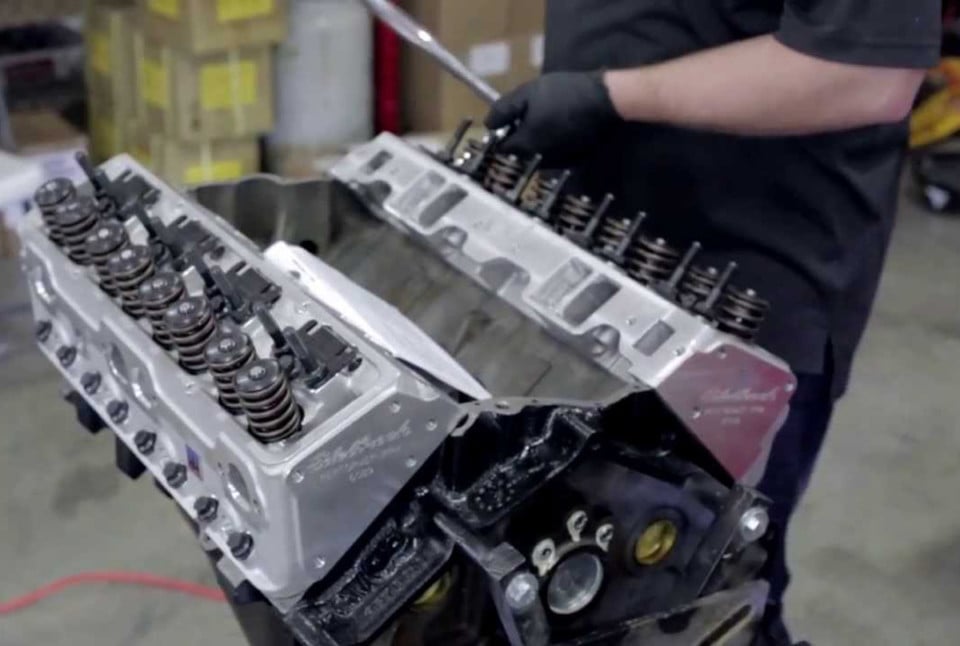

MLS gaskets are designed with two to five sheets of spring or carbon steel sandwiched between the head gasket’s sealing material. Precisely shaped beads and stoppers work with the specific steel properties to increase the clamping force around the combustion chamber.

Speaking of “magic,” if you don’t know enough about Multi-Layered Steel (MLS) head gaskets, this is going to change your automotive life. Everyone focuses on power-making big items that are generally in your face, exciting, and expensive. But all of those parts have to work together. Preferably, without ever breaking.

Head gaskets are ridiculously important, but people rarely give them much thought. Enthusiasts buy the swap meet gasket kit, and place the gasket in the necessary locations. But, head gaskets have to contain millions of explosions, deal with the expansion and contraction of dissimilar metals, and a wide range of chemicals and extreme temperatures. Basically, they are expected to perform silently and flawlessly forever.

MLS Head Gasket Science

We contacted two leading gasket companies, Cometic and Fel-Pro to get the “magic” sorted. We have used products from both of these companies in the past. It turns out, even our jaded and sometimes arrogant selves learned a lot of seriously important information. That made writing this article very rewarding.

No other coatings are necessary on MLS head gaskets. – Jim Daigle Fel-Pro

Chief Engineer Rich Larson and Senior Product Manager Jim Daigle, of Fel-Pro, walked us through all the details. Fel-Pro traces its history back 101 years, that’s when the company began making felt products and got its big break making gaskets for the Ford Model T. One century later, that start has evolved into the company becoming the market leader in automotive gaskets.

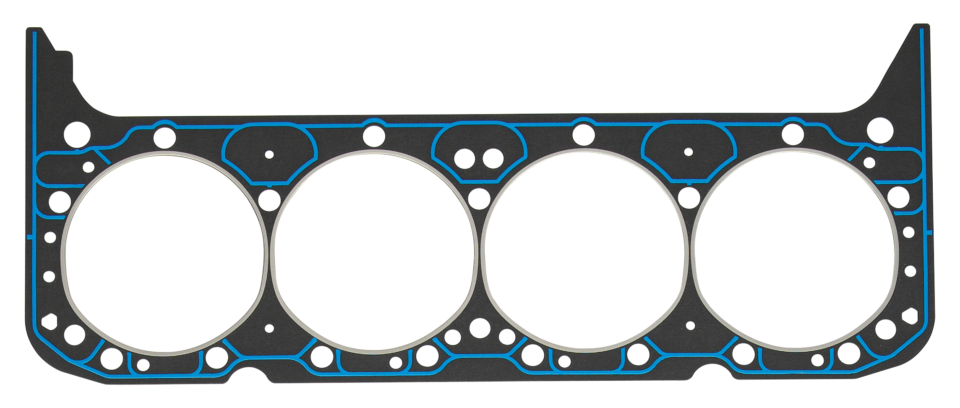

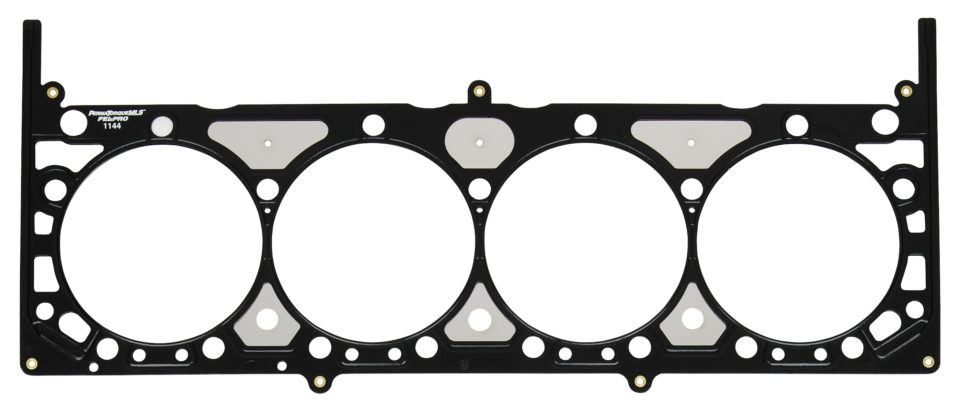

Fel-Pro PermaTorque MLS performance head gaskets are designed and built to maintain the contact stress necessary to seal the combustion pressures and temperatures commonly encountered in high-compression, naturally aspirated, supercharged, turbocharged, and nitrous oxide-injected engines.

“Cometic was started in 1989, and was dedicated to serve the powersports industry,” said Mickey Hale. “To this day, Cometic products are 100-percent American-made, utilizing state-of-the-art technology to be able to make quality, custom gaskets for any application. The company is also family owned. Cometic is a customer-driven company, and is able to offer world-class workmanship directly to race shops and even a one-off part to the little guy.”

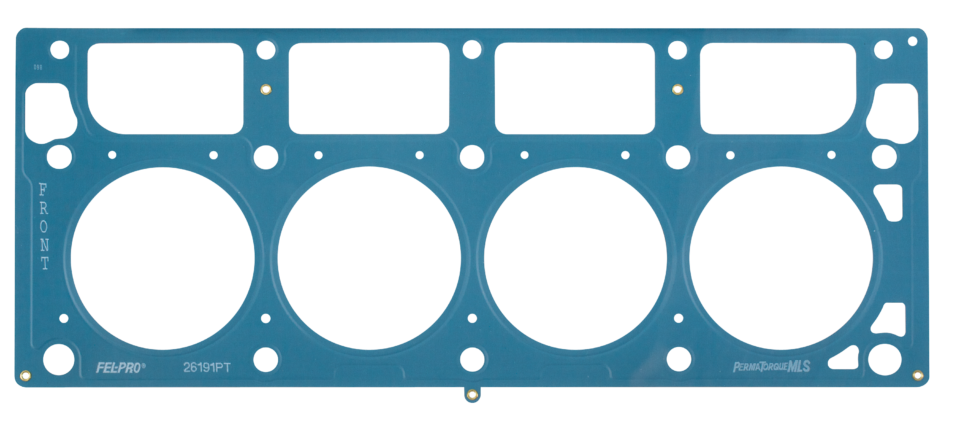

If you need to change the bore size and/or thickness of a gasket, the process starts with a phone call. After Cometic’s in-house technical sales team understands your needs, they work directly with design engineers to create exactly what you need.

MLS head gaskets are exactly as the name sounds. They are very thin sheets of stainless steel held together and coated with specialized surface coatings. They also have embossments to help seal when they are torqued into place. Generally, these gaskets utilize three layers, but there are specialized gaskets that may have up to seven layers depending on the application and needs.

What makes MLS technology so special, is its ability to perform with a greater workload and deliver a better job sealing with much less effort. If we look at old-school composite head gaskets that utilize a fire ring, the basis of comparison becomes clear as to what makes MLS superior. Not only is MLS used across the board in modern day OE cars, it gets refined as time goes by, and is the likely choice for the future of internal combustion engines. There is virtually no reason not to use MLS head gaskets in your application.

Nerdy Details Make Big Differences!

By nature of the stopper and bore beads (embossments) and the spring-like effect of the metal, the builder now has a much simpler task of getting a solid seal at the combustion chamber. This, with less torque required from the head bolts or studs. It is also more forgiving if that torque is not applied evenly. Don’t take that as a reason to be haphazard with your installation. We’re just saying this gasket has your back like no other. This is also vastly important to OE-engineers going for every bit of performance, emissions control, and efficiency. By requiring less torque to make the same seal, there is less chance of casting distortion and cylinder wall distortion.

MLS technology can benefit both old and new engines. But, if your engine was originally designed to use composite gaskets, you will want to have the surfaces checked to make sure they are smooth enough for MLS gaskets, or have them re-machined.

The specialized coatings on MLS gaskets seal the two surfaces on the microscopic level. When you first start up and heat-cycle your engine, this chemically bonds the seal to the metals. An important note: this is also the point of no return, making the gasket non-reusable. An MLS head gasket can be cold-torqued more than once before final assembly, only if the surfaces are smooth and clean.

Heat cycles and dissimilar metals are the scourge of a head gasket. How many people have freaked out about blowing a head gasket if their car got hot? MLS head gaskets are the best design for coping with the movement of different metals expanding and contracting during the engine’s heat cycles. Think of it this way: those multiple layers can slide at the microscopic layer rather than falling prey to the laws of physics that are trying to rip your old-school composite gasket apart.

Getting Custom

Why are there different amounts of layers? Different applications and head-and-block modifications have specific needs. For instance, you might wish to alter compression ratio a bit or dial in your quench area.

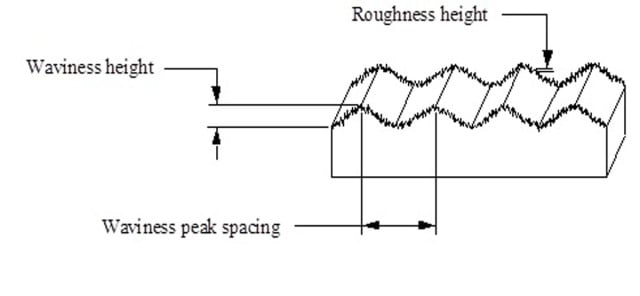

A good sealing surface not only means smooth, but also straight. Checking for waviness as well as how rough the surface is will help determine MLS gasket sustainability.

With Cometic, gasket thicknesses range from .027- to .140-inch thick. MLS gaskets have a very wide range of thicknesses that will effectively seal and be just as reliable as a thinner one. That doesn’t mean that it is a cure-all for improper engine building, or for salvaging an old head that has been milled too many times.

As an example, it is possible to go from a .040- to .080-inch-thick gasket in a big block and drop a point of compression if you are looking to get away from detonation in a forced-induction engine. Of course, the ability to change gasket thickness gives you the ability to fine-tune the quench area.

Adjusting head gasket thickness is really only for fine tuning. – Mickey Hale, Cometic

Mickey pointed out, “people get too hung up on quench. Unless your build is already dialed-in perfectly, there are more important aspects to get right – such as compression ratio. Adjusting head-gasket thickness is really only for fine tuning.”

Got Boost?

Cometic also has the MLX gasket line, which is a special tooled-gasket. While it isn’t infinitely variable in design like an MLS gasket, does have a ring around the combustion chamber that laughs at 20-plus pounds of boost.

MLS gaskets can be very forgiving, but only under strict circumstances. The surfaces of both the block and heads must be sufficient to allow them to properly seal. The tolerance for roughness of the sealing surfaces is much lower – almost half of what you can get away with if using a composite gasket. The smoother the better.

Myths And Hot Tips

We asked both Cometic and Fel-Pro two very important questions. Why should anyone buy from your company or start a relationship with you? Also, what do you wish people knew, but you can’t get through to them?

Fel-Pro was happy to point out they are the industry leader in gaskets. The company’s strength is in creating a wide range of gaskets for various needs. It is able to back them up with rigorous real-world testing and quality control.

Cometic pointed out that they are performance-oriented head gasket people, and not just a one-size-fits-all company. Starting a relationship with them allows the builder to grow, as they can custom-build any gasket. You can buy the products off the shelf at places like Jeg’s or Summit Racing, or you can call them directly for your needs.

Several sheets of stainless steel are layered to give the desired thickness. An MLS gasket’s ability to protect against blow-out in high-cylinder-pressure situations is due to the embossed layers acting as a “spring” to account for increased head lift. The outer layers are embossed, but also feature a special coating to help it conform to both the head and block surfaces.

Daigle wanted people to know, “no other coatings are necessary on MLS head gaskets. As long as your surface preparation is correct, the gaskets are made to specifically work with properly prepared bare metal. That means a properly decked and on-plane surface with a surface finish of 70Ra or lower.” Ra value is a surface roughness measurement. He also wanted to caution builders that today’s hi-tech lubricants can make threads of head bolts and studs so slippery, that it is easy to yield a bolt. That means it may read the correct torque spec, but you have over-pulled the bolt or stud. Lastly, for gasket surfaces, keep it clean and dry.

Just as important as the gasket, is the order in which you torque the head fasteners. Always start with the center-most bolt or head stud, then work your way out in a spiral pattern. That helps spread the loading over the head gasket evenly to give it the most strength possible.

Cometic wanted to add, if you are changing your head-gasket thickness, don’t forget your pushrod length and gasket thickness may have to change as well. Also, do not use copper spray coatings with its product. It is designed to be used without it. Lastly, your fasteners (head studs and bolts) are key. Make sure you are holding that head down to proper manufacturer specifications and torque procedures.