Installing the “spark” portion of the Fuel Air Spark Technology (FAST) system into Project Rover completes our effort to utilize the integrated EZ EFI 2.0 fuel injection system we installed with its mated E6 ignition.

We left off with the project Camaro as we assembled the FAST EZ EFI 2.0 system onto our 482 cubic-inch. big-block Chevy. Though the EFI and ignition system products from FAST will operate with other product brands, their EFI, and FAST E6 capacitor discharge (CD) ignition, and billet dual-sync distributor work in unison together with Weather Pack connectors pre-installed.

There are three levels of E6 CD Ignition. The base standard is the CD ignition, making it ideal for street applications. The ignition produces a series of sparks at lower rpm. Multiple strikes in each cylinder can result in up to 12 sparks at the plug during every 20 degrees of crankshaft rotation through 3,000 rpm. Above 3,000-rpm, the E6 delivers a full voltage spark which will improve the mid-range and higher rpm performance.

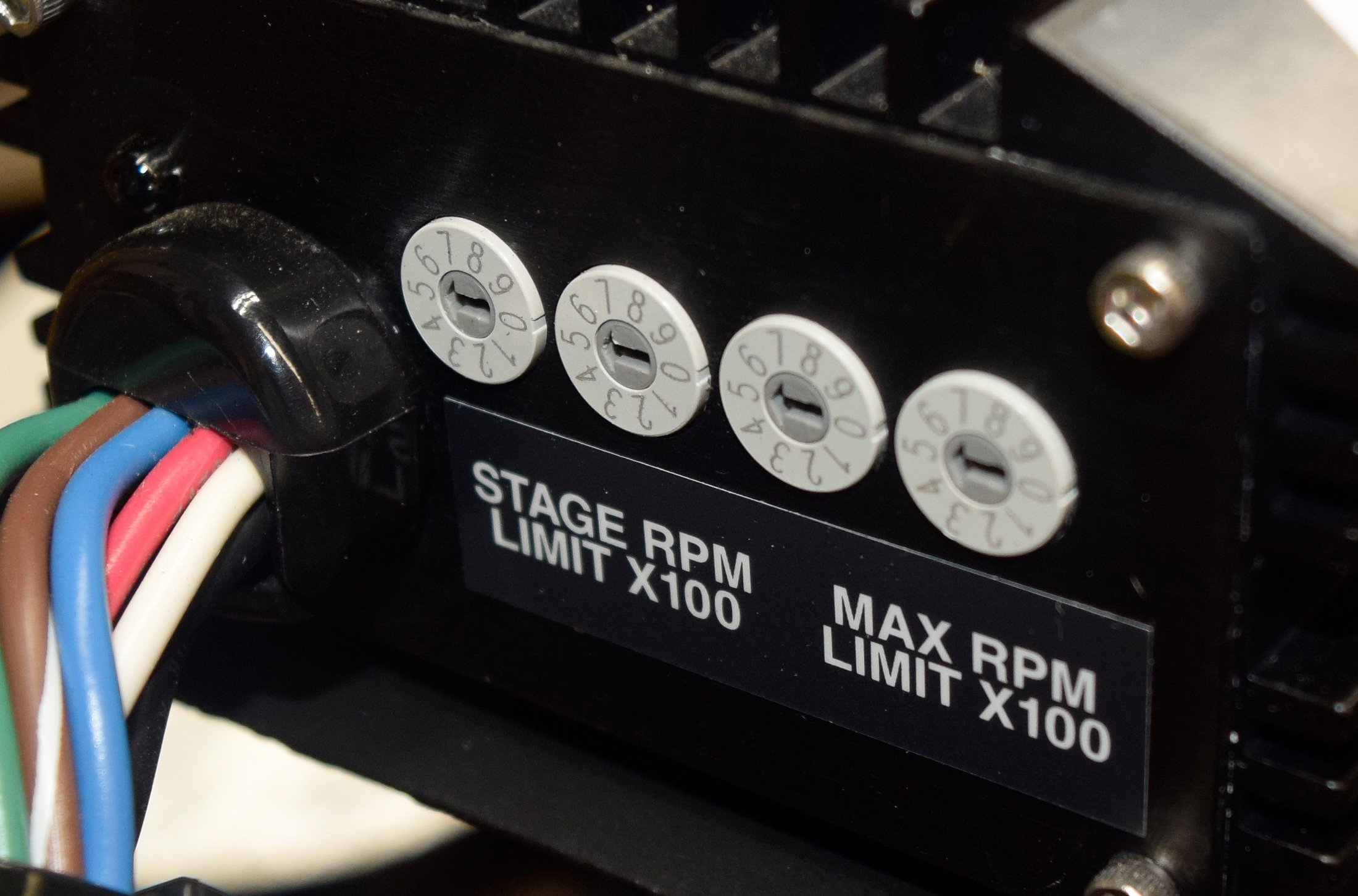

The old school Camaro gets the FAST ignition upgrade, which will work wonders when compared to a dated CD ignition that backfired through the exhaust furiously when the engine rpm was against the limiter. We fabricated a lightweight aluminum mount to place the FAST E6 ignition on the transmission tunnel where the rpm limiter can be easily adjusted from the driver or passenger area. These four dials can set rpm limits at anywhere from 900 to 9,900 rpms.

The second and third model E6 CD ignitions boxes include a single and dual rev-limiter option. A single rev-limiter model can cap your engine rpm redline with an easy-to-adjust rotary dial built into the side panel of the E6. FAST’s top model is designed for a full race application featuring a second rpm limiter activated via a 12-volt switch input wire.

For Project Rover, we are utilizing the E6 with dual rev limiters. We will be connecting the stage rpm limiter as a starting line rpm controller by wiring the activation signal from our transbrake circuit. As we push on the transbrake button, the engine rpm will be limited against the torque converter and transmission until released.

FAST’s rev-limiting technology provides an extremely accurate design. A smooth engine against the FAST rev-limiter replaces the “popping and banging” such as that experienced with other CD ignition limiters. An advanced sequential limiter digitally controls a sequential drop of a cylinder’s spark one at a time, assuring the same cylinder is never canceled twice in a row. This keeps the engine balanced and producing a much more accurate and stable rev limit.

Out of the box, the FAST XDi distributor is easily married to the FAST EFI harness using a single pre-installed Weather Pack connector. The CNC-machined and roller bearing-equipped housing is constructed from high-quality 6061-T6 billet aluminum. The distributor gear was swapped for a COMP Cams melonized distributor gear that is far more durable than the old bronze gears once required to mate to roller cams.

We mounted the E6 ignition module on the side of the Camaro’s transmission tunnel. The two adjustable rev-limiter dials are now easily accessible near the driver. Each rev-limiter can be adjusted in 100 rpm increments between 900 and 9,900 rpm.

The instructions feature multiple options applying the E6 to points, computer-controlled, HEI, and magnetic trigger system hookups. We are incorporating the FAST E92 coil and their XDi Dual-Sync Distributor. Wiring is straightforward with major 12-volt feed and ground, ignition switch, and a rev-limiter circuit for the starting line limiter.

A timing retard input is also available that can be controlled by a separate FAST TRC-2 Timing Retard Control. This controller can offer significant benefits for nitrous oxide, boosted, and even towing applications. It can be set to operate as a nitrous retard control that activates when the nitrous is in use. In supercharged and turbo applications, the TRC-2 can be connected to a MAP sensor allowing you to retard 0-4 degrees per pound of boost with a maximum of 20-degrees.

We mounted the FAST E92 E-Core ignition coil directly in the front of our mounting panel. The coil is computer-designed with robust gauge windings to mate to the E6 CD ignition. The coil wire travels to a firewall feed through posts where we custom fabricated another coil wire to connect to our distributor.

The XDi Dual-Sync Distributor is a plug-and-play unit that can easily be married to EFI systems such as FAST’s EZ EFI 2.0. Setup is easier than some comparable brands as the distributor features reluctors and pickups that are correctly aligned right out of the box. This saves tons of effort when it comes to rotor phasing. Durability is another feature for the XDi distributor since it is constructed with a ball bearing guide within the 6061-T6 aluminum housing. A single Weather Pack connector can be readily married to the Camaro’s EFI controller to gain input from the Hall-effect pickups and to trigger both the ignition circuit as well as the cam sync signal.

The XDi distributor comes out of the box with a cast-iron drive gear for typical hydraulic and solid lifter cams. With our 482-inch big-block sporting a COMP Cams roller cam, we chose to go with another cool distributor gear option. The melonized distributor gear is made of steel and uses a melonized heat treatment process that gives the gear a very finished surface. This makes it compatible with any cam ranging from cast iron, ductile iron, and the billet steel used in our roller cam. With the comparative strength to a soft bronze gear, the new melonized gear is machined with more accuracy resulting in less spark scatter at the distributor.

The FAST FireWire spark plug wire set features one of the lowest resistance values available at only 25 ohms per foot. Our set is ready-made with an under-the-header design and has heat-resistant braided sleeves on the entire wire length from boot to boot.

Once our harness system is completed between the EFI, FAST Dual Sync distributor and E6 ignition, next, we can utilize the electronic timing control. This communication begins with the initial setup of the ECU. Along with setting up the basic run program, you will program in your ignition component options. Our FAST Dual Sync distributor is wired directly into the harness,

Setting up the dual sync distributor related to basic top dead center of your crankshaft is quite easy with two LED indicators visible once the distributor cap is removed. The cam LED illuminates once per revolution based on your engine’s top dead center while the crank LED illuminates eight times per revolution with each spark plug firing point. These are easy to discern with different color LED lights.

The sensor placement and advanced plate sleeve designs make the unit less susceptible to noise or timing fluctuations. There is an LED indicator for cam and sync for ease of phasing the distributor. Once the system is live, timing curve adjustments are easy with the FAST control panel.

With the distributor timed and phased properly for a one-degree reference angle, we can now establish communication with the EFI control panel and create ignition advance timing through the setup parameters. Once things are running well and the entire FAST EZ EFI 2.0 system has had time to “learn” and adjust tuning based on what your engine is telling the sensors, you can access advanced screens on the control panel and tweak your total timing and timing curves.

With the adjustability of the fuel, air, and spark of the complete EFI and ignition system, controllability compared to carburetor jets and twisting the distributor, the FAST package offers so much more.