Welcome back to Centerforce University! In our first installment, we covered the basics of how a clutch works, and in this episode your professors from Centerforce Clutches are going to teach you about how to properly break in a new clutch.

Taking the time to allow a clutch to properly break in is one of the most important things you can do to insure that it lives a long and grippy life inside your bell housing. “Professor” Will Baty, from Centerforce explains, “Just driving around town, taking it easy for about 500 miles is the best way to seat a clutch in. Not 500 miles on the freeway, or going out drag racing. We want the clutch to be heat cycled as many times possible without over heating it, and with minimal power applied. The clutch disc has high and low spots on the friction material, and you want to reduce the high spots and embed the friction material to the pressure plate and flywheel. You want to create a nice even surface on the disc.”

Simple, right? No highway driving and no beating on the clutch for the first 500 miles.

If you want to get the most out of you clutch, and have it last as long as possible, you need to break it in properly.

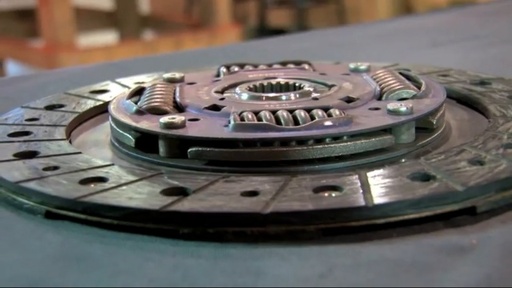

Now, if you get impatient and decide to get rough with the clutch before it’s been properly seated, there can be some pretty bad consequences, the worst of which is glazing the disc. And no, we aren’t talking about covering it in the sugary goodness that donuts have on them.

Baty says, “When a disc is glazed, the friction material is essentially polished smooth because the driver was too hard on the clutch before it was properly broken in. Once a clutch disc glazes, it loses its friction. It’s very much like sanding all the grit off of sand paper or a tire losing all its tread; it’s slick and won’t grip very well. Once the friction is gone from the disc, there is no getting it back, and you’ll have to replace the disc if you want your clutch to work properly again.”

Notice those shiny spots on the friction material? Yeah, that's not good. Someone got a little impatient and went drag racing with this clutch before it was properly seated, and glazed it.

That’s it for this class, but in the next installment of Centerforce University we will go over flywheel design and how to pick the right one for your car, so stay tuned!