Delivering performance improvements has been a hallmark of the team at ProCharger since the company’s inception back in the early 1990’s, where they debuted the ProCharger P600B supercharger to critical acclaim and documented large performance improvements.

Fast forward twenty-plus years to the current timeframe, and they’re on the cutting edge of automotive performance yet again with the incredible ProCharger i-1 supercharger – the world’s first fully-programmable-ratio supercharger that offers features never found before in an automotive supercharger of any type.

The ProCharger i-1 supercharger is based on the company’s proven compressor design – but features a fully-programmable variable-ratio drive system for customized boost levels at the touch of a button.

For years, the company has competed at the top of forced induction racing performance in many different venues. With the i-1 they look to take on the street market with a supercharger system that offers features never seen before, such as electronic control of the supercharger’s drive ratio and a touchscreen controller that allows the end-user to select the drive mode that is most appropriate for the current driving conditions at the touch of a fingertip on the included controller.

“The i-1 offers all the advantages of our current product line, including industry leading efficiency and the ability to utilize highly effective air-to-air intercooling, but also adds three industry-first features: programmable boost, cockpit control, and an optional touchscreen,” says ProCharger’s Ken Jones.

Billet Inside

First, let’s talk about the technology behind the i-1. Each supercharger is built from the same billet stock as the rest of the company’s offerings, and is similar in stature to ProCharger’s successful P-1SC and D-1SC street-going superchargers. Impellers and cases both are crafted from billet aluminum stock that offers excellent strength properties along with superior sealing ability.

Contained within the bottom half of the supercharger assembly is the unique dry-hybrid belt drive that allows for programmable levels of boost.

The gear-driven supercharger design also uses a self-contained oil pump system and proprietary oil that removes the need for an external oil line to the engine. Extensive testing in the company’s aerodynamics lab ensures that every ProCharger’s efficiency is maximized for each particular application. In addition, the transmission design has proven itself over hundreds of thousands of street miles over the last two decades.

Enough with the industry-speak; let’s get to the nitty-gritty on the i-1 in particular. While the supercharger itself uses the same proven internal transmission design we just spoke of, what’s new is the variable-ratio transmission attached to it that takes the engine’s drive power and turns it into varying levels of boost.

How it does this is simpler than you might think – if you’ve ever seen a snowmobile transmission apart, then you’ll instantly understand how the i-1 works. And if you haven’t, here are the simple details. By using a pair of drive pulleys with adjustable diameter contained within the supercharger drive and a unique, incredibly strong dry-hybrid Kevlar-infused belt, the system works in conjunction with the programmable controller to vary the pulley ratios inputted into the supercharger.

The system includes the 900-horsepower-capable compressor design based on the company's P-1SC and D-1SC designs along with high-strength billet brackets, the separate control module, and a new aluminum radiator along with a three-core air-to-air intercooler (not shown here).

“The i-1 has a continuously-variable transmission built into it,” Jones explains. “We can vary the ratio within the gearcase – the CVT can vary the ratio from 0.5:1 to 2:1 over the course of operation throughout engine RPM, which gives you a 4-times range of adjustment. You can run a huge pulley on the supercharger, and you can actually change boost levels without changing pulleys by plugging in your PC and reprogramming your boost table. You bring in more ratio at low engine RPM to spool it up and bring in more boost, and then you start bringing the ratio down as RPM climbs.”

The drive pulleys are arranged in a pair of “V” configurations, and depending upon the information programmed by the controller, one end of the “V” will get “skinnier” while the other end gets “fatter”. This allows the drive belt to adjust the drive ratio instantly, allowing the supercharger’s performance to vary up or down as programmed. Instead of needing a pulley change to change boost levels, the i-1’s transmission design is a mechanically simple process that proved incredibly tough to engineer, both for durability and performance reasons.

Left - Power Automedia Shop Manager Sean Goude prepares to install the i-1 by removing the front bumper cover. Access is needed to install the intercooler. Left Middle - Check out the difference in thickness between the old radiator and new radiator - all the better to keep things cool. Right Middle - The coolant overflow bottle slots right back in next to the new radiator. Right - The crankshaft pulley/damper assembly is removed to install these stand-offs, which secure the new supercharger drive pulley in place.

Programming The ProCharger

There are three pre-programmed curves that are delivered with the supercharger system from ProCharger – and each one can be modified after kit installation. A custom mode is also available, to give you a total of four performance modes to choose from.

Sport mode is designed for daily driving and provides boost pressure that comes on in a fashion between that of a traditional centrifugal supercharger and that of a positive-displacement supercharger.

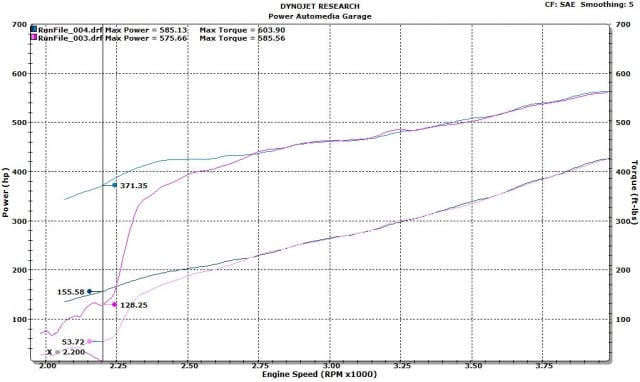

Look at the difference in the boost curves between Sport and Competition mode on the dyno between 2,500 RPM and 3,750 RPM. Sport mode (the bottom pink trace) shows a gradual roll-in of boost pressure, while Competition mode (the top pink trace) shows a much more aggressive curve, with the boost ramp nearly instantaneous.

Touring mode is designed for economy use; for example, on a long drive, or when you need to valet your car at that hot new restaurant in town – it only permits 1.5 pounds of boost.

Competition mode provides full boost by 2,500 RPM, much like a positive-displacement blower – but it doesn’t flatline as RPM increases thanks to the centrifugal supercharger’s tendency to fight heat soak.

Changing Boost Levels

One of the things that was made very clear during our conversation with Ken Jones was that the i-1’s programmer gives the ability to change boost levels in any of the curves. This is possible in both pre-programmed and Custom curves in 250 RPM increments and is done through a simple software interface.

Changing levels without a mechanical change on the supercharger itself is a feature that’s never been possible with any other automotive supercharger. Click on the image above to open a full-size screenshot of the i-1’s Performance Tuner software – and see how easy it is to adjust your boost curves!

No wrenches, no busted knuckles, and no cursing. That sounds like a win to us!

“It’s flatter than a standard centrifugal curve, but it’s definitely not a positive displacement-style curve. But in Competition mode, when you’re at the track with sticky tires, we can run a flat boost curve but with much higher efficiency than a positive displacement blower – because with sticky tires because you’re in a position to be able to hook the car up,” says Jones.

Where this gets really cool is when you get into the programmable mode. Depending on your setup, if you want to tweak the curve that’s supplied by ProCharger, it’s as simple as clicking a few buttons. The Custom curve can be reprogrammed in 250 RPM increments, and you can even change Sport or Competition mode for your particular application.

The programmer can be password-protected and has four readouts per page that are customizable, where you can see impeller RPM, engine RPM, and even the current drive ratio of the supercharger.

The different boost control modes are only a tap away. In addition, once you select a particular boost mode, you can actually detach the control unit and stow it away if you so choose.

Tuning Our Ride

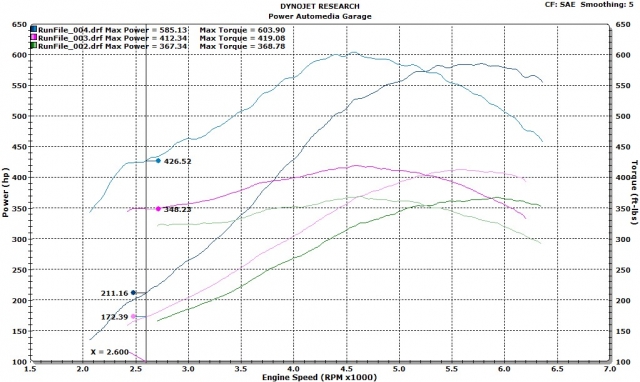

Before we ever got started with any modifications to the Camaro, the car threw down 367.3 horsepower and 368.7 pound-feet of torque to the wheels. After the install of our complete exhaust system from SLP Performance Parts, 412.3 RWHP and 419.0 pound-feet were the final tally on our DynoJet prior to beginning the install of the i-1 system.

Left - The system mounts to the driver's side cylinder head like any other ProCharger using a super-thick bracket and standoffs to place it in the proper position. Left Middle - Check out that badass piece of machinery! The slick black finish looks right at home under the hood. Right Middle - Once the supercharger is in place, it gets filled with ProCharger's proprietary oil blend. Change intervals are every 6,000 miles to promote long system life. Right - The mass-airflow sensor mounts into one of the intercooler's end tanks - this provides it with a constant steady stream of airflow for proper metering.

The kit tune is designed for stock vehicles, or vehicles that have been modified with only a cat-back exhaust system only. We had already installed the headers and complete exhaust system from SLP, so we couldn’t use the supplied kit tune for our application – it was necessary for us to have a custom tune written for our i-1 installation. This is one of the reasons that ProCharger chooses to sell through installing dealers; the company feels they add value not only with performing the installation properly, but by also ensuring that the engine calibration is correct no matter what the engine/power combination.

To that end, we hooked up with Ryne Cunningham of Cunningham Motorsports, who used SCT‘s software to build a custom tune for our particular car. “It was really straightforward, to be honest,” says Cunningham. “It was no different than tuning any other centrifugal-supercharged car, except it made more boost sooner in the RPM range. I was really impressed with the power gains, especially the torque under the curve. It made about 35 more rear-wheel horsepower and 50 more pound-feet of torque than a similar positive-displacement supercharger system I’m used to working with. It has all the benefits of making the torque down low without the high intake air temperatures that I’ve seen with positive-displacement systems.”

The massive intercooler assembly mounts behind the front bumper to provide cool air and is one of the hallmarks of a ProCharger system.

One issue that we faced during our installation is the use of the low-test 91 octane “premium” pump fuel that’s required thanks to the smog laws in our home state of California. Our initial power numbers came in around 560 rear wheel horsepower, which were down slightly compared to what was expected from ProCharger’s testing on their in-house vehicles as well as numbers reported from their customers in other states. However, we were able to run 11-12 degrees of timing advance without even the slightest hint of knock on the 91 octane fuel.

Video With Ken Jones And The ProCharger Team On The i-1’s Design

The i-1 supercharger design provides the most power per pound of boost of any supercharger system. – Ken Jones, ProCharger

By using our fuel blend, we were able to add another two degrees of timing, which put the car closer in performance to what the majority of the country would see using the standard ProCharger 93 octane tune. In fact, we were actually one degree of timing lead lower than the ProCharger tune, but we ran out of testing time on the dyno.

Left - Once the intercooler is in place, it's time to connect all of the ductwork from blower to intercooler, and from intercooler to the throttle body. Right - Fill the car back up with the proper coolant mix, and it's on to the inside to get the system's controller up and running.

With Cunningham’s custom tune in place, the car knocked down a stellar 585.1 horsepower number to go with 603.9 pound-feet of torque. That’s a huge improvement of 172.7 horsepower and 184.8 pound-feet of torque at only 7.5 pounds of boost, still with our mixture of junk fuel and good fuel and a lack of tuning time to maximize the system’s performance on that day.

The Install

In addition to the supercharger, also included in the kit is ProCharger’s 3-core air-to-air intercooler, the touchscreen unit that controls the whole works, along with every other item you’ll need to complete the job.

Believe it or not, despite all its high-tech wizardry, the system installs much like any other centrifugal supercharger system on the market. ProCharger provides a high-quality installation manual that you can follow along step-by-step to do this in your home garage, or you can have one of their network of authorized dealers perform the work for you.

Left - We chose to hide the control box up in the dash, which necessitated removal of the glovebox door to hide it. Right - Make sure to make nice tight, solid connections using proper wiring practices.

The controller requires some quick wiring to be hooked to battery power and the supercharger control unit, but if you’ve installed an aftermarket radio, you can install the controller. The control unit mounts to the windshield using a suction cup arrangement, much like a GPS system, and we wouldn’t be surprised if someone took the time to mount it into the dash in a custom arrangement – it’s that cool.

We’d estimate this project to take the better part of a weekend when done at home, but the end result, as you can see from our Dynojet and track testing in this article, are supremely worth it. The car drives unlike any other centrifugally-supercharged car we’ve driven in the past, as the boost comes on much sooner and much harder, and we like that. While we won’t show the entire process, follow along with our pictures and captions to see the high points of what’s involved with the i-1’s installation.

Here are our three different dyno session – stock (Run 002), after the addition of our SLP exhaust parts (Run 003), and finally, after the installation and tuning with the new ProCharger i-1 supercharger (Run 004). All in all, a fantastic gain, and the car just became infinitely more fun to drive. We’ve seen an improvement of 217.7 horsepower and 235.1 pound-feet of torque since the day we bought the car.

Where the Rubber Meets the Road

As you know, we’ve taken our project Camaro to the drag strip before, and even before modifications it was a challenge to get the three-pedal car launched cleanly with the stock wheels shod with low-profile drag radials. Now, with an additional 200-plus horsepower to the tires, it’s time to upgrade our rolling stock and suspension to maximize the extra power. On the road, the 5th Gen shows its added muscle with power instantly available in any gear and at any speed, making downshifts to pass on the highway almost superfluous.

But of course we are never satisfied, so stay tuned – in addition to improving the car’s bite at the track, we are also going to upgrade the fuel injectors to support even more boost, then see what this Camaro can really do in the quarter mile.