Every racecar engine is built like a full symphony orchestra, but instead of being filled with groups of different musical instruments, it consists of metal engine parts. Just like an orchestra, though, the parts must all work in direct harmony, otherwise they will never create the amazing music, or the horsepower, they were intended to create. For our Evil 8.5 project engine, we chose Steve Morris Engines to be our symphony conductor to make all of our different parts belt out some wonderful horsepower music with our small-block Chevy powerplant.

Steve Morris is internationally known for building some of the stoutest turbo and blower engines in drag racing, that are used in everything from Pro Modified to radical street cars. Over the years, Morris’ customers have put up record performances at the track, and even won a few championships. One of the more notable boosted beasts that Morris created is Tom Bailey’s Drag Week Unlimited class-winning “Sick Seconds 2.0” Camaro that makes several thousand horsepower with a pair of massive turbos.

The ‘How’ And ‘Why’ Of Evil 8.5’s Engine

The objective for Morris on the Evil 8.5 build is to produce a motor that’s a max-effort piece, and can be as efficient as possible using the class-limited blower. When the motor is complete, the goal is to make around 1,800 to 2,000 horsepower on the dyno, while using the Vortech V-24 Xi supercharger to its full potential. For Morris, there was minimal challenge in the design process of the motor. “The engine isn’t an extremely elaborate piece, so it wasn’t hard to spec out. Outside of always making sure we had the correct camshaft profile which I design all of that myself there isn’t anything off-the-hook that’s presented any big problems or issues.”

With a limited blower build like this, you can build an engine that is too big, and too good – Steve MorrisThere are a few hurdles in play when it comes to putting an engine together for a project like this, but with his many years of experience, Morris is more than ready to tackle them.

“Typically, when I approach an engine build similar to this, I’m going to examine what the rules are for the class so I can start tailoring the engine around that. I look at what our limitations are for the class, what the car has to weigh, tire size, fuel type, and many other things. When it comes to this particular engine build, it’s restricted on what blower can be used, so it really limits how much air we can put into the motor,” Morris says.

To that point, every car is going to be different in how it handles the power you’re trying to put down. One of the biggest limitations of Evil 8.5 is the tire size, which impacted how Morris needed to approach where the motor brings power in. “Well, building a bunch of torque for an 8.5-inch tire car is just useless, because you have to take so much horsepower out of it just to get it to launch and make it through the first 100 feet,” Morris explains.

There’s a very delicate balancing act that must be struck when working on getting the selected blower to function with the motor combination, so too much power is not always a good thing. The limits of the classes that Evil 8.5 will be running in cause some careful thought to be applied into how the parts are selected.

With the 8.5-inch tire class Evil 8.5 will be running in, there are a few limiting factors that helped us to decide what parts would be used on the car. Brodix inline heads were selected because they’re an outstanding choice for boosted applications like this, which we will dive into more in a future article. Because the heads are an inline unit, Evil 8.5 will be allowed to take advantage of a weight-break in some classes.

With the limited blower moving too much air through the motor, issues will arise because it will drive up the parasitic losses to the point that it hurts how much power the engine can produce. Morris has a high level of experience with these types of builds and knows what to watch for when choosing parts for the project. “We’re always cautious of how much camshaft we put in a motor like this, and how many cubic inches it’s going to be. We also look at how much air that’s going to move through this motor before it runs that blower out of the map. It’s all about trying to match the blower and the engine size correctly,” Morris says.

The Block Foundation Of Evil 8.5

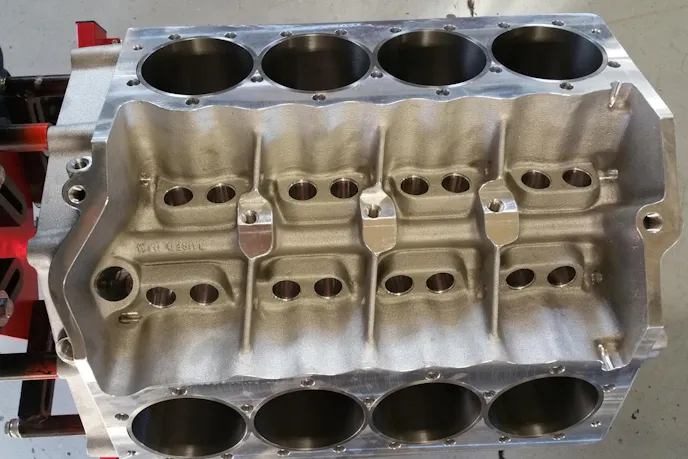

The engine block being used for this build is an aluminum Brodix SBC solid block, so no water will flow through it. This block features a 9.500-inch deck height with 400 mains, wider pan rails, 55 mm roller cam bearings that are raised .391-inches, and it’s set up for .937-inch Keyway roller lifters. Everything about this block screams strength, from the Hot Isostatic Pressure process that’s used to create it, to the strategic extra stiffening measures used throughout the block.

Making this block extra strong is something that Brodix was striving for when they introduced the product. According to Mark Fretz at Brodix, the HIP (Hot Isostatic Pressing) process plays an important role in the goal of producing a tough block that can take power-adder punishment. “With the HIP process, it compacts the metal to the point where it’s as strong as it can be for a cast block. It’s not as strong as billet, but it’s stronger than a standard cast block. This block is the best thing we have available for a blower, turbo, or nitrous engine,” Fretz explains.

The HIP process is also what makes this solid aluminum block such a great choice for a boosted application like Evil 8.5. “The HIP process removes the gasses out of the block casting. When you do that process and it removes anything trapped in the metal out, it compacts it to the point where it’s a more dense, solid, and stronger piece.

“Since this isn’t a billet block it’s not limited in certain classes and offers racers an option for an extremely strong block. With your standard cast block, when you get to a certain power level, you find the pressure limitations it can take. When we HIP the block, it really raises the strength level and helps bridge the gap between a standard cast block and a billet one,” Fretz says.

For this particular block, Morris and his team really didn’t need to do anything different in the machining process. For them, it’s all about taking their time, making sure everything is right, and triple checking the work. Since this motor is being built for a boosted application, Morris only had to adjust a few clearances during the process, so nothing majorly different than other builds.

![IMG_20160322_091304951[2]](https://speednik.imgix.net/2016/07/2016-08-07_00-07-27.jpeg?w=688&auto=format,compress&fm=webp) Morris goes into a bit of detail on just how they make sure the block is right from the start. “The first process is inspection and a little de-burr. Then we line-hone it to make sure it’s correct. Since the Brodix block doesn’t come line-honed, we had to take it to clearance size anyway. Then, we will rough bore and hone the block, followed by a mock-up assembly, and rotate it after that to see what kind of clearancing, if any, we have to do with the assembly. We will then do the O-ring and receiver groove, deck the block, put the O-rings in, and then the final bore and hone is done.

Morris goes into a bit of detail on just how they make sure the block is right from the start. “The first process is inspection and a little de-burr. Then we line-hone it to make sure it’s correct. Since the Brodix block doesn’t come line-honed, we had to take it to clearance size anyway. Then, we will rough bore and hone the block, followed by a mock-up assembly, and rotate it after that to see what kind of clearancing, if any, we have to do with the assembly. We will then do the O-ring and receiver groove, deck the block, put the O-rings in, and then the final bore and hone is done.

“We then go to the lifter side of things. Since it’s Keyway-style, we had to fabricate a tool to make sure we installed them correctly. After that’s done, we do another mock-up assembly where we’ll add the camshaft to be sure everything clears for it, check for valve-to-piston clearance, and then check for pushrod clearance issues,” Morris explains.

The Rotating Assembly

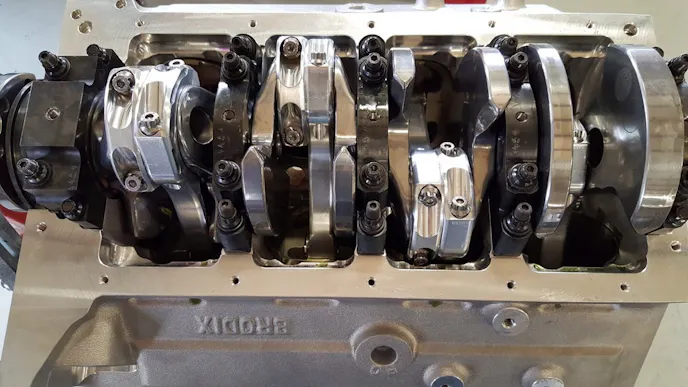

Rotating inside the Morris-massaged block is a billet 4.000-inch stroke Bryant crankshaft that uses 2.100-inch rod and 2.650-inch Clevite main bearings. Minimal work needed to be done to the crank by Morris just a simple balancing job and it was ready for assembly.

Short Block Build Parts

- Cylinder Block: Brodix 9.500-inch deck-height solid aluminum block

- Machining and assembly: Steve Morris Engines

- Crankshaft: Bryant Racing

- Balancing: Steve Morris Engines

- Connecting rods: GRP 6.200 long w/ 1.200 width at pin

- Pistons: Diamond 4.125 bore

- Piston pins: Trend DLC-coated pins

- Piston rings: Total Seal 1/16, 1/16, 3/16 M2 w/13-lb oil ring for 4.125 bore

- Bearings: Clevite

- Camshaft: Custom grind

- Lifters: Isky Keyway .937 Lifters

- Belt drive: CV Products Elite Timing Belt Drive System

- Fasteners: ARP

- Oil pan: Moroso Dry Sump Pan

- Oil pump: Moroso Dry Sump Pump – 6 stage Tri-Lobe

- Damper: ATI Balancer

- Head gasket: SCE Copper Head Gaskets, .072 thick

This crank was selected specifically for the build based on its strength, quality, and design by Morris. There’s solid reasoning for going with a heavier rotating assembly, as he shares.

“Every quality built boosted engine is going to have a heavier rotating assembly than a naturally aspirated motor; that’s just normal in order to keep parts alive. I tell my customers making power isn’t the problem. Making the engine live is the bigger issue. This one is a bit different because of the limited power-adder build, so we have to be sure it’s still making maximum horsepower, but we still have to be sure it lives.”

Rotating on the Bryant crank is a set of billet aluminum 6.200-inch GRP connecting rods. The rods have a 2.100-inch journal, 1.200-inch pin width, and received the L-19 7/16-inch capscrew upgrade. These connecting rods were the best choice in Morris’ eyes because of their strength, and potential for longevity.

“For a boosted application like this, we generally look for something that has some beef, instead of going with a lightweight connecting rod. I’m really looking for something that lasts, and will use the best bolts I can. If they offer an upgraded material, I will go with that just to add to the strength for the boosted applications.”

Finishing the rotating assembly out is a set of 10.42:1 compression pistons from Diamond Racing that have a 4.125-inch bore. The pistons received an extremely durable hard-anodized coating that Morris is a big fan of, because it helps the piston’s strength and longevity. “We use the hard-anodized coating because that’s what I’ve been using for a while and it works well for a boosted application. It’s super-durable and very tough, and that makes it really last under these harsh boosted conditions. Its more than a coating, it’s a heat treat process that doesn’t just wash off or wear off under use, it becomes part of the piston,” Morris explains about the anodizing process. A set of Trend’s .927-inch wrist pins got the nod to help secure the slugs, and they also were coated to match the pistons.

“The factory design from Diamond on these pistons is what made them the best for this boosted application. This one is pretty basic and simple because to give it the compression ratio we wanted using a slight conical dish, I like that the best. We really didn’t need to do specific gas porting or anything like that on these pistons, and we don’t really recommend it. Since it’s not a maximum effort N/A motor, none of those types of tricks are needed to make them work. The quality piston manufactures like Diamond all use good materials and that aids in the design and longevity of these pistons for a boosted application like this,” Morris explains.

For the rings, a set of Total Seal M2 1/16, 1/16, 3/16-inch units with a 13 pound oil ring are used to seal the 4.125-inch bore. “We went with these for their durability and best seal possible. The second ring is a Napier, which is for better oil scraping in the cylinder. We can still use a standard-style ring with standard tension as well with this setup. These are used to again help with keeping the engine alive and deal with the abuse it gets put through in a boosted application like this,” Morris says.

A Top End Full Of Excellence

The top end of the Brodix-based Evil 8.5 engine is where Morris is able to really start to squeeze the extra horsepower out of the blown small-block mill. Sitting on top of the block is another product from Brodix. These aluminum monsters are capable of flowing tons of air, but that was just not enough for this build. The heads were sent to Chris Frank at Frankenstein Racing Heads to have their flow potential truly maximized. Since these heads are an aftermarket item, Moroso stepped up to provide a killer pair of sheet metal valve covers. The valve covers feature an extended height to clear the rockers, a precision machined billet rail for great sealing to the heads that will allow for better vacuum, and they are very lightweight.

“The cylinder heads are really good. I could almost worry about them being a little too good since we are limited on the blower. It’s always just trying to get the motor to work with the blower as best as possible. That’s where the extra horsepower comes in. We can easily with the wrong camshaft profile make a bunch of top end horsepower, but nothing on the bottom, then it won’t go down the track fast or vice versa. There’s a little bit of balancing we need to do there, but it all comes down to the combination of what it does with that blower,” Morris explains.

Cylinder Heads And Induction

- Cylinder heads: Brodix

- CNC machining & port design: Frankenstein Racing Heads

- Valves: Manley Titanium 2.225 intake, 1.625 exhaust

- Valve springs: Manley

- Valve retainers: Manley

- Shaft rockers: Jesel. 1.8:1 ratio

- Pushrods: Trend Performance 7/16 .165 wall

- Valve covers: Moroso

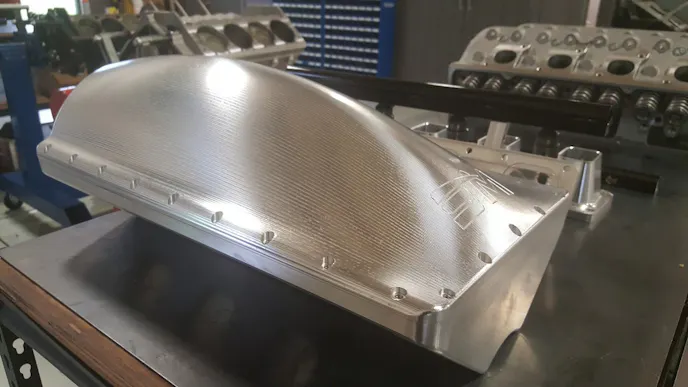

- Intake manifold: Steve Morris Engines custom intake

- Throttle body: Wilson 105mm

- Fuel injectors: Billet Atomizer, 225-pound

A key part to the horsepower symphony that Morris is trying to create with this limited blower build is the valvetrain — specifically, the camshaft. This isn’t the kind of build where a simple off-the-shelf cam will do, and with the block’s specific requirements for cam size, a custom bump stick is the only way to go. The initial cam will feature a 279/293 duration at .050 and .779/793- inch lift with a 115 LSA.

This will be just a start for Morris, as he knows that after the engine hits the dyno, changes will need to be made. “I’ve been doing builds with these centrifugal blowers for a while, so I understand where things need to be changed and applied differently.

The major thing is that if the camshaft is too big with tons of overlap, it will send boost right out of the exhaust pipe. That will drive up the parasitic drive loss on the blower, so it will lay over at the higher RPM and not make any power. So the more air you have going through the blower, the more power it takes to move the blower, so it’s not worth trying to move that much more air on a limited blower build like this,” Morris explains.

There’s a lot of thought and theory put into a limited blower application like this by Morris. Because the Evil 8.5 engine is so good, it requires a special level of tailoring in the camshaft department to ensure it will work properly.

“Looking at this application, we can’t put as large of a camshaft in it since it’s a limited-blower motor. You can only spin the blower so fast to move so much air, and the motor will use up all that air the blower can supply based on the cam. You want the cam to maximize the efficiency of the combination and keep the power in an RPM range where it works well.

If this motor had the wrong camshaft, one that was too large, what it would do is it would make more horsepower and torque at a lower rpm, let’s say 6,000. It would peak at that rpm level still making the same amount of boost. What would happen then is the horsepower would start going backwards, because at that point it’s taking more parasitic drive loss to drive the blower than it’s moving air to generate horsepower,” Morris says.

Working with the Steve Morris Engines custom camshaft is a set of hardened Trend Performance 7/16 .165 wall pushrods. The selection of the correctly sized push rod is critical to help keep the rest of the valvetrain happy and doing its job. “I will try to put the biggest pushrod that I can into something, because it comes down to size for the durability and it keeps the dynamics stable. The bigger pushrod keeps things from bending and flexing. We don’t want that thing flexing around because anything that happens to the pushrod will get transmitted to the valve, and bad things happen when the valve is out of control,” Morris says.

The bigger pushrod keeps things from bending and flexing. We don’t want that thing flexing around because anything that happens to the pushrod will get transmitted to the valve. – Steve MorrisSince this motor would be seeing some pretty high stress levels with the power and boost it will be making, the lifter selection was important. The block was machined for a set of Isky EZ Roll .937-inch Keyway lifters and CHE bushings by Morris. Lifters like these are a new take on the bushing style by Isky that we have covered in a previous article. These particular lifters are preferred by Morris because of their strength and durability properties for boosted applications like this. “We really wanted to go with a good quality lifter, so we used the keyway Isky lifter — they’re nearly bulletproof. You want to go with a strong lifter for a boosted build like this, because broken lifters aren’t a good thing they’ll cause a ton of damage,” Morris explains.

Having such a lifter that can take serious abuse will help the valvetrain live a lot longer. According to Nolan Jamora from Isky Cams, these lifters are designed to be the best available on the market. “These lifters are very strong units. They last four to five times longer and they can take up to 1,600 pounds of open valvespring pressure with a boosted application.”

The lifters were designed to take on cams with very aggressive profiles and not deform like other lifters could under extreme conditions. It allows an engine builder like Morris to go with a big camshaft knowing it will be used correctly. “With this lifter, you don’t get any of that deforming it rides the cam profile exactly as it was designed. Your cam profile stays the same up the ramp there’s no little bounce there that you can see at all when another lifter might start to deform,” Jomora says.

This type of accuracy from the lifter and maximization of the cam profile is important for peak power creation. “It really helps in a boosted application like this and adds performance, because the lifters follow the cam profile exactly how it was designed and will produce more power,” Jomora explains.

The rest of the valvetrain and cylinder head information was covered in more detail during our previous article about the high-flowing Brodix heads that were massaged by Frankenstein Racing Heads. The heads come as a bare casting, so they require some extra port work to fit the need of a particular application. The heads received all the best goodies from the Manley catalog, including a set of titanium intake and exhaust valves. To help control the valves, Manley’s Nextek lightweight dual valvesprings were added to the valvetrain. Finalizing everything on the heads are the Jesel 1.8:1 rocker arms that use full bodies, needle-bearings, and steel ball adjusters, all in the name of strength.

The intake manifold that will sit on top of the Evil 8.5 mill will be one of Morris’ own billet creations that will work with a 105mm Wilson Manifolds throttle body. Feeding the fuel into the intake will be a set of Billet Atomizer 225 pound injectors. Based on what he has done with previous motors and intakes, this particular design should do well on the Brodix-based engine.

“We take into account the line of sight of the runner, capturing the correct length of the runner, the right taper in the runner, and make sure it has enough plenum volume that it never runs out of air. The runner length and the manifold plenum shape are also examined in order to keep air from stacking up in the back of the intake manifold, and changing the cylinder trims front to rear,” Morris explains. “We will be doing a more detailed article on the design and creation of Evil 8.5’s billet intake in the coming months.

Lubrication, Boost, And More

Keeping everything lubricated will be a stout dry sump oiling system from Moroso. The six-stage tri-lobe dry sump pump was chosen because of its ability to move large volumes of oil with ease. The aluminum tri-lobe unit has scavenge sections that have their own timing gears inside. These gears will make sure that the correct clearances are kept in the higher rpm rage. The Moroso unit has springs that are available in various rates to provide the best oil pressure and give reliable pressure readings that don’t jump around under any load. The larger -16 AN fittings for the scavenge outlets will provide options for extra flow back into the Moroso tank.

Morris goes into a bit more detail on why he prefers this unit so much. “Whenever possible, we’re going to go with the Moroso dry sump system because it’s so bulletproof. This unit really can get the oil out of a pan and into the tank in a hurry. For an application like this, the windage is really not an issue since it’s a boosted application. I would rather be moving as much oil as possible with a big enough oil pump, even if it cost a little bit of power. It’s better to error on moving too much rather than not enough.”

The tri-lobe pump will be pulling oil from the tank included in the system in conjunction with the Moroso dry sump pan on the bottom of the Brodix block. For this particular application, a custom pan was provided that was plumbed with the required bungs to work with our dry sump system by Moroso. This pan will also allow the motor to sit lower in the chassis and help with weight transfer when Evil 8.5 roars to life.

The Moroso dry sump system will be pumping Driven XP9 synthetic oil into the Evil 8.5’s small-block Chevy heart at the track. The XP9 formula has several advantages over other oils that come into play in a boosted engine like the one Morris has built. Using a special formula, the XP9 oil provides a much better high-temperature and shear protection. These features help keep the XP9 oil as close as possible to its stated viscosity while maintaining a solid bearing-oil thickness in place. Another advantage to the XP9 fuel is that it will allow Evil 8.5 to run on high octane fuels without experiencing high levels of break-down or contamination.

Speaking of fuel, to help the engine in Evil 8.5 make as much power as possible, we will be feeding it a steady diet of VP Racing Fuels Q16. Using a quality oxygenated fuel like Q16 will help boost the performance of the engine and improve the power output significantly over other fuels. Because Q16 has the additional air in it, we will be adding more fuel volume to the engine to avoid any serious lean conditions that might occur.

Boosted applications that use centrifugal blowers like the Vortech unit on Evil 8.5 can do strange things with the harmonics of the motor. To help counteract those issues, a CV Products XTS Elite Timing Belt Drive System is being used to ensure everything spins correctly. The XTS Elite unit uses a billet back cover that bolts directly to the block and requires no machine work, and has an O-ring seal that helps to eliminate oil leaks at the block. The cam hub/seal plate assembly of the XTS Elite has exact control over the end-play of the camshaft for reduced timing deviation. This also extends the life of the cam and lifters because there is less unwanted movement in the system.

Spinning the Vortech V-24 Xi blower will be a CDS 2.15 ratio gear drive from Chris Alston’s Chassisworks. The advantage to using this type of drive unit for a blower over a typical belt drive is the crankshaft won’t be subjected to a side-load that could cause issues at higher horsepower levels. Another advantage of going with a gear drive unit is that it will eliminate possible belt breakage issues, and add to the overall strength of the system.

Finishing Touches

Assembly And Specifications

- Bore x stroke: 4.125 x 4.00

- Displacement: 427 cubic-inches

- Main torque: 85 ft-lb

- Rod torque: 90 ft-lb

- Head torque: 105 ft-lb

- Main bearing clearance: .0035-inch

- Rod bearing clearance: .003-inch

- Piston-to-wall clearance: .008-inch

- Valve spring pressure: 350 lb seat

- Camshaft duration @ .050: 279/293

- Lobe centers: 116

Final assembly for the heart of Evil 8.5 went smoothly overall for Morris and his team. “For this motor, the short-block went together pretty well. The pushrods proved to be a challenge and required a bit more work, but outside of that, there were no issues. It’s not a crazy build so nothing really different needed done,” Morris says.

During the final assembly process, Morris used his typical procedure that includes the finish machining, mock up assembly, clearancing, final cleaning, and assembly. After everything is put together they will then do a leak check, followed by a pressure check. As a part of the final assembly, special attention was paid to the head gaskets since this is a boosted build.

“The head gaskets are the primary concern, of course, so we have a one piece ring that we make. The compression ring is something that we machine into the top of the block and then add the receiver groove into the cylinder head. We used .072-inch thick SCE copper head gaskets to make sure everything sealed up correctly,” Morris says.

Steve Morris Engines took great care in all areas of building the motor for our project Evil 8.5 Mustang. Years of experience has shown Morris that using quality parts for strength in a boosted application help the longevity of the build, and eliminate downtime due to parts failure. Now that Morris has assembled the long-block of go-fast parts for Evil 8.5, the next step will be to see what kind of music the orchestra will create.

In our upcoming article, we will focus on the details of the Vortech blower, fuel system, and the dyno testing of the engine to see what kind of power Evil 8.5 cranked out.

You might also like

Horsepower Wars C10 Shootout: It’s Coming Down to the Wire (Ep 5)

Watching each C10 come together and their initial testing should serve as a nice appetizer for the upcoming main event – race day!