Over the last season of racing, perhaps no single item has caused more controversy and revolutionized performance more than ProCharger‘s new F-1X supercharger. The supercharger was included in the X275 rules for the 2012 season, then essentially forced out of most combinations when it was determined to be capable of such a large performance increase, one that was not anticipated by the class rules makers. However, the supercharger is still competitive in a number of sanctions, most notable the NMRA and NMCA‘s new Street Outlaw class, in addition to the NMCA West series’ 275 Drag Radial class and PSCA Wild Street, where we will be running one in front of Project BlownZ‘s LSX engine in competition.

Over the last season of racing, perhaps no single item has caused more controversy and revolutionized performance more than ProCharger‘s new F-1X supercharger. The supercharger was included in the X275 rules for the 2012 season, then essentially forced out of most combinations when it was determined to be capable of such a large performance increase, one that was not anticipated by the class rules makers. However, the supercharger is still competitive in a number of sanctions, most notable the NMRA and NMCA‘s new Street Outlaw class, in addition to the NMCA West series’ 275 Drag Radial class and PSCA Wild Street, where we will be running one in front of Project BlownZ‘s LSX engine in competition.

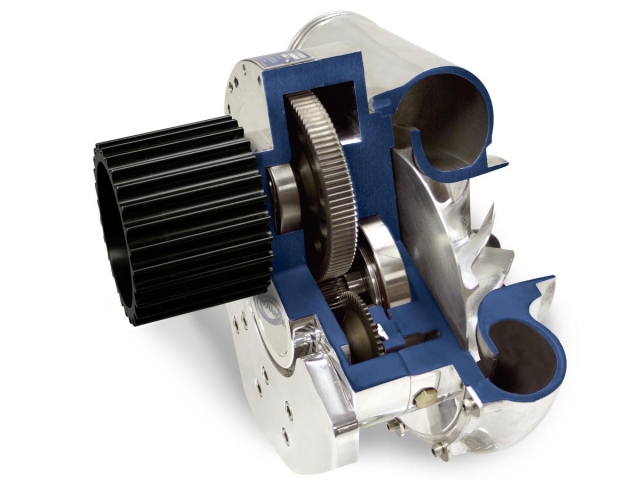

The F-1X isn’t small, as evidenced by the scale of the Pepsi can. It features a 10.5-inch compressor housing, 4.20-inch inlet, and 3.50-inch outlet.

As the 388 cubic-inch LSX engine in BlownZ was motivated in 2012 by one of ProCharger’s F-1R superchargers, it was only logical that the F-1X find a home in the nose of the car as a replacement for 2013. The car has been deemed the quickest magazine project car in history. Last season, the engine was raced with 11.5:1 compression, but for the 2013 season, we decided to drop the compression down to 9.5:1 with a new set of JE pistons.

Additionally we installed an Aeromotive Billet Hex Drive Fuel Pump and upgraded the transmission with a new TCI gearbox combined with a new TCI torque converter. Gun-drilled axles and an aluminum center-section from Moser Engineering were also installed, while the radiator was removed from the car in favor of a new Chiseled Performance ice tank with a Rule pump to help keep the intake charge cool.

These changes, along with the aforementioned F-1X upgrade, are expected to propel the car to mid-seven-second elapsed times at 185 MPH or even quicker, so we decided to take a look at the technology inside the supercharger to better digest where the performance improvements would come from. The car benefits from the use of one of Chris Alston’s Chassisworks CDS gear-drive units, which will permit us to turn the boost up to achieve nearly 30 PSI through the engine.

Rated X

The F-1X, rather than becoming a replacement for the F-1R supercharger we previously used, is actually deemed an upgrade by ProCharger, as both units remain in production and the F-1R is still the blower of choice in the East Coast’s X275 class. The F-1X, as the subject of our technical article, boasts a number of improvements, made possible by ProCharger’s aerodynamics testing lab that was put into use during the development of the F-4 supercharger program a few years ago.

The F1X is a major step up in technology, design, and efficiency. It’s a stout supercharger – even feared. How it came about is an interesting story.

While developing the F-4 program over the 2009 and 2010 racing seasons, the ProCharger team learned quite a bit about impeller design and efficiency, the key to their testing operations. Impeller design is perhaps the most critical component of the entire process, as it must be constructed to induce a minimum of turbulence while providing the maximum amount of airflow.

Far Left - Our awesome gear drive system from Chris Alston's Chassisworks Component Drive Systems division. Left Middle - The gear drive system uses these polyurethane pucks in place of a belt-driven pulley and interfaces with the hub bolted to our ATI Super Damper. Right Middle - Power Automedia's crack wrenches Sean Goude and Dean Jigamian install the F-1X in the nose of BlownZ. Far Right - BlownZ uses these trick quick-release Boost Braces from Race Part Solutions to prevent the tubes from blowing off under nearly 30 PSI of ProCharged boost.

Air is considered a compressible fluid for engineering purposes, and the new impeller design proved critical in terms of performance improvements. In any centrifugal supercharger, air is drawn in through the inlet and accelerated to a high velocity by the impeller. The vane-less diffuser on the back side of the impeller decelerates the air, converting the high velocity into a pressure increase, forcing it into the engine at a high pressure differential. It is this high pressure that is considered “boost”, and is measured in pounds per square inch of pressure. The high-pressure air is forced into the engine, where it combines with increased fuel volume and subsequently makes more horsepower due to the engine’s efficiency gain – more air, plus more fuel, equals higher horsepower.

Left - ProCharger's engineers spend countless hours in their test lab developing, testing, and quantifying their data. Right - The lab was built a couple of years ago and has helped the ProCharger team immensely in developing new product in an efficient manner.

We’ve got two engineers here whose main focus is aerodynamics design, using our new test lab, we were able to design the blade, test it, and make sure it was capable before we even put it on an engine. – Sergio Shifman, ProCharger

It is this higher efficiency that was recognized during the F-4’s development, and the ProCharger team subsequently applied those changes to the smaller housing that contains the F-1X impeller. The F-1X is a clean-sheet design that used the larger volute size of the F-2 supercharger (compared to the F-1R), with a completely new impeller design and smaller inlet hole, to make a completely new supercharger that fits the rules in the above-mentioned small-tire racing classes.

ProCharger’s Sergio Shifman was happy to talk about some of the changes that resulted in the F-1X becoming the new standard in centrifugal-supercharged performance in these classes. “The F-1X came about as the F-2 was outlawed in a few different classes. While the F-1R was legal, we needed to step up its output, and really needed something different between those two blowers. The 10.5-inch compressor housing used on the F-1X was permitted, but the inlet size (as found on the F-2) wasn’t permitted, so we designed something new to fit the rules package. We then needed to design an impeller that would work with the smaller inlet size. We can put it on a test stand and see airflow numbers before we ever go any further,” he explained.

This neat test rig allows the ProCharger engineering team to quantify their results and determine a particular supercharger’s efficiency levels before it ever goes into production.

Mocking up the supercharger in the lab to test its abilities has proven to be a big help in terms of bringing the supercharger to market fully-tested and vetted, rather than using racers to test the product. “The test lab that is on-site at the ProCharger facility allows a great range of testing across various types of applications. We can test in many configurations – types of airflow into different sized engines, different cylinder heads, basically different airflow restrictions. They use flow meters in different areas of the compressor housing and other sections of the supercharger to tell the engineers what they need to know about how the product is performing,” says Shifman.

One area where the F-1X excels is in efficiency, which can be measured in terms of the amount of power it takes to actually drive the supercharger. Sergio explained, “One of the areas that they measure specifically is how much power it takes to drive the supercharger at similar airflow measurements. Impeller design is critical in that area, and we’ve been very happy with the fact that it uses quite a bit less drive power than other designs. It’s different on every combination – every engine has a different boost number, and back pressure, so airflow requirements of the engine play into that as well.”

The F-1X impeller takes advantage of all of ProCharger’s newest engineering data to produce a supercharger that will get us into the mid-7-second zone or quicker with BlownZ.

When it came time to construct the F-1X, the ProCharger team was not constricted by the same 9 3/4-inch housing that the F-1R uses, so they were able to make some changes that benefited the package as a whole. The initial X275 rules permitted the ProCharger team to use the same basic housing dimensions as the F-2 supercharger, which uses a 10.5-inch housing. That single change allowed for the design changes that have made the F-1X so powerful. According to Shifman, the basic outside dimensions of the F-1X impeller changed only slightly from the F-1R, but the growth in housing size made a huge difference in the overall efficiency of the supercharger.

The new supercharger debuted in 2012 at Donald Long’s Lights Out race under the hood of a number of the top running cars, and the increase in performance was felt immediately. From what ProCharger’s engineering team had observed in-house during their testing phase, the F-1X picked up everywhere over the F-1R, gained a couple of pounds of boost in nearly all instances thanks to the improved efficiency, and once deployed into the field, started a firestorm among the competitors in the class.

Sean Ashe setting the NMCA Street Outlaw record with the F-1x in his ’85 Mustang – Thanks to Free Life Films For The Footage

Due to the performances of many teams running the F-1X last season, the supercharger has since been removed from the approved list of X275 superchargers, but it’s being used by a number of other racers currently competing, including Sean Ashe and Phil Hines, who have performed well with the supercharger in NMRA and NMCA competition so far this year. Ashe set the NMCA record with a 7.29 at 195 MPH, while Hines set the NMRA record with a 7.30 at 195 MPH at their respective season openers in March. As the teams get more time to work with the platform and rules package, expect those performances to improve – Hines has already raised the bar with a subsequent 7.128 at 202 in Maryland in May.

Three weeks ago I would have said we’d be happy with a mid-7.30 at 190 MPH from the F-1X. It’s hard to say how much quicker and faster our guys will continue to go – Sergio Shifman

Back to our Project BlownZ, was put into competition at the NMCA West race this past weekend at Auto Club Famoso Raceway in Bakersfield, California. Our team switched to the F-1X over the winter in preparation for this season, and we are still sorting out the car. New cars bugs continue to abound, as each time we sort out one part of the puzzle another item or three pops up that needs to be corrected in their search for ultimate performance and horsepower. It’s a struggle we’re sure many of you face in your own race programs.

The transmission within the F-1X is the same one that ProCharger has relied on for the F-Series supercharger family since day one – it hasn’t changed a bit. The unit features self-contained oiling, ProCharger’s patented, high-speed compound bearing assembly, and precision-ground 9310 steel gears.

At the NMCA West event, the team struggled with a torque converter selection that was not optimal for the combination, but still managed to turn in a best elapsed-time of 8.05 at 152 MPH. The fuel curve was still not optimized either, as the improper converter cost the team quite a bit of performance and compounded the tuning struggles.

Making the Switch

In our case, installation was quite simple, as we were simply removing the F-1R supercharger that previously mounted in front of the CDS gear-drive unit. The F-1X simply replaces the R, as both superchargers use the same mounting provisions on the CDS plate.

Left - The F-1X hung on our Component Drive Systems' gear drive. Check out the Aeromotive hex drive fuel pump hanging out on the accessory bracket. Right - As you can see, the gear-drive solution from CDS offers a relatively-small footprint in the engine bay, while direct-driving the supercharger from the engine's crankshaft.

We introduced the CDS gear drive to Project BlownZ back in January, but here’s a quick rundown of its operation. Not only does it provide a solid mounting option for the supercharger to be driven right from the front of the crankshaft, but there are also various gearing options that can be changed from 40 to 75 percent overdrive depending on the supercharger model. It also has optional accessory-drive options, allowing you to add an alternator, fuel pump, and even a magneto to the unit itself. There are also options for single-blower mounting in either a straight-on or angled-mount design to provide the end user some flexibility dependent upon their engine-bay space. Dual supercharger mounting is also available.

Left - the gear drive internals - not much to it, but plenty of horsepower-handling capability rests on these steel gears. Right - we changed our gearing selection to provide a 1.7 step up ratio from the original 1.65 ratio of the F-1R to get more power out of the F-1X down low.

On Project BlownZ, we needed to source a custom-built damper from ATI Performance Products to work with the gear drive, and they devised a lightweight Super Damper for our LSX engine including a dual-keyway hub and three extra bolt holes to provide the correct mounting option for the gear drive to properly mate with the crankshaft. The CDS gear drive unit also has plenty of clearance for our Jesel belt camshaft drive system.

BlownZ During Qualifying at the NMCA event – 7.69 at 181 MPH

Finally the day came when it would be time to put it all together at the racetrack, and the Power Automedia race team burned a lot of midnight oil in the days leading up to the event. Preparations were made, the car was loaded, and everyone had a prediction about the car’s performance. And then… it was “go time.” As most of you know, shaking down a new combination isn’t the easiest thing; no matter how much expertise and money and hard work you throw at a car, sometimes you just have to keep plugging away, fixing one issue at a time, and that’s been our humbling experience so far.

“The car went 8.05 at only 152 MPH, lifting at around 1000 feet. We feel that it would have gone 7.89-7.91 if we would have stayed in it through the quarter, but it had an extremely rich tune up,” explained Sean Goude. “There is a ton of power left in it” The car is making about 26.5 PSI versus 22 PSI last year, and it all finally paid off at last month’s NMCA WEST Pomona race where BlownZ ran it’s first 7-second pass – a 7.69 at 181 MPH. But that’s not it for BlownZ, as we begin to get our F-1X-powered beast under control.