The battle between carburetors and electronic fuel injection for fuel delivery superiority has been raging for years with Carburetor fans backing the tried and true system as being capable of producing high horsepower numbers and performance without all the complicated wiring and computer mapping. Proponents of the EFI systems claim bigger horsepower gains with more fuel efficiency and integrated control of systems ranging from timing to nitrous injection.

Having recently completed a carburetor shootout between street and race carbs on our Dart small block 440cid “Test Mule” engine, we decided to do a carb to EFI upgrade to take a closer look at the differences between the two systems and their dyno numbers in a controlled environment where we could measure the differences. Is it possible to convert the followers of carburetors to EFI or visa versa? Probably not, but we can show how easy the EFI system is to install and the gains that we experienced.

Holley's HP EFI kit is an extremely tunable and complete kit that optimizes an engine's fuel delivery system.

If you’ve always wondered about EFI systems but were afraid of the perceived complicated wiring and tuning, or if you’ve ever wondered if EFI systems actually outperformed a carbureted engine, then this article is for you.

Holley, the same folks that have been making fuel systems since 1903 and whose name is synonymous with muscle car fuel delivery, have worked to simplify fuel injection systems for everyone from hardcore racing enthusiasts to the daily driver “everyman.” With three new Holley EFI systems on the market today that covers just about every application known to man, we decided to make the fuel delivery system swap on our project engine using a Holley HP EFI System.

The Goal

The major difference between EFI and carburetors is the ability to tune specific areas. When you make a change on a carburetor like main jets, you change the fuel curve for all rpm and nearly all load percentages. Holley’s EFI allows you to change the amount of fuel added at a particular rpm and load without changing anything else. This improves performance and driveability by achieving optimal air fuel ratio at all times.

Armed with the knowledge that the EFI type systems have an advantage over carburetor based systems by having the ability to fine tune the fuel curve at all rpm levels we wanted to know how much improvement in fuel efficiency, performance and theoretical driveability that existed in the EFI system. This test would be more about the entire power curve rather than the max top end horsepower number.

Watch The Video Of Our Dyno Testing Here:

About the Holley EFI Systems

Holley’s entry level EFI system, the Avenger EFI, is an easy to use system that has self tuning capability and requires no laptop computer. Simply install the system and drive around while the system tunes itself. According to Doug Flynn, Chief Engineer at Holley, “the Avenger EFI is an easy to use, bolt on system that is perfect for street applications.”

The next step up in Holley’s EFI line is the HP EFI system. It is laptop programmable and loaded with features including four stages of nitrous control, water methanol injection and boost control. The HP EFI has integrated wide band sensors and integrated data logger. This system can also work with any of the GM LS engine series.

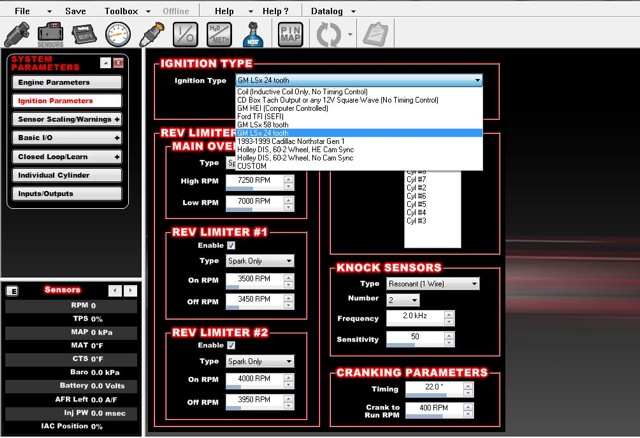

Holley's software for the EFI system is very user friendly with drop down menu options for setting up the system. Holley's focus on the software was making it simple enough for a novice user while keeping the high performance "tunability" in the system.

Holley’s top of the line programmable EFI system, the Dominator EFI, can be used on everything from stock street vehicles to high end, hardcore, race engine applications. From coil on plug, drive by wire and even with electronic transmissions, the Dominator EFI provides controls for almost any application. Like the HP EFI system, it handles four stages of Nitrous Oxide, water methanol injection, boost control plus incorporates two wideband sensor inputs, 2 gigabytes of internal data logging and various other user inputs and outputs.

Holley’s Director of Marketing, Bill Tichenor, breaks down their EFI system, “all of the systems feature self learning strategies users who are not EFI experts can be confident knowing their fuel curves will be accurate. They come with wide band control to let the self learning strategies continually adjust for current conditions.”

The HP EFI system comes with some pretty serious components like Holley's EFI intake manifold with fuel injector mounting bosses and billet fuel rails.

Continuous adjustments for conditions is where the EFI systems have a distinct advantage over carburetion. Tuning a carb is more of a exercise in tuning to an average of the air density that a carburetor will be exposed to. Hotter or colder days will increase or decrease the density of the air flowing through the system. Without tuning for these conditions, a carburetor will be set for the condition that the atmosphere was at during tuning. EFI systems will continuously change to meet the ambient air conditions for better efficiency.

If the whole lap top programming still has you wrapped around the axles, Tichenor had this to say; “Our optional 5.7” touch screen is another feature that sets us apart. Once you get the initial set up done with a computer you don’t need it any longer. You can even do your set up on your desktop and then transfer the files to the touch screen through and SD card, so you don’t have to own a laptop.”

Granted, hand held controllers and touch screens are not new in EFI systems, but a hand held controller or touch screen controller that allows the user to manage sophisticated engine controls with “self learning” software is unique.

We had the crew at Westech Proformance Group remove the Holley HP carb and assemble the HP EFI system and perform the dyno runs for our testing.

Add in that the fuel base table is displayed in actual lbs/hr instead of co-efficient calculation value based throttle position and engine speed. The bonus in this is that you can change injector size and enter the desired lbs/hr. into the fuel map and your fuel rate will be pretty close.

The actual vs. rated flow is corrected in the System Setup for specific pressure and dead time response curves vs voltage for each injector tested. What this basically does is tighten the margin of error for the desired input lb/hr vs actual flow.

Our Project Build

Dart Machinery had put together a pretty stout dyno engine for us to use in tests just like this one. Having a dyno mule that was capable of handling anything that we could throw at it, and run countless times on a chassis or engine dyno, is a big plus in conducting research for article topics.

As with any engine coming out of the Dart Machinery engine shop, our SBC 440cid beast was custom built with precise tolerances to give it a performance edge. Before it even left the Dart machine shop, we had already conducted testing for a carburetor shootout between street carbs and race carbs. Now it was time to investigate a fuel injection upgrade and our test mule was the right bullet to measure the difference.

We opted to go with the mid range Holley HP EFI system because of it’s popularity and functionality. Tichenor explained to us the versatility of the system, “The HP EFI was perfect for LSX engine swaps. The HP EFI system will be comfortable for Street, Drag Race, Road Racing, and is hardy enough to handle Off Road and Marine applications with ease. Available in TBI, 4bbl MPFI or Stealth Ram systems, or as a stand alone ECU and harness kit.

The HP EFI kit's ECU is supported with high quality wire harnesses and sensors to ensure that precise measurements are being relayed back to the ECU.

The HP EFI Kit:

While the HP EFI engine management system is a full feature system with laptop tunability, the major feature in the system is the Holley EFI self learn. You start with a vase tune supplied with the tuning software, which is based on engine displacement, camshaft and any power adders you have.

From there the self learning feature will constantly adjust your fuel tables to the air/fuel ratio of your choice. In doing this, Holley EFI will be able to tune for optimum performance and driveability.

In addition to controlling fuel and spark, Holley HP EFI also has progressive nitrous and water methanol control. The HP ECU will also run an LS engine’s coil system and has cooling fan and fuel pump controls built in. If that wasn’t enough, the software allows you to create inputs and outputs for just about anything you might need. For example these outputs can control nitrous bottle heaters, engine shut down control for high temp, low oil pressure or other safeguard controls.

Holley HP EFI Features:

- Works with 4, 6, 8 cylinder engines

- Unique lb/hr based fueling strategy greatly simplify tuning

- Advanced idle, closed loop, and enrichment strategies allow for very stable operation

- ECU is fully potted and can be mounted in the engine compartment or interior

- Sealed automotive and marine grade connectors

- Allows for use of common OEM sensors as well as customer sensor calibration input

- Ignition Plug and Play with GM 24x and 58x LSX engines, GM HEI, Ford TFI, magnetic and hall effect trigger, and other ignition systems. New Plug and Play applications in process. Custom settings can be configured to allow many other applications.

- 1-5 Bar MAP sensor capability

- Two channel knock control sensor Inputs for both one or two wire knock sensors

- Dedicated fuel and oil pressure inputs

- Controls both stepper and PWM Idle Air Control (IAC) motors

- Speed density, Alpha-N, or combination fueling strategies

- 4 Programmable high or low Pulse Width Modulated (PWM) outputs and 4 fully configurable inputs can be configured for use with the following features:

- 4 Stage nitrous oxide control

- Integrated Water/Methanol injection control

- Advanced idle, closed loop, and enrichment strategies

- Fully featured boost control capability eliminates the need for a separate boost control device

- User configurable input and output programming

- Outputs can be programmed as pulse width modulated or switched

- Unique circuitry allows inputs to be programmed as speed/frequency, 0-5V, 0-20V, thermistor, or switched high or low

- Configurable for: dual cooling fans, dual fuel pumps, AC inputs, basic TCC lockup, and multiple timing retard inputs and rev limiters

- Vehicle speed inputs

- User programmable caution and warning outputs for all sensors

Getting A Baseline

We had recently performed a carburetor shootout on our Dart dyno mule engine but using the dyno numbers we collected from that test session would not be representative of the change in atmospheric conditions and location, we opted to perform a completely new baseline carburetor data at the Westech Performance Group testing facility in Mira Loma, California.

Westech Performance Group’s dyno operator Ernie Mena was asked about the differences between carburetors versus fuel injection, “Carburetors are simpler. You put them on, fire ’em up and away you go. I would rather do the fuel injection stuff because it has a lot more tunability, especially in cruise speed, as the weather changes and altitude changes because all of that is corrected while you’re driving.” This was an important consideration for our testing because the atmospheric and altitude conditions were not going to be changing during the test, and that is where the EFI unit really shows it’s stuff.

Our test platform details for carb dyno run:

- Dart 440cid SBC engine, 10.5:1 Compression Ratio

- Dart Pro 1 215cc heads

- Dart single plane manifold

- COMP Cams Hydraulic roller cam 254/266 .579 -.579

- 1 3/4” Dyno headers with 18” collector

- Timing set at 37 degrees

- Holley HP 1,000 cfm carb with spacer

The Results

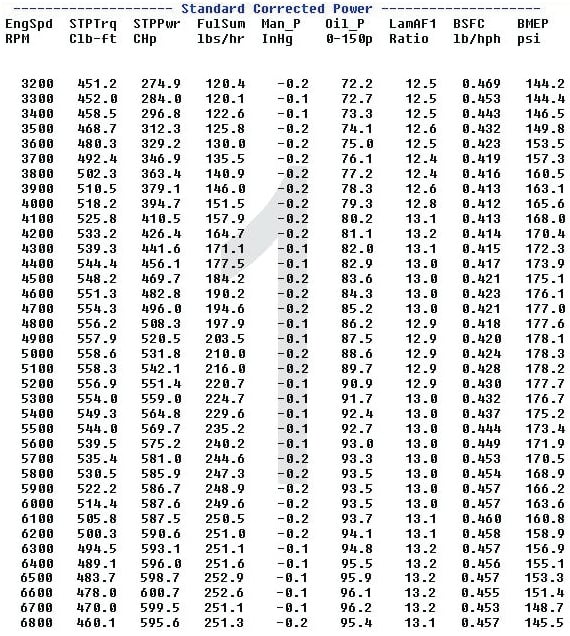

The Holley HP carb performed exceptionally well throughout the rpm range with no lags between circuits making a smooth power and torque curves in the dyno test environment. These results were pretty much what we were expecting to see from a tried and true fuel delivery performer and set a decent baseline standard to measure against. Peak horsepower of 600.7 occurred at 6,600 RPM with the peak torque of 558.6 at 5,000 RPM. Without the ability to change altitude and weather conditions, the real test of the EFI upgrade was going to be in fuel efficiency. EFI systems tend to calibrate fuel flow more efficiently as a routine, and this is where we expect to see the Holley HP EFI kit to really shine.

After the Westech crew installed the system, ignition timing was checked and set before making the first pull.

A Word About EFI Types And Our Choice

The Holley HP EFI kit is available in throttle body, 4 barrel multiport and what Holley calls the Stealth Ram style EFI. Throttle body injection is the closest to carburetion in the way that it operates. Fuel is injected above the throttle plates and the mixture of air and fuel travels throughout the entire intake tract before entering each individual combustion chamber upon engine demand.

We chose the Multi-Port Fuel Injection (MPFI) where the fuel is injected at each intake port in the intake manifold, just above the cylinder head. Because air alone travels through the intake tract until the last moment when an atomized fuel spray is injected into the airstream, the potential for using superchargers and turbo chargers is much greater, depending on the application and intake design.

Holley’s Steath Ram EFI system utilizes a ram air tunnel, which is pretty impressive looking, but is designed for higher RPM applications without compromising on the midrange torque and power. For our testing purposes, the MPFI kit represented a very popular street application type of fuel injection with the potential for easily incorporating power adders in the future. There is no doubt that if we were simply shooting for highest top end horsepower numbers, we would have selected the Steath Ram system, but our test is for the most efficient power and torque curves throughout the entire RPM range.

Installing The Kit

Holley’s installation manual for the EFI system is almost foolproof but there are a couple of items that require some thought. Deciding where to mount the fuel pump and filters as well as the system’s ECU should be well thought out before mounting these items. Take into consideration any planned aftermarket upgrades that you may be considering adding at a later date. View Holley’s HP EFI installation manual here.

Other than a two inch hole saw and a laptop or desktop windows based computer to perform the initial setup of the system, the only tools required are common hand tools to install the system.

The Westech crew kept a close eye on the dyno display as the engine made it's power run with the HP EFI system.

Fuel Lines

Fuel line routing is also a consideration because you will be adding a return line to the fuel tank. Unlike a carbureted system where low pressure fuel is delivered “as needed,” the EFI system continuously delivers fuel at a higher pressure in a volume that is greater than the engine requires a maximum load.

The excess fuel that is not consumed immediately by the engine is returned to the fuel tank. Careful routing of the return line to prevent other parts from pinching the line or exhaust heat burning a hole in the line.

Fuel Pump

You will need to obtain an electrical fuel pump and filter. Holley sells in-tank and in-line pumps that suit this purpose ideally. A quick call to Holley’s tech line will ensure that you get the fuel pump that flows sufficiently to support the injector size for your system.

You may need to round up a mechanical fuel pump block off plate because the mechanical fuel pump will be replaced by an electrical fuel pump that can supply the pressure required of an EFI system.

Oxygen Sensor

Most exhaust system come with Oxygen sensor mounting bosses already welded in to the tubing but if yours does not, you will have to get an Oxygen sensor boss welded into the exhaust between the exhaust ports and the catalytic converter. Closer to the engine is better than further away when it comes to sensor location.

Other than these fairly easy procedures, installing the system is as simple as removing the old intake manifold and carburetor and installing the new EFI system components.

Our EFI Dyno Run

Our test platform details for Holley HP EFI dyno run:

- Dart 440cid engine, 10.5:1 compression ratio

- Dart Pro 1 215cc heads

- Holley throttle body on Dart single plane manifold with Holley HP EFI plenum spacer

- COMP Cams hydraulic roller cam 254/266 .579 -.579

- 1 3/4” dyno headers with 18” collector

- Timing set at 37 degrees

Results

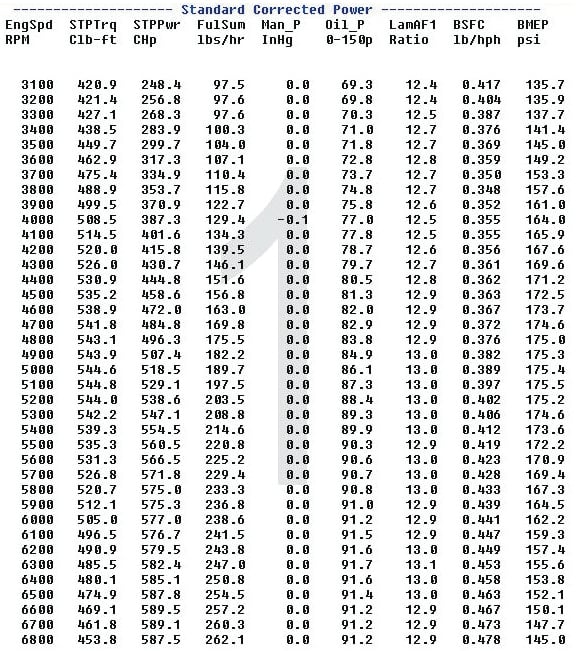

Max horsepower with the Holley HP EFI and base fuel map tuning hit 587.8 at 6,500 RPM and max torque was achieved at 544.8 at 5,100 RPM. Compared to the baseline carb dyno run, there was only slightly over a 13 horsepower difference. The difference in torque was pretty much in the same parameter. As expected, fuel consumption was on the average 15 lbs/hr less throughout the RPM range. A gallon of gasoline weighs about 6.1 pounds and at the current market price, that’s about eight dollars and hour savings. Saving eight bucks every hour you drive will eventually pay for the EFI conversion in fuel consumption alone.

The point of diminishing returns on the fuel efficiency in our dyno run was at 6,400 RPM when the trend started to reverse and the carburetor became as efficient fuel wise as the EFI system. Keep in mind that this EFI dyno run was conducted using the base fuel map that came with the system and had not “self-learned” or been fine tuned. The EFI system allows for fine tuning at each RPM level, so it is extremely possible to improve the fuel consumption rate even more than what we experienced. With some additional time spent tuning the system, we would expect to see horsepower numbers in the low six hundreds.

If a drop of 12 peak horsepower is a concern, consider this: the money that you save in fuel with this system can be invested in a turbo charger which will take the EFI system to a whole new power level.

Affordable, cost saving, simple to install, set up and use. What's not to like about the Holley HP EFI kit?

The Bottom Line

When it gets right down to it, the only complaint about EFI systems in the past has been the skill level required to tune them. Holley’s EFI systems have essentially done away with that fear by introducing the self learning system incorporated in their kits. EFI still has the edge over carburetion in drivability when conditions change and full RPM range performance. They are emissions friendly with excellent reliability, great fuel distribution and excellent compatibility with aftermarket power adders. So… what’s not to like about Holley’s EFI systems?