You know you’ve designed a great aftermarket part when Chevrolet decides to use it on their turnkey race car. That’s the case with Holley’s new Hi-Ram intake for the LS series engines, which GM chose for use on its COPO Camaro Stock Eliminator package. The Hi-Ram modular intake, which is basically a modern-day tunnel ram, was originally introduced for LS3/L92 rectangular-port engines that make peak power in the 7,000-8,000 rpm range. It also made a nice alternative to expensive fabricated sheetmetal intakes for racing applications where induction system height is not limited.

Origins of the Hi-Ram

Holley’s Senior Design Engineer Jim Dralle said, “I first gave thought to the Hi-Ram when I first looked at a LS3 cylinder head and realized the performance potential of that cylinder head with relatively little work or money spent. For a bracket drag race car, a LS block sleeved to a 4-1/8 bore with stock stroke, a solid roller cam, and mildly worked over LS3 heads, easily possessed the power potential at 7,500-8,000 rpm of 750+ hp at a relatively low cost. That with a power adder could be 900-1,000 horsepower. But, there was not a reasonably priced intake manifold available to match-up with the kind of racing engine application of which I was thinking based on the engine and cylinder head performance potential.”

Dralle went on to say, “The original thought was an inexpensive combination of two side-mounted Holley HP carbs on a typical Hi-Ram type intake. As our team thought more about things, we knew that LS engine users are going to want to go EFI with a single throttle body, use forced induction, and would like to have the freedom to build custom one of kind induction configurations using the available technologies like drive-by-wire. This led us to a design a modular, flexible intake manifold concept. The center of the concept is the base intake manifold, configured with fuel injectors and fuel rails, with a runner design configured for achieving max power at engine speeds in the 7,000-8,000+RPM range. The plenum flange on the base manifold is configured so we could provide different plenum top designs or our customers can fabricate their own based on their requirements. All of the flanges are o-ringed sealed to eliminate leaks for forced induction applications.”

The cool thing about the Hi-Ram is not only that it’s available for all three types of intake ports, but also that it’s fully modular.

A Hi-Ram For Every LS…

The first Hi-Ram model that came out was only for engines using the LS3/L92 style heads, but that left a lot of enthusiasts out in the cold. However, Holley has recently released Hi-Ram models with port configurations to match the other two LS cylinder head intake ports; the cathedral-port heads (part no. 300-123, with TB top) and LS7 heads (part no. 300-229, base only).

If you remember the stories we’ve done on the Virginia Speed-built 388 LSX engine for Project BlownZ, we used a set of Trick-Flow’s GenX 265 cathedral-port heads, but we built that engine before the cathedral-port Hi-Ram was available. That meant we had to do the full Frankenstein routine to a rec-port Hi-Ram to fit the earlier heads. With the introduction of these new versions, you don’t have to do that anymore, and we were finally able to switch to a Hi-Ram that was already matched to our heads.

Here you can clearly see the design differences between each of the intake port designs. The rectangular LS7 is short and fat, while the simular L92 is more long and skinny. The original cathedral port design is easy to spot with its pointed top.

The debut of the NMCA West series and it’s Outlaw 8.5/275 Drag Radial class made us realize what we needed to do with our fourth-gen Camaro, Project BlownZ .

The debut of the NMCA West series and it’s Outlaw 8.5/275 Drag Radial class made us realize what we needed to do with our fourth-gen Camaro, Project BlownZ .

The 388ci LSX engine you may have read about in previous installments is now going in this Camaro, and estimates are 1,00 RWHP and 7.80s in the quarter. It’s got all the hardcore drag goodies you’d expect, and we aren’t going to delude anyone into thinking that this is any kind of street car. The interior is pretty well stripped, the ‘cage is serious, and we spent a ton of time building a cowl box to get the ProCharger’s boost through the firewall to the Chiseled air-to-water intercooler in the cabin, and back to the Holley Hi-Ram, which is aimed backwards.

What was changed between the three versions of the manifold? Again, Dralle explains, “The runner entry areas on the LS3 and cathedral-port are the same since those engines stock typically have similar bore sizes, but the runner length is slightly longer and the taper is suited to the cath-port heads. For the LS7 Hi-Ram, the runner entry areas are larger and the runner length slightly shorter for the larger bore size and the higher rpm potential of the LS7 engines.”

Endless Options with Modular Design

The cool thing about the Hi-Ram is not only that it’s available for all three types of intake ports, but also that it’s fully modular. There’s a base intake, of course, but it can be had with a variety of bolt-on plenums that allow everything from multiple carburetor designs to EFI. Holley even has a flange that makes it easy to design your own sheet-metal top.

First, there are two different front mount throttle body EFI options available for the Hi-Ram. One allows for use of a 92mm throttle body (PN 300-218) in a street hot-rod, and the other for a massive 102mm throttle body (PN 300-219) in a street/strip/race oriented car.

For the carb guys, there are also three different tops that will allow for dual-quads. The first features two wide open square inlets for 4150 flanged carbs (part no. 300-216), and the second top is for massive 4500 flanged carbs (part no. 300-215) and has four punched out holes in each mounting position. The last modular top is for 4500 series carbs with huge 2.25-inch throttle bores and has an open inlet. Of course, there’s no reason dual throttle bodies couldn’t be used on any of these for an EFI set up.

In addition to the 92mm and 102mm EFI tops, there are several other tops available for the Hi-Ram. One set up for two 4500-series carbs with 2-inch throttle bores (part no. 300-215), one for two 4150 carbs with up to 1.75-inch bores (part no. 300-216), and the blank top that gives you a canvas to create whatever kind of arrangement you want to (part no. 300-217). Not pictured is the top for two 4500 flanges with 2.25-inch bores (part no. 300-223)

Holley even offers two options for the DIY-fabrication guys. There is the blank top which looks similar to the carb tops, only with a “blank slate” mounting surface for just about any carb or throttle body (part no. 300-217). The second DIY Hi-Ram option is an adapter flange (part no. 300-220) that could be used as the foundation for a completely custom sheet-metal top.

Basically, the world is your oyster when it comes to designing and building your intake manifold. Even when using Holley’s various tops, the bolt pattern allows them to be mounted forwards or backwards depending on the use; for instance, on a blown/turbo combination with an interior-mounted intercooler, you can mount the top so that the throttle body points to the rear to simplify intake plumbing.

No one should ever complain about lack of options, or being cornered into one configuration with the Hi-Ram.

Big Runners For Big Power

The runners (rec-port intake shown here) measure 2.49 inches high by 1.21 inches wide. Hmmm, seems like you could hide some nitrous spray bars in here pretty easily, doesn’t it? The intake can be used with Holley’s 92mm or 102mm throttle bodies.

The base intake has tapered, 2.49 x 1.21-inch runners designed to work well on a wide range of engine configurations, and since you can remove the top, you can perform whatever kind of custom port work you want—to the limit of the aluminum’s thickness, of course. On the EFI manifolds, the fuel rails are machined for -8AN O-ring fittings with passages big enough to work with high-flow fuel systems typical of 1000+ race engines, and accept Bosch-style EV-1 or Magnetti Marelli Pico injectors (an adapter is available for stock LS7 injectors too).

Left to right: There are two different fuel rail options for the intake. This is part number 534-203 for the rectangular-port LS3/LS7 intake; 523-204 fits the cathedral-port intake. This .050-inch-thick machined plate (part no. 300-222) allows you to use a 102mm throttle body with the standard EFI top.

Part number 300-220 is an adapter flange that makes it a little easier to create your own sheetmetal top.

Designed For High RPM

While it was designed and intended for race applications, the Hi-Ram is showing up on more than a few street cars and hot rods. Dralle said, “The design of the LS Hi-Ram intake manifolds is intended for racing applications, peak torque usually occurs between 5,000-6,000 rpm and peak power is designed to occur between 7,500-8,000 rpm. While there may be a loss in torque at low- and mid-engine speeds, we still do see gains above 5,500 on mildly cammed street engines compared to OE-style plastic manifold designs.”

In Conclusion…

Rarely have we seen an intake manifold, or any part really, as versatile and adaptable as the new Holley Hi-Ram. It’ll work with a high-winding naturally aspirated combination or a high-boost blown combo, the latter of which we’re using it for on our Project Blown Z (see sidebar). No longer are we stuck with stock intakes or high-dollar custom sheet-metal pieces. Holley has made it easy as pie to outfit your induction system (at least the last component of it) in whatever way you want.

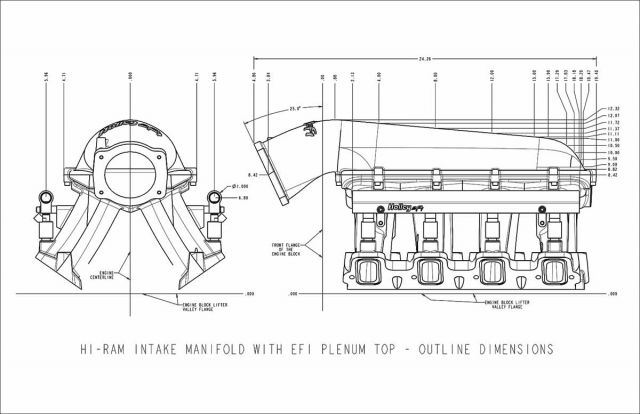

Here are the dimensions of the assembled EFI intake, handy if you’re designing the setup of the engine compartment and induction plumbing.