Ford’s latest and greatest modular engine, the 5.0L Coyote, with its rubber-roasting 412 horsepower and 390 ft/lbs of torque right out of the box, is quite possibly the finest performance mill the blue oval has ever churned out. In our opinion, it is, but that’s an argument for another day.

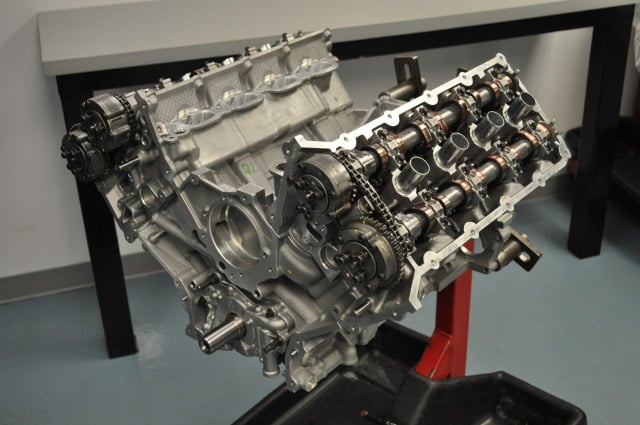

With extensive webbing used in the design of the block casting for reinforcement, 4V DOHC heads with outboard camshafts creating improved intake port geometry, and revolutionary Twin Independent Variable Cam Timing, the new-age 5.0L is not only a stout performer from the get-go, but an exceptional basis for the enthusiast to work with for upgrades and modifications to gain that valuable power and torque.

From the factory, the 5.0L Coyote engine is quite a performer and with plenty of headroom for enthusiasts to create more power by simply swapping out a few weak points, and that's exactly what we're doing today as we team with Livernois Motorsports for a fresh engine build.

Despite what the factory engine and bottom end in particular is capable of, we’re seeing a growing number of complete engine builds utilizing the impressive OEM engine blocks to produce upwards and in excess of 1,000 horsepower. To gain a greater perspective of such builds, we teamed with Livernois Motorsports in Dearborn, Mich. to highlight a recent ground-up 5.0L engine build for a customer.

In operation since 1949, Livernois is one of the most established speed shops in the automotive enthusiast and racing industry, and in the Ford and Mustang communities in particular.

The Build

Block And Crankshaft

We’ve pushed quite a bit of power through these stock blocks and not had any issues. – Mike Schropp

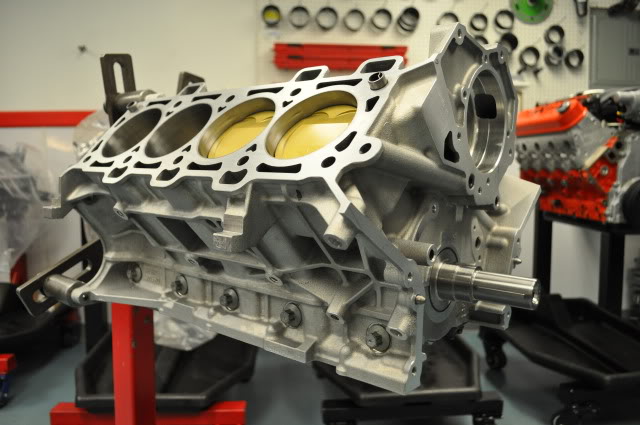

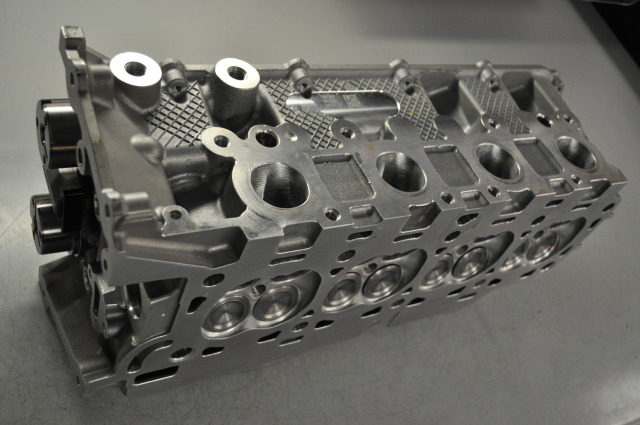

The 5.0L production blocks are made of low pressure cast 319 aluminum with pressed-in-thin-wall iron liners, and are internally balanced. They feature 92.2mm bores from the factory, along with cross-bolted nodular iron main bearing caps, thicker main webs for added strength, and 11mm cylinder head bolts.

For this build, Livernois has utilized the OEM Coyote engine block and swapped out the bore sleeves for slightly thicker pieces, albeit with the same 92.2mm bores.

The OEM production engine block has been regarded by many – including the team at Livernois – to be plenty capable for engine builds to up in the neighborhood of 800 to 900 horsepower, which means this block can easily withstand more than double the power output from the factory. This is thanks largely to main bearing bulkheads that are thicker than their 4.6L predecessor. And with only minor modifications, the power threshold increases.

“We’ve pushed quite a bit of power through these stock blocks and not had any issues,” explains Livernois’ Mike Schropp. “The builds that we’ve done that cross the threshold of 900 to 1,000 horsepower and beyond, we remove the factory sleeves and put aftermarket sleeves in the block with more thickness and stronger material.”

The block used in this build retains the factory 3.623-inch bores on the 3.937-inch bore spacings, as is standard on the production 5.0L Mustang engine. Also utilized from the OEM bucket is the stock 3.653-inch stroke forged steel crankshaft. “We’ve never really had any issues with the stock crankshafts – they seem pretty bulletproof,” says Schropp.

Pistons, Rods, And Hardware

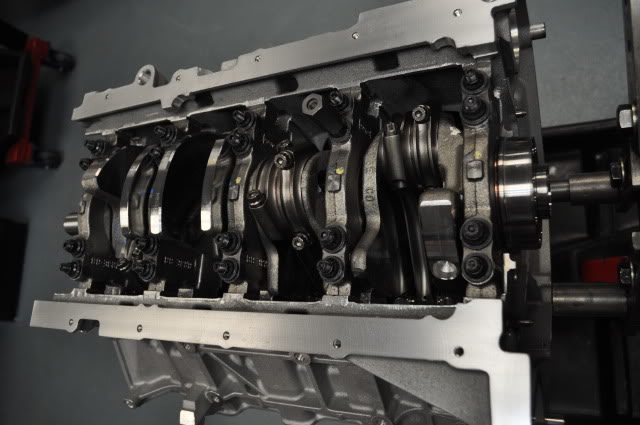

Rounding out the short block assembly is Livernois’ exclusive coated 10:1 compression pistons and in-house exclusive Manley H-Beam rods paired with sturdy ARP 2000 rod bolts.

Through years of development with the 4.6L and 5.4L modulars, Livernois has developed their own piston with improved ring lands and overall thickness for durability in a slate-dish style design. According to Schropp, the ring land stack is critical when it comes to builds far surpassing stock power output.

This build features Livernois' own 10:1 coated pistons, exclusive Manley H-Beam rods, and Livernois' own rings , locks, and wrist pins.

“The stock piston isn’t horrible, but it’s targeted more toward a naturally-aspirated engine, and it works well in that application. Though when you start putting boost or nitrous to it, with the valve notch placement, you run into issues with thickness in the top and the ring grooves where it intersects the valve match.”

The stock piston isn’t horrible, but it’s targeted more toward a naturally-aspirated engine.

Livernois has outfitted the piston and rod combo with their exclusive piston rings, locks, and wrist pins. The rings are 1.5mm in size for a longer lifespan under the pressure of boost or other power adders. Clevite Tri-Armor coated bearings – a harder bearing than stock – have also been chosen as they reduce wear on the edges at higher power levels.

Last but certainly not least, Livernois’ own main studs and head studs have been chosen to compliment this build.

The bottom end assembly, spinning on Clevite Tri-Armor coasted bearings, is held together tightly with Livernois, exclusive mains studs.

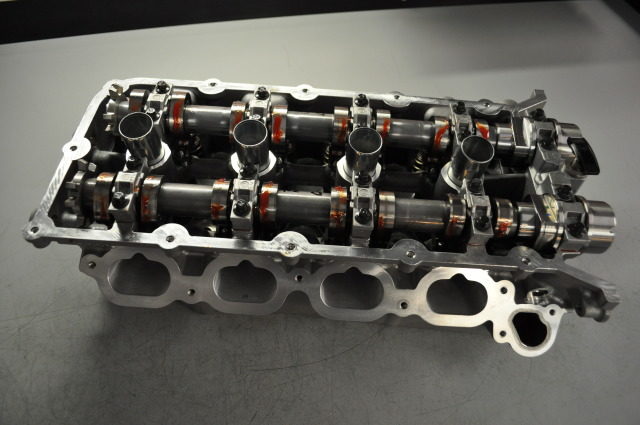

Cylinder Heads

The CNC aluminum heads being placed on this engine are a ground-up design by Livernois that combines some of their own elements with those found in the more recent BOSS 302 heads. Livernois has ported the heads and done some basic pan blending with a grinder to blend the seat into the valve job. The valvetrain itself has been beefed up some, as well.

These are Livernois' own CNC aluminum heads, featuring some minor porting work. The heads house a largely stock valvetrain, with the exception of Livernois' own drop-in valve springs.

Said Schropp, “When we first started testing the Coyote hardware with a couple of different cam profiles, we found that in a lot of cases that the stock valvetrain was pretty adequate if you stayed within the relatively small envelope of the factory performance was. But when you start pushing things, it could cause some issues.”

The heads have been outfitted with stock intake and exhaust valves, stock followers and lash adjusters, along with use of the complete factory rocker assembly. Livernois has upgraded the valve springs to their own pieces, which they claim are the only true drop-in springs for the 5.0L Coyote.

Camshafts

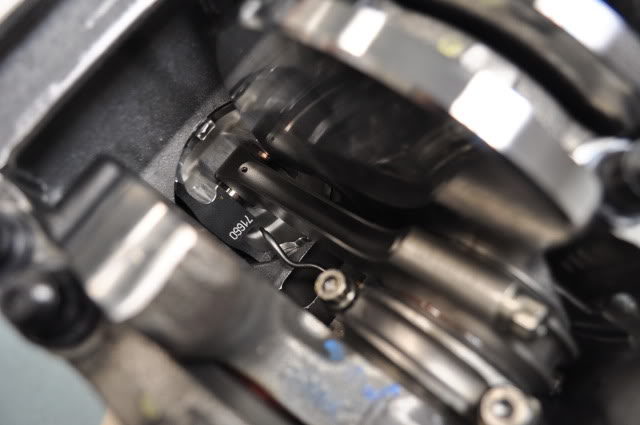

The cylinder heads on this build use the stock intake valves and exhaust valves borrowed from the BOSS 302 with 2mm added left and the same .263 duration. Phaser limiters, set at roughly 15 degrees, limit the cam timing.

Complete Build Specifications:

• Aluminum Production Block, stock crank

• Livernois Exclusive Coated 10:1 Pistons

• Livernois Exclusive Rings, Locks, and Wrist Pins

• Livernois Exclusive Manley H-Beam Rods w/ ARP 2000 Bolts

• Clevite Tri-Armor Coated Bearings

• Livernois Exclusive Main and Head Studs

• Livernois CNC Cylinder Heads

• Livernois Valve Springs

• OEM Intake Cams, BOSS Exhaust Cams (additional 2mm of lift)

• Livernois Billet Oil Pump Gears

• OEM Valve Covers, Oil Pan and MLS Head Gaskets

Rounding Out The Build

Completing the build, the team at Livernois has utilized the factory oil pan, valve covers, MLS head gaskets, an their own billet oil pump gears.

Any time that you can take a stock production engine block and a whole box full of OEM parts and create upwards of 1,000 horsepower with a superb degree of reliability involved, you know you’ve got one stout piece on your hands. Not many engines throughout the annals of car-dom have been able to make such a claim, but that’s exactly what Ford has done with the 5.0L Coyote. The result is a grade-A enthusiast platform right off the showroom floor that’s kept shops like Livernois Motorsports swamped over the last two years and kept the overall cost of an engine build in check for the end user. Not that it needs to be said again,but the Coyote is a winner in virtually every sense, and engine builds mating aftermarket and OEM parts like this are a prime example.