In a boosted engine application, as boost pressure increases, so does the heat generated by compressing the air charge. If you get the incoming air charge too hot, you not only lose engine performance and power, but you also risk detonation and engine damage. Thus, there are ways of cooling that incoming air charge, three in particular, each with their own advantages and disadvantages.

Two of these methods involve intercoolers, either air-to-air or air-to-water. But there is also chemical intercooling and while it’s not a new concept by any means, it has become more popular in recent years, thanks in large part to advancements made by the team at Snow Performance.

Two of these methods involve intercoolers, either air-to-air or air-to-water. But there is also chemical intercooling and while it’s not a new concept by any means, it has become more popular in recent years, thanks in large part to advancements made by the team at Snow Performance.

Going Chemical

Chemical intercooling, if you’re unaware, is the process of injecting a mixture of water and methanol into the intake charge (Snow makes their own blend called Boost Juice). Due to the high latent heat vaporization of methanol and water’s ability to dissipate heat, this mixture has a cooling affect on the incoming air charge. Water/methanol intercooling also boosts the octane level of the incoming air-fuel charge.

With no room for an intercooler and wanting additional octane while running 91 octane pump gas, we turned to Snow Performance and their Stage 3 water/meth system.

Left: We're using the Snow Performance 2.5 gallon reservoir upgrade to ensure we don't run out of Boost Juice driving to and from the track. The reservoir needs to be installed as the second highest object in the system. Right: When the reservoir must be mounted higher than the nozzle, Snow offers a solution in the form of a solenoid upgrade, which was necessary in our case. We installed our reservoir in the trunk using the supplied hardware.

The beauty of the stage 3 is that you can control it from the driver’s seat. The controller itself will show you boost, fuel injector pulse width as well as water/meth injection. – Matt Snow

Another added benefit according to Snow Performance is that the vaporized and steaming water will help remove carbon deposits from valves, combustion chambers and the tops of pistons.

Chemical intercooling results in being able to run more aggressive air/fuel ratios and more aggressive timing curves. When paired with proper tuning it can result in substantial horsepower gains. It can also be run in conjunction with another type of intercooling for greater efficiency.

Another key and distinct advantage to the Snow Performance system is that it is also amazingly simple to install and set up. There’s no removing bumpers or routing of additional air inlet tubing, decreasing engine compartment clutter and increasing available space to work or add other needed components, simplifying trouble shooting, and in many cases reducing weight (if used as the sole form of boost cooling).

The pump provided in all Snow Performance kits is typically overkill for the application, meaning owners won’t wear it out by over-running it. This pusher style pump can be mounted in any position, vertical or horizontal, as long as it is lower than the reservoir so it can easily be gravity-fed a steady supply of boost juice.

Installing the System

Additional Parts

We’re also upgrading our Stage 3 system for peace of mind, and for it to work properly on the car. This kit includes:

- Safe Injection Module, part number 30020

- Dual Nozzle Upgrade, part number 40040

- 2.5 Gallon Reservoir, part number 40014

- Shut Off Solenoid Upgrade, part number 40060

We’re installing a Snow Performance Stage 3 Boost Cooler kit, Part No. 20100 on our ’65 Mustang, Project Biting the Bullitt. Our supercharged engine combination is already making 875 horsepower (690 hp to the wheels), and with the addition of the Snow Stage 3 system, we expect to see more.

The Stage 3 kit comes with everything needed for installation. If you’re a DIY’er then you can do this job with a drill, razor blade, wiring tools and some basic hand tools.

The push-lock style fittings in the system mean that it’s critical to cut the lines with a razor blade as evenly or square as possible with a uniform edge, however, they also allow for easy installation of the lines.

Another convenient feature of this type of system is that if a line end should become damaged due to frequent connection and disconnection, a small section of it can be cut from the end to get a clean fitment, reducing or eliminating the need to replace hoses.

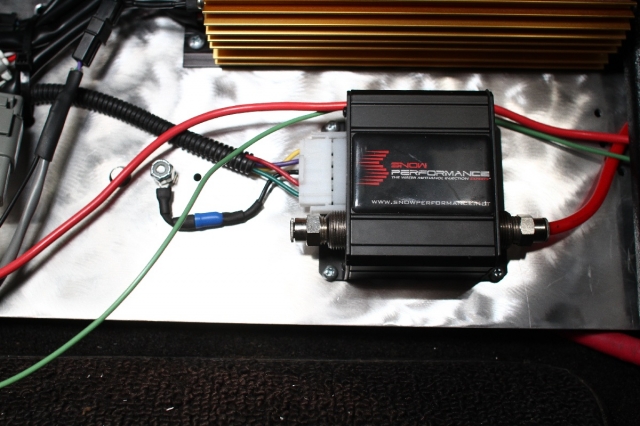

We mounted our Safe Injection module next to our MSD ignition box, and our Racepak Smartwire. Acting as a failsafe device, the Safe Injection module will trigger the Smartwire which in turn triggers the MSD system to retard timing.

Reservoir and Solenoid Upgrade

We’re using Snow’s 2.5 gallon reservoir to ensure we can make the drive to the track, spend the day ripping off passes, and then drive home, without the need to carry extra Boost Juice with us.

The solenoid upgrade prevents the system from gravity or vacuum feeding when there is no demand for it to run by shutting off the flow of Boost Juice. When the on-board controller determines it’s time to run the pump and inject more Boost Juice the solenoid is also activated to allow the liquid to flow freely. We wired the solenoid in-line with the pump to ensure it activates whenever the pump is triggered.

Left: Because our engine makes over 850 horsepower, we're using the dual nozzle upgrade. The T-fitting is installed to split the flow of Boost Juice between the two 600 ml nozzles and is fed directly from the pump. Center: We mounted one nozzle ahead of the supercharger inlet to help cool the supercharger. Right: Our second nozzle is mounted between the supercharger and the carburetor -- running dual nozzles in this manner maximizes the cooling effect and we might add a third as we turn up the power.

Dual Nozzles

You can stagger the onset of flow through nozzles with an optional second solenoid, so you can run a small nozzle initially and then bring on the bigger nozzle to finish it out. – Matt Snow

The Stage 3 kit we’re installing is set up to run just one nozzle, however in higher output applications such as ours, a second nozzle may be needed to get the full benefit of water/methanol injection. The dual nozzle kit is essentially a pair of nozzles, a T-fitting and the necessary line to plumb them. According to Snow, “One nozzle will typically get you to about 650 horsepower and will flow enough to manage detonation.” Since we’re already passed that horsepower threshold, we needed more than one nozzle.

“You can stagger the onset of flow through nozzles with an optional second solenoid, so you can run a small nozzle initially and then bring on the bigger nozzle to finish it out,” Snow explains.

Much like choosing the correct jets or injector size to match an engine’s output in a fuel system, nozzle size must also be matched to the engine output. This in turn dictates how much heat will be removed from the incoming air charge. Snow includes information on this in their provided instructions.

Safe Injection

The Snow Safe Injection Module monitors the flow of the Boost Juice if it detects lower flow than what the user specifies. The module then can trigger any number of devices to act as failsafes. We’ve wired it to signal our RacePack SmartWire, and when triggered our MSD 7531 ignition system will retard timing.

The Safe Injection is easily tuned by using the dials on the side of the unit. The minimal flow can be set tailored to a specific engine’s output. This setting is adjustable in 100 ml increments from 100-600 ml. There is also a delay setting, which will ensure during initial ramp-up of the system that it doesn’t shut down before things ever get going. Since there can be reduced flow at lower demands, the delay must be fine-tuned to give the injection system time to activate and achieve proper flow.

Snow says, “The Safe Injection we feel is mandatory for anybody who puts increased timing and boost into an expensive engine. What the Safe Injection allows you to do is run with confidence. You can run increased boost and timing with confidence in your water/methanol system. Total timing advance as much as 36 degrees in some cases.”

Under Control

The Stage 3 controller is the brains behind the whole operation. This unit is capable of monitoring boost pressure, fuel injector duty cycle (on injected applications), as well as Boost Juice reservoir level. The system is easily programmed and tuned to maximize performance. Wiring the unit is a fairly simple operation, and the clear tube must be connected to a boost source so the system operates properly.

“The beauty of the Stage 3 is that you can control it from the driver’s seat. The controller itself will show you boost, fuel injector pulse width as well as water/meth injection,” says Snow Performance president, Matt Snow.

Top Left: We mounted our Stage 3 controller to the steering column. Not only does it control the system but it also displays boost level and information about the water/methanol injection. Top Right: Since our engine uses a carburetor we set the system up to be triggered by boost. Injector Duty Cycle is the preferred method on EFI engines. Bottom Left: Using the push buttons on the boost controller, we set the boost minimum at 6 psi. This is where the system will begin injecting the water/methanol Boost Juice mix. Bottom Right: We have determined our engine's maximum boost is 10.5 psi, though we set the maximum at 13 psi to deliver a little less than 100% amount under full boost.

There are a few things to keep in mind when performing the initial setup on the Snow Stage 3 system. The system works on a duty cycle principle in which it ramps up performance as boost increases, thereby keeping up with the heat output of the supercharger’s compressed air.

- Injector Pulse width is preferred as the trigger over boost on high-powered EFI engines

- The Boost Start should be set at a psi that’s greater than what’s seen in normal part-throttle cruising

- Maximum boost should be set to the maximum boost pressure the engine sees so the system knows when to operate at maximum

Performance

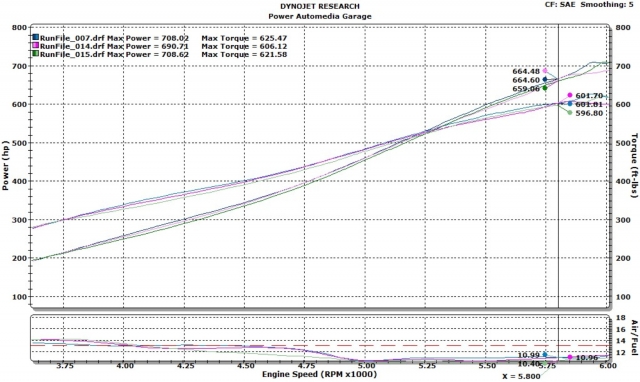

We put project Biting The Bullitt back on the dyno with everything hooked up. With no additional tuning other than our initial setup we saw a gain of 17.3 hp, going from 690.7 at the rear wheels to 708.0 hp, and we also saw a gain of 19.3 ft-lbs of torque over our previous run, jumping from 606.1 ft-lbs to 625.4 ft-lbs, during our dyno pulls. With the water/meth set at 16 psi full, there is virtually no effect on air/fuel ratios versus with the water/meth completely shut off. This means the spray is mostly being absorbed before it gets to the cylinder. By introducing more spray down low, it’s adding about .5 an air/fuel ratio point and thus adding more octane. At 16-17 psi of boost, this motor will consume all the water/meth before it hits the engine, so adding the extra nozzle we can add some octane back into the motor and pull a little bit of the jet off the carburetor.

Run file 007 is our numbers with the water/meth turned on, run file 14 is off, then 15 is back on again. You can see from the graph how consistent our ’65 Mustang is.

Another being difference is the intake air temperatures (IAT) that are monitored in the back of the carburetor’s hat. Our Racepak UDX displayed a max value 119 degrees after a pull and 142 degrees with it shut off. This means that the water/meth is pulling 23 degrees of heat out of the air. When running the Mustang at the track, IATs averaged about 138 degrees at the end of the run. For a non-intercooled car that’s pretty darn impressive.

We suspect we could advance the timing and gain a bit more, but for now we’re going to play things safe and keep the combination just the way it is. It’s nice to know that the Snow Performance water/methanol system is adding one more safeguard to our engine and will allow us additional tuning options as our project progresses.