If you’ve ever tinkered with a basic mini-bike or go-kart clutch before, chances are the design behind Crower Racing Products’ namesake Crowerglide automatic clutch isn’t all that foreign to you. Similar to those relatively rudimentary clutches, the Crowerglide operates purely on engine RPM and load, and while the premise is similar to a traditional pedal-operated clutch, there are advantages in certain applications.

Automatic — or slipper — clutches are certainly nothing new, as they have been utilized in nitro and alcohol racing throughout drag racing history. And while alcohol and Pro Modified combinations have moved to pedal clutches or torque converters as a result of the advantages they provide those particular combinations, it’s nitro applications that adhere themselves well to something akin to the Crowerglide. This is largely due to the nature of a nitro engine that shines when it’s under load, but also a result of the manner in which a nitro car is launched.

“Nitro applications depend on every launch being the same, so the car will react the same, making it more tuneable. If you’re using a pedal clutch and on one pass and you load it a little harder then the next pass, it won’t do the same thing it did the last time. A Glide clutch, because it’s automatic, it takes driver error out of the picture,” Crower’s Roger Levine explains.

In essence, because the driver is merely stabbing the throttle to accelerate, there aren’t variations in how the driver swaps feet or how consistently they release the clutch pedal from one run to the next. For this reason, the Crowerglide and other automatic clutches are very common fare in nostalgia nitro Funny Cars, nostalgia Top Fuel dragsters, and NHRA A/Fuel dragsters.

If you’re using a pedal clutch and on one pass you load it a little harder than the next pass, it won’t do the same thing it did the last time. A Glide clutch, because it’s automatic, it takes driver error out of the picture. – Roger Levine, Crower

That doesn’t mean, of course, they can’t be used in an alcohol combination.

“The alcohol cars are leaving at high-RPM now to gain the inertia and to move the car, and with a Crowerglide you can’t leave at as high of an RPM. Even if you had a pedal to block the arms, which you can do, it would still be pushing back pretty hard. You wouldn’t be able to leave at 7,000 RPM or so like some of these guys are doing,” he says.

How Does It Work?

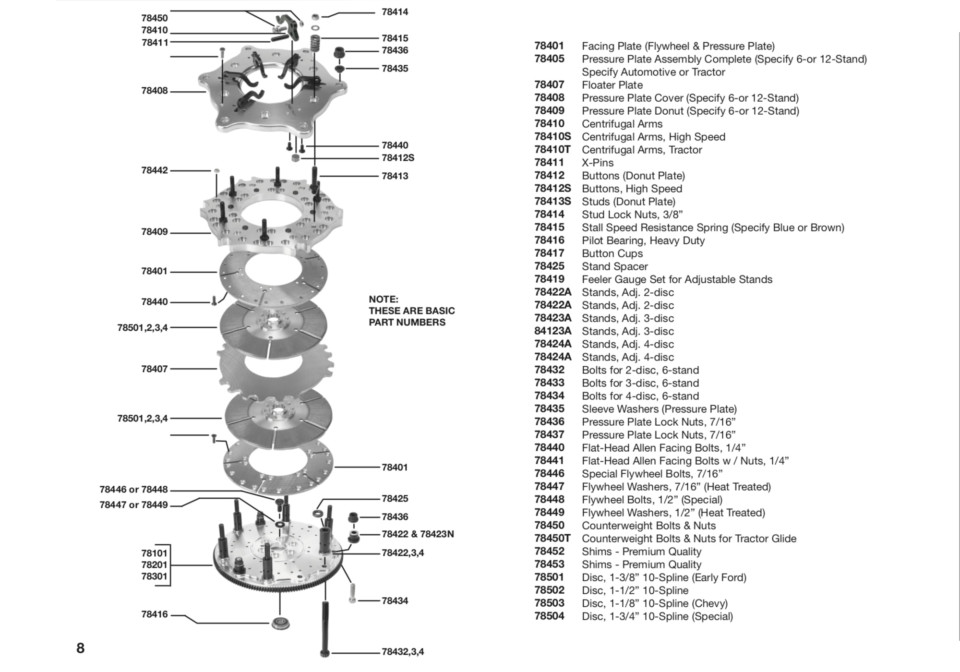

Like a pedal-operated clutch, the Crowerglide has a flywheel with six stands that hold in place a series of plates and discs: first is the Facing Plate, followed by a disc, a floater plate, a second disc, a second Facing Plate, the Pressure Plate Donut, and the Pressure Plate cover (in that order in a two-disc configuration).

The Pressure Plate cover is bolted to the stands and the donut hangs beneath it on a series of six springs. The arms, situated in that gap, oppose the forces of the springs, prying the donut down against the spring pressure. To simplify, the springs try to hold it back by maintaining the air gap between the plates and discs, and the arms work to push it down. The clutch can be adjusted by adding weights to the arms, which will make the stall speed go down — meaning the arms will have more power to overcome the springs. If you decrease weight on the arms or tighten the stall springs, the stall speed increases.

“You just give it throttle; all it knows is RPM, and as the engine RPM goes up, it throws the arms out and they put pressure on the donut, which closes up an air gap in the clutch,” Levine explains. “So when you start the car up and run it at an idle, it’s basically slipping, and then as you bring the engine up, that pack tightens up. It’s often also called a slipper clutch, because we use a compound on the discs that slips, because it’s made out of graphite and various materials that are designed to make it slip but fully lock up. In a lot of cases these cars with a pedal clutch or automatic clutch never fully lock up when they’re going through the lights. It’s trying to, but ideally it might be slipping 50 RPM, which is really nothing.”

According to Levine, once racers get the clutch set to where it’s operating as intended, they’ll tune it by using a feeler gauge to adjust the air gap in the pack (the plate and floater assembly).

“In nitro drag racing, opening up the gap allows the motor to get a slight run at the clutch so it’ll strike the tire harder. An A/Fuel car might be .40-.50-inches, which is pretty tight. If you have a car that likes .40 and you open it up to .45, it might blow the tires off right at the hit. That’s how effective it is. And once an A/Fuel car gets the right amount of counterweight, they can almost leave it alone. So what effects how the clutch works is the radius on the arm — a bigger radius gives the arm more advantage — the air gap, and the spring tension.”

If the effective stall speed is set too low, as you may surmise, it’ll engage at the hit and drag the engine RPM down, possibly never allowing it into its powerband and robbing the car of performance. This will also inhibit the engine from reaching an RPM to lock the clutch up during the run. Nevermind the effect that dragging the engine down has on fuel pressure, which could cause a host of other problems to the engine internals.

Naturally, in order to rev the engine at the line, in the fashion of a blown Top Alcohol Dragster or Funny Car, the Crowerglide would need to be set up to do so — otherwise the rise in engine RPM would simply drag the car off the line, even with the brakes applied. The spring pressure would have to be tighter, they’d potentially have to use the pedal, and as Levine points out, would simply take away the advantage that an automatic clutch provides.

“Alcohol cars used to do it — they’d run it a couple of ways: leaving from an idle, and leaving from sub-stall, where they’d bring the idle up with the pedal, but not hitting stall, so that it’s closer to reaching the point it hits stall,” Levine shares.

…what effects how the clutch works is the radius on the arm — a bigger radius gives the arm more advantage — the air gap, and the spring tension. – Roger Levine, Crower

While the clutch operates by RPM, that doesn’t mean there isn’t a clutch pedal or input from the driver, and Levine suggests everyone using a Crowerglide have one for certain scenarios.

“You can do things with the clutch pedal you can’t do without,” he explains. “Let’s say you do a burnout and it’s dragging and you can’t get it into reverse … the arms might be hanging up slightly. A dab of the clutch pedal against the fingers can put them back to their neutral position (where they sit when it’s not turning or barely turning).”

However, on the starting line they are purely brake and throttle, not unlike a junior dragster with a Salsbury-style clutch.

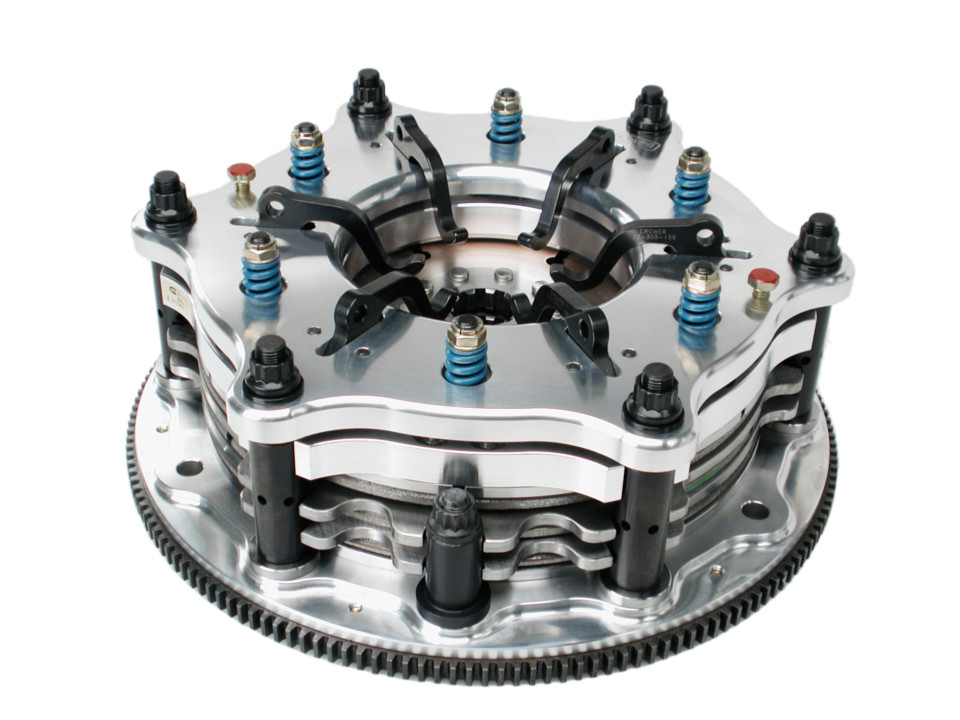

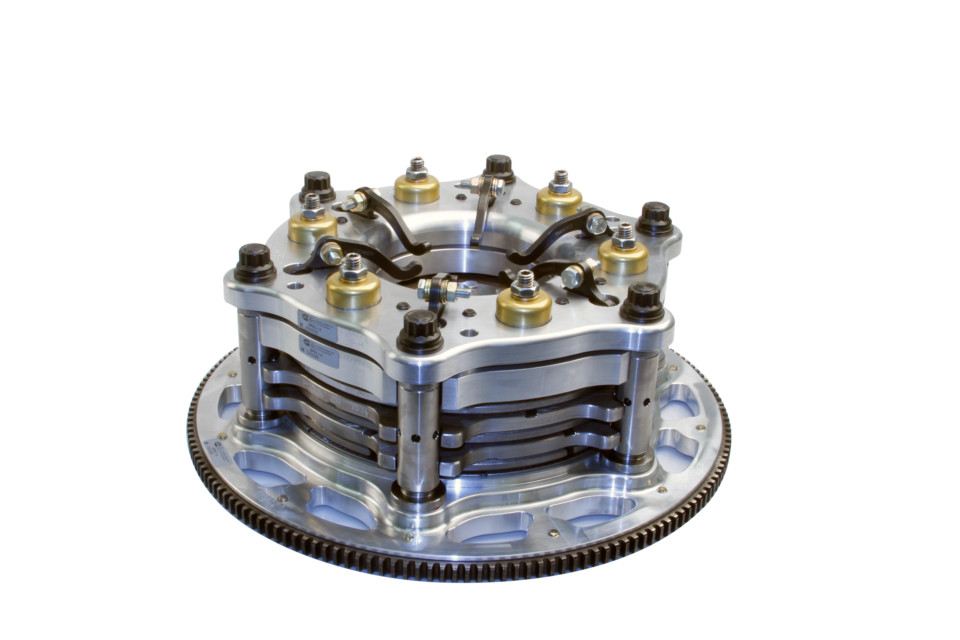

No different than a pedal clutch, the use of both larger diameter discs and floaters, and the addition of more discs are integral as you climb the horsepower ladder.

Per Levine, a 10-inch, big-stand, three-disc is most common in nostalgia fuel racing: the larger the disc the more torque capacity. there is. Likewise, additional discs coincide with ever-higher horsepower engines. “There are certain classes where a certain thing is the norm, like a three-disc in a nostalgia Funny Car. There are a few guys trying two-disc in nostalgia Top Fuelers, since they’re lighter cars. NHRA A/Fuel dragsters typically use four discs, nostalgia A/Fuelers three.”

Versus A Pedal-Operated Clutch

As with anything there are tradeoffs, and the pedal-clutch versus the automatic is no exception.

The plus is that an automatic clutch, as noted previously, will repeat the same pass after pass. Levine says it’s also a little smoother, as well, because one can get overzealous with a pedal clutch adding too much counterweight on the arms and go into tire-shake — especially if it doesn’t have enough base pressure screwed into it. “With a pedal clutch there’s a balance between spring pressure (which adds to the clutch versus subtracting from it) and counterweight to control the initial engine RPM and get the tires moving. Then as you sidestep the clutch, if there isn’t enough spring there and then you try to make it up with counterweight, it’ll pull the motor down and it’ll shake. That drops the RPM and in turn lowers the fuel pressure. If it zips through the base pressure and goes higher than it was intended to, it’s going to hit those arms and bring the engine to reality.”

The downside to the Crowerglide is that you can’t leave the starting line at virtually any engine RPM you want. With the automatic, there’s a point that you can’t leave any higher without dragging the car through the beams. The maximum achievable RPM could be as low as 4,500, Levine notes. Using the pedal with the Crowerglide, you may be able to get away with an additional 1,000 RPM.

Cost and wear-and-tear are similar and vary by how extreme and harsh the application is on parts on a run — a fuel car will go through more parts than an alcohol car might, for example.

The automatic clutch, Levine suggests, is a little more tedious and more labor-intensive to set up, as the air gap has to be set up accurately by sticking feeler gauges in, versus the simple pre-load adjustment on a pedal clutch. Remember, a pedal clutch is engaged when the pedal is not depressed, whereas an automatic clutch is the opposite — the air gap is there until the engine reaches a given RPM.

…all it knows is RPM, and as the engine RPM goes up, it throws the arms out and they put pressure on the donut, which closes up an air gap in the clutch. So when you start the car up and run it at an idle, it’s basically slipping, and then as you bring the engine up, that pack tightens up. – Roger Levine, Crower

Versus A Torque Converter

You may be questioning how an automatic clutch differs from a lock-up torque converter, and from a mechanical perspective, they are similar: each operates off of engine RPM to engage, slipping to a tuned degree before achieving near or full lock-up. But that’s where the similarities end.

First, a torque converter is able to multiply torque, wherein the fluid coming off the vanes of the turbine is redirected off of the stator while locked against the one-way clutch, creating what is effectively a reduction gear. A clutch, however, cannot do so — it can only be slipping or locked up. Levine notes that A/Fuel and nostalgia Top Fuel cars, both high-gear-only cars, will sometimes slip the clutch out to 1,000-feet, using the clutch to take the place of a transmission. But that’s effectively a controlled slip until it can reach an RPM to lock up.

Secondly, the fluid inside a torque converter, which can heat up as much as 100 degrees per second against the transbrake on the starting line, still serves to cool the inner workings of the converter to some extent. But a clutch cannot do so, and if one were to stab the throttle on the starting line to bring up the engine RPM against the clutch pedal (driving it similar to a torque converter), it would quickly destroy the clutch and possibly the inside of the bellhousing (something Levine notes has happened before with racers testing its uses).

Whether it’s an automatic clutch, pedal clutch, or a torque converter, the intent remains the same: to engage and disengage power between two rotating shafts. But the methodology is about pairing the proper mechanical device with the application that best suits its characteristics — what works for one engine or fuel type may not be the best fit for something else, even when the power level is similar. For the applications noted above, it just so happens a high-dollar version of the mini-bike clutch from your childhood does the trick.