Project Grandma started out as a plain-Jane, refrigerator white, underpowered, smog-strangled ’78 Malibu that was in desperate need of attention. After we got our hands on her, she was fitted out with a 25.5 roll cage and an asphalt-tattooing Edelbrock/Musi 555 cubic inch engine. Grandma has become one of the favorites in the powerTV garage, but the best never rest, and it was time to try something a little different. We planning a new power plant, and that switch would also mean reworking the fuel system to accommodate carburetion. Fortunately, with a little help from our friends from Aeromotive, the swap was straightforward, and soon we’ll be hitting the track again with old Grandma.

The Aeromotive fuel system

Switching from an EFI system to a carburetor is not as easy as just pulling off the throttle body and slapping on the 1050. There are many other components that need to be changed out as well, including the fuel system. The fuel system in an EFI application needs to supply gas at 75 psi or higher, a far cry from the single-digit pressures required by our carburetor. Keeping the EFI pump would mean regulating it so far down that the majority of the fuel would be bypassing the carb and returning to the tank, building heat and killing the pump in short order. To avoid all of that, we installed a new Aeromotive fuel system designed to supply fuel at an appropriate pressure and volume.

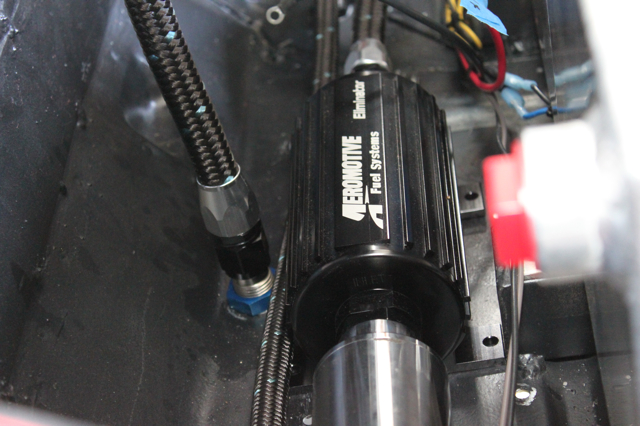

Having the correct components for your application is critical to how it performs, and this Aeromotive system was matched to Project Grandma’s needs. The Eliminator fuel pump (p/n 11104) is able to support a 2300 HP naturally aspirated engine, which will be more than enough for our 970 HP needs. A 100 micron stainless steel element pre-filter screws straight into the suction side of the pump, and a -12 fitting connects the pre-filter to the fuel cell.

The pressure side of the fuel pump drops down to a -10 fitting and from there goes through a 10 micron paper filter, then forward under the car to the fuel log. The Aeromotive fuel log (p/n 14201) has a cool feature added to it – where each side of the log attaches to the carburetor, there are swivel points that allows the user to position the log up or down up to 20 degrees for clearance of throttle stops, nitrous plates, spacers, or other components.

From the opposite side of the log a -10 line runs back to the regulator. The two-port bypass regulator (p/n 13212) is fully adjustable from 2-20 psi, which is perfect for our carbureted application. A -10 line was used as the return line from the bottom of the regulator back to the fuel cell.

Even though installing the fuel system was very straightforward, there is one important rule to remember that can mean the difference between life and death for the fuel pump. Using the wrong filter, or not putting them in the correct order can harm the system. Jesse Powell of Aeromotive explains, “One of the single greatest issues we take phone calls on are filters being in the wrong location, or the wrong size filters that will cause the same problems.” The free-flowing 100 micron stainless steel filter that goes before the pump is designed to catch the large contaminants that would harm the pump. The 10 micron paper filter is what will catch all of the remaining debris that would plug up the carburetor. Mixing the two up can have serious consequences. “The reason the system needs to be set up this way is because the Eliminator fuel pump, or just about any other fuel pump out there, can push fuel out a lot easier than it can suck in,” says Powell. Putting the fine, 10-micron filter on the inlet side will damage the pump by overstressing it as it fights to pull instead of push. The rule to remember is, “Stainless = Suction, Paper = Pressure”.