The 1950s was an iconic era that spawned many incredible new innovations: everything from poodle skirts and rock and roll music to organized drag racing with the birth of the NHRA. The modern torque converter was also produced during that time, and while all types of motorsports technologies have taken tremendous leaps forward since, one surprising component hasn’t seen much advancement: the 8-inch torque converter. Fortunately, ProTorque has stepped in to create its X8 series race torque converter as one of the first major innovations since the original 8-inch was introduced all those years ago.

“We’ve been using the same 8-inch torque converter technology for almost 60 years,” noted Joe Rivera, ProTorque’s forward-thinking founder who refused to believe that the same old design and antiquated technology was truly the best option available. Determined to develop something different, Rivera took the same technology that ProTorque pioneered 15-plus years ago for its Revolution Series torque converters and focused his attention on the 8-inch units. “I used what we learned from outlaw drag racing, the Pro Mods and drag radial classes, and turbo cars, and worked that same technology into our new X8 converters.”

Ironically, it was ProTorque’s acquisition of its new Director of Motorsports and Sales, Tommy Kundrik, in early 2021 that enabled Rivera to run with his idea in the first place. Kundrik had worked with David Barton (of the famed Ray Barton Racing Engines enterprise) on his NHRA Factory Stock Showdown program and the two had a solid mutual trust.

“When I heard Tommy moved to a converter company, I asked him if we could test something,” added Barton, who quickly realized ProTorque’s prowess. Given that ProTorque’s parent company, Boninfante Friction, is located just outside of Philadelphia and Barton’s company is less than two hours away in Robesonia, Pennsylvania, the partnership made perfect sense professionally and logistically.

Rivera had the idea for his X8 converter several years ago but had been waiting for “the right people” to work with on it. Finally, all the pieces had fallen into place and Rivera, Kundrik, and Barton moved forward with the process.

NHRA believed I was running a lock-up torque converter and tore me down, but when you’ve got the right converter like we do now with the X8, you don’t need any of that fancy stuff anyway. – David Barton

At first, the results replicated Barton’s prior performances, but that wasn’t the goal…they wanted improvement. “So, just like anything else, we tested and refined and adjusted and tried different things,” shared Rivera, who has never been scared to pivot his plans. After six or seven iterations, the team hit on something big. “We did some hub dyno testing, went to the track, and then David [Barton] went to the NHRA race in Norwalk, Ohio [in late June of 2021] and that’s where we really made a lot of progress.”

Racing his Ray Barton-backed Chevrolet COPO Camaro, Barton qualified number one in the class with a 7.825 at 177.79 mph pass and made it through to the semi-finals. He ran consistently through the first two pairings to turn the win light on in his lane, and improved to an impressive 7.807 at 181.64 mph run in the semi-finals but unfortunately was taken out by the other lane on a holeshot.

Picking up 3-4 miles per hour in a class with such strict rules and lower (as compared to Pro Mod or Radial vs The World) horsepower is a monumental challenge, but Barton made it look easy – so easy, in fact, that NHRA officials were stumped as to what he was doing and spent a significant amount of time looking into his combination with.

“NHRA kept checking everything on the car after every single run and pulled data to analyze,” noted Barton, who rocketed to the Factory Stock Showdown number one position after the first qualifying session at the NHRA U.S. Nationals in Indianapolis just a few weeks later with his 7.816 at 176.67 mph blast and crushed the rest of the COPO Camaros in the field by comparison. “NHRA believed I was running a lock-up torque converter and tore me down, but when you’ve got the right converter like we do now with the X8, you don’t need any of that fancy stuff anyway.”

The X8 not only delivered on Rivera and Barton’s goals, it far exceeded them. “The first big run can be considered an anomaly. The second is a trend, and the third… well, that means it works,” laughed Rivera, who is flattered by the NHRA’s teardowns because he knows it means he’s on to something big.

Using the vast knowledge he’s gained over the years from outlaw-style drag racing, Rivera created the X8 to perform like a lock-up converter without actually being one. The specifics behind the secrets on how he accomplished the feat are closely guarded, however, as ProTorque and Boninfante collaborated to manufacture the X8 torque converters in-house using proprietary processes and intellectual property.

“All of our products are born from Top Fuel technology, and the stator development has been the key to this entire program. We created a converter that has enough slip and flash stall to get the engine in the right place with more efficiency than any of the other platforms currently available,” Rivera shared, noting that “this is the dream team’s work coming together – myself, Tommy [Kundrik] and Rob [Boninfante] – blended OE-manufacturing with performance and found the right platform to create a new line of billet stators and aluminum back covers to get the desired results.”

In torque converter technology, the smaller the diameter of the unit, the better. However, having enough torque capacity to transfer more power generally has been a traditional struggle of the traditional 8-inch converter…but the X8 puts those capacity concerns to rest, as evident by Barton’s repeated gains of several miles per hour on the top end.

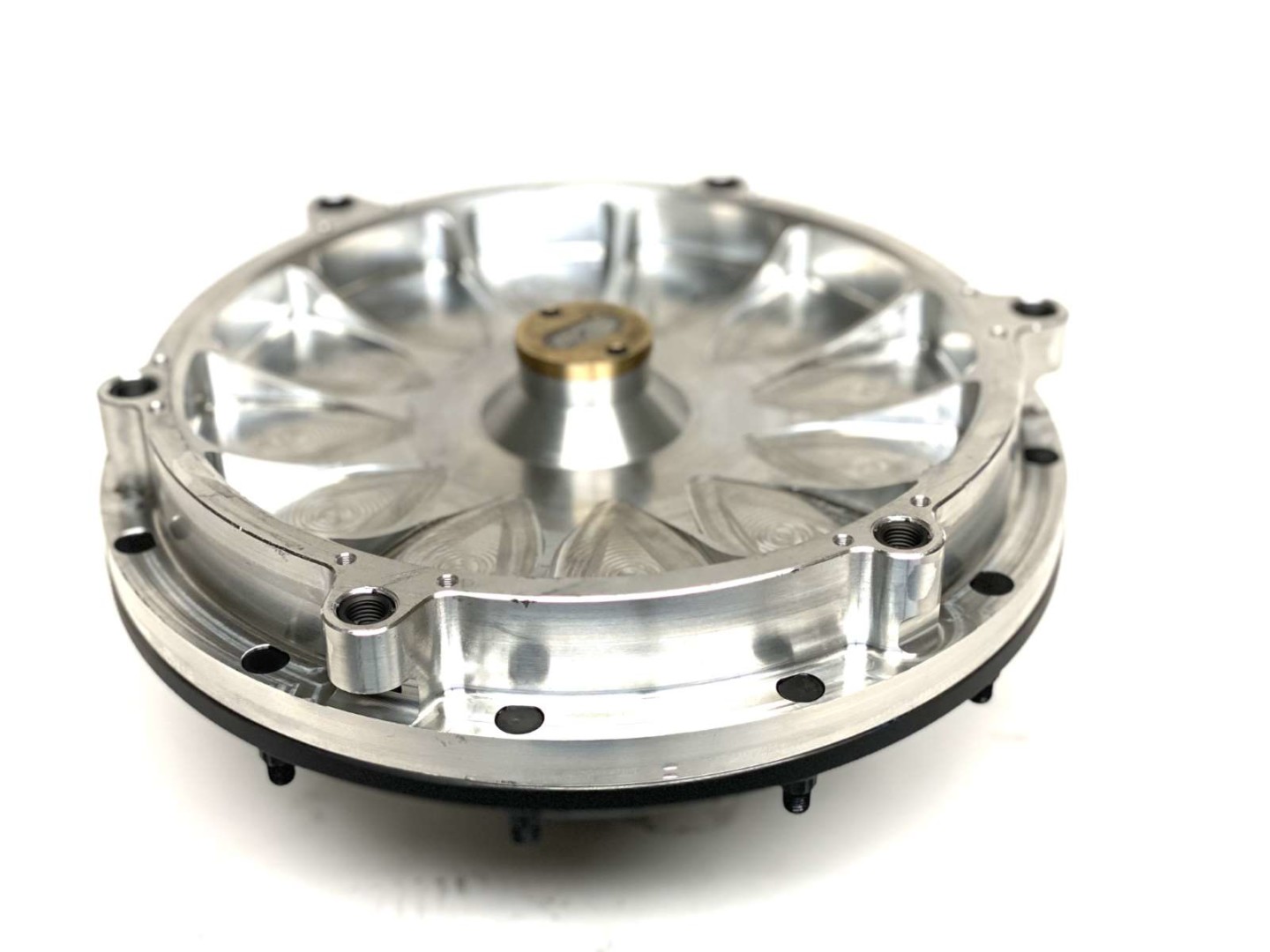

ProTorque’s new X8 converters feature lightweight 7075 T6 billet aluminum bolt-together drive covers and are fully CAD/CAM-designed and CNC-machined to be exceptionally strong yet surprisingly lightweight. Integral strengthening struts provide extra support to critical areas within the converter to prevent flexing or ballooning, and rotating mass has been reduced by removing material from non-critical areas. Additionally, the X8s have been fully radiused to prevent stress risers and include six mounting locations to accommodate both large and small bolt pattern flexplates.

We created a converter that has enough slip and flash stall to get the engine in the right place with more efficiency than any of the other platforms currently available. – Joe Rivera, ProTorque

On the inside, ProTorque’s custom billet stators have also been CAD/CAM-designed and CNC-machined from solid billet steel or billet aluminum. Available with a 10-strut mechanical diode or in a spragless configuration, the bolt-together X8 converters offer infinite adjustability to facilitate power management fine-tuning for specific combinations and conditions while also being fully serviceable.

Purpose-designed for performance, these 8-inch converters also come complete with custom-designed hardware such as 12 custom 4340 rolled thread aerospace-grade fastening studs, “Safe-D” stud technology that’s been indexed into the aluminum front cover to provide a safe and secure way to keep both halves of the converter in constant compression, and steel Keenserts to provide the safest and strongest method of attaching the flexplate to the converter.

In ProTorque’s product line, the X8 can be considered the “little brother” to its record-setting U9 converters, which have shown tremendous proficiency in classes such as Ultra Street. The X8 is geared towards a larger sportsman-style market, including NHRA classes such as Factory Stock Showdown, Stock, Super Stock, Comp Eliminator, Top Dragster, Top Sportsman, and more. Able to support over 2,000-plus horsepower, the X8 is also perfectly suited for cars in the 600 horsepower range and everything in between.

“We’re already further ahead this season than we were a year or even six months ago, and we’re really looking forward to the off-season to be able to refine our program even more,” said Barton, who is currently near the top of the NHRA championship title points chase thanks to his willingness to innovate his program and do something that’s never been done before. “And, it isn’t just us – four people from our shop have won with this platform. We’re winning as a team.”

Rivera has thoroughly enjoyed building a relationship with Barton on the X8 project, as the two have worked well together in sharing/interpreting data, analyzing results, and communicating what changes are needed. “You can’t just buy a timeslip in NHRA Factory Stock Showdown. You don’t just make a change and go fast,” asserted Rivera. “You have to do the work, and our new converters have a larger tuning window than anything else out there.”

Although the X8 is currently being produced to fit the GM TH350, TH400, and Powerglide 30-spline transmissions expanded applications “to improve everyone across the board” will be coming soon. “ProTorque has a mindset of making things better for the masses, which is no different than what Ray Barton Racing Engines does every day on the engine side,” concluded Rivera. Pricing will be in line with ProTorque’s Revolution series converters, slotting in at the $1,900-$2,900 range. The company is accepting pre-orders for its X8 torque converters and expects approximately 30-45 days for the first round of fulfillment.