The small-block Chevrolet engine is without a doubt the most popular performance engine ever constructed. A multitude of configurations in factory form combined with widespread availability of inexpensive performance parts has powered generations of hot-rodders from the street-rod crowd to the racing crowd, along with millions of street cruisers, dirt-track racers, boats – you name it, the small-block Chevy powerplant has been there and done that. The SBC engine responds well to performance modifications and has a massive aftermarket dedicated to the construction of performance hard parts, but is considered to be “dated” by many enthusiasts.

Conversely, the “new” small-block Chevrolet engine – the LS platform – has taken the aftermarket by storm in the last decade-plus since its introduction. In its many different configurations, the LS has been installed in millions of vehicles from GM’s workhorse pickup trucks to the world-beating Corvette, late-model Camaro and Cadillac CTS-V, and has become a very popular swap into older vehicles despite a number of challenges and specialized parts required.

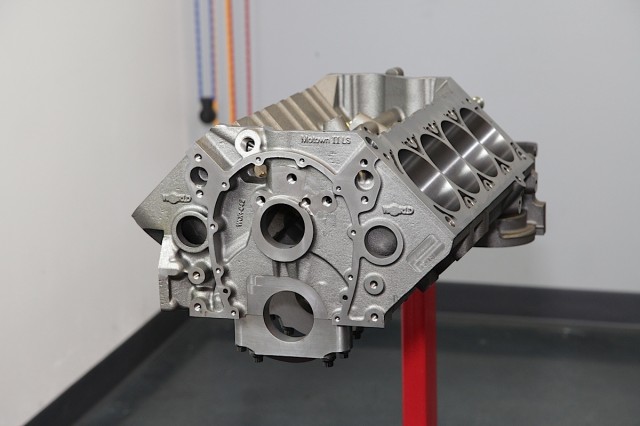

The World Products Motown LS block mixes the features of the traditional small-block Chevrolet engine with the better induction characteristics of the LS platform.

World Products has combined the two designs to build an engine block that uses the traditional small-block Chevrolet footprint but makes use of the LS top end. This strategy allows hot rod owners and other enthusiasts to take advantage of the low entry cost of SBC hard parts and the large improvements seen by the LS induction system in one slick package.

The LS platform makes use of a well-regarded cylinder head design. Shifting away from the SBC’s siamesed intake port and center pair of exhaust ports, the LS engine instead separates each intake and exhaust port in the cylinder head, with resulting performance gains vastly improved over the earlier design.

Behind The Scenes

There are a number of advantages to this design. First and foremost, the block fits any vehicle (be it sports car, hot rod, or boat) that originally made use of the small-block Chevrolet platform, allowing for easy installation. There are no custom engine mounts, special oil pans, or any other ancillary parts that a traditional LS swap requires – this block just bolts right into that Camaro, Corvette, or Chevelle that’s sitting in the garage right now.

The block’s development has taken a while to perfect. There are an abundance of small-block parts out there to use with it. – Jack McInnis, World Products

“People that are trying to make some steam with the LS engine find that it has windage issues. Aside from the oil control improvements from using a regular small-block bottom end, the dyno gains that we’ve seen are in the neighborhood of 30 horsepower with the better oil control of this block design. If you compared the same spec LS engine with the Motown II LS, this design is going to make a significant amount of horsepower over the standard LS,” McInnis explains.

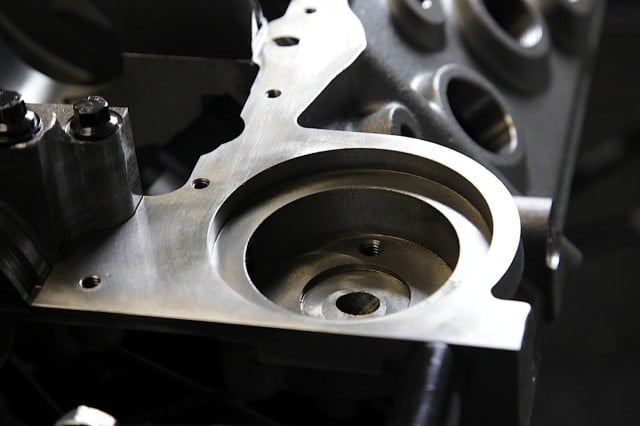

Left - The Motown LS engine is available from the factory in five different configurations, from a 3.995-inch bore to a 4.120-inch bore. 3.995-inch and 4.120-inch are the unfinished bore sizes we ship the block with - the engine builder will have them finished at 4.000-inch or 4.125-inch with the correct tolerances and surface finish for his chosen piston/ring package,' says McInnis. The block can be stretched all the way to 4.200-inch bore dimensions with proper preparation, and cylinder walls remain .250-inch thick at that measurement. Right - The block uses the standard LS bolt pattern of four head fasteners per cylinder.

As both the SBC and LS platforms use 4.400-inch bore centers, the LS cylinder head fits perfectly over the traditional small-block’s cylinders, but the development of the Motown block is not as simple as dropping the LS head right on top – it required some serious reverse-engineering to make communication between the two platforms agreeable.

“The block’s development has taken a while to perfect. It’s a small-block Chevy that uses standard SBC cranks, rods, oil pans, pumps, flywheel, bellhousing, and water pump. There are an abundance of small-block parts out there to use with it,” says World’s Jack McInnis.

Block Details

One dimension that was changed during the development process to better accommodate the use of the LS induction components was the deck height. A standard small-block uses a deck height of 9.025-inch deck height, while the LS engines uses a 9.240-inch deck height.

“In order to use the heads, and more specifically the production-style intake manifolds and such in a bolt-on configuration, this block was developed to use the LS deck height,” says McInnis.

Left - The Motown LS accepts a traditional SBC spin-on oil filter, but the block can also be plumbed for dry-sump configurations. Middle - Two different lifter bore dimensions are available - the standard .842-inch SBC size, and an upgraded .904-inch lifter. LS-style tie-bar lifters must be used, and lifter bore spacing is standard LS. Right - Beefy construction throughout - the intake manifold rails and extra material on the inside of the bores contributes to the Motown's strength.

Improvements To Motown LS

- Cam Location raised .134-inch over SBC

- 55mm camshaft journal size (LS) instead of SBC journals

- Allows for 4.000-inch stroke crankshafts

- Uses LS tie-bar roller lifters and spacing

- Uses LS-style reverse-flow cooling system (cools cylinder heads first, then block)

- Main caps located by ring dowels and stepped registers

- Machining facility is now ISO9000 Certified

- Requires cylinder head plates for SBC accessory drive compatibility (Call World for part numbers) and water pump spacers

The deck height difference is enough that the engine builder needs to pay attention, but McInnis says that the piston design is still a shelf-stock item that’s easy to procure – it requires the SBC wristpin diameter in an LS-style piston.

They use a standard LS piston shape, but require the use of the small block Chevrolet wristpin diameter (.927-inch) to match up with the standard SBC connecting rod design that the engine accepts.

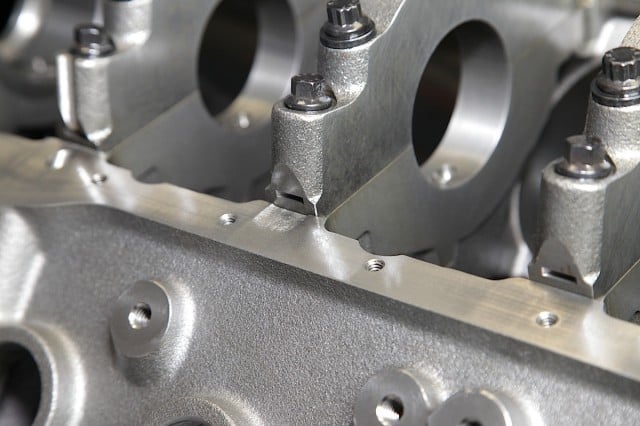

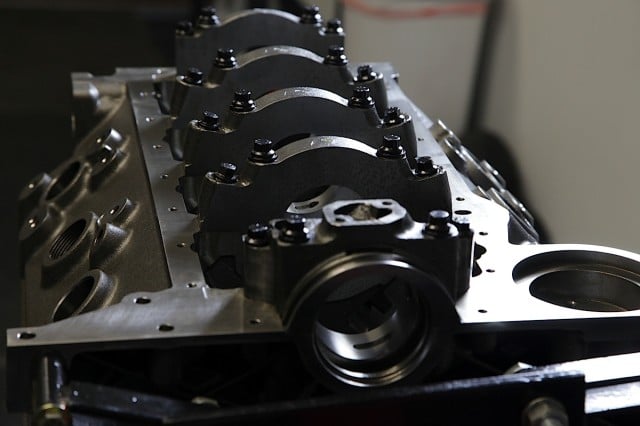

The block is made in six different forms with different bore sizes and specifications. All blocks feature splayed fasteners on the 2-3-4 mains and 7/16-inch ARP hardware is used on all blocks.

Nodular capped-blocks get bolts, while the billet-cap version of the block uses main studs. Ring dowels have been set into place to locate the main caps in addition to the traditional SBC outside registers.

Available Formats

- PN WPI084080: 3.995-inch bore, .842-inch lifter bores, Nodular Iron main caps

- PN WPI084081: 4.120-inch bore, .842-inch lifter bores, Nodular Iron main caps

- PN WPI084081-904: Same as above, adds .904-inch lifter bores

- PN WPI084180: 3.995-inch bore, .842-inch lifter bores, 1045 Billet Steel main caps

- PN WPI084181: 4.120-inch bore, .842-inch lifter bores, 1045 Billet Steel main caps

- PN WPI084181-904: Same as above, adds .904-inch lifter bores

Since World Products fully expects many users to take advantage of the wide range of stroker kits available for the SBC, the solid, stock-width oil pan rails have been clearanced for a 4.00-inch stroke crankshaft. Larger stroke can be used, but will require additional clearancing work on the part of the engine builder.

Left - Beefy pan rails accept a standard SBC-style oil pan, but also have enough clearance built-in for a solid 4.000-inch stroke. Right - 1045 Steel billet main caps are also available - note the splayed design for extra strength on mains 2-4.

In the interest of making the block usable in as many configurations as possible, it’s been developed with SBC engine mounts to fit a wide range of classic musclecars and other platforms, uses standard SBC clutch linkage mounts, and places the starter in the stock SBC location. With block construction following traditional SBC dimensions, McInnis says that all of the special items that need to be purchased in order to do an LS swap disappear.

Other Special Considerations

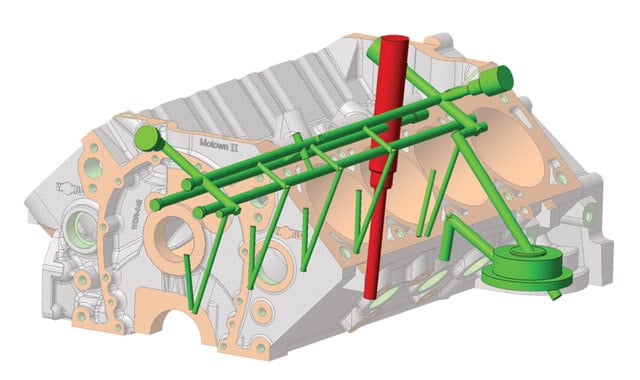

The block uses a unique camshaft; since the lifter location is slightly different for the LS cylinder head, the lobes on the camshaft need to be moved slightly. In addition, the block is delivered with standard SBC lifter bores (.842-inch) or upgraded (at no charge) .904-inch bores; both dimensions are delivered with bronze lifter bushings standard as well. The blocks require an LS-style tie bar lifter, and the lifter bore spacing is also standard LS.

With Erson Cams a sister company to World Products, Erson cam cores for hydraulic-roller applications [PN E115996] and solid-roller applications [PN E115999] are on the shelf and ready to be ground to the specifications of the end-user. McInnis says that with a 4.000-inch stroke, the fitment is very comfortable. With more stroke desired, rod selection and checking other clearances in the engine becomes paramount to fitment – but it will all work with the proper attention paid to the little details.

The reverse flow cooling system is also utilized on this block and uses an external thermostat housing that can be mounted remotely.

The cooling system also required attention during the tooling process. As the LS engine uses a reverse cooling design, where the coolant flows through the cylinder heads first, then progress down to the engine block – the opposite of the traditional SBC platform. This keeps the cylinder heads cooler, which permits more power through higher compression possibilities and more spark advance, but it required the World engineers to take a different tactic during research and development.

“We also have a kit with the items required to make the cooling system work properly. There are lines that exit from the center freeze plugs that will run back to the water return for the radiator, and there is also a remote thermostat housing that’s needed,” says McInnis. There are part numbers for the water return kit with Pro-Lok hose [PN WPI703849-K] and one for braided steel hose [PN WPI703850-K].

The engine also has the capability to use either a traditional distributor-style ignition, or the LS engine’s coil-near-plug ignition system with the use of a crank-trigger system from companies like MSD Performance, but since this block utilizes a stock style SBC oil pump, it needs to be driven by the camshaft.

Valley plates are available for carburetor intake manifolds [PN WPI703844] or LS EFI-style manifolds [PN WPI703844-INJ]. If using the stock injection manifold, the valley tray has a short distributor mount, and an oil pump drive assembly is also available to eliminate the distributor if using the crank trigger.

The block does require the use of custom ARP bolts that are just a phone call away.

We’re Building One

The block in this article is in the EngineLabs shop at this very moment awaiting a host of parts to put it together.

Internals will consist of a forged 4.000-inch stroke crankshaft and 6.125-inch forged connecting rods from SCAT, with as-yet-undetermined pistons to round the engine out at 434 cubic inches when combined with the 4.155-inch bore dimension. Erson is setting us up with a hydraulic-roller camshaft for the engine. On top, a set of Air Flow Research Cathedral Port cylinder heads will be used, fed by a Holley intake manifold and EFI throttle-body system.

In Conclusion

For the enthusiast that’s been running a traditional small-block Chevrolet, and is looking to take a step up in performance, the use of this block with the free-flowing, high-performing LS induction system appears to be an excellent solution. For those looking to win races, the multitude of LS competition cylinder heads on the market combined with the large assortment of reasonably-priced SBC rotating assembly parts make this new Motown block a viable solution for cost-effective performance.