Your experiences while getting to and from the race track can vary from happy tales of trailers and towing mixed in with an equal amount of horror stories. We asked Alan Cape from Flying A Motorsports for his best advice for looking at a new or used trailer to live life on the happy side of getting down the highway safely with your race car.

Alan has been in the race hauler game for 30-plus years. The business he has built around new and used trailers and haulers has thrived with his knowledge of good or bad towing equipment. Here are many suggestions divided by topic:

Brands and Research

Researching the pedigree of a trailer brand is a must. Ask many questions about the trailer brand from a reputable dealership. If you are considering a trailer purchased from an individual, do your homework there, as well. The dragstrip can be a key source of information. If you can find racers who own the brand of trailer you’re considering, ask them the positives and negatives they have with their unit.

I can’t stress enough that in today’s trailer market, it is buyer beware. A new trailer isn’t always a good trailer. – Alan Cape

“Name-brand trailers and even truck conversions are more trusted for their long-term quality,” Cape says. “There are, fundamentally, three levels of trailer quality. As a whole, you have cheap trailers, middle of the road, and high-end trailers. What concerns me is there are increasing numbers of trailers out there I would call terrible merchandise. You typically find them on eBay or other online sources with tiny images. You can’t look at the trailers closely, and their rock-bottom prices are a lure.”

Your local dragstrip can be a great research source. Find trailer brands that match what you are looking for and ask the owner’s opinion of their unit.

Alan described a recent experience with one of these low-quality trailers he recently took on trade. “This relatively new trailer was traded to us with little use and I couldn’t give much value at all. Everything I warn about was wrong with this trailer. The walls were severely bowed, the floor was flexing and more. We were truthful about the trailer; I think we sold it to a local lawn mowing service.”

The internet may be the draw for substandard trailers, but it can also be your friend when doing research. Ask around in your favorite online forums about the quality of a trailer brand. There are also many social media threads that refer to trailer quality experiences. Search away.

Rolling Hardware

As the previous tale by Alan explained, trailers of the same size and shape can vary greatly in price and more importantly, in quality. If you are buying new, carefully research each brand you are considering.

“There is no odometer on a trailer,” Cape cautions. “Detective work on wear and history of a trailer you are looking at is a must. You can find obvious indicators of trouble by looking closely at the tire, wheel, and axle alignment area. I have seen many properly cared-for trailers that despite many miles of use will have more value to me than a similar unmaintained trailer with fewer miles.”

Cape points out that the condition of the trailer bearings and brakes is a significant indicator of the overall care and maintenance a trailer has experienced in its life. There is no odometer to rely on, just tell-tale signs of wear.

“I have seen million-dollar race operations with wheel bearings and brakes going bad,” Cape continues. “If racers don’t maintain this wearable hardware, chances are good the entire trailer is neglected, as well. Completely new electric brake sets with new mounting plates are very reasonably priced. We’re are not talking about a huge amount of money to keep bearings lubricated and brakes operational.”

Hitch Coupler and Tongue

Buying a new trailer? Consider the tongue length based on your load weight. The longer the tongue, the easier it is for the tow and steering qualities of the trailer. Shorter tongues require up to 15-percent of the trailer weight to be on the ball. Longer tongues only need around 10-percent. Any extra dollars spent on an extended tongue trailer typically increase trade-in value, as well.

When looking at a used trailer, inspect the coupler closely. Hook a truck to the trailer hitch and inspect for sloppiness or wear. Make sure the hitch is not twisted or bent and has good welds. Problems here can result in expensive repairs down the road.

Alan Cape recommends that you get up under the hitch coupler with a flashlight and look for grind marks, cracks, and dents to the hitch face (arrows.) Check that the coupler latch works appropriately without binding and make sure there is not excessive rust. Any neglect in the hitch area is a sure first sign of the trailer’s overall maintenance.

“You can tell if it just has been abused and used without lubrication,” Cape says. “With a 30-second inspection, again, it’s a tell-tale sign of the maintenance of the entire trailer. Sometimes there can be damage from people backing into the hitch while not paying attention. This especially happens often on gooseneck trailers.”

Wiring

“Wires either dangling under the trailer or making contact with metal at points is an issue that doesn’t take a few minutes to fix versus being on the road at night with no lights,” Cape says. “All trailers have their good and bad days when it comes to a good wiring job. We really try to catch what we can during any pre-delivery inspections.”

Two points where some manufacturers "cheap out" is on the wiring workmanship and tire quality. This Pace trailer shows how all wiring is properly shielded and passed through the frame with protective grommets. Make sure any trailer is equipped with tires rated specifically for towing. Any cut corners such as these can leave you sitting on the roadside rather than racing.

New or used, a careful trace of all wiring paths is essential to look for bad or repaired points in the circuits. Look for wear points where the wiring comes in contact with metal frames, walls and more. You can call me paranoid, but trailer fires and lousy wiring can be closely related.

Frame and Welds:

Frame material and welds make a considerable difference in the overall trailer integrity. Tubular frame rails and tongue area are by far the best material choice. Channel iron can be fabricated with integrity while angle iron is the lowest quality option.

Carefully check over all welds throughout the trailer. Welds should travel the entire length of intersection points. This example (arrow) shows a critical suspension bracket without a complete weld.

“Inspect all of the major structure welds,” Cape stresses. “Check that the welds travel along the entire joint and not just in the center three inches. Signs of weakness or overloading can be discerned in weld cracks, as well. We do a close inspection of all trailers that come in. We can get ten units of a new trailer in, and one will have some weld problems. The manufacturer will have us take it to a professional repair service to get any structural mistakes corrected. They are all about production; they will pay to have it corrected rather than them see the trailer again.”

Floors and Walls

Flying A Motorsports tell us the floors and walls are the most significant inspection point for them to find problems. The underside of a trailer floor can quickly indicate the use and wear of a trailer. Whether the floor consists of wood or aluminum, look for elongated holes around the fasteners or broken/missing fasteners altogether. Where the floor meets the side walls can be an exceptional point for wear inspection.

The trailer floor and walls are obvious points to find structural problems with a used trailer. Don’t be afraid to get under the trailer and look for elongated fastener holes or broken/missing fasteners which could indicate overloading. These two examples illustrate damage from fuel, oil, and chemical spillage that can shorten trailer life.

“If you are looking for trailer quality, the wall construction is a great indicator,” Cape says. “Pretty well all trailer manufacturers use varied aluminum thickness on the wall construction depending on the model. These typically range from .030-, .040-, to .050-inch aluminum. One of the brands we carry is InTech Trailers. They are a medium to high-quality trailer. As an example of quality, you can compare a new InTech trailer constructed of .030-inch aluminum walls right beside a cheaper trailer built with .050-inch walls. The InTech model will be rock-solid smooth compared to the thicker wall trailer. Workmanship can far outweigh what materials are used.”

Any ripple effect viewed on the outside of the trailer can indicate trouble. The black trailer shows a large cavitation forward of the axle area that could indicate a stress point compared to the ripple-free trailer on the right.

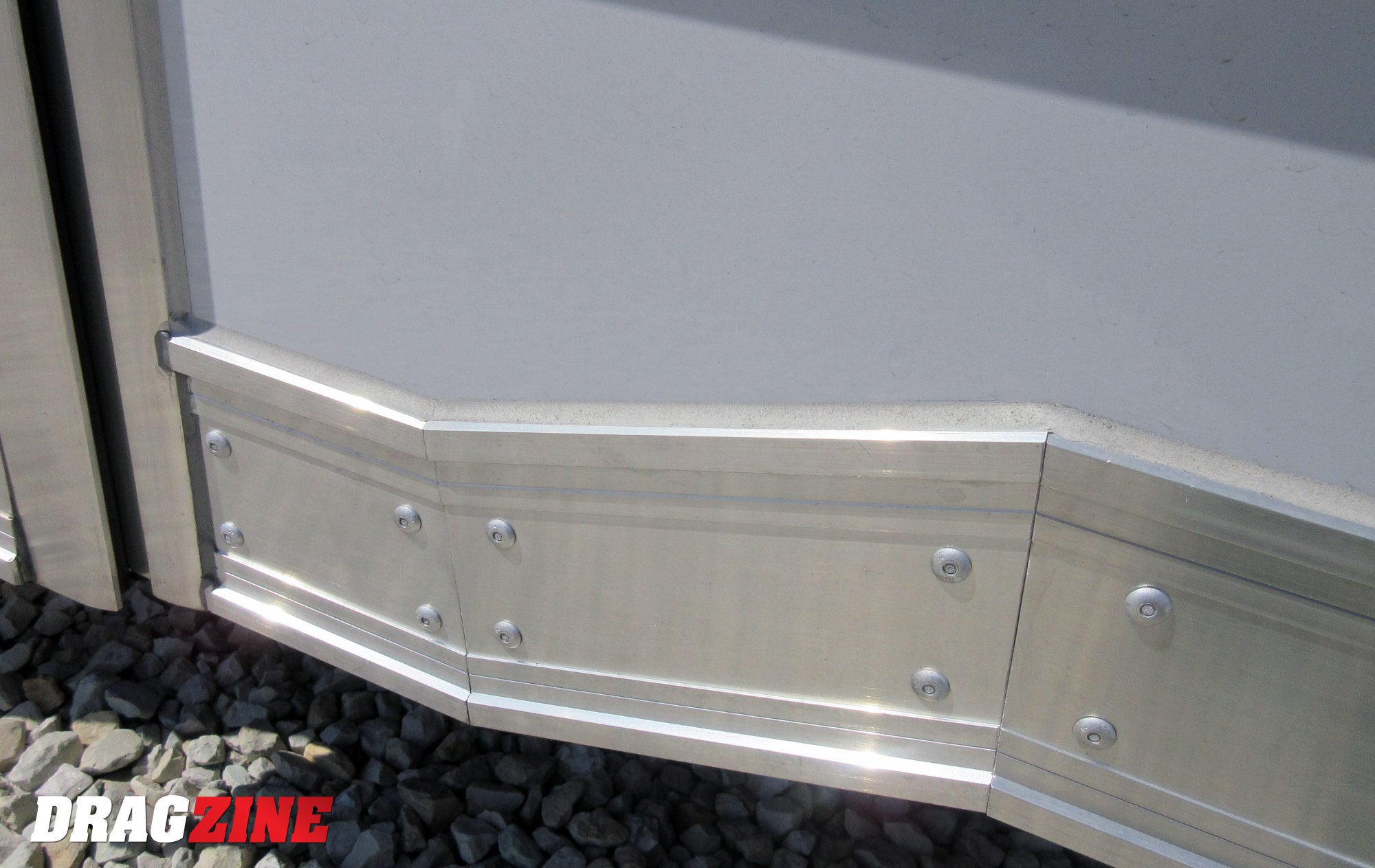

Many trailers now feature heavy extruded aluminum at the floor, ceiling, and corner joints. Though it gives an excellent appearance, it’s an opportunity to cover-up quality problems, as well. Inspect where the floors, walls, and ceiling intersects these corners. If you find scratches, it indicates the walls are moving underneath the corner joints.

If you are considering a stacker trailer, wall fit and finish should be scrutinized by a factor of ten.

Doors

Look at how the rear ramp-door and side doors fit in their frame. Cape explains, “Gently close the ramp and side door to see if they close without any interference where they come in contact with the door joists. If you need to force the doors to fit or to swing on the hinges, even in the slightest, you’re probably looking at signs of trailer flex or wear.”

Any side door or ramp door is an excellent observation point for trailer flexing. Look for wear marks in the door joints and binding when opening and closing.

Documentation

You may be considering a used trailer located out of your state. Do your homework when it comes to the licensing and titling laws of that state. “Documentation regulations can vary greatly between states,” Cape says. “Many race car guys don’t title them properly. They buy a brand new trailer with a certificate of origin from the manufacturer and throw it in a drawer. Using an old license plate from a previous trailer, they never properly title the other trailer. Typically, they think they are getting away with paying any taxes. Trying to properly register that trailer down the road with very dated paperwork is a real mess that I hear about far too often.”

Alan Cape has been dealing in new and used trailers, motorhomes, and toterhomes for more than 30 years. Alan stands to the left of Justin "Big Chief" Shearer and Chris Bell from Kinetic Engineering. One trailer trend Alan points out with his years of experience is the large corner joints that many trailer brands now feature. "This is something to watch closely," Alan adds. "These can add structural integrity to many lines of trailers, but can be used to cover bad workmanship in other brands."

The moral of buying a trailer is to be a detective when it comes to seeking out problems that can arise down the road. Whether it be paperwork, fit and finish, or safety precautions, don’t let your box take you away from concentrating on your race car. You have enough to focus on there.