Successful racers that are ahead of the game look for ways to gain an edge and dial in the performance of their program through various ways to tune their car. Using a bolt-together torque converter is an outstanding method to introduce another tuning tool to a racer’s bag of tricks. We talked with Marty Chance from Neal Chance Racing Converters and Harvey Baker from ATI Performance about the benefits of bolt-together torque converters for racers and what goes into servicing them.

How Torque Converters Work

Creating astounding amounts of horsepower is only part of the equation to going really fast. That power has to be transferred to the ground, and that’s where the torque converter comes in. It doesn’t matter if you have a 400 horsepower bracket car or a 4,000 horsepower heads-up machine, having a torque converter that is matched to your combination and application is a must. Before we dive into bolt-together torque converters, let’s take a look at general torque converter theory to tie everything together.

A torque converter is tasked with being the horsepower liaison between the engine and transmission. When the torque converter begins to rotate, it takes all of the torque created by the engine and multiplies it. The fluid dynamics that occur inside the torque converter are what drives this process of torque multiplication and begin to move the vehicle as the power is moved through the transmission.

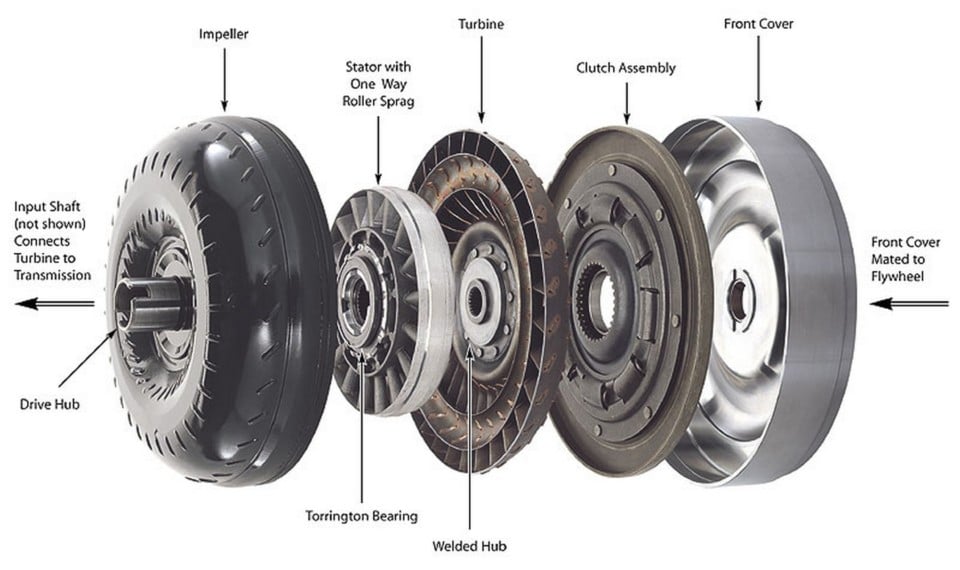

The more RPM the torque converter sees, the larger the hydraulic power transfer it creates, and this occurs as the engine raises its RPM level. When the converter rotates, it moves the impeller pump inside the torque converter towards the stator. The stator inside the torque converter is what ultimately controls how the torque converter behaves as it moves the fluid inside. With the fluid moving as commanded by the stator, it hits the fins of the turbine that is attached to the input shaft of the transmission, rotates the assembly, and the vehicle begins to move.

All of this plays into determining the stall speed of the torque converter. Basically, the stall speed is how the converter interacts with the vehicle as slippage happens with the load versus the resistance the driveline is encountering. The general way that people look at this is the amount of RPM the engine generates in gear before the tires start to break traction. Ultimately, the goal is to have a stall speed that is matched to optimize the powerband your engine operates best in.

Benefits Of A Bolt-Together Torque Converter

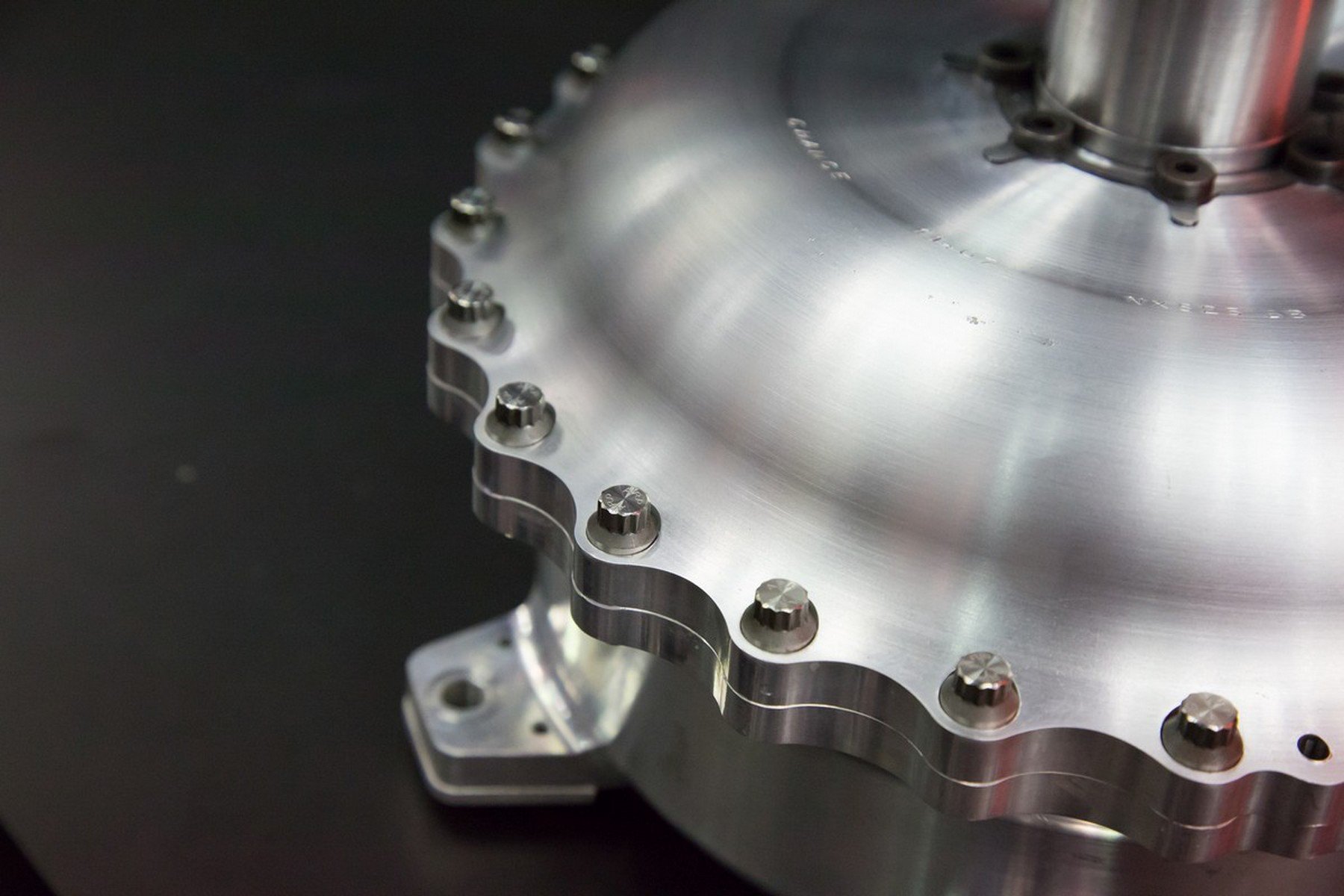

The standard welded torque converter and a bolt-together torque converter function in the same way as a fluid transfer device. The biggest difference between the two is how they can be serviced and adjusted. A weld-together torque converter doesn’t have the same versatility of a bolt-together unit. The weld-together unit provides no adjustability or maintenance abilities to the racer at all. The weld-together unit also doesn’t offer the billet aluminum cover option of the bolt-together torque converter for weight savings and strength.

“In modern racing, it’s crazy to not own a bolt-together converter,” Chance says emphatically. “If you have a weld-together converter, you’re going to spend bolt-together converter money on it eventually, having it serviced and changed to fit your needs.”

When you pull a bolt-together torque converter apart it really doesn't look much different on the inside compared to a welded unit.

A bolt-together torque converter might come with a higher initial price tag, but, as Chance eluded to, the converter will pay for itself with less downtime for adjustments and more adjustability at the track. Think about the amount of time it takes to pull a torque converter, send it in to be adjusted, and then wait for it to be returned. Also, take into account the cost element of having all of the work done and shipping — when you add that up, the bolt-together benefits start to shine.

In modern racing, it’s crazy to not own a bolt-together converter. If you have a weld-together converter, you’re going to spend bolt together converter money on it, eventually having it serviced and changed to fit your needs. – Marty Chance

It doesn’t matter what style of racing you do, whether it’s bracket racing, index racing, or heads-up racing, having the adjustability advantage provided by a bolt-together torque converter is huge. Racers at all levels can benefit from a bolt-together torque converter’s ability to be adjusted on the spot to match the conditions you might be seeing at the track. For racers who travel to different parts of the country regularly, that can give them a wider tuning window to make sure their car is running the numbers it needs to be competitive.

“A big benefit of having a bolt-together torque converter is the simplicity of servicing it whenever and wherever you need to. A bracket racer can swap the stator out to account for changing weather conditions if they need to pick up some elapsed time on the track. A heads-up racer can fine-tune their combination for the track conditions to maximize the amount of power they can use,” Baker explains.

The range of adjustments you have with a bolt-together torque converter is practically endless with the various stator options at your disposal. By changing the stator, you can make minute or large changes based on what your needs are. Converter manufacturers like Neal Chance Racing Converters have the ability to make a custom stator for any application.

“Making a custom stator gives us the ability to take two different stator port volumes and overlaps to custom design a stator. This new stator will have the best attributes of the other two units combined into one. We can also turn a custom stator around quickly if needed. You don’t have to send the converter back to do this, so it saves a lot of time and money in the long run if you’re really trying to maximize what your converter is capable of,” Chance says.

Our Evil 8.5 project car uses an ATI bolt-together unit to assist with tuning the car on tricky tracks.

The performance advantages a bolt-together torque converter can provide are obvious. This style of converter also adds an ease of maintenance factor to a racing program. Since a bolt-together unit is designed to be taken apart, it allows a racer to get inside and make repairs if something goes awry in the transmission. Emergency maintenance can be performed on the spot where the racer is, provided they have the right tools.

“If you’re at the track and smoke a band or clutch pack in the transmission, it’s pretty easy to get another transmission or find someone to fix yours while you’re there. A converter that’s full of transmission debris from a failure needs to be handled right then, or it will kill the bearings in the converter. People will run a weld-together converter full of debris, and that contamination is working on tearing the bearings up inside the converter. That’s what makes the bolt-together unit nice; you can take it apart and clean out all of that contamination and not worry. You just can’t do that with a weld-together torque converter, and that contamination will lead to it failing,” Chance says.

Separating the parts of a bolt-together torque converter make it easy to inspect it for any issues.

With so many benefits and advantages, you would think that every racer in the pits would have a bolt-together torque converter between their transmission and engine, but that’s not the case. Besides the higher cost of the bolt together units, many racers have an unfounded fear in how complex the bolt together torque converters are.

“The biggest thing I hear people say is that they don’t want to get inside a bolt-together torque converter because it’s too complex. A torque converter is the simplest component in your racecar. If you have any mechanical ability, you can service a converter. The torque converter has only four components: you have the two halves of the converter, the turbine, and the sprag/stator unit. Because you have those four parts, you have three bearings in between them, and they only go together one way along with alignment pins. If you put a bolt-together torque converter together incorrectly, it’s because you tried to,” Chance explains.

Servicing A Bolt-Together Torque Converter

As we’ve covered in this article, the bolt-together torque converter has the distinct advantage over a weld-together converter of being serviceable by a racer. This may seem like a daunting task, but these torque converters are brutally simple inside. You don’t need any fancy specialty tools to get the job done, just a basic understanding of what’s inside the converter and where it goes.

“It’s extremely easy to service any bolt together torque converter as long as you have the basic tools that are required. You just need to disassemble the converter, inspect all of the parts for any wear issues or other problems, clean everything thoroughly, and reassemble the torque converter. The only things that might need to be replaced in a standard servicing are the o-rings, bearings, or bushings, if needed. Just have all of the spare parts needed and you can have the whole process finished up rather quickly,” Baker says.

Chance adds some additional details on what you should look for when doing a basic servicing of a bolt-together torque converter.

“The main source of contamination in a converter is the transmission. Racing clutches and bands are made from semi-metallic heavy metals so they are always creating debris. If you drop the pan on your transmission, and it’s full of a black gritty soot, that will create problems. If it gets into the converter, it will kill the bearings and destroy the converter in the process, so being able to do basic service will help the converter last longer.”

It’s extremely easy to service any bolt together torque converter as long as you have the basic tools that are required. – Harvey Baker

If you have a bolt-together converter apart for a stator swap, there are some other items you can look at to see if they need to be serviced.

The stator has a mechanical diode inside that makes sure the stator will stay locked on the transmission input shaft as it rotates in one direction, while allowing free rotation in the other. This diode is what makes the torque converter do its job at the lower end of load speeds and still be efficient. Inside the diode are a series of spring-loaded struts that are used to engage the notch plate. The amount of struts inside the diode will vary based on the application of the converter and how strong it needs to be.

To service the struts, you simply disassemble the diode after removing it from the stator. From there, you need to inspect each strut by measuring it to make sure it still has the correct size based on the recommendations of the torque converter company. If the struts are no longer within spec for size, you just need to replace them when assembling the diode.

It may seem like these converters need to be torn down between every race to make sure they’re sound, but that’s not the case at all. These modern bolt-together torque converters are built strong enough that you don’t need to check for wear that often. They are designed so you can use the time between races analyzing data to go faster.

“You need to read the torque converter data and see what the engine wants. Look at the load sensitivity of your engine. That’s the rate the engine wants to be loaded to lock the converter up. This will make sure the engine helps the car accelerate at its fastest rate. If you lock the converter up too soon, it will pull the engine down, and it won’t accelerate as fast as it could. If you don’t lock it up soon enough, you’re going to make power that never sees the rear tires,” Chance explains.

The typical service cycle for a bolt-together torque converter is just about once a year or if you have a major transmission failure. The biggest enemy of any torque converter is the contamination from a failure in the transmission. It will pump all kinds of debris into a torque converter that will lead to parts wearing out or failing.

Optimizing Your Bolt Together Torque Converter

To get the most out of your bolt together torque converter, you have to make sure it is sized correctly for your application. The size of the converter needs to be matched to your engine, its power potential, and the power adder if one is being used. Typically, a larger converter will be tighter and have more efficiency, while a smaller converter will have more slip since it’s loose.

The attraction to these bolt-together torque converters is their wide range of adjustability with stator swaps and the fact you can service them on your own. Now, there are situations where the converter will need to go back to the manufacturer because an issue is major enough that the converter needs to be inspected professionally.

You can see here how the stator fits into the bolt-together torque converter easily.

“The only time you would have to send the converter back is if it got bent or if you break the bellhousing on your transmission. If either of those two things happen, it’s got to go back to the builder. Half of the converter is aligned by the transmission, and the other side is bolted to flexplate. If you break the bellhousing, that says something was in such a bind that it could have bent the parts of the converter that bolt to the transmission itself. You need to have the converter manufacturer put it on the machine to check the runouts to make sure nothing is bent,” Chance explains.

A bolt-together torque converter isn’t new technology, but it’s something that any racer can use to produce better results at the track. By overcoming the fear of this converter, you can unlock new ways to make your existing combination work better and be more consistent, no matter what the conditions are on race day.