As Larry Dixon continues his quest to build the ultimate 9-second street car, the headers upgrade we will be covering this month has to do with passing gas. Yes I said it, and you can stop laughing at any time – I’ll wait.

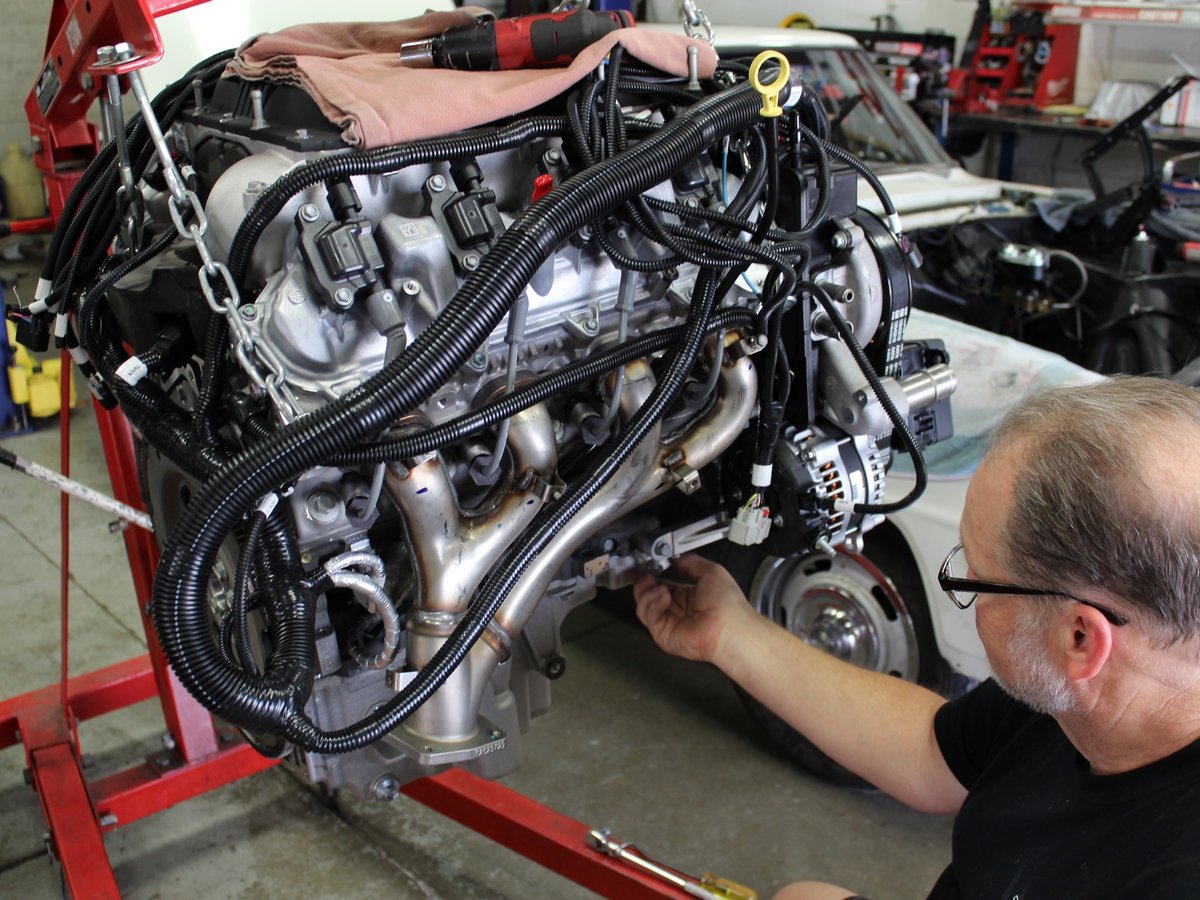

Anyway, when Larry and the guys installed the Chevrolet LT4 engine in his ’66 Chevrolet Nova, there were no off-the-shelf header options available, so they modified the factory manifolds. When Jim Browning of Ultimate Headers found out, he and Larry got together after Drag Week to come up with a plan to remedy that performance-hindering situation.

Throughout Drag Week, Larry’s Nova was breathing through a set of cut and modified stock exhaust manifolds. He later found out they were choking 20 horsepower from the engine.

In case you haven’t been following along with our coverage of Larry ‘s Nova build, he started by rebuilding the suspension with the help of Classic Industries, updating the fuel system, and installing a Chevrolet Performance supercharged LT4 engine. After that, he conquered Drag Week, and then installed a rack-and-pinion steering from Church Boys Racing. If you want to see everything that was done to the car, you can check out all of the articles by clicking here.

Both stock manifolds had the factory collector flanges removed and collector tubes welded on to make the connection to the dual exhaust. The number five tube also needed to be notched for steering shaft clearance. The manifolds worked, but definitely restricted airflow.

As previously stated, the LT4 was breathing through a set of cut and rewelded stock manifolds, and performance was surely hindered. We would be willing to bet that if Larry’s car had the Ultimate Headers installed for Drag Week, the Nova would have easily hit 10-second quarter-mile times. Since Jim and the guys from Ultimate Headers were willing to take on the task of building a proper set for the Nova, Larry’s car would certainly benefit.

What’s more, now these headers are available for others doing a swap like this. That being said, the headers are not designed to fit in a car utilizing the stock steering system. Larry’s car has a Church Boys Racing rack-and-pinion steering system, and the design was initiated with that in mind. But building a set of headers takes more than just cutting some steel tubing and welding it together. Not only does it need to fit the car, but it also needs to improve engine performance as well.

Planning, Planning, And More Planning

We don’t need to explain that header design has a significant effect on an engine’s performance, and is a crucial element in tuning an engine’s output. When discussing header design, the primary considerations consist of fitment, pipe diameter, and the length of the primary tubes. While the fitment is a must-have piece of the puzzle, diameter, and length can be adjusted to accommodate the fitment. These considerations will also be the determining factors of the location of the engine’s power band and the RPM location of peak power output.

An engine’s power producing capacity, the number of cylinders, and the maximum usable engine RPM will influence the decision of what primary-pipe diameter and length to use. In a perfect world, the length of the primary tubes should be equal, but since that is not always an option, a variance of 2 inches or less is an acceptable compromise.

The dyno-specific header only generated two horsepower more than our header, but it’ll never fit in any car. – Jim Browning, Ultimate Headers

Most stock exhaust systems fall short when it comes to supplying a sufficient flow of exhaust gasses at high engine speeds. Restrictions like stock exhaust manifolds, catalytic converters (if so equipped), mufflers, and the pipe connecting it all, play a role in the exhaust’s efficiency.

When you increase the horsepower output of an engine, you will also see a proportionate increase in the amount of exhaust gas produced, placing added demand on the system. To help with exhaust-flow efficiency, Ultimate Headers designs and builds headers that – first and foremost – fit, and provide serious power gains by improving the efficiency of exhaust scavenging from the cylinders.

Knowing how and why a system needs to work, helps in the selection process. According to Jim Browning of Ultimate Headers, “We did a test at Katech, Inc., where we compared one of our mid-length tube headers against a dyno specific header and a ZR1 Corvette manifold. The dyno-specific header only generated two horsepower more than our header, but it’ll never fit in any car. Our header also produced ten more lb/ft. of torque than the Zo6 manifold, and six more lb./ft. of torque then the dyno-specific header. Since we’re talking about street cars, that two horsepower is negligible, but fitment and improved torque is not.”

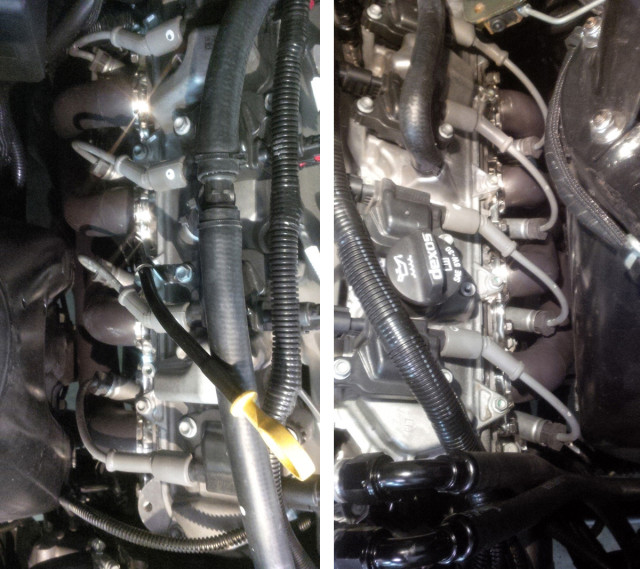

Mock ups ready for final welding.

Strong, High Flowing, And No Hammer Required

When it came to header fitment for Larry’s Nova, no one had ever properly designed or built any, so Jim and his crew had to start from scratch. To begin with, their aerospace-derived engineering techniques and metallurgical processes have helped them develop a header-to-cylinder head flange that not only helps prevent exhaust leaks but looks so much better than a laser-cut, flat piece of steel. The die-cast 316L-grade stainless steel flange has a rib design that delivers exceptional strength, yet reduces weight when compared to traditional solid steel flanges. Their design and construction also help them remain cooler due to increased surface area, reducing the tendency to warp. Jim was also happy to tell us, “All of our products and parts are manufactured right here in the USA.”

The limited space offered in the engine bay when filled with the supercharged engine was another challenge that needed to be overcome. According to Browning, “We knew that a header like this with a very large radius would not fit into Larry’s car, so our engineered, stainless steel investment-casting bend, creates the turn exiting the chamber with a radius much tighter than other header designs. The investment casting also uniformly holds the desired wall thickness from end to end. The result is a more compact header, keeping the exhaust system in a narrower space.” That is how Ultimate Headers came up with the slogan Big tubes for tight places.

Collecting Power

Header collectors do more than simply connect the header to the exhaust system. Their design has a measurable impact on torque production. While the merging of a header’s primary pipes affects header tuning, it is the header collector volume that alters torque output. The collector used on the Ultimate Headers pieces in Larry’s Nova do not use a traditional three-bolt collector. Rather, these headers use a smooth collector with a special clamp designed to connect to the exhaust.

The Extreme Low Profile Clamp accommodates up to 13 degrees of pipe angle during exhaust connection and uses a claw-style hinge. One end of the clamp is welded to the header collector (or any pipe for that matter), and the other connects to the exhaust. This style of clamp creates a quick and easy-to-achieve connection.

But the proof of the header’s ability to improve engine output needs to be quantified on the dyno, and the results that were achieved with the Ultimate headers are definitely substantial. Before the stock, modified exhaust manifolds were removed, the car was placed on the dyno and delivered 512 horsepower at the rear wheels. After the new headers were installed, that number jumped to 532 horsepower. To say the LT4 is breathing easier is an understatement.

With the technical stuff out of the way, we were curious as to how well these headers fit, and if there were any “problems” that caused an issue during the installation. To find that out, we contacted Chuck Church Jr. of Church Boys Racing, because he was the guy that handled the installation of the headers into Larry’s car.

This mock-up image shows that it’s a tight fit, but both the passenger’s side (left image) and the driver’s side (right image) fit with no problem.

Installation Insights

When we asked Chuck Church, Jr., what his thoughts were about fitment, he told us, “I think these particular headers will accommodate a lot of different applications. The reason is, that these are designed around one of the tightest applications found – the ’62 through ‘67 Nova. They are tight to the block, do not hang down too far, and the 1-7/8-inch primary tubes make these a win-win for everyone.”

Badge Of Honor

Attention to detail is paramount at Ultimate Headers, and they have something to make your engine bay stand out at a show – a cloisonné badge. A cloisonné is a technique for decorating metalwork objects with a vitreous enamel. The badge not only adds another touch of bling to your engine, but lets everyone know that you’re running the ultimate headers.

Now that you know the reasons why Larry chose to use Ultimate Headers in his ride, and what needs to be done to accommodate their fitment, maybe you should also check them out for your classic. Remember, they have headers for more applications than just an LT4 swap.