Building a racing fuel system for a naturally aspirated engine – in the sub 10-second range in the quarter-mile on nothing but good old natural atmosphere – can be a challenge. When your power plant is going to be quite self-reliant, that means no turbo, no blower, no nitrous, it’s motivation down the track will come only from whatever air and fuel it can manage to ingest in for itself. That makes fueling a critical part of the equation.

Recently with one of our race projects, we knew we would a need stout fuel pump and a reliable pressure regulator, along with some big lines and precision fittings to tie the fuel system together. To provide these vital components we turned to two trusted names in fuel systems today – MagnaFuel and Earl’s Fittings.

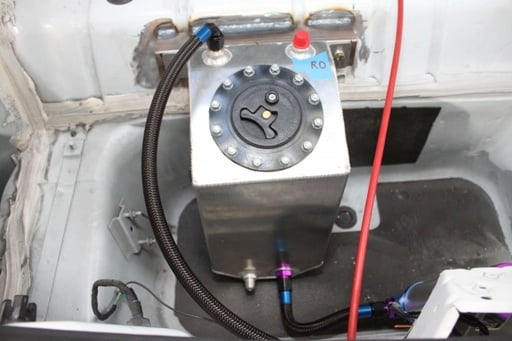

To further cut down on weight, we went with a small 1.5 gallon fuel cell mounted right in the trunk for easy access.

For safety, we installed a roll-over tube on top of the fuel cell. If the car should flip, the roll-over tube creates a low pressure area to keep the fuel from spilling out of the tank. You can also see where we made our hole in the trunk floor to run the fuel line to engine bay.

Going “QuickStar”

After talking to the experts at MagnaFuel, we decided to build our system around MagnaFuel’s QuickStar 300 fuel pump for high horsepower carbureted engines (part number MP-4650). Rated at 950 horsepower at 25 PSI in naturally aspirated applications running pump gas, the QuickStar 300 is a perfect match to help us meet our lofty 9-second goals. Of course there are several steps higher in the MagnaFuel performance ladder that we could have gone, but the QuickStar 300 will still leave us a bit of room to grow if we need it.

Here's the QuickStar 300 mounted in the trunk. The silver canister on the suction side of the assembly is the built-in pre-filter. The black line running straight up is the fuel return line, which makes installation much easier since we don't have to run two lines the full length of the car.

To get more info on the QuickStar 300, we called up Rob Ward, Tech Expert at MagnaFuel. “The Quickstar 300 is rated from 950 to 1,000 horsepower on gasoline, and you can run it continuously for up to an hour and a half. A cool feature is that the fuel pressure the pump produces can be adjusted from 25 to 36 PSI to help with fine tuning. You also can get the Quickstar fuel pumps with or without a built in pre-filter, which has a cleanable element that can be taken out, cleaned and reinstalled, so there’s no need to search for a replacement element when it needs cleaned.” Ward explains.

As many of you may already know, it’s always best to use a return style fuel system, regardless of whether or not you are using a carburetor or EFI. Ward tells us, “On Magnafuel’s fuel pumps for carburetors, there are fuel by-passes built right into the pump, meaning you can use a dead-head type regulator, saving you from having to run two lines the full length of the car. The returned fuel leaves the pump and is sent right back to the tank.”

Ward continues, “The Quickstar needs to be mounted close to the fuel cell or tank because they are a pusher type pump, but it still has an incredible amount of suction. So the Quickstar can be mounted as high as 12 inches above the liquid level, since it doesn’t absolutely have to be gravity fed. Gravity fed is still always best, and is better for the pump, but in some cars you don’t have as much flexibility in where you can mount the pump. For example, if you need to use a stock type tank, mounted below your trunk floor, and you want to put the pump in the trunk, you’re going to have to be able to pull fuel up, and the Quickstar can do that. You just have to keep the line from the tank to the pump to a length of 3 feet or shorter.”

Feeling the Pressure

To bring down the 25 plus PSI the QuickStar 300 produces down to a useable level with our carburetor, we also picked up one of Magnafuel’s Hi-Flo regulators for carb applications (part number MP-9833). The MP-9833 is a large two port design that can be adjusted from 4 to 12 PSI, and support engines producing in excess of 1,600 horsepower. And since we will be going straight N/A, our MP-9833 doesn’t have 1:1 boost referencing. This regulator should be just what we need to keep steady and reliable fuel pressure on our carbed LSX.

Since we needed to bring down the fuel pressure about 20 psi before it makes it to the carb, we needed a dead-solid fuel pressure regulator. We went with MagnaFuel's MP-9833 two port regulator for high horsepower N/A carb'ed applications.

Plumbing: A Heavy Issue

To tie everything together, and carry the fuel to feed our 800 horsepower fire we looked to the experts at Earl’s Performance Plumbing. Originally, we were going to use braided stainless lines and standard reusable threaded AN fittings, but since this project is going to be a dedicated drag car, we wanted to save as much weight as possible anywhere we could, and Earl’s had just what we needed.

Earl’s Pro-Lite 350 nylon braided hose offers the same benefits as using a stainless braided hose, but weighs only about half of what an equivalent braided stainless hose does. On the fittings end of things we went with Earl’s Ano-Tuff Auto-Crimp hose ends, which are designed to live up to their name in harsh conditions and offer a bit of weight savings as well.

For fittings we used Earl's light weight Ano-Tuff Auto-Crimp fittings. These fittings aren't reusable, but they do offer a bit of weight savings since they have fewer parts than regular fittings. For hose, we really went looking to cut some weight and used Earl's Pro-Lite 350 hose, which is nylon braided instead of heavy stainless.

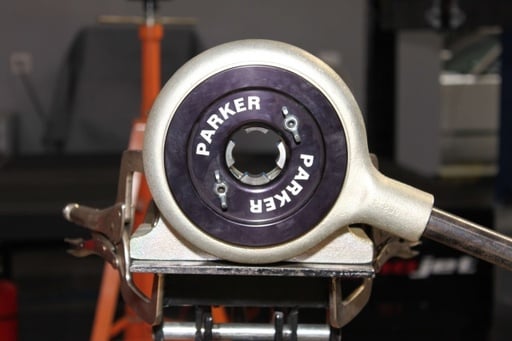

Since the Auto-Crimp fittings don't just screw together, "Mr. Parker" is here to give you a hand. This is the crimping tool you will need to assemble Auto-Crimp fittings, which is available from Earl's. Now don't go getting all scared on us. Having to use a special tool can be a bit intimidating, but like most jobs, once you have the right tool the job is very easy. Our shop guys commented that assembling the Ano-Tuff Auto-Crimp fittings was actually easier than many of the reusable threaded fittings they've had to deal with.

The Auto-Crimp fittings are really easy to put together, and combined with the nylon braided Pro-Lite 350 hose, are a great way to save a decent bit of weight.

Kevin Cochran, Sales and Product Manager at Earl’s tells us, “The Pro-Lite 350 hose can be used with Fuel, Oil, Water and Air, and is designed to be used in medium pressure (350PSI) and medium heat (300F) environments. It is easy to assemble, has low abrasion, with great flexibility.”

“The Auto-Crimp hose ends can be used anywhere the Pro-Lite 350 hose can be used. With their MIL SPEC hard anodizing it helps the hose end last much longer over traditional Brite-Dipped ends in extreme environments, such as salt water marine applications and cars running corrosive fuels, like alcohol.”

“The Ano-Tuff hard anodizing also helps to extend the life of a threaded piece tremendously, protecting the threads by adding an extra layer of structural integrity to them. It makes it harder to gall or cross-thread your fittings so they will last longer. These are important features if you are always working on your car and removing the hoses and fittings. You may pay more up front, but they will last longer and perform more dependably in the long run.” Cochran explains.

Since our main reason for going with these specific fittings and hose is to save weight, we asked Cochran just how much weight the typical race car might save by going with the Pro-Lite 350 hose and Ano-Tuff Auto-Crimp fittings. He had this to say: “An average race car could save 5 to 15 pounds, or even more depending on how extensively they used the nylon hose throughout the car. Just for example a 24 inch length of -10 size Perform-O-Flex Stainless Steel hose with two 90 degree AT Swivel Seal hose ends weighs 10.4 ounces. A -10 Pro-Lite 350 Nylon hose 24 inches in length, with two 90 degree AT Auto-Crimp hose ends only weighs 4.8 ounces.”

“The majority of the weight savings comes from the removal of the stainless armoring for the nylon braid, but the Auto-Crimp hose ends also have fewer components than removables. So even more weight savings is gained by using them with the Pro-Lite 350 hose.” Cochran says.

We routed the Pro-Lite hose from the trunk along the side of the wheel well. This is just one example of how much easier it is to plumb a stripped down race car, where you can pretty much pick whatever route is best; versus plumbing a street car where you have to go around obstacles all over the place.

General Advice on Plumbing

Cochran also offered us some advice on plumbing a race car in general. He tells us, “When you are running your lines, you need to let the hose end route the hose, not just use straight hose ends and bend the hose. This is the reason we offer so many different degree bends. Hose is for taking fluid from point A to point B without getting it on the ground. The safest, most efficient way is a straight line, so use the different angles of the hose ends to accomplish this.”

“There is also no specific time to hose longevity, but things such as quality, routing and maintenance can dramatically increase the life of the hose. Compare hose in your fuel system to a climber’s rope. The rope might look fine after 10 assent/descents of usage, but it has been cycled over and over from taunt to slack. It constantly is being weakened. Same with the hose on your race vehicle, hose does not last a lifetime. You need to regularly check and replace your hose when necessary, especially the plumbing for the fuel system.” he added.

Cochran was also kind enough to share with us the most common plumbing mistakes they see, in this “The Seven Sins of Plumbing”:

- Leaving insufficient clearance between each hose end and anything that it might be able to contact or vibrate against.

- Allowing a hose to come into contact with a sharp corner, a nut, a bolt, a rivet stem or anything else that is not smooth.

- Allowing a hose to rub on anything – even a flat smooth surface.

- Kinking the hose, either by bending it too tightly or by placing the hose in a torsional bind.

- Over tightening the hose ends onto their adapter fittings or into the ports.

- Stretching the hose or not allowing enough room for flex (cycling).

- Allowing things to hang by their hoses. Especially brake lines.

When you are plumbing any car, you want to avoid sources of heat (like the exhaust) as well as any moving parts or sharp edges that might snag your hose. You also want to avoid creating any drastic bends in the hose.

To get the line into the engine bay, we cut another hole in the inner fender well, and covered it with plastic sheathing to protect the line from getting cut on the metal.

We found the most logical location to mount the FPR, and made sure we left ourselves enough room to run the two feed lines to each side of the carb.

Once you get everything plumbed and in place, you're ready to wire up your pump. Magnafuel sends all the necessary wiring to wire in the pump, and it’s just a simple three-wire hook up with a power, ground and an ignition connection. Regular 12 volt power sources will work, and they include an inline fuse and other goodies to make wiring simple. We used a relay kit from MagnaFuel, but they tell us that you don't necessarily have to use one if you don't wish to.