BlownZ Tech Article Archive

Not only are we providing a pretty comprehensive build diary here, but we dive into tech details with full length articles. Check them out below:

LSX 388 Build Part 1 – Block Prep

LSX 388 Build Part 2 – Short Block Assembly

Individual Cylinder Tuning With AEM’s 4-Channel Wideband

Building BlownZ’s Driveshaft with Dynotech

Installing Moser Engineering’s Drag Brakes

Tuning With AEM’s Dual 4-Channel Wideband UEGO

The Jesel Valvetrain In Our LSX 388

Shifting Weight and Steering Straight – BlownZ’s Front Suspension

Project BlownZ: Plumbing With Fragola Performance Systems

Dropping Weight With Five Star Bodies Windows

Wilson’s Manifold Magic: Holley Hi-Ram For BlownZ

Tech: Installing A Chiseled Water Tank and Intercooler

Tech Review: Chassisworks CDS Gear Drive On BlownZ

Keepin’ It Slick: BlownZ’s Dry Sump Oil System

Dyno And Track Testing With Our 388 LSX BlownZ

388 LSX Race Engine Part 3: Trick Flow/TEA Cylinder Heads

Exhaust System Tech: BlownZ Gets Its Pipes

Feeding The Beast: Project BlownZ’s Fuel System

Project BlownZ Upgrades In 2013; Testing And Troubles…

BlownZ: 388 LSX Rebuilds Adds Boost, Lowers Compression Ratio

BlownZ Runs 7.59 To Earn Title Of Quickest Magazine Project Car

Tech Install: losing Weight With Fiberglass Doors

See the latest updates in our 2014 Edition Build Thread

If you had a 5,000 square foot shop, two full time pro fabricators, and the cell phone numbers of every engineer, marketing guy, and owner for all the aftermarket companies you’d ever heard of at your disposal, and you DIDN’T build some crazy, bad-ass race car, you would be out of your mind. Here at powerTV, we happen to have those resources at our fingertips, so it should come as no surprise that we’re putting together a no-effort-spared NMCA 275 Drag Radial Camaro right under our own roof.

Our shop dawgs Sean G. and Dean J. are in the middle of a flat-out thrash to get our 2002 F-Body aka “BlownZ” ready to hit the track this race season, and every day brings us a little bit closer to completion. We’ll be racing in the NMCA West 275 class, but will also venture into Outlaw 8.5 and possibly some LSX Shootout races. We’re documenting everything in detail for full tech articles on each aspect of this build, but we want to keep you up to date on some of the important milestones we’re passing every week. Bookmark this page – we’ll be updating as we go along, and putting in links to all the detailed stories.

Where do we begin? When our “new” Z28 rolled into the shop, it was a running, albeit not completely sorted, race car. But since our motto here is “never leave anything untouched,” we dove right in and began reworking the car into our own vision of what we wanted.

Project Build Diary:

November 7, 2013: That’s A Winner!

It was a hard fought battle not without its peaks and valleys of high moments and immense struggles, long hours, and broken parts, but at the season-ending NMCA West World Street Finals at the Auto Club Famoso Raceway in Bakersfield, Project BlownZ emerged victorious for the first time, not just winning the race, but recording the quickest pass to date in the west coast 275 Drag Radial category.

As we’ve documented in previous build updates, we’ve been on a mission to get BlownZ down from it’s hefty state of more than 200 lbs. over the required minimum weight for the class based on our engine/power adder combination. Having already run 7.60’s, we knew shaving some mass off the car could very well push us right into contention, and the diet plan couldn’t have come at a better time, as we found ourselves locked in a three-way battle for the class championship at Bakersfield.

Right away we saw the performance gains had in getting the car down to weight, as BlownZ made it’s best run ever early in the weekend, going 7.53 at 186 MPH, which was followed up by runs of 7.46, 7.41, a 7.44 to open eliminations, and with the race on the line, a 7.35 at 189 MPH in the final to oust Kevin Young. While we narrowly lost the title to Young, we did exceed all expectations for the finale and the year in general, and now we know that we can come out swinging in 2014 and chase the title.

CLICK HERE TO READ THE FULL STORY FROM BAKERSFIELD

September 16, 2013: Losing Weight With Fiberglass Doors

We’ve got a strong engine and a great car in BlownZ — a combination perfectly capable of winning races and putting up stout numbers — but one thing holding us back has been weight. You see, the car has tipped the scales 200 pounds over the required minimum weight all season, and as those of you that have raced before know, every pound adds up on the timeslip.

We knew to be competitive with the frontrunner on the West coast, we’d have to get down to weight, and so that’s exactly what we’ve set out to do this year.

Because there’s only so much you can do per the rulebook, the first place we turned was the factory doors that we’d been running on the car. If you’ve ever picked up an OEM steel door, you know they’re heavy, and by switching to an aftermarket fiberglass version, we could shave off a considerable amount of weight. So we tracked down a set of bare, fiberlgass doors for the fourth-gen Camaro, and then called up our friends at Tim McAmis Performance Parts, who manufacture a whole catalog of parts for DIY projects just like this one. TMPP supplied us with a range of their top-notch parts (of the very same quality you find on their all-out Pro Mod builds) to help us get the doors completed and installed, including a window frame and screw kit, upper and lower door latch kit, door hinges, door stop strap kit, and other associated parts and tools.

The end result of our work (which is walked through in detail) is a reduction in total door weight by 1/3, from the 72 pounds of the stock doors to a meager 23 pounds, 2 ounces for the new fiberglass versions. Figure in both doors and that’s a savings of 98 pounds in total vehicle weight — something we’ll certainly notice on the track. But we’re not done there, as we have other weight-saving projects on tap for the future to get the car to its goal of 3,200 pounds.

CLICK HERE TO READ THE FULL STORY

August 6, 2013: BlownZ Tubing Gets Super-Sized With Race Part Solutions

As many of you know from previous project updates, we switched over to ProCharger’s popular new F-1X supercharger for the 2013 season, allowing us to make considerably more horsepower in our quest to reach the sevens and hurt some feelings in the 275 radial class. That switch netted us excellent results, as we recorded our first seven-second pass and clawed our way into contention at virtually every race. Of course, we couldn’t accomplish this with simply a supercharger swap, as there’s more involved than just the source of the boost. We have to get the boost to the engine, as well.

And that’s where Race Part Solutions came in.

The more boost you’re making, the more air you’ve got to be able to move. It’s all about resistance. So to help us improve our airflow from the supercharger to the intercooler and back to the intake manifold, we grabbed aluminum transmission cones, silicone couplers, T-bolt clamps, and V-band clamp hardware to tie it all together.

CLICK HERE TO READ THE FULL ARTICLE

July 30, 2013: The Quickest Magazine Project Car In History

It took us more than a year of preparation and testing, plus a lot of hard work, late nights, and sheer determination, but we finally achieved our goal with Project BlownZ of putting a seven-second number on the scoreboard!

In the third round of qualifying for the 275 Drag Radial category at the NMCA West Coast Shootout at the fabled Auto Club Raceway at Pomona, the Camaro marched to a 7.699 at 181.13 mph, going well beyond our conservative expectations with a run well into the seven-second zone. The run, which came by way of a 1.219 short time and a 4.992-second, 145.02 mph half track clocking, officially made BlownZ the quickest magazine-built Project vehicle of all-time.

From the time we unloaded at Pomona, we knew that BlownZ was ready to eat, it was just a matter of getting the combination right and everything coming together for one great pass. On our very first pass, the car showed its potential as, unlike any other pass previously, the car hoked the front end about fifty feet out and kept climbing until our driver wisely lifted. In the second round of qualifying we pulled five degrees of timing to get the car down the race track, ultimately coming up with a clean 8.09 after our driver had to pedal.

With the track there, we reduced the launch retard to 3-degrees at launch for the third session and crossed our fingers. And 7.69 seconds later, our first big goal was in the bag.

Of course, that first “seven” is just the first step in our adventure with BlownZ, as there’s still plenty of work to be done to put ourselves into contention with the frontrunners of the 275 Radial class who are consistently in the 7.40-7.50 range. Looking ahead, BlownZ will need some weight shaved from its portly 3,400 lb. frame, and, if we keep up the performance, a 25.3-spec chassis upgrade may be in our future.

CLICK HERE TO READ MORE ABOUT BLOWNZ’S FIRST “SEVEN”

July 9, 2013: Spring-Time Upgrades And Updates

If you’ve been following along, we’ve had a number of pseudo project updates lately on BlownZ to help catch up on all of the work, changes, and upgrades the Camaro underwent during the winter off season (if you can really call it winter in California) to get us closer to our goal of running in the sevens.

The first such tech piece highlighted the Derale Hyper-Cool remote fluid transmission cooler unit that we installed on the car to provide us with optimum cooling for such a racing application in a compact and uncluttered package. Of course, the lack of clutter is owed to the remote design of this cooler as, thanks to its design that allows air to pass through so the can can pull from the bottom, thus allowing it to be mounted virtually anywhere on the car and on any surface and still perform. On BlownZ, we mounted the unit under the rear of the car, behind the rear housing.

From there, we jumped into the installation of our ProCharger F-1X supercharger, was part of our plan all along to provide us the power to reach our performance goals. We already had our Chris Alston’s Chassiworks gear drive in the car, but to accommodate the new combo, we had to step down to some 9.5: 1 JE Pistons, a new Aeromotive Hex Drive fuel pump, and a new TCI transmission, among other adjustments.

More recently, we offered a brief glimpse at the super-tall new valve covers from the folks at Granatelli Motorsports to fit the LSX 388 powerplant that look as good as the car is fast. And finally, in our most recent update, we dug into Meziere’s trick billet flexplate that we’ve outfitted on the car. This new flexplate is a one-piece, 168-tooth, lightweight part designed for GM LS1 to LS8 engines. And with SFI certification, we know it’s perfect for a seven-second racing application.

May 3, 2012: BlownZ 388 LSX Rebuilds Adds Boost, Lowers Compression Ratio

In our debut season with BlownZ last year, our primary goal was more or less to get our feet wet and learn the race car. This was our first endeavor with a race car with this much power on this kind of tire, and so while we certainly had every intention of going rounds, our primary focus was making good, clean runs to gather data and knowledge from. As we looked forward to 2013, however, we were ready to take the gloves off, and that meant that during the off season, our 388-inch bullet had to come out and go under the knife, so to speak.

Our goal in the horsepower department was 1,500, and to do so, we needed to step up to a larger ProCharger supercharger, which in itself, prompted the need for not only a winter refresh, but a lowered compression ratio and other new components to support the increased boost levels.

The off season adventure got underway by removing the LSX engine and sending to L&R Engines in Santa Fe Springs, Calif. for disassembly and inspection. Once everything checked out fine, it was time to begin tackling our list of changes and upgrades.

The Lunati Pro Series crank was mic’d and the measurements compared to dial-bore readings of the mains to ensure a .0028-inch clearance. After the crankshaft was positioned in the block, the mains were lubricated and torqued down: 60 ft-lbs on the inside bolts, 50 ft-lbs on the outside and 25 ft-lbs on the side bolts.

(Left) The Trick Flow heads were cleaned and the Ferrea valves lapped in place. New Comp 1.625-inch dual springs were tested (350 pounds on the seat, 950 pounds open) and installed at 1.950-inches using Manley titanium retainers and locks. The SCE Titan gasket was copper coated and positioned before the ARP 1/2-inch head studs were threaded in place. The heads were positioned and the main bolts torqued down to 95 ft-lbs, with the smaller bolts in the lifter valley and inside of the head tightened to 35 ft-lbs. (Right) The long block was dropped into the Camaro, then topped off with the Wilson-modified Holley ram intake manifold, FAST 160-pound injectors, Holley fuel rails, MSD ignition and Fragola plumbing. Also installed were the Jet-Hot-coated Kooks headers and Petersen dry-sump tank. Blown Z does not have a radiator; instead, cooling is through a Chiseled Performance water tank, which also feeds the air-to-water intercooler.

The rebuild was fairly routine, as we had the block hot-tanked, checked, and honed to fit our new JE Pistons and Total Seal rings. We also installed Clevite bearings for the Lunati Pro Series crank and GRP rods, while the Comp Cams camshaft was placed back into the block with its original roller bearings.

Of course, at the heart of our new combination is the awesome new ProCharger F-1X blower, with a 72,000 rpm maximum impeller speed (up from 68,000), a half-inch larger outlet diameter, and a full inch larger inlet diameter from the F-1R that we ran last season. In a conversation with engine builder Steve Morris, who specializes in ProCharger engine applications, he told us that the F-1X is good for about 300-400 more horsepower over the F-1R, and will deliver up to 38 psi of boost from its self-contained design that relies on a 5.4:1 step-up ratio.

Here’s a comparison of the Procharger F-1R on the left and the upgraded F-1X. The outlet diameter on the F-1X is a half-inch larger than the F-1R. On the other side, the inlet diameter is a full inch larger. The photo was taken with the F-1X right out of the box. The orientation of the internal 1:5.4 step-up gear drive (shown on the right) was later adjusted to match the F-1R’s position for installation in the car. The maximum impeller speed increases from 68,000 to 72,000 rpm on the F-1X.

We’ve only got so much space here in this project update that only scratches the surface of our detailed tech feature highlighting the rebuild of BlownZ’s LSX 388, so do yourself a favor and click on over and read the complete story and see tons of high quality images from L&R Engines at the link below.

CLICK HERE TO VISIT THE COMPLETE ARTICLE

April 3, 2012: BlownZ Upgrades In 2013; Testing And Troubles…

We had a fairly successful first year of racing with our Project BlownZ Camaro, running a best of 8.24 at 168 MPH that, while a little short of our expectations, was quick enough to earn the title of the quickest and fastest magazine project vehicle in history. But we’re not content with running in the eights, and so the car underwent some wholesale changes in the off season in an effort to improve upon our performance and, hopefully, crack into the seven-second zone early on in the 2013 season.

The first big change, which was part of our plan from the very beginning, was a switch over to ProCharger’s killer new F1-X supercharger that’s taken the X275 world by storm over the last year since it’s release. We made just over 1,100 RWHP with our F1-R bolted to the 388-inch LSX bullet, but we knew the X would get us over the performance hump and into the same realm as our competition in the 275 Drag Radial class.

There were some changes made in the latter part of last season, including the addition of Chris Alston’s Chassisworks’ new CDS gear drive system for the blower, but the bulk of it all came during the winter (if you can call it that in California) as we went all-in for an even better sophomore season.

Our changes included:

- ProCharger F1X Supercharger

- Re-build the 388 with JE 9.5:1 compression pistons

- Aeromotive Belt-Driven Fuel Pump

- New TCI Transmission w/TCI 6-bolt Convertor

- Moser Gun-Drilled Axles, Aluminum Center Section

- Remove the Radiator for a Chiseled Water Tank/Rule Pump

Once everything was buttoned up, we headed out to our local 1/8-mile strip in Barona, Calif. in February for some shakedown runs, but the outing didn’t go quite as planned, as we discovered a few gremlins that only track-time can truly expose. We made three passes, and all of them were busts. Out main issues revolved around a soft tune, a converter that we determined to be a little too tight for our combination, and a “phantom” rev-limiter that wasn’t allowing the engine to exceed 7,700 rpm, causing the car to leave and run like a snail.

Left: We attempted to get ahead of the “curve” with BlownZ by testing twice in 2013 prior to the first NMCA race. It didn’t work out all that well. Right: We broke something in the drivetrain on the second pass in Bakersfield at about 80 feet out. There simply wasn’t enough data to figure anything out other than we were still far too rich with our tune up. Back to the drawing board to get ready for NMCA Bakersfield. Such is the life of a race car team! Some minor repairs, a new crank trigger system, and we’ll be ready.

With a few weeks to work on things, we then towed up to Bakersfield and Auto Club Famoso Raceway for the WCHRA season opener to make some laps and compete in the True 10.5 class. We had a new converter in the car and hoped that our rev-limiter issue was solved, but as we quickly found out, the problem was still present. To add to that, our tune-up was pretty fat. We did record a best of 5.50 at 130 MPH, but that’s certainly not where we want to be. Hey, no one said this drag racing thing was easy.

CLICK HERE TO READ THE ENTIRE UPDATE ON OUR CHANGES AND EARLY SEASON TESTING

March 12, 2013: BlownZ’s Fuel System And New Lithium Pros Battery

So we’ve dug into our valvetrain combination and then our exhaust system in our two latest project updates; now we’ve got to work on feeding this bad boy.

Our newest tech feature regarding Project BlownZ dives into our new Aeromotive fuel system that we’ve selected to fuel our supercharged engine, along with he components from Fragola Performance Systems that we’ve picked up to complete the setup.

Our pump, an Aeromotive EFI Pro Series unit, is designed for and can easily handle as much as 1,700 horsepower in a forced induction EFI engine and a staggering 2,600 horsepower in a naturally aspirated, carbureted motor. With almost double the flow capabilities of Aeromotive’s famous A1000 pump, this thing is killer and more than enough to accommodate our needs. In addition to the pump, we’re utilizing Aeromotive’s EFI Pro Series Fuel Pressure Regulator and EFI Pro Series fuel filters. The VP Racing Fuels C16 fuel is fed through Fragola’s 3000 Series race hose and fittings from a custom-built two gallon fuel cell to Holley LS fuel rails for our Hi-Ram intake outfitted with FAST 160-pound fuel injectors.

No inadequate fuel pressure or volume problems with this beast. The Aeromotive Pro Series EFI fuel pump can easily flow enough fuel to meet our 4-digit power goals, and even leave some room to grow.

We plumbed in a Pro Series Fuel Filter on each side of the fuel pump - one immediately after the fuel leaves the cell, and another before it goes on to the FPR. You might be thinking that the first filter is too close to the oil cooler, and will heat up the fuel. If his were a street car, we would agree. But the fuel will have plenty of time to cool down between rounds, so we aren't too worried about it, and it made the packaging much simpler up front.

CLICK HERE TO READ THE DETAILED FEATURE AND INSTALL OF THE FUEL SYSTEM

Elsewhere, we’ve also made a change in the battery department on BlownZ in the name of saving precious weight, opting for one of Lithium Pros‘ ultra light lithium batteries. Within our fuell-length tech review, we’ve dug deeper into the technology of lithium ion batteries and its advantages, but oen of the big selling points for drag racers is that these batteries are 60-80% lighter than a comparable lead acid battery. The battery seen here that we installed in BlownZ weighs just nine pounds, which is 26-1/2 pounds lighter than a same-size lead acid battery for the car. Of course, with an impressive depth of discharge of 80 percent and quick charging, there are obvious pluses beyond just weight.

Left: This lead acid battery of the same size as the Lithium Pros battery we use in BlownZ weighs 35 pounds, 14 ounces. Center: The Lithium Pros battery used in BlownZ weighs just nine pounds, six ounces. That's a weight savings of 26-1/2 pounds. Far Right: This is the Lithium Pros battery out of BlownZ. It is nearly impossible to hold a comparable lead acid battery like this.

You might recall in our recent feature on the Chassisworks gear drive unit that we’ve intentionally changed our combination around to run the fuel pump directly off the crank as an accessory drive so that we could cut down from two batteries to one, and this is a part of that process.

READ MORE ABOUT THE LITHIUM PROS BATTERY IN BLOWNZ

March 12, 2013: Exhaust System Tech: BlownZ Gets Its Pipes

In our last update, we took a closer look at the engine build of our LSX powerplant, and in specific, our cylinder heads and valvetrain combination. As any gearhead knows though,once that air makes its way past the exhaust valve, it takes a well designed set of headers to make the entire package work well, and that’s the subject of our latest BlownZ tech article, as we take a glance at the new headers that the folks at Kooks Custom Headers have ‘Kook’d’ up for us.

Based on our engine combination, power output, power adder, and other attributes that all come together int a header-building formula, the team at Kooks fabricated us a set of 304 stainless long-tube headers, featuring two-inch primaries and a 3.5-inch collector. Kooks developed these headers, which weigh in at 35 pounds with all the hardware attached, specifically for LS-powered, fourth-generation GM F-bodies like our Camaro.

At many drag strips, and particularly those here in California, we can’t simply run open exhaust, so we’ve got to make ourselves legal, and for that, we turned to Vibrant Performance and their four-inch Race Mufflers. We’ve also picked up two four-inch oval stainless steel tubing sections, two oval-to-round four-inch OD transition adapters, and stainless V-band flange assemblies to complete our exhaust setup.

Here are the 304 stainless steel Kooks long-tubes spec’ing in with 2-inch primaries and 3.5-inch collectors (PN 6501-2R-MC). You’ll also note in this photo the patented scavenger spikes.

Left: Here, shop dawg Sean welds the O2 sensor bung for the F.A.S.T EFI into place on the Kooks headers. Thankfully, we have a full line of Lincoln Electric welding products to complete the job at hand! Right: Our completed exhaust system simply looks awesome under our Camaro, and we're more than happy with the components we've selected. We admit it would be a bit much for a street car, so you may want to consider that if you're looking to mimic this setup.

In this update, we offer a glance at the components we’ll be utilizing before getting our hands dirty, welding the O2 sensor bungs to the header and piecing the entire system together out in the shop.

CLICK HERE TO READ THE TECH ARTICLE ON OUR EXHAUST SYSTEM

March 12, 2013: New Video From The Track

Last week, our video crew churned out an awesome new highlight video filmed last season at the Auto Club Raceway in Pomona during one of our first outings with BlownZ, showing our shutoff 9.57 pass followed by a our much improved 5.62 to the 1/8-mile in eliminations. Hit the video below and have a look!

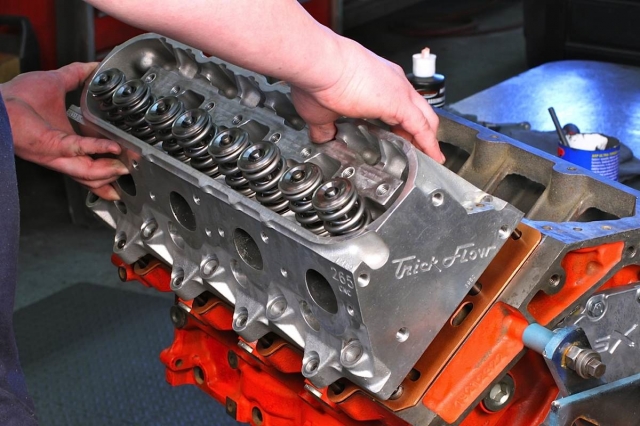

February 1, 2013: 388 LSX Race Engine – Trick Flow/TEA Cylinder Heads

We’ve already covered the short block build of our 388-inch bullet in-depth here on Dragzine, and with that complete, it’s time to move on to the rest of the engine build. Naturally, as we work our way upward, that brings us to the cylinder heads, for which we’ve called upon Trick Flow Specialties/Total Engine Airflow.

As any novice engine builder can attest, cylinder heads are one of the primary ingredients for making peak horsepower, so we knew we had to select the proper head (that also fit within the rules) to flow the kind of numbers we had in mind. Our good friend Shawn Miller at Virginia Speed, who performed the engine build, determined with the folks at Trick Flow that a set of their TFS 265cc LSX-R heads were just the answer. Once in Miller’s hands, Total Engine Airflow in Tallmadge, Ohio port the head for maximum flow.

Filling out the drivetrain, Ferrea supplied us with a set of their titanium intake valves stainless steel exhaust valves, all from their 6000 series Competition lineup. For valve springs, we turned to COMP Cams, who hooked us up with their Elite drag race dual 1.500-inch diameter valve springs to handle the valves while under operation at more than 9,000 RPM with a big lift cam and high cylinder pressures, because a set of wimpy just don’t do in those conditions. Last, but certainly not least, we turned to Jesel to supply us with their very trick shaft rocker setup and a set of keyed lifters, topped with some of their drop dead sexy billet aluminum valve covers.

We put a lot of thought into the cylinder head choice for the ProCharged 388ci LSX for Project BlownZ, and in the end we went with a set of Trick Flow’s LSX-R 265 heads and let the guys at Total Engine Airflow work their magic on them.

This article covers every step of the cylinder prep process, and even dives into the flow numbers and the specific details of the port work performed by Total Airflow, so if you’re curious to know more about our setup or just want to glean some knowledge for own engine build, you’ll want to check out the story in its entirety.

Left: We finished off BlownZ's TFS LSX-R 265 heads with Jesel's trick long-slot rocker arms. Right: High rpm and lots of boost means you’ve gotta run a lot of spring, and we handled that with Comp Cams’ Elite Drag Race dual springs with 350 pounds on the seat and a whopping 950 open.

READ THE COMPLETE UPDATE ON OUR CYLINDER HEAD SELECTION AND INSTALL

January 15, 2013 – Keepin’ It Slick: BlownZ’s Dry Sump Oil System

If the absolute end goal of your racing program is to make horsepower (by not giving up horsepower) at all costs, there’s simply no other choice in the oiling department but a dry sump system. And in the vast majority of heads-up race cars where power wins and a lack of horsepower misses the qualifying field, dry sumps are a virtual requirement. There are of course other benefits — and cons — to a dry sump, which are hit on in detail in this latest update on BlownZ.

Getting down to the nitty gritty details, most of the hard parts of our dry sump puzzle come courtesy of our friends at Peterson Fluid Systems, including their lightweight, five-stage R4 dry sump pump, pre-filter, a seven-inch drag racing reservoir tank, oil tank heater, inline temperature sender housing, and their remote oil filter mount with a system primer. For the oil pan, we went with an ARE piece designed for the LS engine, and Fragola 3000 Series hoses and fittings completed the dry sump system loop for us in great fashion.

Naturally, even more important than how you circulate oil through the intricate system that is a race motor is WHAT you circulate through it. An engine is a sizable investment, and good oil is like a insurance policy on your investment. So, we got hooked up with Royal Purple, who turned us on to their XPR (Extreme Performance Racing) 10-W40 oil designed specifically for the demands of a high-horse race engine.

Left: A dry sump oil system makes perfect sense in a dedicated drag car like BlownZ. We want to keep the windage and parasitic power losses to a minimum - and that's just what a dry sump will do for us. Right: The Peterson -12AN pan mount and 90-degree pre-filters were a perfect match for our ARE dry sump oil pan.

Left: We used Fragola's Series 3000 Braided Stainless Race Hose for all of BlownZ's cooling, fueling, and oiling plumbing. We matched the hose with Fragola's Series 3000 billet swivel hose ends. Right: After all this hard work, there's no way we're trusting our engine to just any old off-the-shelf oil. For us, Royal Purple's XPR 10w-40 Race Oil was just what we were looking for to keep our engine healthy and not cost us power.

In this update, we take an in-depth look at each part of the dry sump system on BlownZ’s LSX bullet, providing a break-down of each of the components needed to make it operational.

CLICK HERE TO READ THE FULL ARTICLE

January 14, 2013 – Chassisworks CDS Gear Drive On BlownZ

Hardcore supercharged racing applications like our Project BlownZ have for years been shifting away from the more standard use of supercharger belts in favor of a gear drive system that takes the stress and load off the snout of the crankshaft, while also alleviating the problems that belts inherently have in all-out race use. With BlownZ in the shop for the winter for upgrades for the coming 2013 season, we took the opportunity to upgrade our drive system with Chris Alston’s Chassisworks’ new Component Gear Drive system that brings to the table not only a gear drive setup for single and dual superchargers, but some really trick accessory drives on the single blower units that can drive your alternator, fuel pumps, water pump, steering pump, and distributor, should you so choose.

Chassisworks has developed these units for a number of different engine combinations, and we had the opportunity to bolt on one of the first pieces designed for the LSX powerplant to mate up with our ProCharger F-1R blower (and eventually the F-1X). We also opted for a lone accessory drive for our new fuel pump from Aeromotive that we’ve gone to. The fuel pump, Aeromotive’s Billet Hex Drive, was a necessary addition to fulfill our goal of downgrading our power draw, as we’re not running an alternator and recently went from two 16-volt batteries to one.

From this angle, you can see the direct connection of the ATI damper to the flange of the gear drive.

Another part of this update on BlownZ, and one that comes as part of the move to the gear drive, is our new ATI Super Damper balancer that ATI Performance Products whipped up for us to our specifications. What we received was a lightweight damper that actually encompasses seven different part numbers, with a dual-keyway hub (a must when running a blower), a thinner physique, and a face with three extra bolts to bolt to the face of the six-puck hub of the gear drive.

Here's an up close and personal look at our finished product ready for a crack at the dyno. We'll be bringing you additional updates on our experiences with the gear drive after we get some testing hits on the new combo.

READ THE COMPLETE ARTICLE HERE

January 10, 2013 – Installing A Chiseled Water Tank And Intercooler

If a supercharger is going to make the optimum power — and that’s pretty well the reason why we drag racers do what we do — then cooling that air being forced into the engine at an incredible rate is key. To keep our 388-inch LSX bullet fed with cool flowing air from our ProCharger F1-R blower, we set out to install a brand new intercooler and water tank system inside the confines of our Camaro.

The new setup consists of a water tank and intercooler from Chiseled Performance, a Rule in-tank pump, 3.5-inch intercooler piping and VanJen clamps from Vibrant Performance, and water lines and fittings from Fragola.

The new intercooler comes out-of-the-box with the tank already mounted inside, however, the end-user is required to perform a little welding work to install the mounting brackets for installation. After all, not every car is the same.

We began assembly by starting from the engine bay and working our way back. The green tape you see was applied prior to installation, as to prevent any kind of unnecessary scratching to our brand new intercooler tubing while other work was being performed on our 388.

The completed Chiseled intercooler and water tank, ready for installation into BlownZ. At this point, we weren’t sure if we wanted to actually install them, or just stare at them for a while. They really are that pretty.

Left: Dean routes our Vibrant ducting from the engine through the firewall, to the intercooler. Right: This is what our air charge system looks like inside the cockpit. You can forget about taking a passenger down the 'strip with us because it's just not happening.

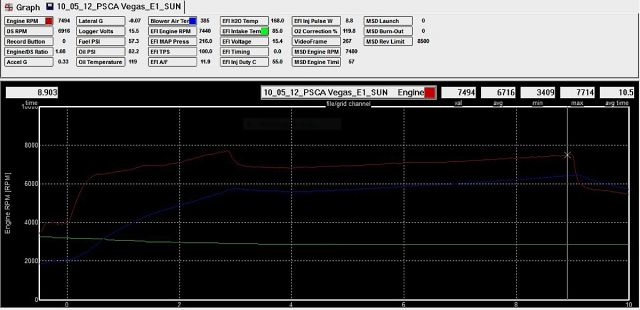

When all was said and done and testing was complete on the dyno to see how the new intercooler and water tank setup performed, we recorded a maximum blower air temperature of 385 degrees at 6.250 RPM, with an intake temperature of 85 degrees at 3,500 RPM. Plus, our water temperature never peaked over 168 degrees — much lower than a car typically runs at.

CONTINUE READING BY CLICKING HERE

October 25, 2012 – Our New Holley Hi-Ram Intake From Wilson Manifolds

Those of you familiar with our 2002 Camaro BlownZ will know about our desire to run 7s with our ProCharger F1R equipped 388 LSX engine. As part of our mission, we equipped the engine with TFS 265cc cathedral port heads and the new Holley Hi-Ram intake manifold. The Holley Hi-Ram (see our article here) is an outstanding intake manifold that is a tunnel ram-type intake for the LSX engine. However, because the Hi-Ram is built for everything from hot street applications (500 hp) to entry-level race engines, it simply can’t be all things to all people. After we go the engine running down the race track and on the dyno, we discovered that for our power levels of 1,300-plus horsepower, the Hi-Ram simply didn’t have the plenum volume that our engine needed in order to produce maximum horsepower with optimal efficiency.

Step one in the Holley Hi-Ram Wilson project was removing the Holley plenum. Using a mill, Wilson’s fabricators cut out the stock runners from the original Holley plenum.

(Left) The Holley-Hi Ram runners were welded to the Wilson sheet metal base. To make it look good, Wilson polished all of the welds flush and then bead blasted the intake. This helps make the lower look uniform and aesthetically pleasing. (Center) Welding together the upper sheet metal intake. Everything Wilson touches that is aluminum is rig-welded by experts with years and years of welding experience. A fine touch is needed for welds that look awesome. (Right) During initial mock up, Wilson test fits the Hi-Ram with the new sheet metal plenum. Those vertical aluminum spacers are welded into the upper plenum area to keep the manifold from distorting and getting tweaked during the welding process. Wilson also shortened the Holley runners about 3/4-inch because of the 8,500 rpm range of our LSX intake.

READ THE REST OF THE STORY HERE

October 15, 2012 – Moroso’s LS Valley Plate And Our Cooling Setup Swap

Despite the best-laid plans when piecing a race car together, there are certain things that you simply can’t determine without taking the car out to the track, putting some laps on it in a true racing environment, and evaluating all of its functions and operations.

For the cooling setup on BlownZ, we chose one of AFCO’s premier doorslammer radiators (Part No. 80104N), which features an all-aluminum, tig-welded construction, and paired it with a single 8-inch fan. Because we were going to run a Meziere radiator-mount water pump rather than an engine-driven pump, we had to do some modifications. We began by replacing the large inlet at the top of the radiator with a pair of -16 AN bungs and fittings, one of which was drilled and welded on the side of the radiator. The crew at AFCO then assisted in modifying the water pump and bracket so that it could be mounted on the radiator. In lieu of the water pump mounted on the motor, we installed an adapter with four AN fittings — two of which fed to the inlet and the other two to the water pump.

This cooling setup peformed admirably, but if you’ve ever been to California, Nevada, or Arizona in the summer time, it’s hot, and with some of the delays that are common at the track, like waiting for officials to check the track or for a car to clear the top end, we were running a little on the warm side. So we turned to our friends at AFCO, who set us up with a larger 10-inch fan and a shroud to bring those temperatures in check and allow us to run the car for a longer period of time without concern.

Here’s the AFCO radiator with the larger 10-inch fan and shroud that AFCO supplied us to deliver some cooler temperatures to the motor.

Shown here is our AFCO aluminum radiator, which was recently retrofitted with a 10-inch fan and a shroud for improved cooling, along with a view of our radiator-mounted Meziere water pump that's routed to the block via AN bungs and fitting that we've plumbed into the block and radiator.

Elsewhere, another recent addition to the project is one of Moroso’s LS Lifter Valley Plates. These plates, which cover the lifter valley’s atop factor and aftermarket GM LS Series engines, replaces the OEM GM plate and lacks the two provisions for knock sensors that generally aren’t used in racing applications, as open headers, slid lifter cams, and stiff suspensions can false trigger the sensors. Aside from the more streamlined functionality that’s more appropriate for racing purposes, this plate is made of aluminum and simply looks great on our LSX powerplant.

It's not easy to see with the top of the engine assembled, but this is Moroso's aluminum LS Lifter Valley Plate that replaces the stock GM piece. The primary benefit is the lack of provisions for knock sensors found on the OEM plate, but it also looks great.

September 20, 2012 – Dropping Weight With Five Star Bodies Windows

In our latest project update, we’ve highlighted the replacement of BlownZ’s front windshield with an aftermarket, race-intended windshield from Five Star Bodies. Now, make no mistake, there’s a lot of weight to be lost by swapping the heavy factory glass for plexiglass or polycarbonate windows, but beyond that, the added level of safety gained by eliminating the actual glass from a 180 mph race car is immeasurable.

Five Star Bodies manufactures windshields for the 1993-2002 Chevrolet Camaro and Pontiac Firebird using a “top secret” process that delivers incredible strength and durability, in thicknesses that include 1/8, 1/4, and 3/16-inch. Rear windows are offered in 1/8 and 3/16-inch.

With the OEM windshield removed and all of the sealer cleared away, the direct-fit windshield drops into place. From there, without over-tightening, we simply begin at the corners and work out way around the windshield installing the allen head screws. The result here? A lighter — and more importantly — a safer race car.

CLICK HERE TO READ THE FULL STORY ON OUR WINDOW INSTALLATION

CLICK HERE TO READ THE FULL STORY ON OUR WINDOW INSTALLATION

September 10, 2012 – BlownZ’s Front Suspension

CLICK HERE TO VIEW THE TECH ARTICLE COVERING BLOWNZ’S FRONT SUSPENSION INSTALL

CLICK HERE TO VIEW THE TECH ARTICLE COVERING BLOWNZ’S FRONT SUSPENSION INSTALL

Getting a high-powered, heavy race car down the drag strip on a set of 275 Drag Radials using stock-style suspension is no easy task, but it’s the task that we’ve accepted. In order to give ourselves the best ride possible and all of the tuning adjustments we need to dial the nose of the car in to the power and the race track, we’ve commissioned a new K-Member, Control Arms, and a Pinto Steering Rack for the front suspension department. In addition, we’ve also obtained a set of AFCO’s double-adjustable front coilover shocks that will allow us to independently set our compression and rebound to tune for the race track.

Tying it all together is PA Racing’s lightweight chromoly drop spindles that will allow us to drop the ride height two-inches and utilize a longer shock, but even moreso, drop sound 60 pounds off the car over the stock OEM spindles.

(Left) The biggest advantage to PA Racing's F-body Drop Spindles is that they helped us drop weight off the front of BlownZ. (Right) Here's the basis of our front suspension - the Spohn Performance tubular K-member, chromoly control arms, and Pinto manual steering rack with bumpsteer corrected tie-rods.

September 10, 2012 – Plumbing With Fragola Performance

When building and operating a race car, you really want the fluids to remain in the race car, because nothing good can come from errant oil, water, power steering fluids, and the like. In effect, hoses and fitting aren’t something that you want to skimp on, and we haven’t.

For BlownZ, we’ve called upon Fragola Performance to hook us up with their braided hoses, fittings, and fittings ends from their Series 3000 Race line of products for the fuel and cooling systems on our supercharged Camaro. The 3000 Race hoses can withstand pressures of 1500 psi with their two woven layers of stainless steel that’s compatible with alcohol and any natural or synthetic-based lubricants from -40 to over 300 degrees.

(Left) Using Stainless Braides Hoses and Race Hose Ends from their Series 3000 line, Fragola Performance Systems supplied the parts necessary to help deliver fuel & oil to this supercharged 388 cubic inch LSX beast we call Project BlownZ. (Right) The Fragola fuel lines and fittings plumbed on BlownZ.

September 5, 2012 – AEM’s 4-Channel Wideband UEGO

One of the most recent additions and certainly one of the most useful tools on our BlownZ Camaro is our new dual 4-Channel Wideband UEGO controllers from our friends at AEM Electronics. This setup is state-of-the-art, with a single oxygen sensor for each hole rather than one sensor for each bank that averages the results.

By being able to monitor and control each cylinder separate of the other with our accompanying XFI 2.0 engine management system, this offers us unparalleled tuning insight.

From the get-go with our chassis dyno testing, we had to work to line out our tune-up, and we were able to take the data gathered from the sensor in each hole to pinpoint where the cylinders were blowing out and get ourselves on the right path as we headed to the track.

The unique heat-sink design of the oxygen sensor bungs allows them to be placed in the perfect position to monitor each cylinder closely.

READ THE DETAILED TECH FEATURE ON OUR AEM WIDEBAND HERE

August 30, 2012 – The Jesel Valvetrain Setup In Our LSX 388 Mill

CLICK HERE TO READ THE FULL ARTICLE ON THE JESEL VALVETRAIN COMBO IN OUR LSX BULLET

As one of the most extensive projects we’ve undertaken to date, a lot of components have played into the construction of BlownZ, with the assistance of a long list of partners in the industry. The folks at Jesel Valvetrain, along with COMP Cams and Trick Flow Specialties, were a part of our most recent tech piece centered around BlownZ, in which we take a look at the trick valvetrain setup that’s been devised for the 388-inch powerplant.

Here's the recipe for our serious LSX valvetrain - first you start with a Jesel belt drive for easy degree changes and dampening, then mix in some Jesel keyway lifters for ultra-high RPM durability. Finally, we topped everything off with a set of Jesel's long-arc rockers, and their trick valve covers for the needed clearance.

Here’s one of the TFS heads with all the Jesel gear installed, and the custom valve cover that is required with the Jesel LS conversion. Said Virginia Speed’s Shawn Miller, “It’s the best thing out there for the LS engine. It takes a while to do the conversion and it’s expensive, but it’s worth it. And the Jesel billet valve cover, while pricey, is beautiful.”

August 21, 2012 – BlownZ’s NMCA West Debut In Pomona

For months, our goal had been to complete BlownZ in time to debut it at the NMCA West coast Shootout in Pomona, and although we only had a couple of test hits on the car to this point, we were off to Pomona. We arrived at the Auto Club Raceway still in test mode, but with every intention of making a showing, and we’d like to think we did just that. BlownZ qualified No. 4 in the five-car field at 5.86 at 117 mph, and although we dropped out first round match with eventual 275 Drag Radial winner Kevin Young, we did card a much-improved 5.62 with a 1.34 short time and our first full 1/8-mile pass with the car. This run would equate to a high eight-second lap at around a buck-sixty in the quarter. We’re getting there. Baby steps…

For months, our goal had been to complete BlownZ in time to debut it at the NMCA West Coast Shootout in Bakersfield. This was the first NMCA race of the year. We didn’t make it. We reset our sight on the PSCA Fontana race, and Fontana got shut down. Just our luck. We quickly eyeballed Pomona – the legendary Pomona raceway that hadn’t seen a fast street car in over 10 years – and although we only had a couple of test hits on the car to this point, we were off to smog city. Driver James Lawrence, Crew Chief Sean Goude, and Crew Member Dean Jigamian finished the last minute thrash and loaded up the trailer.

We arrived at the Auto Club Raceway still in test mode, but with every intention of making a showing, and we’d like to think we did just that. We competed in the NMCA West 275 class, which features mid 7 second runs, and some very competitive racers including the Young Brothers (Jeff and Kevin). The Young’s consistently run in the 7.50s and 7.60s with ProCharger F2 small block Chevys.

We arrived at the Auto Club Raceway still in test mode, but with every intention of making a showing, and we’d like to think we did just that. We competed in the NMCA West 275 class, which features mid 7 second runs, and some very competitive racers including the Young Brothers (Jeff and Kevin). The Young’s consistently run in the 7.50s and 7.60s with ProCharger F2 small block Chevys.

Our goal for the weekend was to get some seat time in the car and learn the chassis and setup, and work on the tuneup. High 8s would be fine, we weren’t trying to really win – but we wanted that sweet nectar called progress. During Friday’s first test and tune session, we were going to start out with a 1/8 mile hit to get a baseline. Buckled into the car, it was hot, hot, hot – almost 100 degrees. We left our setup the same from Barona, a very conservative timing and air fuel ratio, and almost 5 degrees of timing pulled out at launch. After a spirited burnout, we pulled to the line and put BlownZ on the trans brake. We dialed in 3,800 rpm for the launch, and the ProCharger F1R was just started to get work done with 6 psi when we let go off the button. A 1.38 60′ foot was promising, but the car began to the pull to the right soon after launch. Our driver pedaled the car at 300′ before getting back into it, and lifted right around 500′ well before the 1/8 mile mark. We carded a 5.90 at 121 mph in the 1/8, and a 9.57 at only 117 mph in the quarter mile.

For the first round of qualifying, we made some tweaks, but ran into a similar challenge. The car drifted right. We lifted and ran 9.56. BlownZ was practically a bracket car, but not for the right reasons. For a long time, we have been battling an issue with fouled spark plugs. They reared their head again in the second round of qualifying, and the car shut off on the line. We were unable to test our sway bar adjustments. Without a third round of qualifying, that left us with one-shot, one-kill for the first round of eliminations. Good thing we were lining up with the class champion.

BlownZ qualified No. 4 in the five-car field at 5.86 at 117 mph, and although we dropped out first round match with eventual 275 Drag Radial winner Kevin Young, we did card a much-improved 5.62 at 128 mph, with a 1.36 short time and our first full 1/8-mile pass with the car. This run would equate to a 8.70 at around a buck-sixty in the quarter. We’re getting there. This was still on a very conservative setup – think less than 18 degrees of timing and 10.8:1 air/fuel ratio. We’re going to work on fixing a few things, and will get BlownZ back to the track soon in pursuit of the 7-second zone soon.

Pomona TnT Run

Pomona Qualifying Run #1

August 21, 2012 – Testing At Barona And Oiling With Royal Purple

After more than a year in the making, from a complete engine buildup with Virginia Speed to a virtual nose-to-tail overhaul of the Camaro, the day of reckoning finally dawned as BlownZ took her maiden voyage at the nearby Barona 1/8-Mile Drags in Barona, Calif. We knew we'd have to crawl before we could walk, and after a mad thrash all week to get the car ready, this debut was intended to get some data and a little experience behind the wheel for our driver -- not to set the world on fire. We made two runs at Barona: the first netted an early lifting 6.54 at 86 mph, with a 3,000 RPM launch RPM, 10 degrees of timing pulled at launch, and a 6500 RPM shift. On our second run later that evening, BlownZ broke into the fives, despite lifting at 3.2 seconds onto the run. On this pass, our launch RPM was at 3,000 and timing retard at 5 degrees over 1.5 seconds, netting a nice 1.34 short time and a 5.99 at 90 mph. As noted in a prior project update, we utilized VP Racing Fuels C16 for our high compression, supercharged engine. We learned a lot and didn't break anything, and that's a winner in our book.

Bakersfield First Shakedown Run

Testing at Barona

You’ve heard us say countless times that quality, well-maintained oiling is priority number one, and it’s a point we preach and one we live by. Our friends at Royal Purple shipped us some of their XPR 10W-40 extreme performance synthetic racing oil to run through BlownZ’s LSX 388 mill. the XPR combines the highest quality synthetic base oil with Royal Purple’s proprietary additives and other enhancers to create a lubricant that delivers more horsepower and torque, along with more protection against heat and wear.

Here you can see the crew out in the shop filling the dry sump reservoir on BlownZ with the Royal Purple XPR.

Before heading to the track, BlownZ gets an injection of VP’s C16 racing fuel. C16 is designed with turbocharged, supercharged, and nitrous-aided engines in mind, and with compression ratios of up to 17:1. This blend is considered by many racers as their fuel of choice, and is in fact the No. 1 selling racing fuel for high-boost engines.

June 20, 2012 – Finishing Little Pieces

In this installment we wire up BlownZ’s XFI engine management system and ignition, cut our light weight windows, and fire up the ProCharged 388 LSX for some base line dyno tuning. When it came time to tune BlownZ, we went to one of the best in the business. Brian Macy from Horsepower Connection. Brian is one of the most talented XFI tuners in the country and he also is the lead XFI instruction for FAST XFI for EFI University. We have a full story coming soon on the dyno results and our tribulations on BlownZ. While we aren’t telling you the full story yet, rest assured it’s an interesting one!

We highly recommend Macy and Horsepower Connection for XFI tuning. If you need help with XFI, or need to purchase a full system, con sider him and their team. Brian can be reached at brian@horsepowerconnection.com.

So now that we’ve got the engine, transmission, suspension, and rear end ready to go, we just need to get BlownZ wired up. Sounds easier than it looks, but wiring isn’t anything to be intimidated by as long as you take your time and follow the instructions. We selected MSD’s PowerGrid with the MSD ARC control and XFI 2.0. We will also be doing a piece on Davis Traction control.

Since we’re using a distributor to light the fire on our LSX (more on that in a minute), we picked up an MSD Power Grid Ignition to provide plenty of steady spark. Best of all, its got some very cool tuning features we’ll be putting to use. This is a CAN-driven system where we can add additional accessories to the Grid. We have the MSD “ARC” Module which stands for Advanced RPM Control – which will help us dial in our timing retards.

The FAST XFI 2.0 is going to be the brains of this operation, controlling the injectors, spark timing, and giving us all the tuning ablities we really need to get the most out of the 388 LSX. We are working with one of the leading XFI Tuners in the country, Brian Macy from Horsepower Connection.

Electric water pump, electric fans, electric oil warmer, electronic fuel injection – all this stuff takes a lot of power to run, but we don’t want to be hauling around more dead weight than we have to. So we picked up two XS Power 16V light-weight batteries and mounted them in the trunk where the extra weight might do us a little bit of good.

Back in the engine bay, we started fabbing up some brackets for the MSD coil near where the front mount distributor would finally make its home.

The FAST XFI will be controlling BlownZ’s spark, but the MSD Power Grid does have some cool features like timing retards and timing decay that we will be using at the racetrack to plant the 275 Drag Radials.

We used the wiring system from the aptly named Spaghetti Menders to delegate electricity where it needs to go.

After several hours of soldering, crimping, and testing, things were finally starting to come together. Here you can see the FAST XFI, the MSD Power Grid, and the Spaghetti Menders block roughly where they will stay in BlownZ.

We also wired up our Racepak V300SD Data Recorder, and installed one of the most valuable sensors for a car like BlownZ – the driveshaft sensor. The driveshaft sensor can tell us if there was a loss of traction, bumps in the track, torque convertor slippage, and where there convertor lock up occured (slip ratio) in high gear.

Some racers might still be afraid of using EFI and Data Logging to tune their racecar, but we plan to exploid modern technology for all its worth.

One area where we actually decided to use old-school technology was the ignition. We’re running a front mounted Jesel Extreme Distributor Belt drive which used a MSD cap and Hall Effect sensor to supply spark to all 8 cylinders. Why? That’s a good question, and a topic that is hotly debated among racers. However, in the end we went with the distributor because it has proven over yeaers and years of use to be reliable in high RPM applications. Considering that we plan to spin the 388 LSX to almost 8,500 RPM, we need that kind of reliability.

Switching gears, we took the time to test fit our new light-weight polycarbonate windows from Five Star bodies.

On a car like BlownZ, every ounce counts, and polycarbonate windows are 75% lighter than the stock glass in addition to offering the same clarity.

Now things are really starting to happen…We checked everything over, bolted up the Mickey Thompson wheels and tires, rolled it up on the dyno, and filled the fuel cell with VP C16 race gas. VP C16 is our fuel of choice for our higher compression (11.5:1) F1R ProCharger SuperCharged race engine.

It’s dyno time – and that means breaking in the engine, and getting a baseline tune up. We have a long, long story about how this all went down, and we will tell it to you in the next update.

When it came time to tune BlownZ, we went to one of the best in the business. Brian Macy from Horsepower Connection. Brian is one of the most talented XFI tuners in the country and he also is the lead XFI instruction for FAST XFI for EFI University. We have a full story coming soon on the dyno results and our tribulations on BlownZ.

BlownZ Breaking Up On The Dyno

May 22, 2012

With the engine finally in the car, we needed to start pulling together all of the extra parts it needs to actually run. We got our throttle cable and one of Lokar’s Anchor-Tight flexible transmission dipsticks.

The Lokar Anchor-Tight trans dipstick is actually really easy to install, and a pretty trick part. It’s designed to do just what its name implies; anchor tight into the transmission and not leak.

Of course, you have to have the transmission pan out to be able to install the new Anchor-Tight trans dipstick. Here’ a look at the inner workings of our TCI Pro-X Powerglide trans.

The Lokar Anchor-Tight trans dipsticks use a locking mechanism to make sure the dipstick stays in the tube no matter how much pressure builds up in the transmission. It’s a perfect fit for a car like BlownZ.

The nice thing about a flexible dipstick hose is that you can mount it where it’s most convenient for you.We bolted ours to the firewall right underneath where the intercooler piping will enter the cabin.

May 17th, 2009

With the cross brace and cowl box both finally finished up, it was finally time to get the engine installed for what we hoped would be the final time.

BlownZ will be using a dry sump oiling system from Peterson Fluid Systems. Look for a full tech article on the oil system in the near future.

One nice thing about all the cowl work we did is that we could drop the 388 LSX and TCI Pro-X Powerglide into the engine bay from the top rather than up from the bottom like in a stock 4th Gen.

But even with all the extra room we made in the cowl area, it still too a bit of finesse to keep from slamming the engine into our new cowl box. Luckly by now we were getting pretty good at getting the engine in and out of the car.

When we got the engine where we wanted it and the engine plate secured to the mounts, we could start putting the Afco radiator and Aeromotive fuel system back in the car. We were using a custom made Afco radiator with integrated Meziere water pump; Fragola hoses and fittings, an an Aeromotive EFI Pro Series pump.

It might be hard to believe, but that one simple Afco electric fan provides all the cooling BlownZ needs in the staging lanes and after a run. Hey, it’s not like we’ll be sitting in rush hour traffic in a dedicated drag car.

The Holley Hi-Ram Intake manifold is just the icing on the cake. We’re using their new cathedral port version for early style LS heads, and aimed it right at the cowl box.

Now that we’ve got BlownZ’s heart in place, it’s time to get some blood and other vital fluids pumping through the veins. We once again went with Fragola FPS 3000 hose and fittings for the plumbing we had left to do.

…because we have a LOT of plumbing to get done. Here you can see that we’ve got our feed and return lines ran to the fuel rails, as well as the coolant and oil lines to the block. At this point we really started looking forward to the first time we would get to hear this beast roar to life.

In order to contain all of the fuel system lines in an NHRA legal fashion, Sean G. is building a front cross brace and frame for the fuel pump, filters and lines. This will protect the front end components in case of accident.

Moroso’s breathers got the call for BlownZ. These are really nice sheet metal oil breathers – and we hid them behind the front head lights. They also have a nice petcock in case we need to drain them.

You can see how we had to arrange and carefully design the Aeromotive Pro Series pump with a vertical orientation – using a careful selection of Fragola 90-degree and 45-degree -12 fittings.

This is the fuel system layout we’re running on our front fuel-cell equipped F-body. -12 from the cell, Fragola -12 stainless line, Aeromotive Pro Series fuel pump and filters. We’ll need to build a frame around the fuel lines and filter of 1-1/8-inch moly tubing to comply with NHRA rules.

Moser’s M9 for F_body ready to go back into the car. We filmed a video for Moser on their new drag brake setup we’re running – that’s why it’s back out.

We cleaned up the VA Speed built 388ci bullet. Trick Flow 265cc cathedral port heads, Jesel Belt Drive, and an LSX block get the magic done.

This is BlownZ on March 20th. The engine is coming in and out of this car more than you can believe. We’ve got the cowl box finished and waiting for the Five Star Bodies poly windows. You can see our Afco radiator and 2 gallon fuel cell.

Fragola “FPS Series” 3000 Race Hose is what we chose for the plumbing. Manufactured to the highest aerospace-quality standards for years of trouble-free service even in the most demanding circumstances, we were pretty comfortable with it.

Fragola “FPS” 3000 “billet” swivel hose ends got the call for our series race application. With tire shake being common for fast drag radial cars, we wanted some serious hose ends.

Afco’s micro-custom radiator mounted at a 50-degree angle so that we can fit a large 8-10″ inlet tube to the front of the ProCharger F1 series blower. Check out our integrated Meziere water pump.

In order to get our torque arm to clear the floor under suspension compression, we had to slightly clearance the floor.

Today was welding – specifically the Vibrant intercooler tubing. Shop Dawg Sean Goude got down and dirty welding our Vibrant aluminum tubing with our kick ass Lincoln Electric 275 Precision TIG welder. And let me tell you – one look at this welder and you’ll know – that’s a serious piece of hardware. Offensive lineman weigh less than this bad boy. We can’t wait to show off the welds we laid, but you’ll need to wait a few more days.

One of the first things we wanted to address was traction, and in order to make the most of our small-tire car, we turned to Moser Engineering for their M9 Ford 9-inch rearend, harnessed to their torque arm suspension. The Moser M9 is a fabricated 9-inch, and it’s combined with 3.89 gears and Moser’s 40-spline axles. We also went big with the new Moser Drag brake kit.

Here’s a closer look at that rear swaybar – it’s a double-tube unit from Wolfe Race Craft that can handle the massive torque loads our blown 388 will be delivering, while still offering a progressive response and far more adjustablity than a single bar. Wolfe recommends the double bar for cars quicker than 8.50.

Under the hatch, a pair of battery trays from Chris Alston’s Chassisworks are test-fit. The location will put the weight of our dual batteries where it’s most advantageous.

Up front, we’re using a Spohn Performance drag K-member, Spohn chrome-moly control arms, Spohn’s Pinto-style manual rack, Spohn bump steer kit, Afco double adjustable shocks, Strange front brakes, and a PA racing 2-inch drop spindle. Since we’re using motor plates, we elected for the no motor mount option.

We turned to Fragola Performance Systems for our cooling, trans, and fuel system plumbing – Making sure the fire stays fed is critical to the success of our project, so no corners are being cut here… We’ll go into a lot more detail on the Fragola hardware in an upcoming story.

BlownZ’s air-to-water intercooler comes courtesy of Chiseled Performance is a 2,000 HP air-to-water design with 4-inch V-band clamps and Chiseled’s special high-boost 1-piece end tank design.

Our intake tubing comes to us courtesy of Vibrant Performance, as well as mandrel bends, Vanjet clamps, and other critical fittings. We elected for 3.5-inch tubing for the supercharger to intercooler. Vibrant has an amazing selection of stuff, we were especially impressed by the quality of the tubing bends. There was literally zero deflection in the tubing.

With the VA Speed 388ci engine in place and the motor plate more or less in its final position, it was time to start mocking up all the tubing from our ProCharger to the intercooler and back to the engine. We’re running a ProCharger F1R and a Dan Schoneck-designed reverse belt-drive.

Here is the Chiseled Intercooler mounted with the Vibrant hardware and proprietary Vanjet band clamp.

Our 388-cubic-inch LSX built by Virginia Speed arrived, and the challenge became shoehorning it beneath our Camaro’s cowl. This was no small task.

In the interior of the car, we mocked up the Vibrant tubing, and Dean began playing the game of musical tubing… We were planning the entire time to build a removable panel inside the cowl so we could access the throttle body. Compared to a Mustang, the cowl area of an F-body is a complete mess for a supercharged or forced induction application.

We worked very hard on the ride height of BlownZ. This shows our lowered ride height, plus our new M/T wheels. Pretty sweet looking. We had some concerns about the fender to tire clearance but it turned out that under virtually any scenario there was no problem with clearance.

Wolfe’s double sway bar and the Afco double-adjustable shocks installed. Due to the lowered ride height, we did need to use an Afco shock that was one-inch shorter than the factory extension length. However, Afco does make an F-body shock in the shorter configuration.

Our interior – and yes – it looks messy. When we bought the car, it had a factory column in it, and our short-ass driver couldn’t reach anything – the pedals, steering, wheel etc. Building a removable race-style column was the easiest solution.

There just isn’t as much room in an F-body engine bay as in a Fox body or late model Mustang, never mind a classic muscle car. Since our 388ci VA Speed LSX engine required a dry-sump, we needed to think pretty hard about where to put it. There is a lot going on in the front of the car – reverse blower drive, radiator, our fuel cell and pump, and the dry sump. We elected to trim out the inner fender and found a cozy spot ahead of the front wheel.

Probably the toughest part of this project has been the cowl area. Our LSX engine is within 1/2-inch of the factory location, yet you can see what a mess the lower cowl is. Remember in a factory LSX the engine sits part way under the cowl. Try to run a normal reverse-intake blower setup is just a disaster. This shows you how much cowl trimming is needed to get the engine in the car. We’re building a very clean cowl plate and setup here, once it’s done it will look almost factory.

Another shot of how difficult it is to build an F-body blower car without liberal use of the plasma cutter.

Kooks gorgeous 2-inch headers with AEM 4-channel wide bang 02 bungs. We’ll be running 8 02 sensors on the car. These are stainless Kooks headers and they are a work of art.

We modified the Kooks headers to install a 4.5-inch collector. The merge collectors on the headers were amazing, but probably not optimized for a 1,300+ horsepower boosted engine. We wanted to get the exhaust gas out as efficiently as possible. Our header collectors weren’t nearly as pretty as the factory Kooks merge collectors, but at 1.5-inches larger in diameter, they’ll let more exhaust gases out more quickly.

Moser M9, Wolfe double sway bar, and Afco double-adj rear shocks all installed in the car. You’ll notice we did quite a bit of work strengthening up the pan hard bar area and getting the geometry right.

Final mock up of the steering rack. This shows you our entire front suspension setup. We needed to move the steering rack from the way Spohn did it originally due to the dry sump pump. We added some a billet steering rack bracket from Chris Alston Chassisworks to help make the job simple and quick.