Drag racers are continually looking for ways to optimize the performance of their drag racing machines, from the engine, to the chassis, to the aerodynamics. But one of the most overlooked and under-serviced — and yet, most vital — components on a race car is the torque converter. There are very few components on a modern race car that can control the rate at which the vehicle accelerates, manage the horsepower, and gets down the track like a torque converter.

Jeff Sitton, driving the Killin Time Racing nitrous-assisted Camaro, set the Outlaw Drag Radial world on fire with a 3.90-second pass at 192.04 mph at No Mercy 6 in Georgia last fall with an NCRC converter.

Marty Chance of Neal Chance Racing Converters (NCRC), one of the leading designers and manufacturers of torque converters in the drag racing industry, is one of those guys that knows what it takes to build a torque converter. If you haven’t heard of Neal Chance Racing Converters, then you might want to check your pulse, because their torque converters power some of the baddest door cars on the planet, with world records and championship hardware to prove it.

NCRC developed the first production bolt-together drag race torque converter in 1987 and went on to win the SEMA Best Engineered New Product of The Year with it. Since then, the team at Neal Chance has continued research and development to bring new features and technology to the racing torque converter.

Torque Converter 101

Rich Bruder smashed the X275 record with a 4.389-second pass at 167.52 mph at Maryland International Raceway on October 11, 2015.

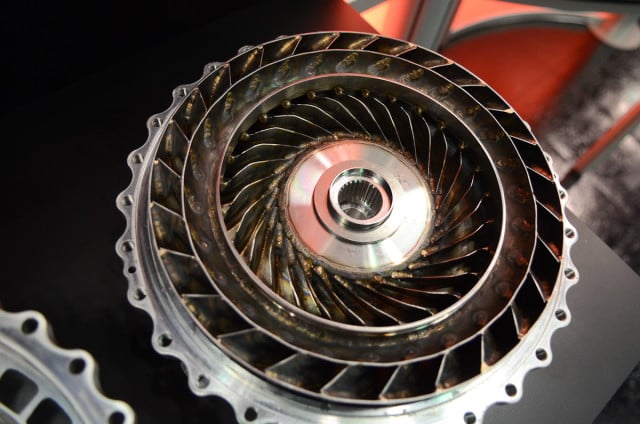

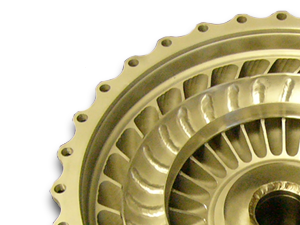

From the outside, a torque converter might seem like a relatively simple component, but once you see one from the inside for the first time, you’ll realize the level of engineering that goes into building a converter that’s optimized for a specific racing application. The turbine and pump vane angles are mesmerizing to look at, because at first glance, it’s difficult to understand how a torque converter really works.

A torque converter allows the engine to operate in a predetermined RPM and load range that is defined by the converter manufacturer. This is usually based upon the customer specifications of their engine and power adder combination, chassis, tire, and performance goals. The torque converter is critical to optimizing the performance of your race car because it controls the rate at which the vehicle accelerates.

In the simplest terms, a torque converter is a hydraulic power transfer component that’s responsible for transferring the torque from the engine to the driveline. The hydraulic power transfer is achieved by directing the flow of transmission fluid across the stator within the torque converter. The torque converter allows the engine speed to increase until the stall speed of the torque converter has been reached, which results in minimal slippage of the torque converter assembly.

The unique advantage of the torque converter is that it enables torque multiplication by way of the design of the stator house inside. The torque multiplication only occurs when the stator is stationary. This torque multiplication is a key advantage in a drag racing vehicle, since it helps to accelerate the car at launch.

Chance was quick to point out that “torque multiplication is the only time in life when you can actually get something for nothing.”

A NCRC full billet bolt-together converter is shown above to illustrate the complex flow paths of the transmission fluid.

The Components Of A Torque Converter

The torque converter is comprised of four major components: the turbine, pump, stator, and transmission fluid. Transmission fluid enters the torque converter between the converter hub and the transmission stator support. As the torque converter spins, centrifugal force causes the transmission fluid to pass through the angled fins of the turbine and exit toward the center of the converter. The fluid then hits the stator, which directs the fluid toward the center of the pump section. The fluid then passes through the angled fins from the center of the pump to the outer housing, where it is directed back towards the transmission housing.

Torque Converter Physics

Marty Chance of NCRC explained physics behind torque multiplication. “The stator is what causes torque multiplication by changing the direction of fluid flow at low RPM/low conditions. When stator is stationary, it causes the fluid to change direction and aims it at the pump side fin, which causes a brief moment of torque multiplication.”

Modern torque converters can momentarily multiply the torque of the engine by factors of over 2.0 in some applications. Now, before you run screaming that you want a torque converter with 2x torque multiplication, please keep in mind that this multiplication only happens for a fraction of a second.

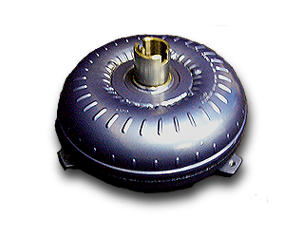

The torque converter type is often driven by the racer and the intended application of the vehicle, as Chance points out. If the racer is on a tight budget, they will most likely chose a welded torque converter, since it allows them to step into a quality converter at a lower price point. One of the negative aspects of a welded converter is a result of the OEM-style housing, which limits what the shop can do with the vane angles inside of the unit.

Another downside to a welded torque converter is that they’re not serviceable at home, which means you’ll need to send the converter back to the manufacturer and pay to have it rebuilt. Also, if you need to change the stall speed of the converter, you must ship it back to the builder. With a bolt-together piece, you can easily change the stall speed based upon your needs and go back to a known good stall speed if the new setup didn’t work as intended.

Many racers with a welded converter will often leave it in the car until it experiences a failure or starts to exhibit a performance problem. Instead of starting the race season with a fresh converter, they assume that it will still work well since it’s been in the car during the offseason. Typically, when a converter fails, it’s due to a cheap roller bearing that could have easily been replaced with a bolt-together design.

The welded steel torque converter is shown on the right next to the billet steel converter. The welded converter allows racers to step up to a high quality product with a relatively small investment. Racers that need to freshen up their converter before a major race or need to make frequent stall adjustments should consider a bolt-together unit.

Billet steel converters typically utilize a traditional passenger car housing originally intended for grocery-getter car and not a drag racing application. Essentially, they share the same housings as the weld-together units, with the exception of the machined bolt-together flange around the perimeter of the converter. A bolt-together steel converter is slightly heavier than a welded converter, as the bolts and outer flange add additional weight to the unit.

Neal Chance Racing Converters also offers a billet lock-up converter option for those racers needing the increased efficiency of a lock-up unit.

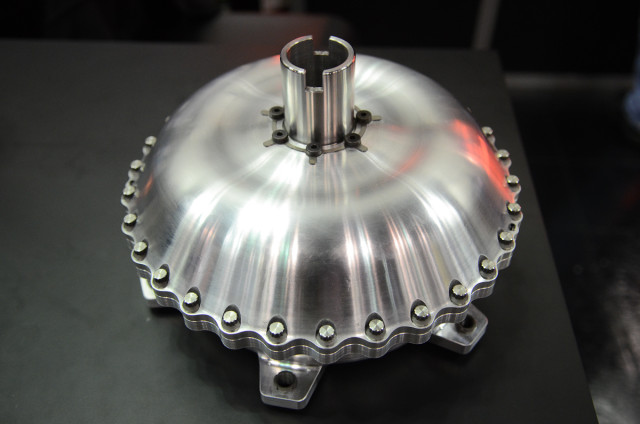

Neal Chance offers a full billet converter option for racers in the most demanding applications. A billet aluminum torque converter starts out as a solid chunk of billet aluminum, so the design and fluid profile of the converter can be optimized for your exact application. A billet aluminum converter typically weighs about 10-20 pounds less than a steel torque converter, which helps to reduce the weight of the car and the rotational weight of the driveline.

NCRC also offers billet titanium options for certain critical parts within their torque converters, based upon the customer power requirements and needs.

Weight reduction in a race car is an important consideration when trying to squeeze the most power out of your race car and the torque converter is the largest diameter component in the driveline of the car. It makes logical sense that this would be a perfect place to remove precious weight out of the car. A simple lesson in physics states that the larger the diameter an object is, the more the rotating mass weighs further from the center and the more parasitic loss.

The engineering team at NCRC are checking a lock-up converter clutch height using a precision height gauge.

Torque Converter Build Sheet

The engineering staff at NCRC will help you with optimizing a torque converter to a specific vehicle application. They design and build torque converters for nearly every application from street/strip to supercharged and turbocharged Pro Mods producing well over 4,000 horsepower.

A small displacement engine with a centrifugal supercharged engine that runs 9,500 rpm wants RPM, but a 5.3 bore-space, 900 cubic inch nitrous engine needs load to make the engine happy. – Marty Chance

Then NCRC uses the build sheet to find the proper torque converter settings to allow the converter to best accelerate the mass of the vehicle. In order to do this, they have to fully understand the load characteristics of the power source, which can be heavily dependent on the power adder and displacement of the engine. Much in the same way that you tune an engine to find what makes it happy, the torque converter manufacturer tries to find what RPM and load range makes the engine happy.

Chance stated, “A small displacement engine with a centrifugal supercharged engine that runs 9,500 rpm wants RPM, but a 5.3 bore-space, 900 cubic inch nitrous engine needs load to make the engine happy.”

When you consider the different types of power adders, such as screw-type, roots, and centrifugal superchargers, each of these have different load characteristics that the converter manufacturer needs to take into consideration when specifying your new converter.

Torque converters are very dynamic components, because they respond differently depending on the RPM range and power of the engine in the race car. If you have a naturally-aspirated big-block engine producing 600 horsepower, the torque converter might only stall at a lower RPM, but if you add a large shot of nitrous oxide, the torque converter stall speed might increase by several hundred RPM.

The Importance Of Data Loggers

Walk through the pits at any drag strip in the nation and you’ll find a data logger on virtually every heads-up car in the pits. The use of data loggers in racing has become so commonplace that many racers and tuners wouldn’t know what to do without one.

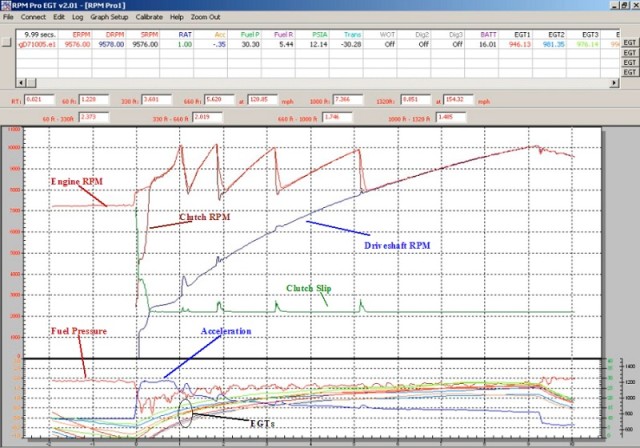

Neal Chance Racing Converters also sells data loggers for racing applications that feature software to allow the user to overlay different graphs from a run. The engineering team at NCRC is able to identify areas within the run where the car is not performing to its fullest potential.

Neal Chance often reviews their customer’s data logger files together over the computer using a screen sharing application, which is just a click away. By doing this, the experts and NCRC are able to identify any areas in the customer’s combination that might not be fully optimized. Chance stated, “there are many times that we can identify other problems with the vehicle over the phone that the customer might have overlooked since we have a great deal of experience working with nearly every type of drag car imaginable.”

The team at NCRC typically look at vehicle speed, engine RPM, G-meter and driveshaft RPM to make sure the converter stall adjustment is optimized for that specific application. If needed, they can tweak the stall speed of the converter by adjusting the vane angle or modifying internal components.

Billet drive covers that are fresh off the mill. Since NCRC has all of its machining operations in-house, making custom one-off torque converters for customers is a common occurrence.

In an effort to ensure customers are getting the most out of their application, it’s often helpful to review the data logger in real-time with the customer to explain what their car is doing at various points on the race track and then offer advice on making adjustments to the tune-up.

Stator Technology

It takes hundreds of thousands of dollars and countless man hours on research and development to bring the latest stator technology to drag racing. The engineering team uses the latest 3D design software and analysis packages to design and evaluate different stator and vane concepts prior to even cutting a part on the CNC machine.

Unfortunately, even the best computer software in the world cannot replicate real-world test conditions, and so a lot of time is spent on research and development at the track testing actual race cars. This provides Neal Chance with a continual stream of data and information on how their converter and stator designs work at the track.

Custom-made forging blanks made from NCRC top secret formula await to be machined in the CNC lathe. Neal Chance Racing Converters goes so far as to purchase the entire mill of these aluminum blanks so they can ensure its parts are made with the best material possible.

According to Chance, “I think we’ve only scratched the surface with torque converter technology, and we have already seen the next technology breakthrough that racers may start seeing in the near future.”

Companies tend to treat their stator and converter designs as highly coveted trade secrets. By having their CNC machining in-house, they can control the quality of their products and protect their proprietary designs, as well as utilize custom alloy metals that are produced to their exact specifications. NCRC has several CNC milling centers, including several high-end 5-axis CNC mills.

With torque converters largely displacing the tried-and-true clutch and manual transmissions of yesteryear, the competition amongst manufacturers has become as cutthroat as segment of the industry. For that reason, manufacturers like NCRC keep their trade secrets — from how their converters are designed to how the stators are set up for a given combination — very well-guarded. That competition, however, has bred unparalleled gains in performance over the last decade, and as you can see by the dedication of the staff, it’s unlikely we’ve seen torque converter technology reach its peak yet.