Any bracket racer will tell you that consistency is king, and they’ll do anything they can to make a racecar be as predictable as possible. The transmission and torque converter plays a big role in how consistent your bracket car will be, and a high-quality Powerglide transmission and the correct torque converter have long proven to be a great combo if you want to build a car that will print tickets.

Project Number Cruncher is Dragzine’s purpose-built bracket/index racing project car. We needed a transmission and torque converter that would run the number day in and day out. After talking with numerous racers and transmission builders, we decided the tried-and-true Powerglide transmission with a custom torque converter would help us reach our goals. Justin Cooper and the team at FTI Performance assisted us with choosing the right Powerglide, and made sure the torque converter would work well with our engine.

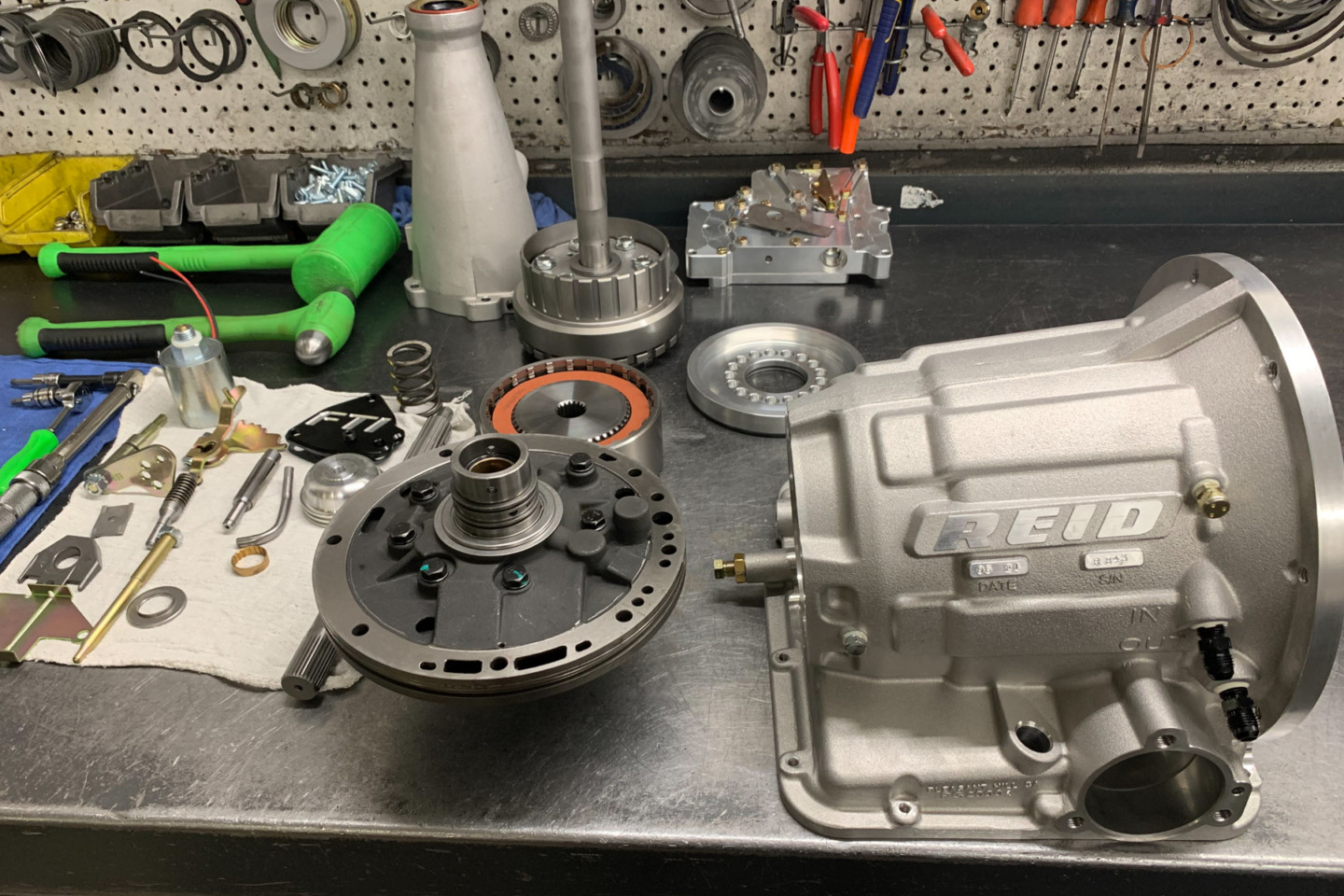

You can get Powerglide transmissions in many different forms. Our Level 4 from FTI was built with all new and aftermarket parts.

Using A Powerglide For Bracket Racing

The transmission plays a big role in sending horsepower back to the rear tires of a racecar, so it needs to be matched to the racing application it’s being used for. The wrong gear set inside the transmission can impact how well your car performs at the track, and weak parts will affect durability.

An advantage of a Powerglide transmission is its simplicity. There aren’t a lot of moving parts inside one of these transmissions and that makes maintenance fairly easy. If you’re mechanically inclined, have a service book, and a couple of specialty tools you can rebuild one of these transmissions at home. Parts aren’t exotic, and they’re generally plentiful and easy to find, even in a pinch at a racetrack.

The Powerglide transmission is a simple beast of burden that doesn't require anything fancy to work perfectly in a bracket racing application.

There’s a second part to the simplicity advantage of a Powerglide: the fact it’s a two-speed transmission. Cooper explains why having only one gear change can help a bracket racer.

“Typically, what we’ve found in bracket racing is the less the engine is being lugged down under a load, the more consistent it’s going to be. With the engine only being interrupted by one shift versus two or three, it will be more consistent, because the recovery on the gear change is only going to happen that one time, versus multiple times with other transmissions.”

A Powerglide transmission is very durable in stock form — start adding some aftermarket parts and you have one stout unit. This elevated level of durability is another reason a Powerglide is perfect for bracket racing, as they can take a beating for an extended amount of runs. You can use the bulky and strong OEM parts, add a better valve body, and a high-capacity pan to create a beefy transmission. That type of build will last for a long time behind a 600-700 horsepower engine with basic maintenance, and the cost to build it won’t break the bank for most racers.

Moving to an aftermarket case is a great way to get more performance out of a powerglide. – Justin Cooper FTI Performance

The aftermarket has blessed racers with a bounty of parts for the Powerglide, all of which make it an attractive choice for bracket racers because you can build a transmission that will hold a lot of horsepower.

“There’s a massive aftermarket parts segment for the Powerglide. You can get aftermarket bolts, cases, planetary setups, valve bodies, and pretty much anything else that makes up one of these transmissions. There’s no need for a junkyard core anymore with all the parts you can get from multiple aftermarket companies,” Cooper says.

What Parts You Should Upgrade And Maintenance Best Practices

If you plan on throwing a lot of power at a Powerglide and want a bulletproof transmission, there are some parts you can upgrade to improve the unit’s durability and performance. FTI recommends getting away from the OEM case as one of your first upgrades. Most OEM Powerglide cases have been in service since the 1960s and ’70s, so they’ve got a lot of years on them.

An aftermarket case is going to be thicker in several critical areas, one of which is the reverse gear side of the case, where the OEM units will crack. The aftermarket case is going to be made of better materials and have greater machine work on the inside.

The OEM Powerglide case is a known weak point and should be upgraded if you plan on sending a lot of horsepower through the transmission on a regular basis.

“Moving to an aftermarket case is a great way to get more performance out of it. We’re running elevated line pressures in these transmissions now at 210-255 psi, and you can’t run that level of line pressure in a stock transmission case. Those line pressures will cause the transmission to leak, crack the case, or cause a total case failure. That could happen when you’re staging the car or while you’re making a pass, and you don’t want to run that risk. The safety features of the aftermarket case are great: they’re SFI approved, so they won’t blow up and send parts at you through the floor in your general direction,” Cooper explains.

Upgrading the internals of a Powerglide transmission will make it a very strong unit capable of working in any bracket racing application.

The Powerglide case holds everything together, but there are a couple of parts inside the transmission you should also upgrade to. If you add a better planetary and front pump to a ‘glide, you’ll have a transmission that can work behind any engine. These parts are going to add to the durability of the transmission just as much as the aftermarket case will.

“The front pump needs to be up to the task of what you’re trying to do. An OEM pump that’s been rebuilt will just start to wear out faster and that will lead to leaks or low pump pressure. Those are the kinds of problems that will take you out of a race and can easily be prevented with good parts. The planetary is important and you really should use an aftermarket part whenever possible. If you put a cheap planetary in the transmission it won’t last long. The planetary needs a good gear set that will provide plenty of longevity. The 93/10 straight-cut gears are a lot stronger and have better materials. You will have to deal with more noise, but it’s a racecar so that shouldn’t be an issue,” Cooper explains.

You just installed a brand new Powerglide that’s built to the max…now you can just run the transmission for hundreds of passes and it will last forever, right? Well, that’s really not the case at all. The transmission will suffer in the performance department, and not performing any maintenance will also cost you consistency. As a bracket racer, if you want to get the most out of your transmission you’d better be ready to have a good maintenance program.

If you really want to get the most out of your Powerglide it’s important to change the fluid on a regular basis. FTI offers its own transmission fluid that helps to fight internal transmission wear issues.

The place you want to start with Powerglide maintenance is the fluid and the fluid change intervals. FTI has learned a lot about transmission fluid over the past five years and even developed its own lubricant. Clean transmission fluid is very important to ensuring your unit will perform at a high level for an extended period of time.

“We tell people between 50 and 100 runs to partially drain the transmission and top it off with fresh fluid. The fluid is a key to consistency. The fluid also helps the gears last longer, too. As the fluid starts to break down, all the polymers and additives that are there to protect the gears will attract metal shavings. The cleaner the fluid, the better a transmission will perform. A transmission cooler can also help to keep the transmission happy and longer-lasting. It keeps the fluid cleaner and keeps the debris out of the important parts,” Cooper states.

Selecting Our FTI Powerglide

When we hit the point in our build where it was time to select a transmission we called FTI to discuss our needs. FTI offers a Level 3, 4, 5, and 5.5 in its lineup of purpose-built bracket racing Powerglide transmissions — these are designed to work with different horsepower levels and feature parts that work best in a bracket racing application.

Our 427 cubic-inch SAM Tech-built LS engine cranked out over 780 horsepower on the engine dyno, and could actually make more if we tweak a few things. After looking at the engine’s dyno graph and noting the other specs of our Firebird, Cooper decided the Level 4 ‘glide from FTI would be the best fit for our project. The Level 4 unit is rated up to 1,100 horsepower, uses a Reid case, sports FTI’s billet aluminum valve body, a deep aluminum pan, an eight clutch drum, and all new internal parts. This transmission also features a 300M high flow input shaft, 4340 steel output shaft, and a bushed tail housing.

Our Level 4 Powerglide shouldn’t have any issues with the SAM Tech LS engine that we’re using to power Project Number Cruncher.

“The Level 4 and Level 5 Powerglides are the units we sell the most of. The Level 5 is good for dragsters since it can handle up to 1,500 horsepower, and the Level 4 is perfect for door cars since it can handle up to 1,100 horsepower. It’s important to make sure you’ve got a transmission in bracket racing that matches the power you’re putting down,” Cooper says.

Getting The Right Converter

A customer torque converter really isn’t considered a speed secret these days…it’s a standard part that racers will use to maximize their engine’s horsepower. In bracket racing, the converter is arguably one of the most important parts of your combination, so you need to get it right no matter what transmission you’re using. FTI asks customers to provide every detail about the engine they’re using, the car itself, and the type of racing you plan on doing when building a converter.

The right torque converter is critical if you want to get the most out of your Powerglide transmission.

FTI was able to use our engine dyno sheet to determine the proper converter for our application. Since Project Number Cruncher is naturally aspirated, an 8-inch torque converter was selected to help free up the engine. The smaller converter won’t excessively pull the engine down, and that will help the car be more consistent when there are changes in the weather.

We tell people between 50 and 100 runs to partially drain the transmission and top it off with fresh fluid. – Justin Cooper FTI Performance.

“An engine under 900 horsepower needs something smaller than a 9-inch converter. It comes down to the surface area of the converter, and the bigger converter just won’t work well with an engine that’s not making enough power, since it has more surface area to move. You want the RPM to drop between 500-800 on the fallback of the gear change, and the smaller converter makes that possible. Too much of a fallback is going to hurt the consistency. You want to be on the ragged edge of driving through the converter and it slipping. What happens by doing that is as the weather cools off, the engine makes more power, and the engine will drive through the converter, thus helping it be consistent versus getting faster,” Cooper explains.

The Powerglide has earned its place as the go-to transmission for bracket racers. When you build one of these transmissions right, they’re bulletproof and will help you maintain a higher level of consistency when eliminations kick off on race day. Make sure you follow Project Number Cruncher right here and see what else we have in store for our bracket racing machine.