When making a lot of power, the rear suspension of a vehicle shouldn’t be a place to cheap out. Not only do you need a suspension that is designed to plant (and not blow up) the engine’s power to the tires, you also need a tire with a wide enough foot print to transmit that power to the pavement.

Our 1965 Mustang project “Biting the Bullitt” recently had a complete TCI Engineering Custom IFS front suspension installed to make way for our Dart 427ci behemoth that pumps out over 1000 hp and 875 lb/ft of neck-snapping torque. But not to worry, we have no intention on trying to put that much power through the stock 7.5-inch rear end!

Much like the front suspension, the rear was going to need a complete overhaul if we wanted to make the Mustang hook. Enlisting the help from Strange, Calvert, Wilwood, Autoworks, Mickey Thompson and Weld, we built a simple yet effective rear suspension that will handle all the power we can throw at it.

As any first generation Mustang owner knows, it’s damn near impossible to put a large enough tire in the stock wheel houses without diverting away from the stock leaf spring geometry, or doing some outter fender work. Trying to keep this project as simple as possible, going to a link-type rear suspension was going to be out of the question.

But the suspension was only going to be half the battle in this war for traction. The stock wheel houses in the Mustang are not very wide and have a very sharp bend, inhibiting a tall tire from fitting without the stance of a 1960s Gasser. We wanted to fit up to a 28×10.5-inch tire on the Mustang so mini tubs were a requirement for this project.

Autoworks Mini Tubs

The stock tubs have a very sharp taper and additional metal must be added to their width to do a 'poor man's' mini tub kit. The Autoworks tubs allow for better tire clearance and are built at the proper width.

Just getting the stock suspension out was a chore. The bolt and sleeve on the front mounts were ceased up so bad that we actually had to cut the old leaf springs, and then dissect the mount like a science project to get everything free. After we drilled out the spot welds that hold the trunk hinges onto the stock inner wheel houses, we busted out our Cornwell plasma cutter and sliced through the sheet metal like butter...and with minimal fires.

After a few trial fitments and some clean up, the Autoworks tubs fit snug as a bug. The inner sheet metal lines up with the factory stop, though we cut it out for more clearance. Having this flat sheet of metal on the frame rail really allows us to properly weld the tubs to the old outer houses. Installation isn't overly complex, it's really about slowly cutting back the inner houses to get to a point in which everything lines up perfectly. The trunk hinges will need to be cut down slightly due to the taller wheel houses and some sealer is a good idea to keep the trunk area dry.

Next, were the inherent limitations of the stock leaf spring placement. We could do full tubs in the Mustang but without relocating the leaf springs, it was going to be a waste. We initially started with a Money Maker Racing relocation kit that is pieced together from early Mopar parts, though after test fitting the kit on the car, we decided to only use half of the kit.

It comes with one inch offset shackles that are paired up to forward mounts with four through-floor studs. While the offset shackles worked perfectly, the forward spring mounts are recommended to be installed just inside the frame rail. This would put the forward mount at a three inch offset in relation to the rear shackle.

Wanting to have a completely straight leaf spring, we opted for a new pair of forward weldable mounts that were moved in one inch from stock. They are much more durable than the stock two piece formed mounts.

Wanting to have a completely straight leaf spring, we opted for a new pair of forward weldable mounts that were moved in one inch from stock. This movement not only allowed us to safely clear a 275/60/15 or 28×10.5 tire, it also eliminated the two piece spot welded mount and replaced it with a thicker, single piece formed mount from AFCO.

Strange Custom 9-inch Rear End

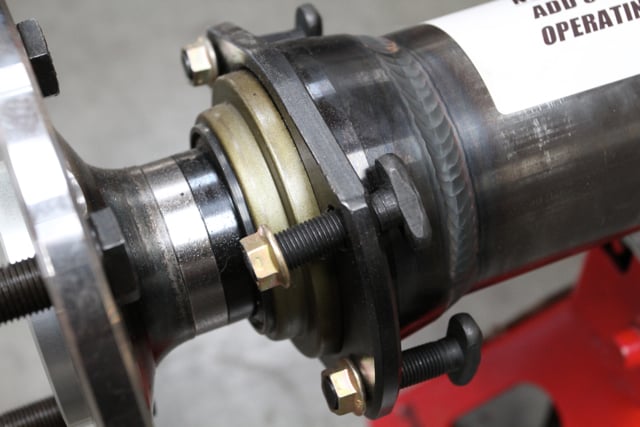

With our rear spring debacle squared away, we moved onto building our Strange Engineering 9-inch rear end. We opted to shorten the rear end with by one inch, which is the most we could remove to properly fit our Wilwood rear brake kit.

The rear end starts as their H1115 9-inch housing that is slotted for full tube engagement and has reinforced face plate for superb housing rigidity. The nodular iron case boasts chromemoly bearing caps retain by socket head cap screws that exceed aircraft grade 8 specifications as well as steel adjuster nuts. “The aluminum case is 20 pounds lighter, though we typically don’t recommend them on cars over 2600 pounds,” said J.C. Cascio of Strange. “The reason is that with a heavier car, the case is more prone to deflect, and with that deflection the gear pattern shifts; that can lead to premature gear wear and failure.” In case you didn’t know, Strange machined all of the SVO 9-inch cases for Ford during their production run.

The Strange rear end is all about strength and it will be the least of our worries when it comes to parts breakage on a high horsepower application like ours.

Filling the case is none other than a 35 spline Detroit Locker differential. While most people would go with a spool when making this much horsepower, we stuck with the “Bitting the Bullitt” mantra and went with a differential for better street driveability. The Eaton Detroit Locker is designed to deliver 100% of the torque to both drive wheels while still allowing wheel speed differentiation to maximize traction between the wheels and around the corners.

Mated to the Detroit Locker is a Motive Gear 3.70:1 ring and pinion set. The front of the case is sealed off with a Daytona style taper bearing support that features a larger than stock rear pinion bearing. Due to the oil porting this support provides the best solution for street/strip users who are seeking an increase in strength over stock pinion supports. “It has the same oiling capacity as the cast iron pieces we sell, but the forged aluminum body is more rigid, and will give you less deflection at the pinion bearing,” said Cascio.

Strange's S Series axles are designed for a street car because they have the ability to flex, unlike their Pro Series axles that are completely hardened.

Induction hardening is a type of heat treatment that hardens the case of the shaft while the the core remains soft to allow for a bit of bending during street use without snapping.

A pair of Strange S Series CNC machined 35 spline axles make the connection from the differential to the wheels. With years of testing experience behind them, Strange has engineered a modified version of 1550 steel that is then induction hardened. The process of induction hardening is where the axle is pulled through an electrical coil where it is heated and quenched. This type of heat treatment is ideal for hardening the case of the shaft while the the core remains soft to allow for a bit of bending during street use without snapping, and since we are going to be driving this car on the street a lot, the S Series axles were the perfect choice. “On the 35 spline S Series axle we recommend up to about 1000 HP before one might want to consider going to a race series axle,” recommends Cascio.

Strange Engineering Custom 9-inch Street/Strip Rear End

• H1115 9-inch housing with tubes and big Ford housing ends

• 35 Spline Detroit Locker differential

• 3.70:1 gear ratio

• S Series 35 spline axles

• Nodular iron case

• Upgraded Daytona style billet pinion support

Calvert Suspension Components

If you are a leaf spring drag racer and you have never heard of Calvert Racing, then you have been living a sheltered life. They are renowned for building everything from traction bars to leaf springs and we had to get, well…all of it. Virtually everything Calvert makes, we have equipped on the rear end of our ’65 Mustang project.

It starts with Calvert’s HD spring perches that we purposely left off during the rear end manufacturing process so we could properly locate them on our adjusted spring location. While a spring perch doesn’t seem to be a complex piece, it does come tabbed for optimal welding penetration, gusseted for added strength, and extends to the center of the axle tube for added contact surface.

The spring perches were purposely left off during the rear end manufacturing process so we could properly locate them to our adjusted spring location. The Calvert HD mounts cover 50% of the axle tubes for the highest strength possible.

Multi-leafs are designed to give progressive dampening when driving and while this is fine and dandy for a daily driver or road course racer, going to a single rate split mono leaf was going to be much more desirable from a weight savings perspective. Also with a split mono leaf one can expect more repeatable launches pass after pass. Calvert offers these springs in 220-225 pounds and a variety of heights.

Calvert’s most well-known product by far are their CalTracs traction bars. Think about the dynamics of a leaf spring; as the tires try to grab for traction, the leaf springs begin to curl upwards in an S-shape, lifting the axle off the ground and instantly causing traction problems. The tire turns into a basketball and that dreaded feel of wheel hop leaves the rear suspension and driveshaft begging for mercy.

Calvert's CalTrac bars keep the leaf springs from coiling during launch, which can lead to a dramatic traction loss. The split mono leaf shocks weigh nearly half that of a traditional multi-leaf.

The CalTracs are simple in design but work to keep the spring from wrapping under hard acceleration. It replaces the lower shock mount, connecting with a threaded piece of tubing that finally mounts to the lower leaf spring mounts. Not only does this triangulate the leaf spring to reduce wrap, but as the leaf spring begins to move upward, the forward mounting brackets also limit the leaf spring upward movement. Adjusting the threaded pipe effects the pre-load of the spring. John Calvert of Calvert Racing recommends, “What we first recommend is putting the forward heim joint in the hole that puts the bar most level at ride height. Next, put a quarter turn of pre-load (extending the bar length) on both sides. You should run it that way for the first couple track sessions. After the first session though, we would verify that pre-load was still set properly after initial break in.”

Calvert continued, “The real goal is develop a baseline for tire pressure, starting line RPM, and shock settings that the car is most comfortable with before adjusting the CalTracs any further. For radial cars, even an eighth to quarter inch of air gap can be ideal because it allows the rear end to rotate slightly before engaging the CalTracs. We like to recommend even a few back-to-back passes experimenting with air gap versus pre-load to see what the car likes the best. What you want to do is hit the tires as hard as you can without spinning and sometimes adjusting from pre-load to an air gap setup will help slow that cycle on bad tracks.”

Calvert's adjustable shocks are offered in a wide range of bolt on applications and feature an eight way adjustment dial that effects the shock's rebound.

Rounding out the suspension is Calvert’s CR Series nine-way adjustable shocks. The adjustment for these shocks are primarily designed to control rebound after launch to control rear body separation. Calvert continued his setup techniques by explaining, “Shock adjustment mainly depends on if it’s a foot-brake car or a trans-brake car. On a trans-brake car we recommend to run the shocks very loose while a foot-brake car should be ran tight. If separation between the tire and the fender happen at a really fast rate, there can be instances where all four tires will come off the ground; this is an instance where you want to slow the separation by tightening up the shocks.”

• Complete bolt-on – no cutting, welding needed

• Keeps axle from rotating, helping maintain pinion angle

• Eliminates spring wrap-up

• Full pre-load adjustability

Calvert CR Series 9 Way Adjustable Rear Shocks PN# CR44116

• 9 way externally adjustable knob

• Dial primarily adjusts rebound, enabling driver to control excessive body separation

• Heavy duty industrial steel bodied design

Calvert Split Mono Leaf PN# 2000

• Complete with aluminum bushings in front eyes and urethane bushings in rear eyes

• Split mono leafs made to work in conjunction with CalTracs

• 200 – 225 pound spring rates available

• Substantially lighter than multi leaf springs for unsprung weight savings

Wilwood’s Four Piston 12-Inch Rear Brake Kit

When going 140+ mph down the quarter mile, you really need a set of brakes that will stop you before the run off ends. Nothing gets the pucker factor fired up faster than running out of brakes before a safe turn off. While many hardcore race cars go with a lightweight plate-style rotor to reduce rotating weight, we went with a traditional Wilwood vented rotor that has been cross drilled and slotted.

In addition to the aesthetic appeal, the venting and cleaning action of the hole and slot pattern helps to reduce pad glaze and minimize irregular pad build-up on the rotor faces. The results are a smoother engagement feel at the pedal and consistent response from the pads.Again, we want to enjoy driving the Mustang around the street and we are willing to Bite the Bullitt by carrying the additional weight.

Bolting to the 12 inch rotors (the biggest Wilwood rotor we can fit behind our Weld wheels) is a Dynalite four piston caliper. These calipers are super light; only weighing 2.8 pounds each and are stress-flow forged. The process of stress-flow forging re-aligns the metal’s grain structure within the contour of the caliper body. This process eliminates the breaks and interruptions to the internal grain structure that occur when machining a straight block billet.

This rear kit actually carries the exact same specifications as our front brake kit. When it comes to proportioning the kit, Wilwood’s Michael Hamrick suggests, “You want to put the proportioning valve on the set of wheels that are going to lock up under hard braking. In a drag racing application, you have plenty of tire out back and not enough on the front, which will lead you to wanting more rear brake bias.”

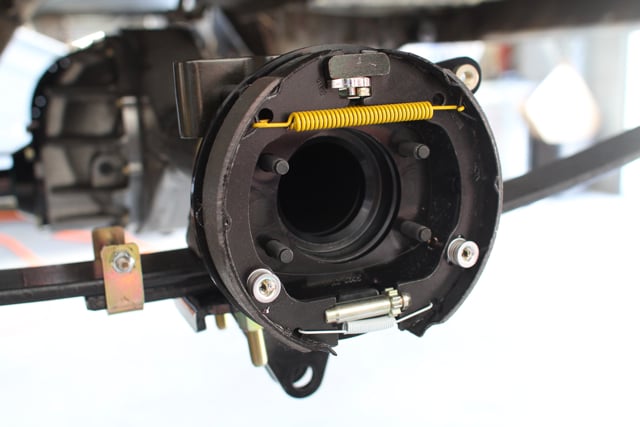

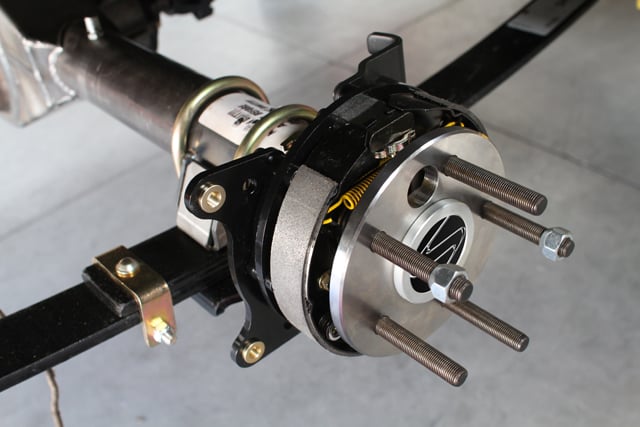

Included in the kit is Wilwood’s parking brake assembly with integrated billet caliper mounts.

Wilwood Dynalite Rear Parking Brake Kit PN# 140-7140-D

• Black Electro Coat drilled, slotted, and vented 12.19-inch Rotors

• Forged billet 4-piston calipers

• High performance Wilwood brake pads

• Parking brake assembly with integrated billet caliper brakes

The axle must be removed so that the parking brake assembly can be installed. After that, the axle is slid in place, the bearing retaining plate then slides in place and is secured with the included bolts through the axle's access hole.

The calipers slide in place and are retained by two bolts. The pads slide in place and are secured by an easy to remove cotter pin.

Capped off with Weld Wheels and Mickey Thompson Tires

Capping everything off is a set of Weld Classic RT wheels wrapped in Mickey Thompson rubber. Weld’s RT wheels are a multi-piece design for the maximum strength with the lightest weight possible. Also the wheels easily clear our 12-inch Wilwood rotors, though Weld also touts these wheels for F-Body, S197 Mustang GT, & other late model performance applications for their brake clearance capabilities. Weld’s RT wheels surpass all applicable race wheel & SAE street wheel standards and carry a maximum load rating for street applications is 1200 pounds per wheel with a 28-inch tire.

While the $199 paint job is toast on our Mustang now, she will be getting a full make over after we get a few passes on it so she can look as good as the wheels.

The wheels are available with a black anodized or polished center and are designed for use with a 5/8-inch drive stud or short shank mag style lug. In the rear we went with a 15×9 width and a 5.5 backspace that is accompanied by a half inch spacer to give proper clearance to the leaf spring. Mickey Thompson supplied a set of their proven 275/60/15 street radials plus a pair of 26×4.5×15 front runners. Both tires are radials and do not require tubes.

Our Project “Biting the Bullitt” ’65 Mustang has come a long way in recent months with the completion of the TCI front suspension and most recently the rear. Combining the simple yet sturdy design of the Mustang’s leaf spring rear suspension with modern technology will help us be as consistent as possible off the line. For Strange’s 9-inch and Wilwood’s brakes, having a bullet proof means to transmit and also slow down all the power we will be making is insurance we can look forward to on and off the strip!