You can’t win in drag racing if your vehicle isn’t consistent, so eliminating anything that can inhibit consistency should be considered a priority. One easy way to address this is through a robust maintenance program that covers every inch of your car, including the rod ends that are a part of the suspension. By establishing a maintenance program and knowing what to look for in worn parts you can remove suspension issues from the consistency equation.

It should be no surprise that a healthy racecar maintenance program starts in the offseason — this is when you can look the car over from bumper to bumper to see what needs to be serviced or replaced. Going through the suspension and looking at every joint will help set a baseline. Doing so lets you know going into the next season everything is functioning as it should and it will assist you in seeing when there is a problem after the season starts.

This is what the ball surface of a rod end that has been properly lubricated looks like that has metal on metal contact.

During the season you should have a preventative maintenance approach to the suspension and its joints. This is where you can catch issues in advance either through pre-race or post-race inspections. John McCrory from Aurora Bearing Company explains further what you need to look for when examining the suspension and its joints.

“You should check for play, especially taking note as to how they feel compared to the start of the season baseline. If they are PTFE lined, have they developed clearance? If they are metal-on-metal joints, make sure they are lubricated. Spraying with a rust preventative/moisture displacing spray is not lubricating them. A good, quality grease is needed. There are a lot of products that are appropriate. Every racer should have a can of quality wheel bearing grease — a grease with a high-pressure additive works well, especially synthetic greases.”

If you feel something is off with your car that might be its way of telling you there’s an issue. A simple check with the car on jackstands will let you know if there is an issue with the rod ends causing some type of binding problem. Catching an issue early could prevent a crash on the track due to a part failing in the suspension.

There are always the obvious signs of wear you need to look for on rod ends — stretching, bending, or wear in PTFE parts that need to be addressed immediately. There can also be additional play in parts that have metal-on-metal contact and a discolored surface; these are symptoms of lubrication issues in your rod ends.

Having rod ends that are serviced regularly are important to making sure a racecar's chassis performs as it should all the time.

“The bearing surface is getting hot under dynamics load due to increased friction and that can cause discoloration. If this continues, the part will start to gall or micro-weld the ball to the race. The ball surface then becomes rough. Often this is mistaken as abrasive wear from contaminants such as sand or grit getting between the ball and race. Actually, it is adhesive wear from the two surfaces welding together and breaking apart on a very small, micro level. If the ball is discolored, more lubrication is required to prevent the surface from degrading,” McCrory explains.

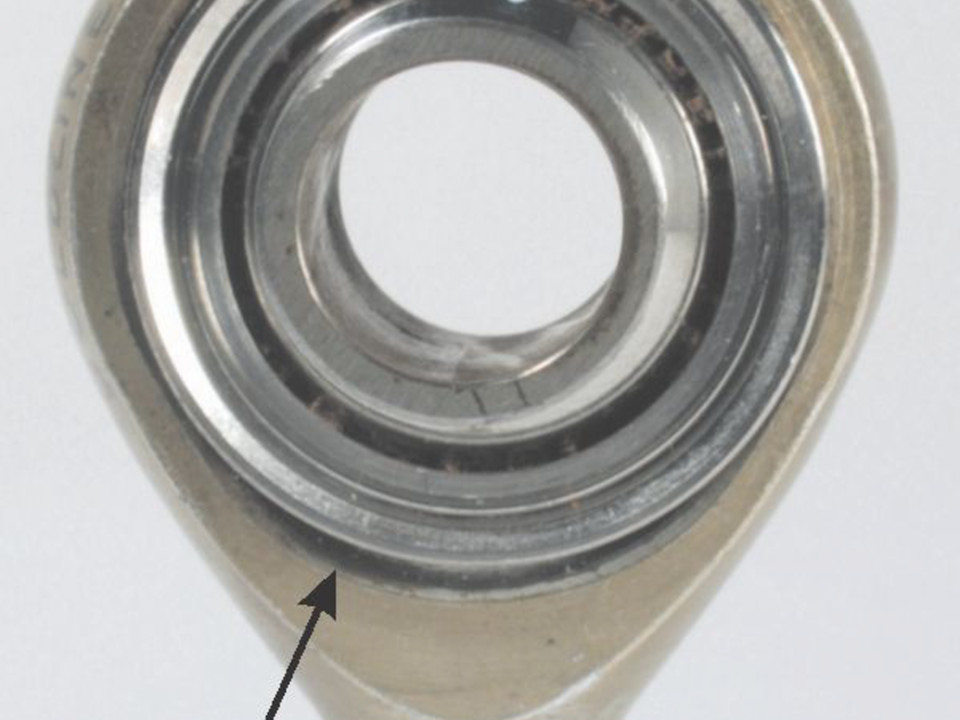

This rod end has experienced an overloading situation and has been stretched, You can see the arrow pointing to a gap between the bearing race and the rod end body.

Preventing wear issues with rod ends is fairly simple if you stay up to date on maintenance. Keeping metal-on-metal surfaces and bearings lubricated is vital for them to function correctly. By checking these joints often you can ensure they have the right amount of lubrication. For PTFE lined bearings you won’t need to lubricate them, just make sure they aren’t damaged.

Aurora Bearing has taken the time to ensure their rod ends are engineered to prevent basic wear issues via the materials they select and their manufacturing process.

“Aurora has a unique background and customer base, ranging from lawn and garden equipment to spacecraft applications. We have a full range of SAE AS approved products as well as approvals from major airframe manufacturers. The engineering expertise that allows us to build products to these demanding standards, as well as a quality system certified to ISO 9001 and AS 9100 results in the highest quality standard catalog items. In addition, we manufacture special products, engineered for specific motorsports applications,” McCrory says.

If you want to learn more about rod ends for your racecar check out the Aurora Bearing Company website right here.