From high-RPM Pro Stock and Competition Eliminator to big cubic-inch torque monster engines, the custom fabricated intake manifold is individually designed for an exact match to every engine parameter.

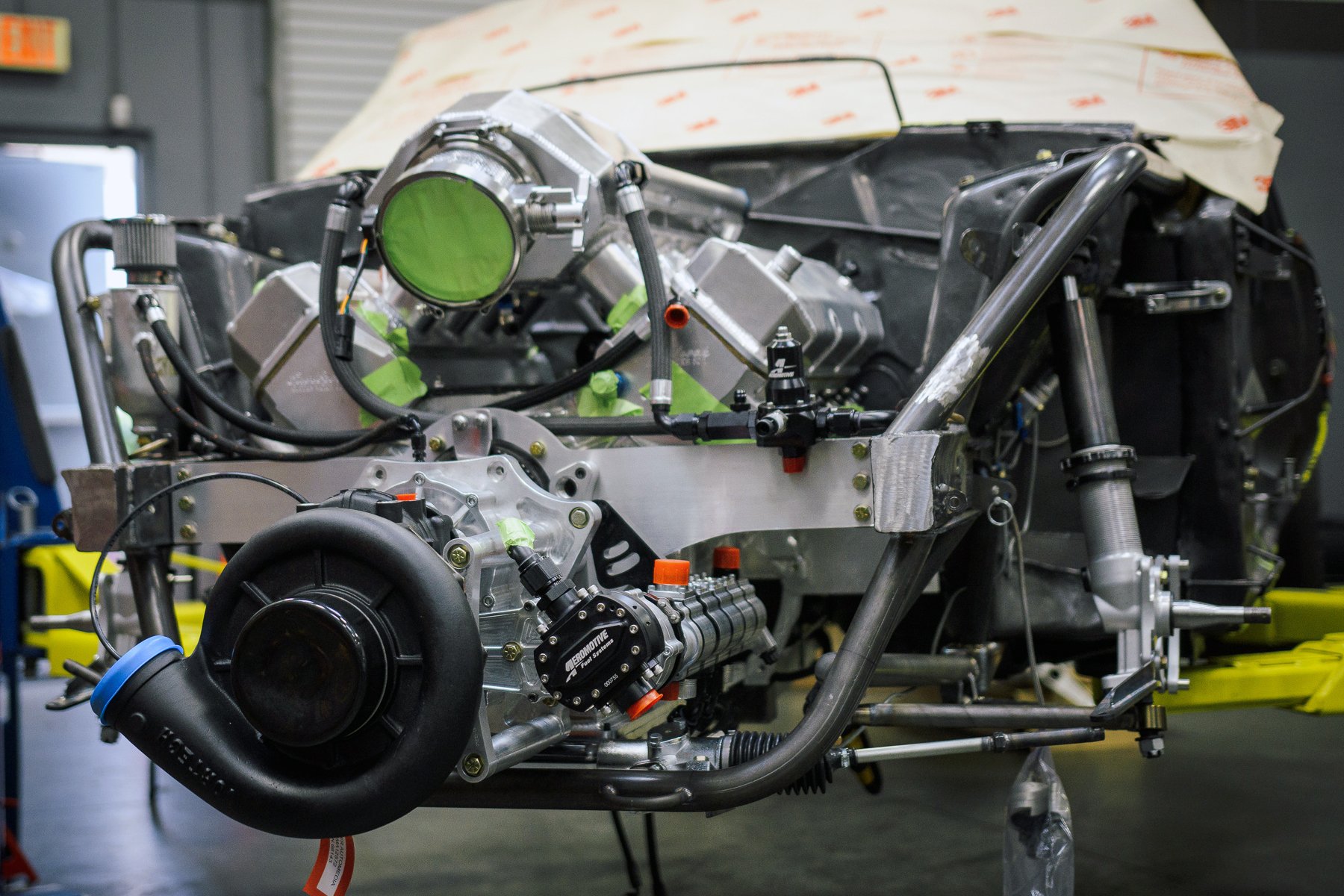

One prime example of today’s design for extreme motorsports is the intake manifold explicitly developed for the Dragzine Project Evil Mustang as it prepares for a 2019 assault on X275 class competition across the United States.

Understanding intake manifold design is a technology within itself. Analysis of the varied induction angles, plenum designs, and runner lengths reveals the most effective manifold for each situation.

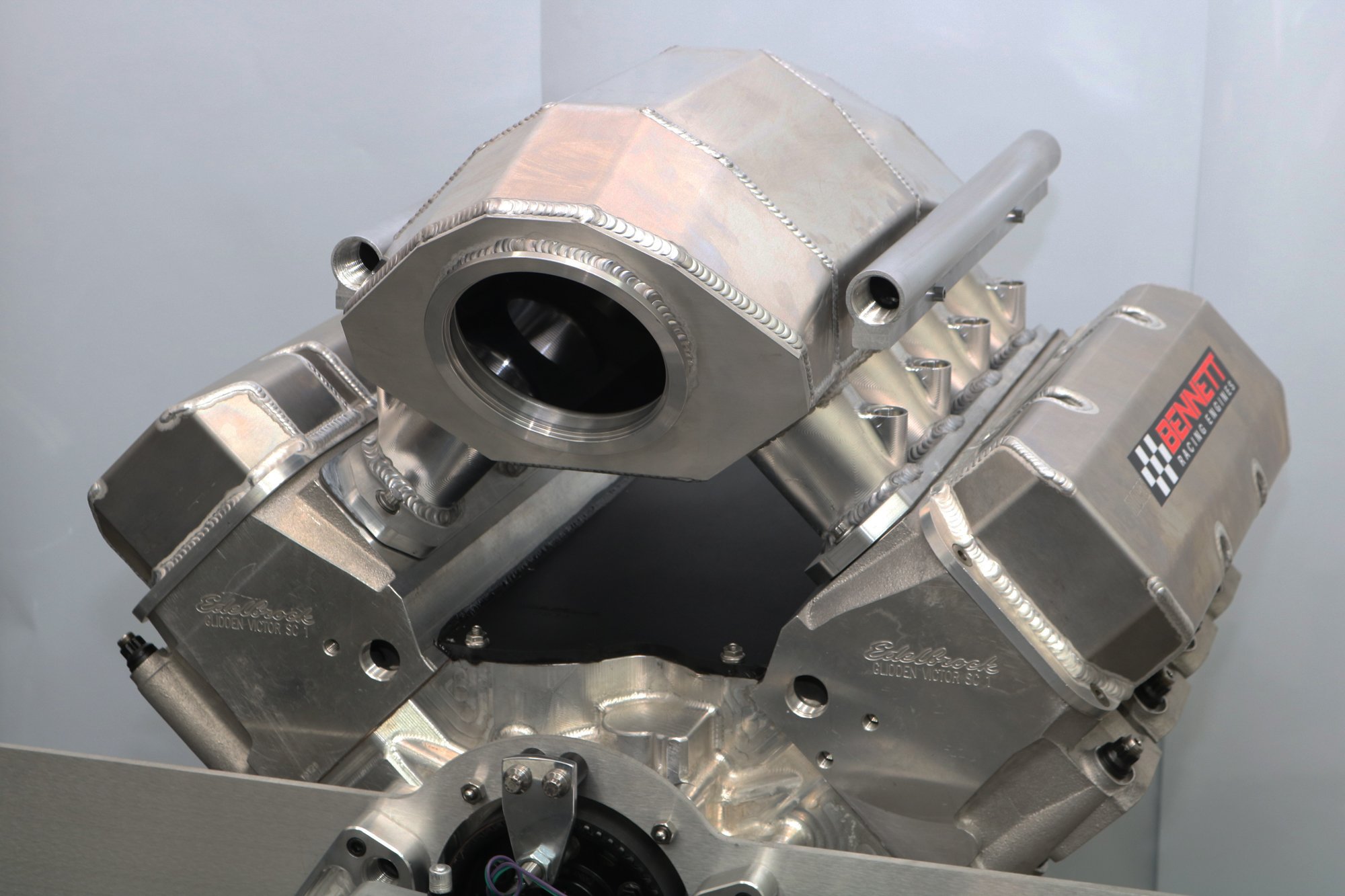

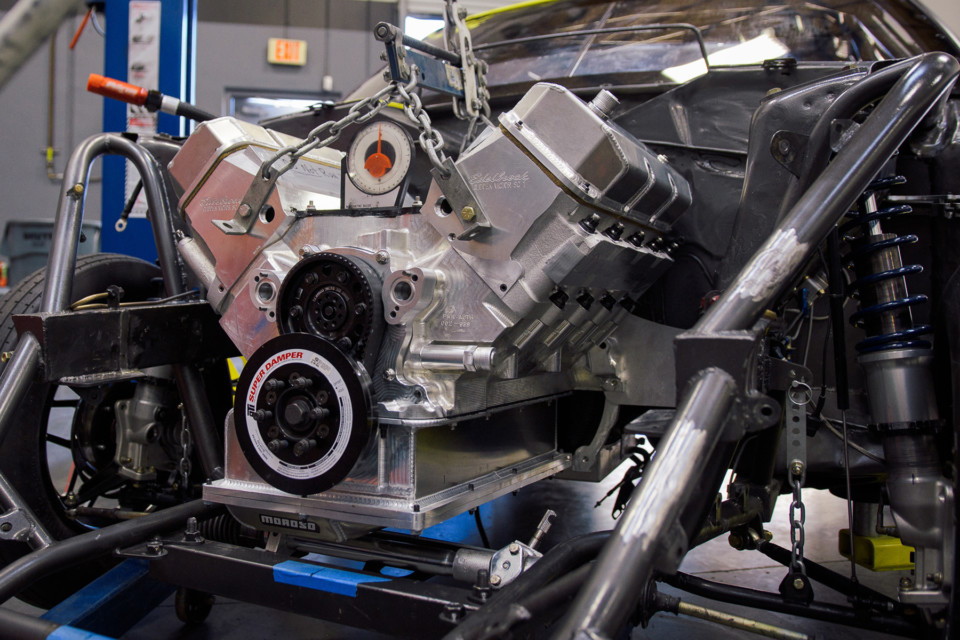

The new manifold made for the Mustang is an integral component connecting the 441 cubic-inch small-block Ford with the Vortech XB-112 billet supercharger. The effort in fabricating this custom manifold was a collaboration between CFE Racing Products and engine builder Jon Bennett at KBX Performance and Bennett Racing Engines.

“We worked with CFE on the intake runner design, runner length and how the taper of the runner mated between the plenum and cylinder head,” noted Bennett. “Turbocharged and supercharged engines require very little overall intake runner length. The intake runner does contribute power when the taper is designed into each runner — a large opening at the plenum then tapering to the intake port architecture of the Edelbrock SC1 cylinder heads.”

Engine builder Jon Bennett was instrumental in the intake runner design. The drastic taper between the huge inlet diameter and the cylinder head port takes advantage of CFE Racing Products' new option of CNC machined intake runners.

Scott Kieffer from CFE expands further into the intake design. “With this Vortech supercharger application, we listened to Bennett’s input on the runner design,” Kieffer says. “We then developed custom CNC-machined intake runners utilizing his taper theories. Not only does CFE utilize sheet-metal fabricated runners for our intakes, but we also feature an innovative CNC-machined runner option.”

Many customers present us with a set of one-off cylinder heads or a unique block deck height. The CNC-machined intake runners are a big help in those situations. – Scott Kiefer, CFE

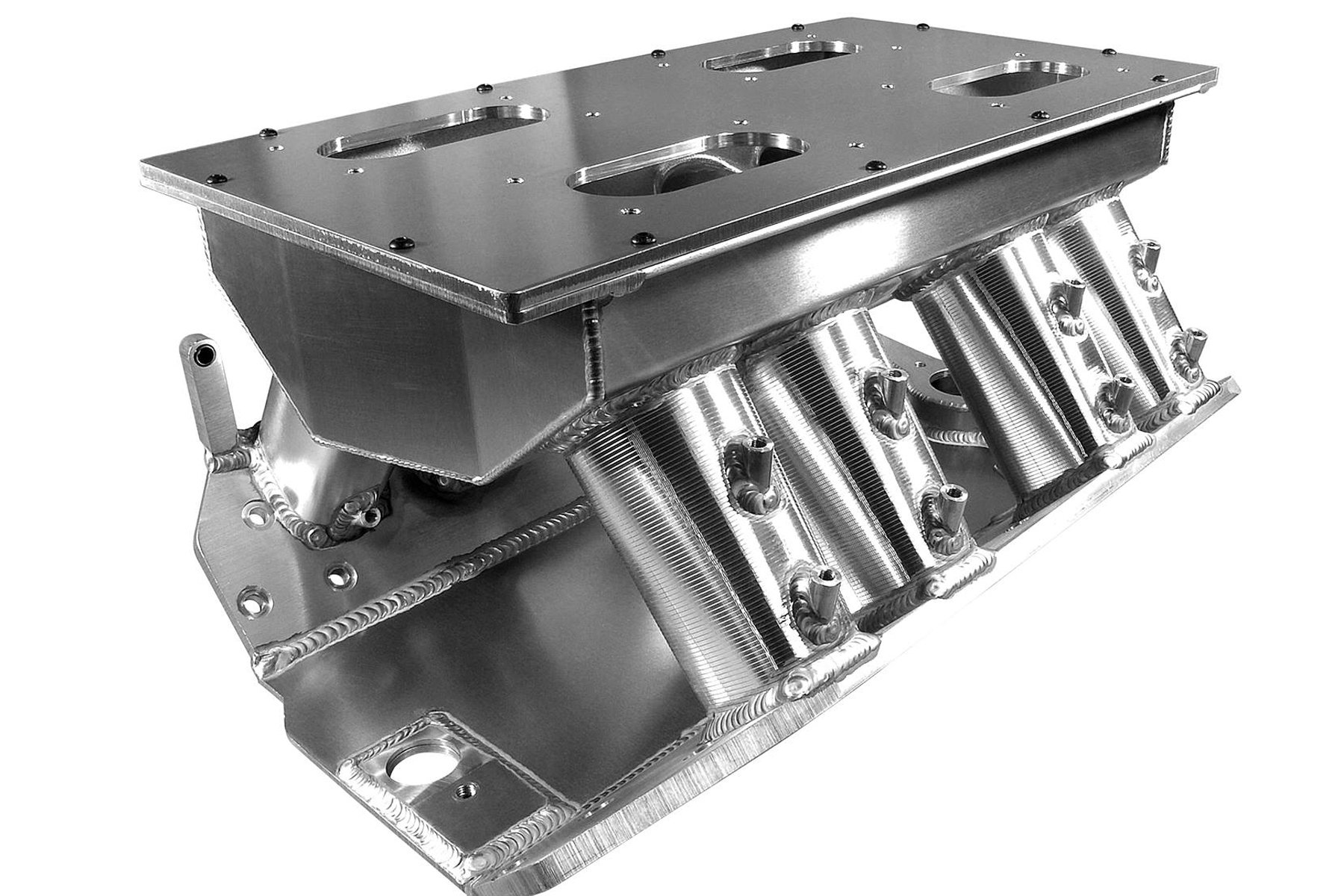

“We still create handmade sheet-metal runners in a majority of our applications,” Kieffer explains. “Utilizing CNC machined billet runners is an advantage when it comes to unique or one-off designs. Many customers present us with a set of one-off cylinder heads or a unique block deck height. The CNC machined component options are a big help in those situations.”

Carl Foltz began in the early 1990s developing custom ported cylinder heads along with his own intake manifold designs when “sheet-metal” intake manifolds were in their infancy. A blossoming business soon emerged from his reputation for achieving significant horsepower gains for many Pro Stock racing teams by his new company, CFE Racing Products.

Foltz’s products were an integral part of the 1996 Pro Stock Championship won by Jim Yates. From that point, CFE became a leading developer of ever-increasing performance levels throughout NHRA, NASCAR, and IndyCar from the ’90s to present day.

The overall design of the sheet metal intake not only accounts for intricate plenum and runner designs, but for other stipulations. Many supercharger, turbocharger and normally aspirated race cars have restrictions placed on parameters like the inlet location and body modification rules.

CFE is always in a state of constant development to keep its intakes and head porting designs at the forefront of technology. These CNC-machined runners are an effective way to not only quickly create unique intake components in such cases as these tapered runners, but also to allow them to implement different designs quickly using dyno and flow bench R&D.

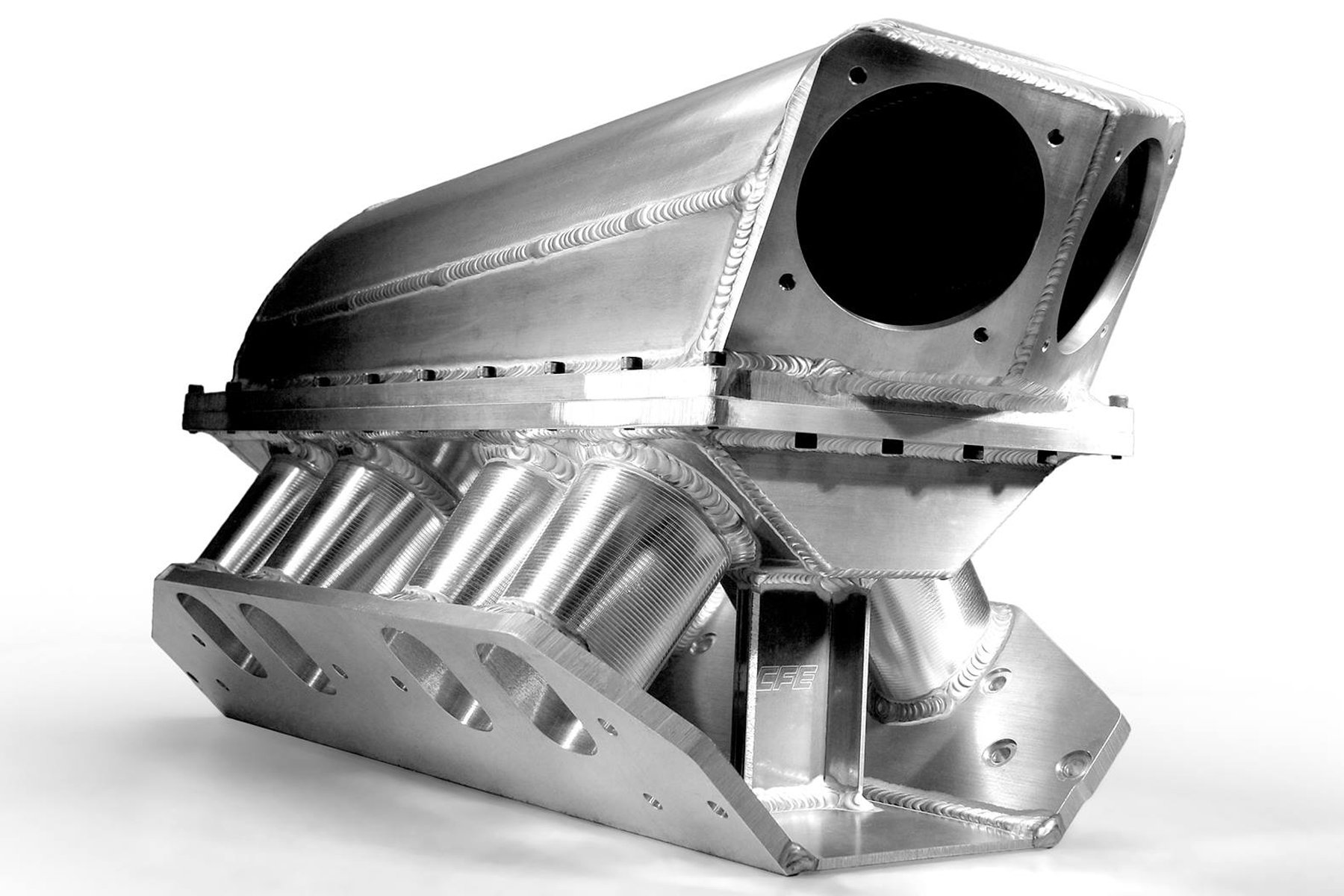

Within the plenum area, the Evil Mustang intake design gravitated toward CFE’s expertise. “The ideal layout for any normally aspirated engine would be to have the throttle positioned directly above the runners in an uninterrupted line of sight,” Kieffer continues. “In a boosted application such as this intake, air can be introduced in various locations depending on the turbo, supercharger, and intercooler location.”

Work on the plenum begins with a design that is the result of CFE's blends of extensive R&D. This knowledge stems from flow benches and dynomometer work as well as careful record keeping from proven intakes they have built for similar parameters.

He adds, “When we receive an intake order from many Outlaw or Pro Modified racers, it is sometimes a balance between the most effective design for engine performance and the external limits that will be placed on the intake such as hood limitations or turbo/supercharger locations. There have been some scenarios where the intake design would be too restricted; we have turned down creating an intake that could never work properly.”

Custom plenum designs have different goals between applications. However, whether it be a normally aspirated or boost application, most have the common goal of even distribution” to each cylinder runner.

“In the Evil Mustang supercharged/EFI application, we are creating an intake plenum with the throttle body extended from the front of the intake,” Kieffer expands. “The Wilson Manifolds 123mm throttle body uses a V-band mount. Our goal is to distribute the air charge upward with the top of the plenum and evenly across the plenum and all cylinder runners.”

The intake plenum for the Project Evil Mustang is a precise design that guides the air charge along a convex top and a tapered rear allowing for an even charge between each runner.

The plenum then gravitates to a tapered top toward the rear of the plenum. Once again, the design evens the distribution to all cylinders. These exact dimensions and shapes are held very close to the chest by the CFE engineers. Not only can you starve the rearmost cylinders, but the wrong design can also create a dead pressure area around the middle cylinders.

“An opposite situation comes into play with many racers utilizing boost and intercoolers within the driver’s compartment,” Kieffer describes. “In this situation, everything is turned around. The throttle body is located at the back of the intake with limited room through the firewall and under the cowl area. Then an entirely new set of questions needs to be asked related to the intercoolers used and our ducting limitations.”

Another advantage to the CNC machined intake runners is the incorporation of any fuel injectors or nitrous ports into the solid design.

“Plenum shaping can not only affect performance but also can lead to engine damage from rich or lean conditions,” Kieffer says. “The plenum’s shaping at the top can break up a boosted air charge. In many instances, this helps in distribution, so it doesn’t pick on certain cylinders. The same principle can also affect a manifold design for normally aspirated engines. A poor design can inadvertently cause a dead space throughout different RPM ranges.”

Reversion characteristics in racing engines are another situation where the various intake manifold shapes and sizes will play a key role. Reversion is the instance where a momentary pulse of reverse flow of cylinder pressure can enter back into the intake runner and plenum. This happens when a high overlap racing cam begins to aggressively open the intake valve before the piston reaches the bottom dead center.

This reversion can pulse exhaust gas back into the intake before the next intake cycle begins, thus affecting that next intake charge. Customized intake designs like these examples can reduce or eliminate the effects of that pulse.

Many variables go into the design of each CFE intake. Their practice is the careful logging of all the engine specifications along with the mating intake design. This stored data is continuously referenced when a new design challenge is presented.

Each intake designed and constructed by CFE is drafted from a list of engine specifications as long as your arm. Intakes of every shape and size are constructed, from a short runner supercharged application to a big cubic inch carbureted engine.

“An intake design considers carburetor or throttle body location, RPM range, cubic inches, cylinder head specifications, and a list of other variables as long as your arm,” Kieffer explains. “Our research time shows cases where very similar engines may only differ by a few hundred RPM at peak horsepower, but R&D has shown that a very different plenum volume benefits each one.”

Research and development seem to be the essence, not only for the intake manifolds but also for their own lines of cylinder heads and racing engine blocks. As a top developer for carbureted NHRA Pro Stockers for over 25 years, the recent changes to electronic fuel injection rules are prime examples of how constant R&D has given CFE its running start.

As the KBX/Bennett 441 cubic inch small-block Ford is lowered into Project Evil Mustang, you can imagine how body rule limitations and power adder locations can affect intake design from the outside as well as the intricate plenum and runners.

“Our development with EFI intakes for outlaw-style racing gave us a great starting point for 500-cube Pro Stock Engines,” Kieffer says. “Even some of our manifold developments for today’s top Pro Stock engines have provided us with some design ideas back toward the manifolds in other classes such as in the Project Evil Mustang.”

The sheet-metal intake offers nearly unlimited design options. Designers have the ability to put together the ultimate grouping of shapes and sizes to use for your specific racing application. Project Evil will be taking advantage of CFE’s years of experience in hand-forming these shapes and sizes, along with the modern advances in CNC machining, to stay on the cutting edge of X275 racing.