There is little doubt that the Coyote engine is one of the best platforms ever developed by Ford. With over 400 hp on hand in a stock Mustang GT, and the stock block and crank capable of handling well over 1,000 hp, there are few engines that rival it in terms of power handling capability.

With insane power levels being made by the Coyote and Ford also utilizing the block as the engine foundation in the Cobra Jet program, eventually some additional work needs to be done. Whether that work is for more cubic inches, strength in a naturally aspirated combination, or to endure the brute-force capability of a forced induction combination, there are a number of reasons why a Coyote block could need some additional work – mainly in the realm of sleeving the cylinder bores. A leader in developing a method for sleeving the Coyote and executing it with precision is Livernois Motorsports.

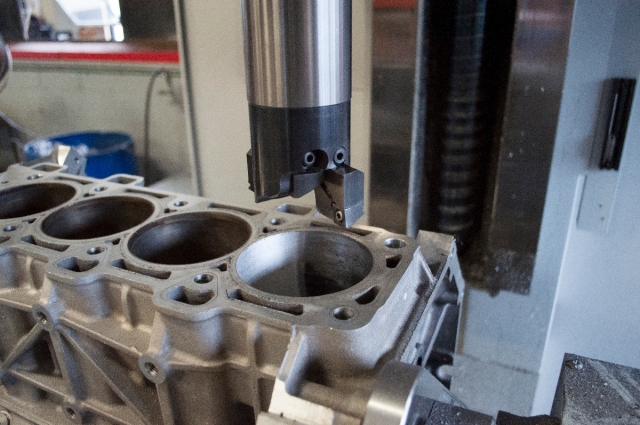

After measuring the block, each block is bored by a CNC boring machine. This process cuts the stock thin wall sleeves out of the block.

Sleeving a modular engine platform block is nothing new. We’ve seen this done since shortly after the DOHC 4.6 made it’s debut in the SVT Cobra in 1996. Livernois’ Mike Schropp tells us, “The Coyote blocks respond very much like their 4.6 and 5.4 liter predecessors.” Livernois began sleeving Coyote blocks first at the request of some manufacturing companies. As the platform’s popularity increased Livernois made the service available to their machining customers.

The Process

According to Schropp, the sleeving process takes approximately two days to complete. This is in part due to tight controls that Livernois has in place to prevent damaging the aluminum block and to make sure the sleeves are fixed into position properly and won’t shift later.

Left: The CNC boring machine determines exactly how much material to remove. Right: After boring the blocks they are thoroughly cleaned.

Why Sleeve

So why sleeve the Coyote block? The simplest answer is strength. The distance between the cylinder walls are tight and the separation to the water jackets on the top of the bores can give way with a lot of boost. Also, when boring the block the thin wall sleeves are not ideal for high power output applications. By installing the sleeves, the block can maintain integrity and benefits from increased strength over stock due to the much thicker iron sleeves. Schropp tells us, “We’ve sleeved approximately 40 blocks at this point and we have customers with these blocks making 1,400-1,500 hp in some instances.” Try doing that with many other stock blocks, and sleeved or not you’ll end up with a failure in many cases.

CNC Controlled

All of the work on each block is done by CNC equipment. A CNC milling machine first measures to determine the existing dimensions of the block in factory form. The CNC machine allows Livernois to precisely locate the bore centers in the block. Schropp says, “We use block blueprint data from Ford to ensure that the bore centers are located exactly where the blueprints call for. The factory machine work is usually close, but we make it perfect.” This prevents the aluminum from being compromised by over boring the blocks and also ensures the best possible assembly as the bore centers remain in-tact.

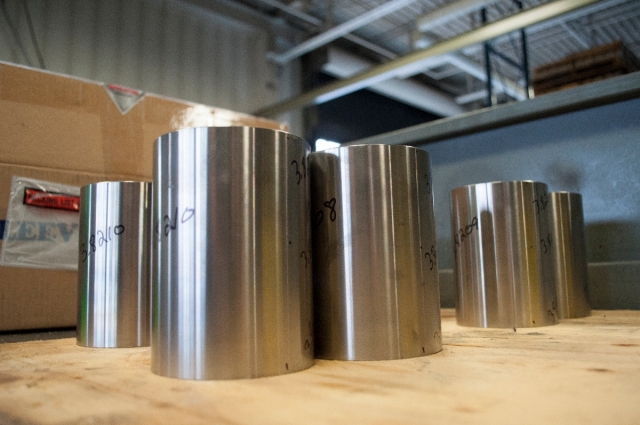

Livernois has a large selection of sleeves to choose from with varying inside and outside diameters. The majority of these blocks will have a 3.700-inch inside diameter bore, while a few higher output applications will get a slightly smaller 3.660 inside diameter sleeve.

Bake Until Warm

After the blocks are bored they are then heated slowly with Livernois proprietary process for several hours. This process takes the better part of the day. Once the proper temperature is achieved, the block is removed from the oven and technicians install the specified sleeve size. The sleeves are made from centrifugally cast spun iron. “Sleeve selection is dictated by what the block can be bored to and what the customer’s application is. Higher horsepower applications will use a smaller diameter bore with a thicker sleeve, while naturally aspirated applications can typically run a larger bore and sleeve with a thinner wall thickness,” says Schropp. Also according to Schropp around 95 percent of the blocks will receive the 3.700 inside diameter bore, while a few of the very high powered applications get the slightly smaller inside bore diameter of 3.660, that uses a thicker outside diameter sleeve for higher strength.

Left: Blocks are placed in an oven and slowly heated before being removed for sleeving. Right: With the block still hot, two technicians carefully install all eight sleeves.

Cool Down

Once the sleeves are installed, a special fixture is put in place to keep tension on the sleeve and prevent it from shifting in the bore. The block is then placed back in the oven with the fixtures installed and brought back to room temperature slowly. These strict temperature controls not only prevent the sleeves from slipping or shifting, but Schropp says they also protect the aluminum from cracking during the process.

The block goes back in the oven for a slow, controlled cool down with these fixtures attached to prevent the sleeves from shifting or slipping during the cool down. Once cooled the sleeves are set, the deck will be milled to ensure a uniform surface.

Finishing Touches

The final step in the sleeving process is to mill the surface of the deck to ensure the sleeves and deck are parallel and square. Schropp says that the milling usually removes .002-.003 of an inch from the block surface giving a final deck height of around 8.934 to 8.936 inches.

Livernois also offers other machining services on the blocks including the typical line-honing and line boring. Schropp says about 75 percent of the blocks they complete this process on are then built into complete short or long block assemblies at Livernois. The remainder are shipped to engine builders, customers and machinists across the country.

Our Up Coming 3.700 bore build – The Carb’d Cobra Jet Coyote

The block featured in these photos is for an upcoming StangTV project we’re calling the Carb’d Coyote Cobra Jet. In the coming weeks we’ll be building what will be the first single carb’d Coyote engine ever. We’re working closely with top names in the industry including Livernois Motorsports, Oliver Racing Parts, Moroso, Mahle, Comp Cams, Holley and Rich Groh Racing.

The engine will utilize this 3.700 bore block as well as a rebalanced stock crankshaft. Oliver is supplying a set of their Ultra Lightweight 5.933 rods and Mahle sent us a set of Cobra Jet specific pistons which will yield a compression ratio of around 11.5:1. We’re topping this engine with a set of fully CNCed heads from Livernois with Ferrea valves, and Cobra Jet spec camshafts from Comp Cams. A custom built, one of a kind carbureted intake from Rich Groh Racing. A Holley Ultra HP850 cfm 4150 will supply the fuel, as the engine screams towards our goal of 9,000 rpm.

Presently we’re working out the electronics end of things trying to retain the factory Ti-VCT system, as well as the coil on plug ignition.

We’ll strap it all to the engine dyno at K&N headquarters and see just what kind of power it makes. This should be an exciting one of a kind build, and we’re looking forward to breaking some new ground in the realm of Coyote performance.