It’s a sunny morning after a light evening rain and you’re ready to race. The engine is tuned, the car is ready. You make your first pass and….the track seems slicker than expected. As the morning chill gives way to a hot afternoon sun, the track still isn’t hooking up. What should have been a quick and easy pass is surprisingly slow. What happened? We’re diving into some of the track and weather conditions that might affect your run on a given weekend at the track.

For an unprepared track surface, the traction is between the tire patch and the surface. Any dirt, oil, or humidity limits traction. Surface treatments are a common alternative to a “no-prep” track. The treated surface is a coating applied to the track. A loss of traction can be between the tire and the coating or the coating and the track.

Loss of traction at the tire is in the hands of the tuner. Loss of traction between the coating and the track may be in the hands of the track crew. For example, delaminations can occur from excessive high track surface temperature or from excessive track surface humidity.

The Sun Affects The Track

On a cool, sunny day of around 60-degrees Fahrenheit, track temperature can be 10 degrees hotter. At our local track near the coastline, the lower limit of the surface temperature for reasonable traction is in the low 60’s. It is hard to hook up below that temperature.

On a hot, sunny day of around 100-degrees Fahrenheit, track temperatures can reach 120-degrees Fahrenheit or more. Mike Walker, NHRA Operations Manager for Lucas Oil Raceway, reports that surface treatments commonly used for drag racing events get gooey at surface temperatures above that.

Stringers appear behind the tires as they roll over the surface pulling off the gooey surface treatment with poor traction. Walker said the crew will scrape excess surface treatment away as the temperature increases and do a spot treatment to bare concrete in the hot weather. They use PJ1 resin to help bond the PJ1 brands surface treatment to their concrete.

Humidity Affects The Track

When the dew point gets close to the outside temperature, humidity in the air condenses out onto surfaces. Dew point is the temperature at which moisture saturates the atmosphere and liquid occurs in the form of dew, fog, or rain. Any liquid that occurs will coat the track and make traction more difficult.

In coastal regions, 90 degree days at 40-percent humidity are commonly followed by 60 degree nights at 80-percent humidity. The amount of moisture in the air may be the same. However, the cooler temperature means there is less available space for that moisture and, therefore, a higher relative humidity. Generally, when the temperature gets to within a degree of the dew point, racing is over.

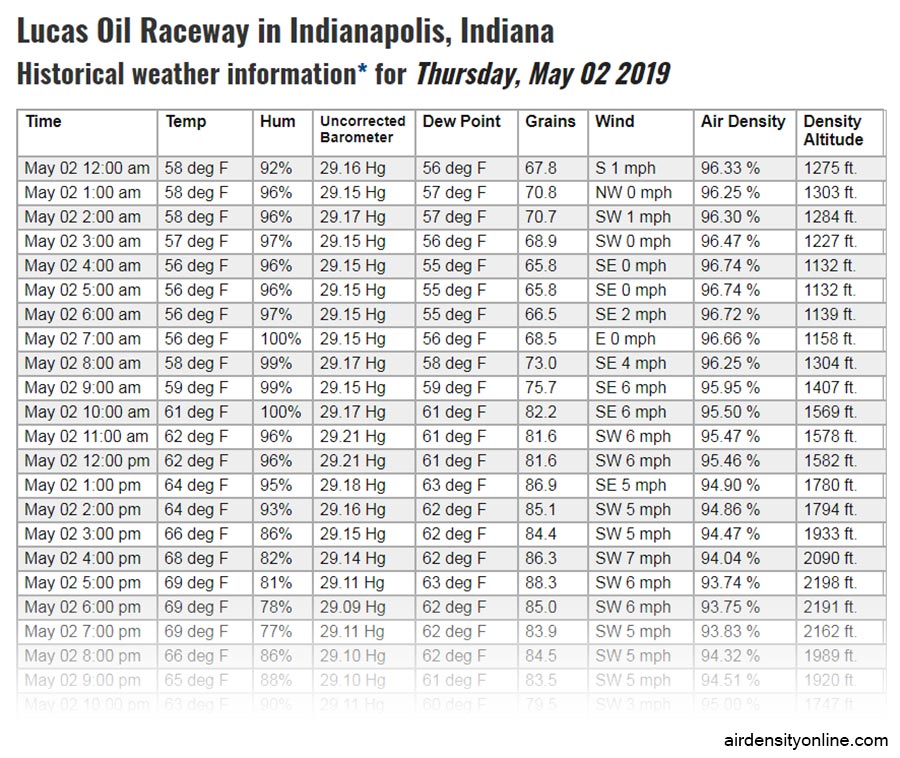

Hourly air density weather for Lucas Oil Raceway, Indianapolis, IN, for May 2, 2019. The early morning temperature was around 60-degrees Fahrenheit while the dew point was close. At that point, humidity condenses out and coats a racetrack surface even if it is not currently raining.

Suppose the temperature is dropping from sundown. You’re in staging lanes and your windscreen has fog on it. You wipe it off, and you can see. The windscreen is cooler than the racetrack surface in the early evening. The ground will be warmer in the evening from heat soaking in during the day. Racecars are still flying down the track and hooking up because the track surface is still warmer than the dew point.

According to IHRA‘s track prep staff, continued traffic on busy event days helps maintain traction even in damp conditions. The air washing from each race vehicle blows away debris and moisture that helps keep dew from forming. Often the racing groove can narrow under these conditions. With dew on the track on a cool evening, IHRA staff reports that the groove could be as little as 10-feet wide.

Hidden Sources Of Water On The Track

We walked across a track surface right after a week of heavy rain. The weather was sunny and warm but groundwater had collected under the track surface. Drainage is a significant characteristic for any track with rainy weather. It is a good reason to walk the racetrack during downtime: to see idiosyncrasies such as this or confirm their absence.

This racetrack had poor drainage under the track. After a lengthy rainstorm, water seepage came out of pavement cracks causing racing slick hydroplaning and loss of handling.

Track Cleanliness

A common practice in national event competition is to wash the pavement with regular detergent before surface treatment to remove residual oil, exhaust waste, and dust. If a track was recently rained on for several days with good drainage, it would already be clean without washing on a subsequent warm sunny day.

A clean connection can then be established between the surface treatment and the pavement. Even if the surface treatment is sticky to the racing slick, a poor bond to the pavement from a dirty interface limits the tire plant. Examination of delamination or rubber balling up may be an indication of a track limitation and not your race vehicle.

Track Dust

Dust is more of a problem at tracks with exposed land or fields nearby. Unpaved pits, driveways, or farmland surrounding the track kick up dust and windy conditions bring more dust to the track. If it is present prior to surface treatment, it can limit the bond to the pavement reducing the available traction. After surface treatment, it can limit traction between the tire and the surface treatment.

Dew Point, Humidity, & Surface Treatment

Spray-on surface treatments with subsequent dragging provides an exceptional track surface for low levels of moisture from dew. However, after heavier amounts of dew formation, track coatings even with dragging cannot compensate, and the track becomes too slippery for drag racing. According to Chad Head, PJ1 Brands consultant, TrackBite is not water-soluble.

Spraying surface treatment onto the racetrack prior to dragging in preparation for high powered drag racecars

Methanol is a common thinning additive for some spray-on surface treatments used to spread the treatment out. Many tracks develop mixtures for various track conditions. A common mixture of 80-percent surface treatment and 20-percent methanol is used. Our local track often uses a 60-40 mixture. Walker reports a 75-25 mixture for the Indianapolis track. Different brands of spray-on surface treatment are available, as well, that may have different recipes.

Surface Treatment Amount And Contamination

Thicker surface treatments are often used on cooler track surfaces while thinner amounts are used for hotter days. Chemical studies reported a major problem when surface treatments are mixed with methanol that may be water-contaminated. Water-contaminated methanol also contaminates the surface treatment and leaves a gooey surface with poor traction. Scraping removal is necessary.

Dragging Surface Preparation

After the track is cleaned and surface treatment is applied, rubber tire tread from discarded racing tires is dragged over the surface treatment to form a coating of fresh rubber on the sticky surface. Using a surface treatment without dragging creates a surface that is a bit more gummy with less traction.

Walker reports that racing slicks that are take-offs from recent racecars are used for dragging. Occasionally new ‘blems’ are available that work best. He avoids tires approaching a year old, as they are too dried up for dragging.

Concrete vs Pavement

Concrete is popular but pavement is a more common surface type. Some racetracks begin with concrete and transition to pavement somewhere along the length of the strip. Often, there is a remarkable drop in traction when the racing vehicle leaves the concrete and hits the pavement.

At our local track, when the starting line was fresh concrete, the track maintenance crew would spray water over the hot track when surface temperatures got too high. The water would quickly evaporate cooling the track surface, and traction improved.

That does not work with older concrete starting lines. Walker shares that older concrete is more cured and porous. It will absorb moisture more readily than newer concrete, so much so that water should not be used for cooling a hot track, especially with well-cured, older concrete.

Paul Bradner is an expert who worked drag racing track preparation for decades. He agrees that concrete, which is common on starting lines, is porous and absorbs more moisture from the air than pavement. Sunlight will heat the surface. Rubber will accumulate from burnouts and multiple launches from powerful racecars. Bradner says water will emerge from concrete under the rubber, breaking the bond between the rubber coating and the track. The surface rubber will pull off in chunks.

This is a good example of a failure between the track surface coating and track surface. Your racing vehicle is hooking up to the surface coating. The surface coating is not staying connected to the track.

You can get an idea if there’s a traction problem between the tire and the track (your problem) or the bond between the track surface coating and the pavement (racetrack problem) by examining tire chatter marks. Twist your shoe on the bumps and the valleys to see if there is a difference in resistance. If the difference is remarkable, the bond may be breaking between the pavement and the surface coating.

Bradner was one of the first to use spray-on surface treatments such as VHT (now TrackBite), starting in the late 1970s. He said that more recently there’s a difference in track preparation for small-tire versus big-tire racing, radial versus bias-ply.

According to Rhett Gardner, Darlington Dragway General Manager, “Big-tire cars that race in NHRA and PDRA want wheel speed. If you ever watch a slow-motion video of a Pro Mod or any type of big-tire car, you’ll see that car tires start to “slip” when it takes off and by the 80-foot mark the slip is gone. Prep-wise, not much glue is sprayed on the starting line, but at about 60-feet the glue is sprayed and drug in. Radials, they want a very tight track but with more glue used for traction. Radials do not want wheel speed — they dead-hook and go.”

Bradner says a sticky track can cause tire shake, as it causes the tires to ball up and snap loose. Some racecars have tire shake also when the racetrack is not well prepared. Attention to the level of stickiness is needed to determine which is occurring.

Flatness

Many years ago, we walked down Rockingham Dragway, North Carolina in the rain. We saw very even runoff indicating a level track. That levelness is ideal for high-powered drag cars. Several years before that, we raced on a drag strip in the midwest that had a noticeable dip at the end of the track. It was a challenge to stay on the throttle going over that dip.

Horizontal and Longitudinal Groove

Track preparation is concentrated in the center since that is where most cars and motorcycles line up. Some racers will line up intentionally off-center for less traction to get wheel speed up. The horizontal groove is ignored by most. Behind the starting line, the best traction is an average wheelbase-length away from the staging beams. Of course, long wheelbase dragsters place their rear tires behind the point where most other drag racing cars launch. Differences in traction can occur from long wheelbase to short wheelbase cars as a result.

Walker said bald spots will occur at the common rear tire locations behind the starting line that often require touch-ups during the rounds.

Scraping

Rubber will build up, especially on the starting line. Scraping is done to remove that rubber. A propane torch is often used to heat the surface rubber, and hand scrapers lift the rubber away..

The shiny surface seen under the rear center and to the side of this dragster is surface treated pavement. Flat black tracks seen under the tires are from burnouts and launches from previous racecars that lay down an added coating of tire rubber on the surface.

Racing Slicks On The Track

Tire traction is best in a newer tire with a durometer hardness in the mid 30s. After the first use, the tire hardness will increase with age and the tire will have less traction. A racing slick will have a durometer over 40 after six months beyond its first usage and over 50 beyond a year of usage. As the tires get harder, traction is lower on any racetrack surface regardless of the preparation. We encountered a year-old set of slicks with only one prior run on them that measured over 50. The Pro Mod using these tires would not hook up on a well-prepared track surface.

A racing slick that is spinning during launch – turning hard to get-up-on-the-tire – may heat up to a surface temperature of well over 180-degrees Fahrenheit (optimum rubber tire surface temperature reported in some road racing circles) and result in reduced traction. Older tires have a traction failure temperature that is more sensitive. Racing slick age is all-important.

The hotter the surface, the hotter the starting point for the slicks. A cold track surface establishes a cold starting point for the racing slick surface temperature. Long burnouts on a cold track can be useless to heat up the tires. Tires cool down from rolling back over a long cold track surface when returning to the starting line.