A fuel system that’s expected to perform at a high level needs to be protected with the correct filter, otherwise, there will be performance issues and possible engine damage. It doesn’t matter if you’re running a carburetor or fuel injection, a fuel filter is a must-have item and it needs to match your application.

The role that fuel filters play in a high-performance engine is that of protector — they make sure any debris in your fuel or fuel tank doesn’t make it through the system. Parts like the fuel pump, fuel injectors, or the jets in a carburetor are all under their care. The last thing you want is some nasty bits getting through the fuel system and damaging these parts, causing a fuel-starvation situation.

Every fuel pump will have different requirements for a pre-filter and they can range anywhere from 75-100 microns depending on the unit. The goal is to have the correct amount of filtration to protect the pump, without causing a flow issue that can lead to pump cavitation. The majority of pumps have the ability to push head pressure without any problems, however, there could be issues if the restriction on the suction side is too high.

For post-pump filtration, there are several different areas that need to be considered before a filter is selected: the type of induction system, whether it’s EFI or a carburetor, and the type of fuel that is being used. Josh Davis from Fuelab provides his thoughts on how he guides customers through choosing a fuel filter.

“Personally, I prefer to see our 10-micron or 6-micron element after the pump on both carbureted and EFI applications. The 10-micron paper element is good for pump gas and race gas, but not alcohol-based fuels. Common E10/E15 pump gas is still fine with the 10-micron paper element. If you’re looking for the ultimate in filtration and/or you’re using E85/E98/Alcohol/Methanol, the 6-micron micro-fiberglass element is what you would want to use. Some folks that call in are scared of the 6-micron filter, thinking it’s going to hurt the flow or cause a lot of pressure drop. In all actuality, you can expect to see less than 1/8 psi drop across that filter element – that’s nothing to be concerned with.”

Davis also notes that different injector manufacturers and service companies claim they’re able to tell if a user has installed a 6-micron element in a fuel filter. These companies claim there is a noticeable difference in buildup and more wear when a different micron size filter is used by different companies.

The fuel that you’re using will change the type of filter you will need to use for several different reasons. Since there are different materials that can be used in the construction of the filter housing along with the filter media, they need to be matched to the fuel to keep the protection level up.

“Typically, stainless steel is going to be compatible with pretty well any fuel short of nitromethane; the stainless is, but usually the glue inside the filter is not. Paper elements are safe to use with pump gas, even common E10/E15 pump gas and race gas, but should not be used with alcohol-based fuels. The 6-micron element is much like the stainless – it’s compatible with all commonly used pump and race fuels short of nitromethane,” Davis says.

When sizing a fuel filter for your carburetor or EFI system there are a few different schools of thought: you can go with what is considered good enough, or subscribe to how Davis recommends the sizing of a filter.

“Most injector manufacturers prefer very fine filtration, so the 40-micron filter should not even be a consideration if you’re using an EFI setup. Usually, a carburetor does not require as fine of a filter as EFI. The 40-micron filter element is usually OK for a carburetor customer, but I usually don’t suggest it. With that said, I try to steer folks towards the 10-micron or 6-micron post-pump filters, no matter if they’re using a carburetor or EFI. The pre-pump filtration is typically going to be the same between carburetor and EFI. The pump is what determines pre-filter requirements rather than the type of induction downstream,” Davis says.

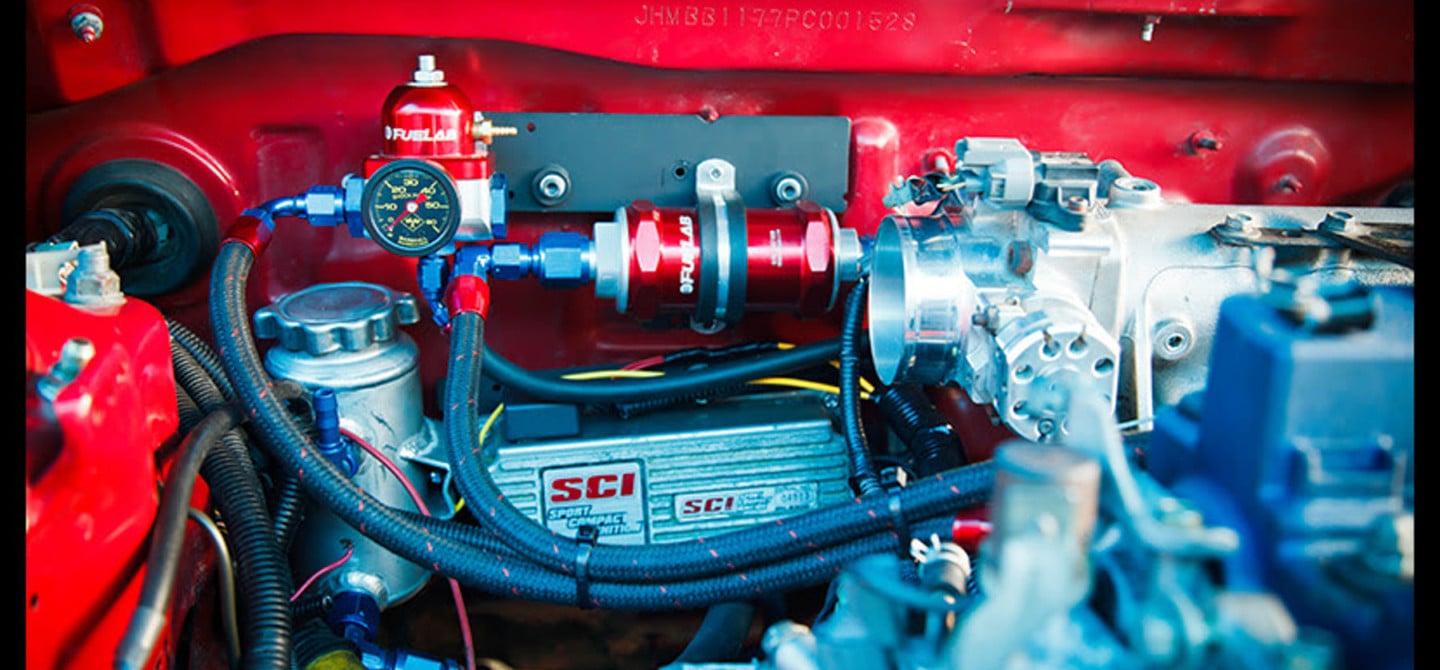

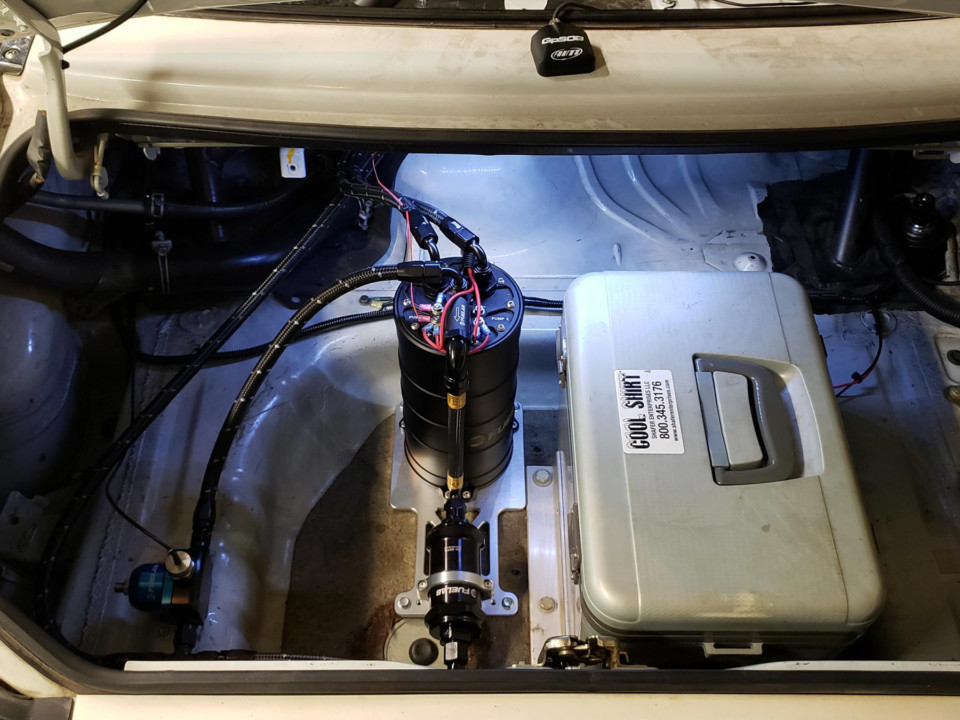

Fuelab has a diverse line of fuel filters designed for any application or fuel type. These filters come in six different colors that include black, red, blue, purple, gold, and green. The filters have from -6AN to -12AN inlet/outlet, staggered inlet/outlet, 3-inch or 5-inch elements depending on flow needs, and with or without an integrated check valve.

“Our filters won’t necessarily help you make more power unless they’re replacing a clogged piece, but what they will do is allow you to make more reliable power. Making sure the engine receives a clean stream of fuel is paramount when it comes to making horsepower. This is true whether it’s a completely stock vehicle or something wild that’s hard to keep strapped down to the rollers,” Davis says.

Check out the Fuelab website right here to see all of the different fuel filters they offer.