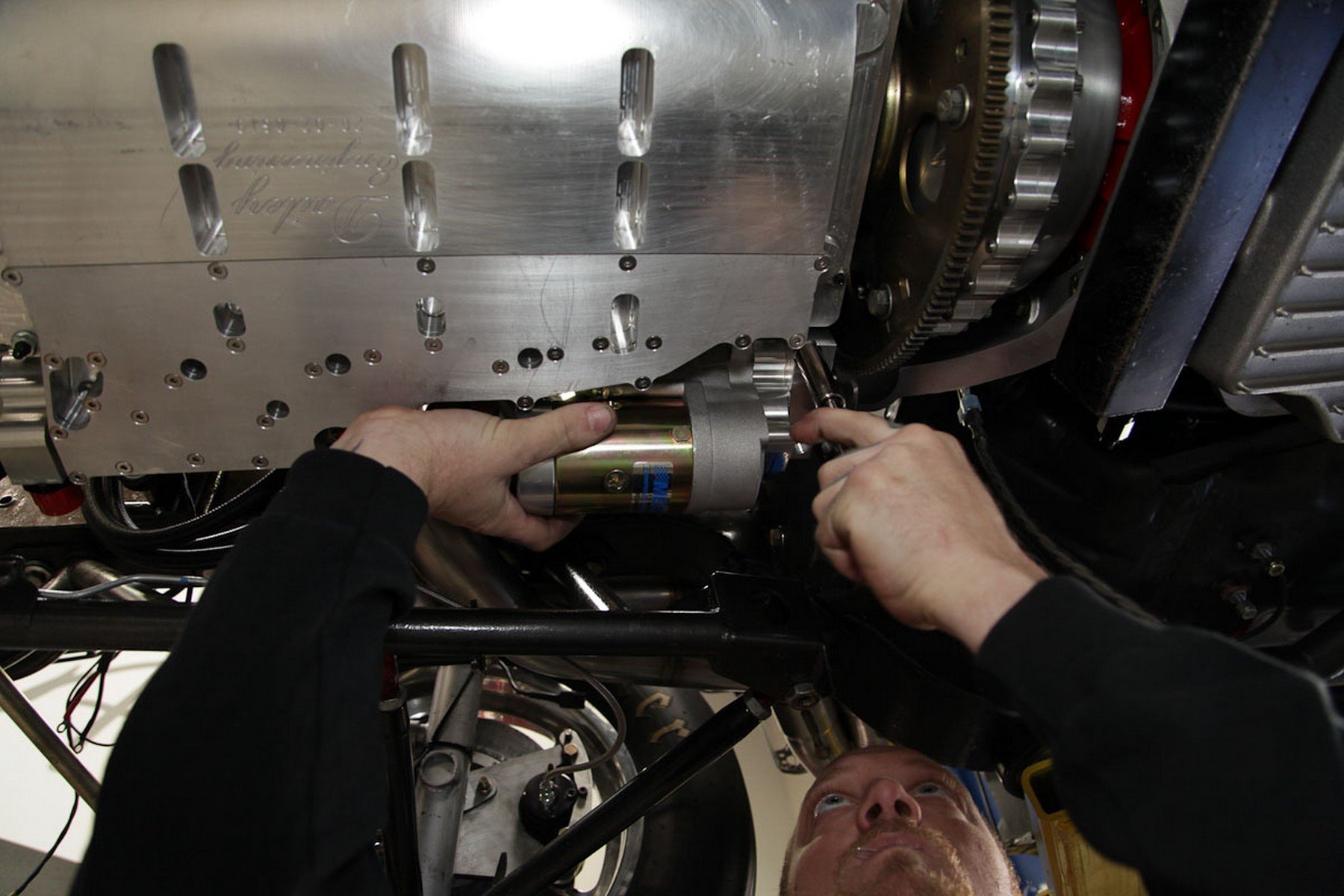

You can have the fastest or the most consistent car on the property at an event, but if you can’t get it to start when it’s time to race, all that performance potential won’t do you a bit of good. A round loss when it counts at the hands of a failing starter can be avoided by making sure it’s set up right when you first bolt it to your engine.

The engagement between a starter and a flexplate or flywheel is critical if you want your engine to start without any issues each time you hit the ignition switch. Making sure your starter is engaged correctly with the engine is something that can easily be forgotten about, and it will prevent failure and premature wear on the unit. If you have the gear on the starter lashed correctly you should be able to grab it with pliers and remove it without any issues. If that lash is too tight it will put extra load on the teeth, and if the lash is loose it can cause the gear to hang up in the ring gear when the engine has started.

Don Meziere’s company, Meziere Enterprises manufactures heavy-duty starters that are designed for racing applications. Meziere is able to add some detail as to why making sure it’s important to have the right clearance for your starter gear, much like the rearend gear of a racecar.

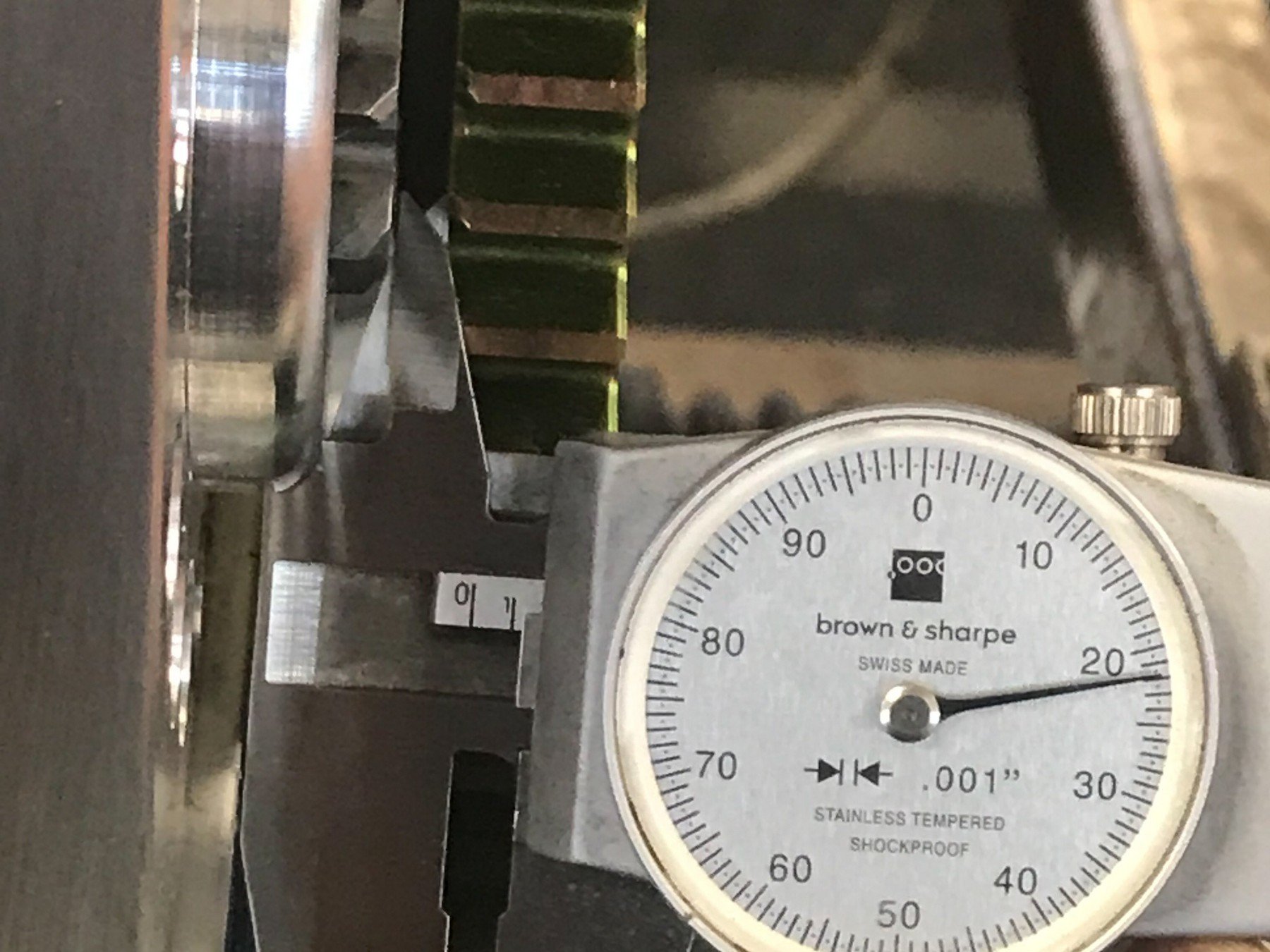

“The idea of proper clearances when setting up your starter pinion in relation to your flywheel or flexplate ring gear will help to ensure a long life for the gear set, as well. If the distance between the two centerlines is too close the surfaces of the gears will have a ton of pressure against each other, creating lots of extra friction and noise. Over time this will cause severe wear on the gears.

If the distance between the two centerlines is too large the contact spot between the two gears will be much higher on the face of the tooth than it was designed to be. The net effect is that it puts the gear tooth at a mechanical disadvantage and will be much more likely to break the tooth. If the distance is correct, the pinion tooth face will swing into the opening and contact the ring gear about at the midpoint and exit without touching on the back side.”

Besides the clearance of the starter pinion, you need to take into account the distance the pinion must move before it enters the ring gear. Not taking the time to make sure these measurements are correct can also lead to starting problems for your engine.

“At rest, we recommend that the pinion be .10-inches away from the ring gear. There is some room for leeway here but we do not like to see less than .06-inches and no more than .14-inches. This measurement has a significant role in the way the solenoid advances the pinion, ensuring that the pinion rotates correctly into the ring gear and main power is applied at the right point in the cycle. If the pinion is too close to the ring it may collide and not allow the pinion to enter. If the distance is too great the pinion may have too much rotational speed or, at the extreme, may not have enough travel to fully engage the ring gear,” Meziere says.

By making sure you have set your starter up correctly you will boost your engine’s cranking ability, and avoid issues like broken teeth on a starter or the dreaded no-start situation at the ready line. To learn more about how to get a starter to align correctly checkout the Meziere Enterprises website right here.